Kemppi Kempact Pulse 3000 Operating Manual - Contents

EN

COntents

1. Preface

......................................................................................................................................

3

1.1 General

.......................................................................................................................................

3

1.2 Product introduction

............................................................................................................

3

2. Before you start using the unit

..............................................................................

4

2.1 Unpacking

.................................................................................................................................

4

2.2 Placement of the unit

...........................................................................................................

4

2.3 Serial number

...........................................................................................................................

4

2.4 Distribution network

.............................................................................................................

4

2.5 Connection to the mains supply

......................................................................................

4

2.6 Ground cable

............................................................................................................................

4

2.7 DuraTorque™ 400, 4 wheel wire feed mechanism

.....................................................

5

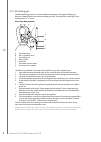

2.8 Installation of welding gun

.................................................................................................

6

2.9 Mounting and locking of wire reel

..................................................................................

6

2.10 Automatic wire feed to gun

................................................................................................

7

2.11 Adjustment of pressure

........................................................................................................

7

2.12 Adjustment of tightness of spool brake

........................................................................

7

2.13 Shielding gas

............................................................................................................................

8

2.14 Cooling unit (KempactCool 10)

.........................................................................................

9

3. Operation

.............................................................................................................................

10

3.1 Main switch and signal lights

...........................................................................................

10

3.2 To select polarity for welding

..........................................................................................

10

3.2.1 Changing the polarity

...................................................................................................

10

3.3 Panel

..........................................................................................................................................

11

3.3.1 Choosing start switch function

.....................................................................................

11

3.3.2 Choosing the welding method

.....................................................................................

11

3.3.3 Selecting 1-MIG/Pulse MIG synergy curves

.................................................................

12

3.3.4 Adjustments, display and weld data

............................................................................

14

3.3.5 Timer

...............................................................................................................................

14

3.3.6 Adjustment of welding dynamics

................................................................................

14

3.3.7 Remote control

..............................................................................................................

15

3.3.8 MIG extra functions

.......................................................................................................

15

3.3.9 Use of gas test

................................................................................................................

16

3.3.10 Testing wire feed

............................................................................................................

16

3.3.11 Memory channels, MEMORY

.........................................................................................

16

3.3.12 SETUP

.............................................................................................................................

17

3.3.13 Error codes

.....................................................................................................................

18

3.4 Cooling unit operation (KempactCool 10)

..................................................................

18

4. Maintenance

......................................................................................................................

19

4.1 Daily maintenance

...............................................................................................................

19

4.2 Regular maintenance

..........................................................................................................

19

5. Disposal of the machine

............................................................................................

19

6. Ordering numbers

.........................................................................................................

20

7. Technical data

...................................................................................................................

20

Kempact Pulse 3000, KempactCool 10

2