- DL manuals

- Kemppi

- Welding System

- MinarcMig 180

- Operation Instructions Manual

Kemppi MinarcMig 180 Operation Instructions Manual

Käyttöohje • Suomi

Bruksanvisning • Svenska

Bruksanvisning • Norsk

Bruksanvisning • Dansk

Operation instructions • English

Gebrauchsanweisung • Deutsch

Gebruiksaanwijzing • Nederlands

Manuel d’utilisation • Français

Manual de instrucciones • Español

Instrukcja obsługi • Polski

Инструкции по эксплуатации • По-русски

MinarcMig™ 180

191017210

0640

Summary of MinarcMig 180

Page 1

Käyttöohje • suomi bruksanvisning • svenska bruksanvisning • norsk bruksanvisning • dansk operation instructions • english gebrauchsanweisung • deutsch gebruiksaanwijzing • nederlands manuel d’utilisation • français manual de instrucciones • español instrukcja obsługi • polski Инструкции по эксплуат...

Page 3: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 1 operation instructions english en.

Page 4: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 contents 1. Introduction ..................................................................3 1.1. Properties .............................................................................3 1.2. About welding .......................................................

Page 5: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 1. Introduction minarcmig™ adaptive 180 is an easy-to-use mig welding machine suitable for both hobby and professional use. Before using or doing any maintenance work on the machine, read the operating manual and keep it for further reference. 1.1. Properties...

Page 6: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 4 © kemppi oy 0640 suitable for stainless steel wires. Argon is suitable for welding aluminium wires. Some filler wires form a shielding gas from the wire’s filling as it melts thus eliminating the need for a separate shielding gas. 2. Safety instructions the machine is safe ...

Page 7: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 take into account dangers caused by special workplaces, such as fire risk and danger of explosion, when welding container-like pieces. Note! Fire caused by sparks may brake out even after several hours! Caution! Welding in inflammable and explosive sites is s...

Page 8: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 6 © kemppi oy 0640 3. Machine use the machine is delivered ready for operation without adjustments with 0.8 mm diameter filler wire. If you use different thickness filler wire, make sure that the feed roll groove, welding gun contact tip and machine polarity are suited for th...

Page 9: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 3.2. General view of the machine figure 3.1. General view 1. Welding gun 2. Earthing cable 3. Main switch 4. Supply voltage cable 5. Shielding gas hose connector 3.3. Cable connections connection to the mains the machine is equipped with a 3.3 m long supply v...

Page 10: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 8 © kemppi oy 0640 welding gun the welding gun is already connected to the machine. The welding gun leads the filler wire, shielding gas and electric current to the weld. When you press the welding gun trigger, shielding gas flow and wire feed begin. The arc ignites, when the...

Page 11: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 figure 3.2. Connecting the gas hose to a typical control valve 1. Connect the hose to the gas bottle’s control valve and tighten the connector. 2. Adjust the flow rate with the control valve screw. A suitable shielding gas flow rate is 8-15 l/min. 3. Close th...

Page 12: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 10 © kemppi oy 0640 3.4. Filler wire the machine is delivered with the welding gun connected to +pole making it suitable for steel solid wire, stainless steel wire and aluminium wire welding without adjustments. 3.4.1. Changing the feed roll groove the feed roll groove is fac...

Page 13: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 11 3.4.2. Threading the filler wire figure 3.4. Threading the filler wire 1. Open the reel housing by pressing on the opening button and install the wire reel in such a way that it rotates counter clockwise. You can use either a 5 kg (diameter 200 mm) or 1 kg...

Page 14: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 1 © kemppi oy 0640 9. Press the welding gun trigger and wait for the wire to come out. 10.Close the reel housing cover. Caution! When driving the wire in to the gun, do not point the gun at yourself or others or put, for example, your hand in front of the tip, because the cut...

