Available in either l.P. Gas vapor withdrawal or natural gas configurations. Models output (btuh) fuel hd120 120,000 congratulations! You have purchased the finest direct fired greenhouse heater available. Your new l.B. White heater incorporates the benefits from the most experienced manufacturer of...

2 warning fire and explosion hazard ■ not for home or recreational vehicle use. ■ installation of this heater in a home or recreational vehicle may result in a fire or explosion. ■ fire or explosions can cause property damage or loss of life. For your safety if you smell gas: 1. Open windows. 2. Don...

This owner's manual includes all options and accessories commonly used on this heater. However, depending on the configuration purchased, some options and accessories may not be included. When calling for technical service assistance, or for other specific information, always have model number, conf...

Specifications maximum input (btuh) 120,000 minimum input (btuh) 65,000 300 cfm 120 sq. In. 120 sq. In. 13.5 11.0 11.0 7.0 5.2 3.1 1.3 0.8 5.56 lbs. 120 cu. Ft. 3.01 lbs. 65 cu. Ft. 1/3 h.P. 1,100 rpm 115/60/1 11.8 4.5 30 3/4 x 18 1/4 x 28 1/4 top 1 ft. Sides 1 ft. Back 1 ft. Blower outlet gas propa...

5 lp ggas aand nnatural ggas hhave m man-m made oodorants aadded sspecifically ffor ddetection oof ffuel ggas lleaks. If aa ggas lleak ooccurs, yyou sshould bbe aable tto ssmell tthe ffuel ggas. That’s yyour s signal tto g go iinto iimmediate aaction! ■ do not take any action that could ignite the f...

1. Do not attempt to install, repair, or service this heater or the gas supply line unless you have continuing expert training and knowledge of gas heaters. Qualifications for service and installation of this equipment are as follows: a. To be a qualified gas heater service person, you must have suf...

Installation instructions general direct fired heaters discharge combustion by-products with the heated air in to the area being heated. These include co, co 2 , no, no 2 , and ethylene. These gases can result in harm to the worker or the plants. The greengro greenhouse heater has been specifically ...

-- with the main burner in operation, check all connections, hose connections, fittings and joints as well as the gas control valve inlet and outlet connections with approved gas leak detectors. -- if a leak is detected, check the components involved for cleanliness in the thread areas and proper ap...

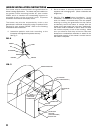

Eyebolt nut flat washer cage nut chain case top powered exhaust fan 1 ft. Clearance (back of heater to wall) entry/exit shuttered air inlet chain/cable sediment trap gas hose manual shutoff valve second stage regulator (vent pointed down) gas supply line heater (supported by metal frame of greenhous...

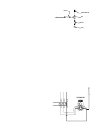

Thermostat gr ound br o w n red red yello w yello w white bla ck white black green 8 9 10 hi lo yellow blue red nipple hose adapter tee nipple cap to gas control.

11 b. Single s stage tthermostat 1. Operate on first stage heat only. -- remove jumper at terminals 8 and 9. -- connect thermostat to terminals 8 and 9. 2. Operate on second stage heat only. -- remove jumper at terminals 8 and 9. -- move jumper to terminals 9 and 10. -- connect thermostat to termina...

Heat power cord selector switch vent white white white white white white black bla ck bla ck bla ck bla c k bla ck black green jumper terminal strip contr ol po wer vent contr ol po wer hea t gr ound 7 6 5 4 3 2 1 neutral(s) from control power vent mode contacts heat power cord selector switch vent ...

On off for initial start-up after heater installation, follow steps 1-6. For normal start-up, simply set the thermostat above room temperature. 1. Connect electrical cord to an approved electrical outlet. 2. Set thermostat to desired room temperature. 3. This heater has a manually operated toggle st...

14 1. Before cleaning, shut off all gas supply valves and disconnect electrical supply. 2. At least once a year give the heater a thorough cleaning, preferably before the beginning of the fall heating season. At that time, remove the fan and motor assembly and brush or blow off the fan wheel. Additi...

15 1. Open the motor end access panel, and disconnect the motor leads. 2. Remove the motor mounting plate screws and pull the fan and motor assembly from the housing. 3. Loosen the square head set screw(s) on the fan wheel. 4. Pull the fan wheel from the motor shaft. Use a wheel puller if necessary....

