- DL manuals

- Kemppi

- Welding System

- MXF 65

- Operating Manual

Kemppi MXF 65 Operating Manual

1923680

0920

Gebruiksaanwijzing • Nederlands

Manuel d’utilisation • Français

Manual de instrucciones • Español

Instrukcja obsługi • Polski

Инструкции по эксплуатации • По-русски

操作手册 • 中文

Operating manual • English

Käyttöohje • Suomi

Bruksanvisning • Svenska

Bruksanvisning • Norsk

Brugsanvisning • Dansk

Gebrauchsanweisung • Deutsch

FI

EN

SV

NO

DA

DE

NL

FR

ES

PL

RU

ZH

F

AST

M

IG™

MXF65

MXF67

Summary of MXF 65

Page 1

1923680 0920 gebruiksaanwijzing • nederlands manuel d’utilisation • français manual de instrucciones • español instrukcja obsługi • polski Инструкции по эксплуатации • По-русски 操作手册 • 中文 operating manual • english käyttöohje • suomi bruksanvisning • svenska bruksanvisning • norsk brugsanvisning • d...

Page 3: Operating Manual

En operating manual english fastm ig mxf65, 67 / © kemppi o y / 0920

Page 4: Contents

En contents 1. Preface ....................................................................................................................................................... 3 1.1 general ..................................................................................................................

Page 5: Preface

En preface 1. General 1.1 congratulations on choosing the fastmig mxf equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenance and safe...

Page 6

En do not expose the machine to high temperatures, as this may cause damage. • keep intermediate and earth return cables as close to each other as possible throughout • their length. Straighten any loops in the cables as this limits inductive effects on welding performance. This also minimizes your ...

Page 7

En never lift a gas cylinder and the welding machine at the same time. There are separate • provisions for gas cylinder transportation. Never use a welding machine when suspended unless the suspension device has been • designed and approved for that particular purpose. Do not exceed the maximum allo...

Page 8: Installation

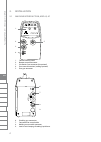

En installation 2. Machine introduction, mxf 65, 67 2.1 wf # 5. 1. 2. 3. 4. Control function panel 1. Remote control connector 2. Sub feeder sync connector (kit optional) 3. Gun water connections (cooling optional) 4. Euro gun connector 5. 6. 7. 8. 9. Shielding gas connection 6. Connection for contr...

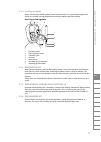

Page 9

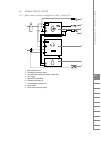

En connection of system 2.2 water cooled system: fastmig pulse + mxf + fastcool 10 2.2.1 1. 4. 8. 2. 3. 9. 5. 6. 7. 1. Mxf wire feed unit 2. Fastmig pulse power source 3. Fastcool water cooler and power connection 4. Gas supply 5. Mma electrode holder 6. Remote control device 7. Liquid cooled weldin...

Page 10

En gas cooled system: fastmig pulse + mxf 2.2.2 1. 4. 5. 6. 8. 2. 3. 7. Mxf wire feed unit 1. Fastmig pulse power source 2. Gas supply 3. Mma electrode holder 4. Remote control device 5. Air cooled welding gun 6. Power cable 7. Earth return lead and clamp 8. Assembly of mig/mag system 2.3 assemble t...

Page 11

En accessories corresponding to wire diameter 2.4 colour coded wire feed rolls and guide tubes are available to suit a variety of filler wire types and sizes. Drive roll groove geometry and design, vary depending on the application. Further details are available in the spare parts tables. Mxf wire f...

Page 12

En loading the filler wire and automatic feed 2.7 automatic wire feed makes wire spool changes faster. When changing the wire spool, the pressure of feed rolls need not be released. Simply ensure that the groove of the feed roll matches the diameter of filler wire used. Release the wire end from the...

Page 13

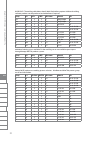

En wire feed rolls ø mm colour drawing pressing fe, ss, al, v-groove 0.6 pale grey w001045 w001046 0.8/0.9 white w001047 w001048 1.0 red w000675 w000676 1.2 orange w000960 w000961 1.4 brown w001049 w001050 1.6 yellow w001051 w001052 2.0 grey w001053 w001054 2.4 black w001055 w001056 fe, fc, mc, knur...

Page 14

En burn back time 2.11 fastmig electronics controls the burn back time. When welding stops an automatic sequence ensures that the filler wire does not stick to the work piece and that no ball is formed at the wire tip, ensuring reliable re-ignition. This system works regardless of the wire feed spee...

Page 15

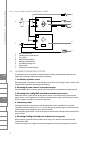

En installing gas bottle 2.13.1 always fasten the gas bottle properly in the vertical position, in a special holder against the wall or on a cylinder carriage. Remember to close gas bottle valve after welding. Parts of gas flow regulator 5 2 4 7 1 6 3 gas bottle valve 1. Flow regulation screw 2. Con...

Page 16: Control Panel Operations

En control panel operations 3. Mxf wire feeders can be connected to either fastmig pulse or fastmig synergic power sources. Pf65 function panel is compatible with fastmig pulse and sf53 and sf54 panels enable compatibility with fastmig synergic kms power sources. Connecting and mounting 3.1 1. Faste...