Page 15: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 1 3.5. Controls and indicator lights figure 3.6. Machine's front panel in automatic mode 1. Welding power control (automatic mode) or wire feed speed control (manual mode) 2. Arc length trimmer (automatic mode) or welding voltage control (manual mode) 3. Stan...

Page 16: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 14 © kemppi oy 0640 when you switch the machine on, a green standby light switches on. Simultaneously, the main switch indicator light switches on. If the machine overheats or the supply voltage is too low or too high, the welding operation automatically switche...

Page 17: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 1 during welding, the wire feed speed chart displays the wire’s speed. Of all the welding parameters, only filler wire feed speed is visible on the display all the time. Welding voltage and welding current are visible on the display during welding. The last u...

Page 18: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 16 © kemppi oy 0640 if, on the other hand, you want to weld with a colder arc to prevent for example the parent material from burning through, adjust the arc shorter by turning the control counter clockwise. You can also adjust the welding power, if need be. When adjusting th...

Page 19: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 1 3.5.5. Adjustments in manual mode in manual mode, the wire feed speed and welding voltage are both adjusted separately. Welding current and power are defined according to wire feed speed. The desired arc and welding properties can be reached by adjusting th...

Page 20: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 18 © kemppi oy 0640 4. Service when servicing the machine, its utilization degree and environmental circumstances should be taken into account. If you use the machine appropriately and service it regularly, you will spare yourself from unnecessary malfunctions. Caution! Disco...

Page 21: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 1 cleaning the wire guide pressure of the feed rolls remove metal dust from the filler wire’s surface which then finds its way to the wire guide. If the wire guide is not cleaned, it gradually clogs up and causes wire feed malfunctions. Clean the wire guide i...

Page 22: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 0 © kemppi oy 0640 4.3. Machine disposal do not dispose of electrical equipment together with normal waste! In observance of european directive 2002/96/ec on waste electrical and electronic equipment and its implementation in accordance with national law, electrical equipment...

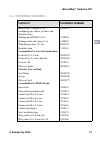

Page 23: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 1 product ordering number minarcmig™ adaptive 180 (includung gun, cables, gas hose and shoulder strap) 6108180 welding gun mmg20 (3 m) 6250200 earthing cable and clamp (3 m) 6184003 shielding gas hose (4,5 m) w001077 shoulder strap 9592162 consumables for wir...

Page 24: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 © kemppi oy 0640 5. Troubleshooting problem cause the wire does not move or wire feed entangles feed rolls, wire conduit or contact tips are defective • check that feed rolls are not too tight or too loose • check that the feed roll groove is not too worn • check that the wir...

Page 25: Minarcmig™ Adaptive 180

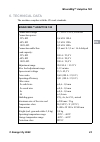

Minarcmig™ adaptive 180 © kemppi oy 0640 6. Technical data the machine complies with the ce mark standards. Minarcmig™ adaptive 180 connection voltage 1 ~ 230 v ±15%, 50/60 hz connection power: • 25% ed 8,6 kva 180 a • 60% ed 5,3 kva 120a • 100% ed 4,2 kva 100a connection cable/fuse 2,5 mm² s–3,3 m ...

Page 26: Minarcmig™ Adaptive 180

Minarcmig™ adaptive 180 4 © kemppi oy 0640 7. Terms of guarantee kemppi oy provides a guarantee for products manufactured and sold by them if defects in manufacture and materials occur. Guarantee repairs must be carried out only by an authorised kemppi service agent. Packing, freight and insurance c...

Page 27: Www.Kemppi.Com

Kemppi danmark a/s literbuen 11 dk – 2740 skovlunde danmark tel 44 941 677 telefax 44 941 536 e-mail: sales.Dk@kemppi.Com kemppi france s.A.S 65 avenue de la couronne des prés 78681 epone cedex france tel (01) 30 90 04 40 telefax (01) 30 90 04 45 e-mail: sales.Fr@kemppi.Com kemppi oy pl 13 fin – 158...