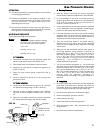

Sensor igniter 3/16 in. Heat chamber face burner igniter lead sensor lead enclosure to remove igniter / sensor assembly remove screw, lift assembly from its mounting slots to gap igniter, loosen screw. Move enclosure up or down to allow proper positioning of igniter to burner. 16 1. The igniter and ...

17 testing the manual reset high limit switch reset button sensing surface terminal flame mounting leg the high limit switch should be tested a minimum of once per year when the heater is given a thorough cleaning. 1. Disconnect the heater from its electrical supply. 2. Remove the high limit switch....

18 gauge 00764 nipple, 1/2 in lo hi tee, 1/2 in bushing, 1/4 in x 1/8 in bushing, 1/2 in x 1/4 in gas control gauge 00764 off on outlet pressure tap 0 5 10 20 25 30 35 15 attention ■ the following explains a typical procedure to be followed in checking gas pressures. ■ consult the dataplate on the h...

Troubleshooting instructions read this entire section before beginning to troubleshoot problems. The following troubleshooting guide provides systematic procedures for isolating equipment problems. This guide is intended for use by a qualified gas heater service person. Do n not aattempt tto s servi...

20 problem led constant on le d ll ig ht n ot oo n normal operation is select or switch set t o heat? Is f an r unning? Set select or switch t o heat ye s ye s no ye s ye s ye s is te m perature contr ol set ab ov e r oom te m perature? Set contr ol a bo ve r oom te m perature. Is te m perature cont...

21 problem led flashing is air -pr oving switch shor ted? (check continuity on air -pr oving switch in open and closed positions). Ye s r epair air -pr oving switch o ne tt im e fl as h p pa tt er n b eg in s im m ed ia te ly af te r c c on di tio n o cc ur s. Is air pr oving switch stuck closed? Ch...

22 tw o t ti m es fl as h p pa tt er n b eg in s t tw o ( (2 ) m in ut es aa ft er c on di tio n o cc ur s. Pp at te rn in di ca te s l la ck of aa ir p pr ov in g i in fa n s s ec tio n o of u ni t. R epair . Is air -pr oving switch stuck open? Check continuity . Ye s no ye s is air flo w switch bi...

23 th re e t ti m es (f la sh pp at te rn b eg in s i in 44 0 s ec on ds aa ft er c on di tio n o cc ur s. ) t th e m od ul e h h as g on e i in to ss af et y lo ck ou t. Is proper fuel supplied to heater inlet? Connect pr oper f uel supply t o heat er . Open all gas shut of f valv es. Ye s no is pr...

24 pr ob le m m ot or dd oe s n ot rr un is heat er plugged in? Is select or switch set t o vent? Plug heat er in. Mo ve the select or switch to the vent position. Ye s no ye s ye s is pr oper v oltage supplied fr om select or switch to mo tor? R eplace select or switch r eplace mo to r check all el...

25 electrical connection and ladder diagram yell ow yell ow l1 ind l.E.D. Mv ps2 ps1 w fs com dsi control r x c direct sense igniter high limit switch air proving switch gas valve solenoids burner ground thermostat high heat low heat electrical ladder diagram heat vent selector switch motor tr ansfo...

26 heater component function air proving switch safety device used to insure that the proper air flow is being achieved before the gas valve is opened. Burner cast iron component used to channel gas and provide an area at which the fuel may ignite. Burner orifice brass metering device used to feed g...

28 parts identification parts list item description part n number 1 regulator, lp gas, 2nd stage, vent over outlet 06553 regulator, lp gas, 2nd stage, vent over side 06665 regulator, natural gas (5 psig inlet, 13.5 outlet) 23360 2 nipple, 3 1/2 in. 07148 3 valve, manual shut off 05548 4 hose, 1/2 in...

Contact your local l.B. White dealer for replacement parts and service or call the l.B. White co., inc. At 1-800-345-7200 for assistance. Be sure that you have your heater model number and configuration number when calling. L.B. White co., inc. Warrants that the component parts of its heater are fre...