- DL manuals

- Kemppi

- Welding System

- Minarc Mig Evo 200

- Operating Manual

Kemppi Minarc Mig Evo 200 Operating Manual

Operating manual • English

Käyttöohje • Suomi

Bruksanvisning • Svenska

Bruksanvisning • Norsk

Brugsanvisning • Dansk

Gebrauchsanweisung • Deutsch

Gebruiksaanwijzing • Nederlands

Manuel d’utilisation • Français

Manual de instrucciones • Español

Instrukcja obsługi • Polski

Инструкции по эксплуатации • По-русски

操作手册

•

中文

Manual de utilização • Português

Manuale di istruzioni • Italiano

EN

FI

SV

NO

DA

DE

NL

FR

ES

PL

RU

ZH

PT

IT

MinarcMig

Evo 200

Summary of Minarc Mig Evo 200

Page 1

Operating manual • english käyttöohje • suomi bruksanvisning • svenska bruksanvisning • norsk brugsanvisning • dansk gebrauchsanweisung • deutsch gebruiksaanwijzing • nederlands manuel d’utilisation • français manual de instrucciones • español instrukcja obsługi • polski Инструкции по эксплуатации •...

Page 3: Operating Manual

Operating manual english m inar cm ig e vo 200 / © kemppi o y / 1110

Page 4

En contents 1. Preface ...................................................................................... 3 1.1 general ....................................................................................................................................... 3 1.2 product introduction ................

Page 5

En 1. Preface 1.1 general congratulations on choosing minarcmig evo welding equipment. Used correctly, kemppi p ° roducts can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenance...

Page 6

En can be 0.8 mm, 0.9 mm or 1.0 mm in diameter, the aluminium wire 1.0 mm and cusi wire 0.8, 0.9 and 1.0 mm. 1.2.2 about welding in addition to the welding machine, welding outcome is influenced by the work piece to be welded, welding technique and the welding environment. Therefore, recommendations...

Page 7

En 2.2 positioning and location of the machine place the machine on a firm, dry and level surface. Where possible, do not allow dust or other impurities to enter the machines cooling air flow. Preferably site the machine above floor level; for example on a suitable carriage unit. Notes for positioni...

Page 8

En 2.6 cable connections connection to the mains the machine is fitted with a 3 m long supply voltage cable and plug. Connect the supply voltage cable to the mains. Should you need to fit an alternative plug or mains cable, ensure installation is completed by an authorised electrician. Note! The fus...

Page 9

En shielding gas shielding gas is used for replacing air around the welding arc. For steel wires, use co₂ (carbon dioxide) or a mixture of ar (argon) and co₂ for shielding gas. Welding performance will be improved when using mixed gas products. For stainless steel wires, use mixture of ar and co₂ (2...

Page 10

En 2.7 filler wire the machine is delivered with the welding gun connected to the positive pole (+) making it suitable for welding with solid steel, stainless steel, aluminium and cusi filler wires without extra adjustments. 2.7.1 changing the feed roll groove when the machine leaves factory, the fe...

Page 11

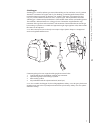

En 2.7.2 loading and threading the filler wire 1., 10. 1. Open the filler wire cabinet door by pressing the orange door latch button and installing the filler wire spool in such a way that it rotates counter clockwise. You can use either a 5 kg (diameter 200 mm) or 1 kg (100 mm) filler wire spool wi...

Page 12

En 5., 8. 7. 9. 6. Open the pressure control arm which then opens the feed mechanism. 7. Thread the filler wire through the wire guide to the wire liner inside the gun cable. 8. Close the feed gear and secure it with the pressure control arm. Make sure that the filler wire runs in the feed roll groo...

Page 13

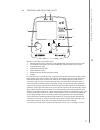

En 2.8 controls and indicator lights s u 1. 7. 2. 3. 4. 5. 6. Machine's control panel in automatic mode 1. Welding power control (automatic mode) or wire feed speed control (manual mode) 2. Arc length trimmer (automatic mode) or welding voltage control (manual mode) 3. Standby indicator light 4. Ove...

Page 14

En 2.8.1 display in automatic mode 1. 2. 4. 5. 7. 6. 3. Machine display in automatic mode 1. Material thickness 2. Visual material thickness and weld shape indicator 3. Operating mode reference 4. Material selection 5. Shielding gas and wire diameter recommendation 6. Wire feed graphic 7. Welding va...

Page 15

En 2.8.3 arc length trimmer in automatic mode the arc length/weld shape/voltage trimmer adjusts the length of the arc, either shorter or longer, and affects the welding temperature. A shorter arc is colder and a longer one hotter. The arc length trimmer also affects the arc’s welding properties and ...

Page 16

En arc dynamics in manual mode you can select from two different arc dynamics settings. Press manual mode button once to pre-select either arc dynamic value i or value ii. Changing between setting i and setting ii will adjust the short circuit characteristics to suit different welding applications. ...

Page 17

En having checked that the minarcmig evo is prepared in the correct way for the welding task ahead, and that you are wearing the necessary protective equipment, you are ready to commence welding. Mig/mag welding can be performed down hand, vertically and overhead: either right to left (right handed ...

Page 18

En 2.10 using the shoulder strap 1. 3. 2. 4. Using and fixing the shoulder strap the machine is delivered with a fabric shoulder strap and metal clip set. The shoulder strap can be used as a convenient and comfortable way to transport both the machine and cables set. There are two identical metal cl...

Page 19

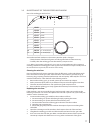

En 3.2 maintenance of the wire feed mechanism parts of the welding gun and wire liner 1 2 7 8 9 3 4 5 6 1 9580101 10, 11 2 9591010 3 9876634 0.6 mm 4 9876635 0.8 mm 5 9876633 0.9 mm 6 9876636 1.0 mm 7 9580173 8 9591079 9 4153040 45° 10 4307650 0.6–1.0 mm (fe, cusi) 11 4307660 0.6–1.0 mm (ss, al) ser...

Page 20

En 5. Tighten the wire guide in place with the mounting nut. 6. Cut the wire guide 2 mm from the mounting nut and file the sharp edges of the cut round. 7. Reattach the gun in place and tighten the parts to spanner tightness. 3.3 troubleshooting problem cause the wire does not move or wire feed enta...

Page 21

En 3.5 disposal of the machine do not dispose of electrical equipment with normal waste! In observance of european directive 2002/96/ec on waste electrical and electronic equipment, and its implementation in accordance with national law, electrical equipment that has reached the end of its life must...

Page 22

En 5. Technical data minarcmig evo 200 connection voltage 1 ~ 50/60 hz 230 v ± 15 % rated power at max. Current 35 % ed 200 a/6.2 kva supply current 35 % ed i 1max 26.2 a 100 % ed i 1eff 13.2 a connection cable h07rn-f 3g1.5(1.5 mm2, 3 m) fuse type c 16 a output 40 °c 35% ed 200 a/24 v 100% ed 120 a...

Page 24

Www.Kemppi.Com 1910020 1110 kemppi oy hennalankatu 39 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel ...