- DL manuals

- Kemppi

- Welding System

- MinarcTig Evo 200

- Operating Manual

Kemppi MinarcTig Evo 200 Operating Manual

Operating manual

Käyttöohje

Bruksanvisning

Bruksanvisning

Brugsanvisning

Gebrauchsanweisung

Gebruiksaanwijzing

Manuel d’utilisation

Manual de instrucciones

Instrukcja obsługi

Инструкции по эксплуатации

Manual de utilização

Manuale d’uso

EN

FI

SV

NO

DA

DE

NL

FR

ES

PL

RU

PT

IT

MinarcTig

Evo 200, 200MLP

Summary of MinarcTig Evo 200

Page 1

Operating manual käyttöohje bruksanvisning bruksanvisning brugsanvisning gebrauchsanweisung gebruiksaanwijzing manuel d’utilisation manual de instrucciones instrukcja obsługi Инструкции по эксплуатации manual de utilização manuale d’uso en fi sv no da de nl fr es pl ru pt it minarctig evo 200, 200ml...

Page 3: Operating Manual

En operating manual english.

Page 4

En contents 1. Preface .......................................................................................... 3 1.1 general ....................................................................................................................................... 3 1.2 product introduction ............

Page 5

En 1. Preface 1.1 general congratulations on choosing the minarctig evo equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenance and sa...

Page 6

En 2. Before you start using the unit note! Please read the separate safety instruction booklet provided before you commence welding. Pay particular attention to the risks associated with fire and explosion. 2.1 unpacking always before using the equipment, make sure it was not damaged during transpo...

Page 7

En 2.5 general view of the machine ttc 220 1. 2. 3. 6. 4. 5. 1. Welding torch 2. Earthing cable and earthing clamp 3. Main switch 4. Mains cable 5. Remote control connector 6. Shielding gas hose connector 2.6 connecting cable connections connection to mains the machine is equipped with a 3 m long su...

Page 8

En 3. Use note! Welding fumes may be dangerous to your health. Ensure that there is ample ventilation during welding! Never look at the arc without a face shield specifically designed for arc welding! Protect yourself and your surrounding area from the arc and hot welding spatter! Prepare to weld no...

Page 9

En 3.2 manual metal arc welding (mma) in manual metal arc (mma) welding the filler material is melted from the electrode to the weld pool. The rate of welding current is selected on the basis of the welding electrode size used and welding position. The arc forms between the electrode tip and work pi...

Page 10

En shielding gas in tig welding, shielding gas is used to prevent atmospheric contamination of the molten weld pool. Normally, the shielding gas is argon (ar), and the gas flow rate is approximately 8–15 litres per minute, but this can vary according to the welding current used and the size of gas n...

Page 11

En 3.4 operating functions 1. 2. On panel hf 4t 2t vrd a s minarctig w005721 3. 4. 5. 6. 7. 8. 9. 10. 11. 1. Machine ’on’ green light 2. Vrd safe light. Solid green vrd safe ’on’. Solid red if vrd failure. 3. Pre/post gas, upslope/downslope and main current parameter indicator. 4. Welding parameter ...

Page 12

En 3.4.1 welding current regulation and remote control the welding current can be adjusted with the control knob, if panel adjustment (panel) is selected. If you want to adjust the welding current with the remote control, connect the remote control to the machine and then select remote control with ...

Page 13

En 3.4.4 additional features for mlp models 5. On panel hf 4t 2t vrd minilog minilog pulse a on pulse s minarctig w005722 8. 11. Minilog with the minilog feature, you can switch between two current levels by pressing the switch briefly. The levels are the welding current and the minilog current. To ...

Page 14

En 3.5 using the shoulder strap 1. 3. 2. 4. Using and fixing the shoulder strap the machine is delivered with a fabric shoulder strap and metal clip set. The shoulder strap can be used as a convenient and comfortable way to transport both the machine and cables set. There are two identical metal cli...

Page 15

En 4. Setup features configuring additional features the machine has additional features that can be selected and adjusted with the setup feature. To activate and deactivate it, press both arrow buttons (3) simultaneously for at least 5 seconds. In the setup mode, the display will show the name of t...

Page 16

En 5. Error codes the machine always checks its operation automatically during start-up and reports any failures detected. If failures are detected during start-up, they are shown as error codes on the control panel display. Error 2: power source undervoltage the device has stopped because it has de...

Page 17

En 6. Maintenance all electromechanical devices require routine service maintenance depending on usage. This type of routine maintenance will prevent hazards and malfunctions. We recommend that you schedule a service inspection of your welding machine every six months. An authorised kemppi service a...

Page 18

En 7. Ordering numbers minarctig evo models minarctig evo 200, ttc 220 4 m p0640 minarctig evo 200, ttc 220 8 m p0641 minarctig evo 200mlp, ttc 220 4 m p0642 minarctig evo 200mlp, ttc 220 8 m p0643 minarctig evo 200 au, ttc 220 4 m p0672 minarctig evo 200 au, ttc 220 8 m p0673 minarctig evo 200mlp a...

Page 19

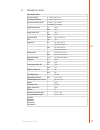

En 8. Technical data minarctig evo models connection voltage 1 ~ 50/60 hz 230 v ±15 % connection voltage (au) 1 ~ 50/60 hz 240 v ±15 % rated power at max. Current 35% ed tig 200 a/4.9 kva 35% ed mma 170 a/5.7 kva supply current, i1max tig 21.1 a mma 24.8 a supply current, i1eff tig 12.7 a mma 14.7 a...

Page 20

Www.Kemppi.Com kemppi oy kempinkatu 1 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46 8 590 783 00...