- DL manuals

- Kemppi

- Welding System

- MinarcTig 180

- Operating Manual

Kemppi MinarcTig 180 Operating Manual

Summary of MinarcTig 180

Page 1

Operating manual brugsanvisning gebrauchsanweisung manual de instrucciones käyttöohje manuel d’utilisation gebruiksaanwijzing bruksanvisning instrukcja obsługi Инструкции по эксплуатации bruksanvisning 操作手册 en da de es fi fr nl no pl ru sv zh minarctig 180, 180mlp, 250, 250mlp.

Page 3: Operating Manual

Operating manual english.

Page 4: Contents

En 4 contents 1. Preface .................................................................................... 5 1.1 general ...................................................................................... 5 1.2 machine properties ...................................................................

Page 5: Preface

En 5 1. Preface 1.1 general congratulations on choosing the minarctig equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenance and safe...

Page 6: 1.3

En 6 1.3 about welding minarctig is a precise welding tool and will provide high quality results time after time provided the correct operational procedures are followed. Welding quality is not only influenced by the machine itself. Personal expertise, ancillary equipment and consumables also play a...

Page 7: Machine Use

En 7 2. Machine use 2.1 before commissioning the machine minarctig is packed in purpose made, recyclable packaging. However, always ensure that the equipment has not been damaged in transportation. Even so, make sure that all in-transport damage is reported to the machine supplier. Do not unpack the...

Page 8: 2.2

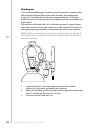

En 8 2.2 general view of the machine 1. 2. 3. 5. 4. 1. Welding torch 2. Earthing cable and earthing clamp 3. Main switch 4. Mains cable (minarctig 180 in the picture) 5. Shielding gas hose connector 2.3 distribution network all regular electrical devices without special circuits generate harmonic cu...

Page 9: 2.4

En 9 2.4 cable connections connection to mains the machine is equipped with a 3.3 m supply voltage cable and plug. Plug the mains cable to a single-phase electric network. The minarctig 250 is supplied with a 5 m mains cable without a plug. Note! Check the fuse size in technical specifications. The ...

Page 10

En 10 shielding gas in tig welding, shielding gas is used to prevent atmospheric contamination of the molten weld pool and cooling weld. Normally, the shielding gas is argon (ar). Normally the gas flow rate is approximately 8–15 litres per minute, but this can vary according to the welding current u...

Page 11: 2.5

En 11 2.5 welding power selection and electrodes tig welding electrodes and gas nozzles in dc tig welding we recommend the use of the wc20 (grey) type electrode, however other types are available. The welding electrode size (diameter) is selected depending on the welding current/power to be used. An...

Page 12: 2.6

En 12 2.6 adjustments and indicators (180 and 250) 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 1. Standby indicator. 2. Pre/post gas, upslope/downslope and main current parameter indicator. 3. Welding parameter selector arrow keys. 4. Welding process selection button (mma or tig). 5. 2t or 4t tig torch switch se...

Page 13

En 13 2.6.1 welding current regulation and remote control the welding current can be adjusted steplessly with the control knob, if panel adjustment (panel) is selected. If you want to adjust the welding current with the remote control, connect the remote control to the machine and then select remote...

Page 14

En 14 setting parameters select the welding parameters with the arrow keys (3) and adjust the parameter values with the control knob (8). When setting the parameters, the display (2) will show the parameter being adjusted as well as the numeric value that will be set for it. After three seconds, the...

Page 15: Setup Features

En 15 pulse welding to use the pulse welding feature, press the pulse button so that the on indicator is lit. Specify the desired welding current average (a) and pulse time (s). The machine will set the remaining pulse values automatically. For small welding current values, the chronological pulse r...

Page 16: Error Codes

En 16 t -9…0 0 electrode ignition pulse (-9 = no pulse / 0 = max pulse) u 1/0 0 disable automatic remote control recognition. 0 = enable automatic recognition, 1 = disable automatic recognition. *) happens when exiting setup mode and value is 1. 4. Error codes the machine always checks its operation...

Page 17: Maintenance

En 17 5. Maintenance all electromechanical devices require routine service maintenance depending on usage. This type of routine maintenance will prevent hazards and malfunctions. We recommend that you schedule a service inspection of your welding machine every six months. An authorised kemppi servic...

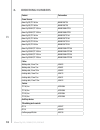

Page 18: Ordering Numbers

En 18 6. Ordering numbers product part number power sources minarctig 180, ttc 160 4 m minarc180ttc4 minarctig 180, ttc 160 8 m minarc180ttc8 minarctig 180 mlp, ttc 160 4 m minarc180mlpttc4 minarctig 180 mlp, ttc 160 8 m minarc180mlpttc8 minarctig 250, ttc 160 4 m minarc250ttc164 minarctig 250, ttc ...

Page 19: Troubleshooting

En 19 shielding gas hose (4.5 m) w001077 carrying straps 9592162 remote control units r 10 6185409 r11f 6185407 mains cable (minarctig 250) w002982 7. Troubleshooting problem cause the main switch indicator will not light up no electricity connected to the machine • check the mains supply fuses. • c...

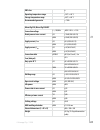

Page 20: Technical Data

En 20 8. Technical data minarctig 180, 180 mlp connection voltage 1 ~, 50/60 hz 230 v ±15 % rated power at max. Current tig 6.7 kva (180 a/17.2 v) mma 7.0 kva (140 a/25.6 v) supply current, i 1max tig 29 a (180 a/17.2 v) mma 31 a (140 a/25.6 v) supply current, i 1eff tig 18 a (120 a/14.8 v) mma 22 a...

Page 21

En 21 emc class a operating temperature range -20 °c...+40 °c storage temperature range -40 °c...+60 °c recommended generator > 7 kva minarctig 250, minarctig 250 mlp connection voltage 3 ~, 50/60 hz 400 v –20 %... +15 % rated power at max. Current tig 7.2 kva (250 a/20.1 v) mma 8.2 kva (220 a/28.8 ...

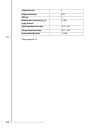

Page 22

En 22 temperature class f degree of protection ip23s emc class a minimun short circuit power s sc of supply network* 1.5 mva operating temperature range -20 °c...+40 °c storage temperature range -40 °c...+60 °c recommended generator > 15 kva * see paragraph 2.3. 22 minarctig 180, 180mlp, 250, 250 ml...

Page 24

1910190 1339 www.Kemppi.Com kemppi oy kempinkatu 1 pl 13 fi-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46 ...