Page 17

En 3. Finally secure the panel into place with the additional black plastic security clip provided. 3. Ensure that the clip is positioned correctly. You will notice that the clip does not seat snuggly if its positioned upside down. Welding software delivery profile 4. Fastmig pulse is designed to al...

Page 18

En work pack. The welding table below details work pack delivery option. Additional welding software products can be purchased and added later if required. Group n:o pulse 1-mig wire ø mm material gas alu a01 x x 1 almg5/almgmn ar alu a02 x x 1.2 almg5/almgmn ar alu a12 x x 1.2 alsi5/alsi12 ar fe f0...

Page 19

En pf65 panel button functions 5. 1. 3. 2. 4. 5. 6. 7. 8. 9. 10. 11. On / off button 5.1 1. Short press: panel returns to default display. Long press: when welding panel (pf65) is on => welding panel is turned off. When welding panel (pf65) off => welding panel is turned on and setup panel (p65) tur...

Page 20

En wire inch button 5.4 4. Wire feeder will start immediately when the button is pressed. The default wire inch speed is 5.0m/min. Wire inch speed can be adjusted (+/-) using the pulse encoder. When the button is released the wire feeder will stop. If the button is pressed again, the wire feeder sta...

Page 21

En remote selection button 5.9 9. Short press: panel /gun remote / hand remote selection. If remote auto recognition is selected on (see p65 panel menu) only those remote controls which can be found are selected. Long press: ch remote function on/off. Gun remote or hand remote control must be first ...

Page 22

En pf65 panel overview 5.12 9. 13. 10. 11. 12. 7. 8. 1. 4. 3. 5. 2. 6. Main switch (long press) 1. A) wire feed speed/welding current display 2. B) display of selected adjustable parameter a) activation of mig welding dynamics / arc force adjustment 3. B) selection of wire feeder (= paralleled wire ...

Page 23

En sf 54 panel overview for fastmig synergic 5.13 1. 2. 3. 4. 9. 5. 10. 6. 11. 7. 12. 8. 13. M/min a v arc force dynamics wire inch gas test mma panel sf 54 mls™ u mig weld 4t setup mma 2t data w001322 main switch 1. Display of wire feed speed/welding current 2. Selection of mig dynamics for adjustm...

Page 24

En sf 53 panel overview for fastmig synergic 5.14 9. 14. 10. 15. 11. 16. 12. 17. 13. M/min a v arc force dynamics wire inch gas test mma synergic program panel sf 53 mls™ u mig set on ch panel save set quick setup ch clear ch remote memory power weld 4t setup select mma 2t data w001257 1. 2. 3. 4. 5...

Page 25: Basic Troubleshooting

En basic troubleshooting 6. Note! The problems listed and the possible causes are not definitive, but serve to suggest some standard and typical situations that may present during normal environmental use when using the mig/mag process with fastmig pulse. Problem check the following machine won’t wo...

Page 26: Maintenance

En maintenance 7. When considering and planning routine maintenance, please consider the the frequency of machine use and the working environment. Correct operation of the machine and regular maintenance will help you avoid unnecessary downtime and equipment failure. Note! Disconnect the machine fro...

Page 27

En cooling unit fastcool 10 6068100 sub feeder synchronisation unit mxf sync 65 w004030 supersnake gt02s sub feeder 10m 6153100 supersnake gt02s sub feeder 15m 6153150 supersnake gt02s sub feeder 20m 6153200 supersnake gt02s sub feeder 25m 6153250 supersnake gt02s w sub feeder 10m 6154100 supersnake...

Page 28

En ws 35 al 1.2 mm 6 m 6253516a12 ws 30 w al 1.2-1.6 mm 6 m 6253516s10 ws 30 w al 1.2 - 1.6 mm 8 m 6253048a12 ws 42 w al 1.2 - 1.6 mm 6 m 6254206a12 ws 42 w al 1.2 - 1.6 mm 8 m 6254208a12 ss 1.0 mm 6 m 6253516s10 ss 1.0 mm 6 m 6253046s10 ss 1.2 mm 6 m 6253046s12 ss 1.0 mm 8 m 6253048s10 ss 1.2 mm 8 ...

Page 29: Technical Data

En technical data 10. Mxf 65 mxf 67 operating voltage (safety voltage) 50 v dc 50 v dc rated power 100 w 100 w load capacity 40° c 60 % ed 520 a 520 a 100 % ed 440 a 440 a wire feed speed 0 ... 25 m/min 0 ... 25 m/min wire feed mechanism 4-roll 4-roll diameter of feed rolls 32 mm 32 mm filler wires ...

Page 30: Warranty Policy

En warranty policy 11. Kemppi oy provides a warranty for products manufactured and sold by the company if defects in materials or workmanship occur. Warranty repairs are to be carried out only by an authorised kemppi service agent. Packing, shipping, and insurance are at the orderer’s expense. The w...

Page 32

Www.Kemppi.Com kemppi oy pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 www.Kemppi.Com kemppikoneet oy pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 734 8398 e-mail: myynti.Fi @kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46 8 590...