Kerosene #1 diesel/ fuel oil congratulations! You have purchased the finest indirect fired construction heater available. Your new l.B. White heater incorporates the benefits from the most experienced manufacturer of heating products using state-of-the-art technology. We, at l.B. White, thank you fo...

General hazard warning ■ failure to comply with the precautions and instructions provided with this heater, can result in: — death — serious bodily injury or burns — property damage or loss from fire or explosion — electrical shock ■ read this owner’s manual before installing or using this product. ...

Table of contents 3 general information this owner's manual includes all options and accessories commonly used on this heater. When calling for technical service assistance, or for other specific information, always have model number, configuration number and serial number available. This informatio...

Specifications m mo od de ell net weight shipping weight electrical supply (volts/hz/phase) dimensions (inches) l x w x h minimum safe distances from nearest combustible materials starting continuous operation motor characteristics heater specifications fuel type 1 h.P. / 1,700 rpm 4 135 cfm 62 cfm ...

5 safety precautions 1. Do not attempt to install, repair, or service this heater unless you have continuing expert training and knowledge of liquid fuel heaters. Qualifications for service and installation of this equipment are as follows: to be a qualified liquid fuel heater service person, you mu...

18. Never move, handle, refuel, or ser vice a hot, operating, or plugged-in heater. 19. Never attach duct work to rear of heater. 20. Never attach heater to external fuel tank. 21. Heaters used in the vicinity of tarpaulins, canvas, or similar enclosure materials shall be located in safe distance fr...

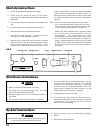

7 fig. 3 venting to outside through wall fig. 2 venting to existing chimney a) minimal 4 ft. B) minimal 4 ft. C) the shortest d) the same or bigger than the stacks outlet diameter 4 ft. Heater e) minimal 4 ft. 1) anti-wind device provided with the heater 2) horizontal crossing with minimal upside an...

8 tth hee ffu ueell s syys stteem m the motor turns the fuel pump. The fuel pump pulls fuel from the fuel tank. The fuel pump pushes fuel through a filter and a solenoid valve and out the burner head nozzle. A fine mist of fuel is sprayed into the combustion chamber. Tth hee aaiir r s syys stteem m ...

To connect a thermostat refer to the following instructions: a) pull latch away from thermostat plug on control panel. B) disassemble the plug. C) remove jumper at terminals 2 and 3. See fig. 5. (keep the jumper. The jumper may be reinstalled if manual operation of the heater is desired later.) d) r...

1. Turn thermostat dial to lowest temperature setting. This will cause heater flame to go out. The motor will continue to run during the purge cycle. This allows the fan to cool the combustion chamber. When the purge cycle is finished, the motor will stop. Do not unplug heater until purge cycle is f...

14 11 iin niittiiaall ppr reeppaar raattiio on n -- disconnect electrical supply. C clleeaan niin ng g the heater should have dirt or dust removed periodically: a. Before each use give the heater a general cleaning using compressed air or a soft brush or dry rag on its case and internal components. ...

Pump gauge service instructions igniter probe gapping ensure that gapping between spark electrodes is as shown in fig. 7. Fig. 7 1/8 in. 1. Remove pressure gauge plug from fuel pump port marked “p” located in the upper right hand corner of the pump. This requires a 4 mm allen wrench. 2. Install a pr...

The heater may be operated at different altitudes. Although there are not any parts that need to be changed, you must set the air adjustment ring at the burner to compensate for the change in altitude. 1. Remove the upper shell at the fan end of the heater. 2. Using a 5 mm. Allen key, loosen the loc...

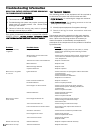

Read this entire section before beginning to troubleshoot problems. This guide is intended for use by a qualified heater service person. Do n not aattempt tto s service tthese heaters u unless yyou h have b been pproperly ttrained. Test eequipment r required the following pieces of test equipment wi...

Electrical connection and ladder diagram 15 ground transformer hi limit solenoid v al ve phot o-cell fa n thermost at cap acit or fa n mot or n l1 fuse heated filter indicator light thermostat plug ignition control board 1 2 3 4 5 6 7 8 9 10 11 12 n switch relay 1 2 3 4 5 6 7 8 9 10 11 12 115/60/1.

Parts identification 16 parts schematic.

Parts list 17 part number item description director 100 director 300 1 handle 24712 24290 2 leg, support frame 24713 24291 3 plug 24292 5 axle 24714 24293 6 wheel 24602 24294 7 wheel holder 24603 24295 8 fuel tank 24604 24296 9 drain plug w/ seal 24251 10 drain plug seal 24298 11 fuel cap 24252 12 f...

18 parts list (cont.) part number item description director 100 director 300 54 seal, filter, housing 24330 55 seal, filter, upper 24331 56 oil filter 24265 57 filter housing 24266 58 fan switch, thermostat 24724 24267 59 limit switch 24268 60 electrode 24269 61 ignition boot 24332 62 oil supply lin...

19 contact your local l.B. White dealer for replacement parts and service or call the l.B. White co., inc. At (800) 345- 7200 for assistance. Be sure that you have your heater model number and configuration number when calling. L.B. White co., inc. Warrants that the component parts of its heater are...