Congratulations! You have purchased the finest radiant heater available for the heating of livestock in agricultural animal confinement buildings. Your new l.B. White radiant heater incorporates the benefits from the most experienced manufacturer of heating products using state-of-the-art technology...

Warning fire and explosion hazard ■ not for home or recreational vehicle use. ■ installation of this brooder in a home or recreational vehicle may result in a fire or explosion. ■ fire or explosions can cause property damage or loss of life. For your safety if you smell gas: 1. Open windows. 2. Don'...

This owner's manual includes all options and accessories commonly used on or with this heater. However, depending on the configuration purchased, some options and accessories may not be included. When calling for technical service assistance, or for other specific information, always have the model ...

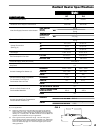

I 17 i 34 maximum input (btuh) 17,100 34,200 ventilation air to support combustion 5 psig 5 psig 5 psig 2.5 psig 5 psig “a” 16 7/8 in. 26 3/8 in. “b” 17 in. 20 1/4 in. “c” 8 3/4 in. 10 3/8 in. Net weight 8 lbs. 10 oz. 15 lbs. 8 oz. L.P. Gas .80 lbs./hr. 1.58 lbs./hr. Natural gas 120/60/1 0.5 chicken...

Lp ggas aand nnatural ggas hhave m man-m made oodorants aadded sspecifically ffor ddetection oof ffuel ggas lleaks. If aa ggas lleak ooccurs, yyou sshould bbe aable tto ssmell tthe ffuel ggas. That’s yyour s signal tto g go iinto iimmediate aaction! ■ do not take any action that could ignite the fue...

1. Do not attempt to install, repair or service this heater or the gas supply line unless you have continuing expert training and knowledge of gas heaters. Qualifications for service and installation of this equipment are as follows: qualifications for servicing and installation: a. To be a qualifie...

1. Read all safety precautions and follow l. B. White recommendations when installing this heater. If during the installation or relocating of the heater, you suspect that a part is damaged or defective, call a qualified service agency for repair or replacement. 2. On initial installation and before...

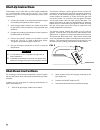

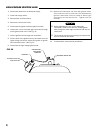

Installation layout for safe clearances i17 & i34 - 3 ft. Minimum brooder top to ceiling position the gas hose and electrical power cord outside of the hot zone directly above the heater. Position the gas hose and power cord to avoid any opportunity for contact with the hot canopy surface of the hea...

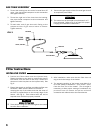

1. Thread the bushing into one end of manual shut off valve. Use pipe thread compound at this connection and tighten securely. 2. Thread the rigid end of the hose into the bushing. Use pipe thread compound at this connection and tighten securely. 3. Thread other end of gas hose with fitting to the a...

Cleaning the filter 1. During eeach fflock — remove the filter and shake out the dust. Reinstall the filter according to previous instructions. 2. After eeach fflock — if necessary, remove the filter and use compressed air and/or water to clean the filter. Make sure to squeeze out any excess water f...

On/off switch on 11 the building’s environmental temperature control system will shut the heater down after proper temperature has been achieved. If heater is to be shut down for cleaning, maintenance or repair, follow steps 1-4. 1. Shut off all gas supply valves to the heaters. 2. Allow heaters to ...

Air nozzle 12 it is important to clean the heater on a regular basis to maintain proper combustion and to eliminate future problems. The frequency of cleaning will vary depending upon livestock being raised and overall ventilation of the building. Cleaning with backpack blowers and heater blower blo...

Service instructions 1. Disconnect the gas supply to heater before attempting to service unless it is necessary to have it connected for your service procedure. Use special care to avoid being burned by hot surfaces or make sure the heater is cool to touch before servicing. 2. Do not attempt to repa...

Ignition lead ignition control mounting screws 1. Disconnect heater from its electrical supply. 2. Close fuel supply valves to heater. 3. Remove dust filter and filter sleeve. 4. Remove the screws that secure the control box cover to the control box and lift cover from box. 5. Disconnect all electri...

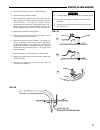

15 1. Disconnect heater from its electrical supply. 2. Close fuel supply valves. 3. Remove filter and filter sleeve. 4. Remove the control box cover. 5. Disconnect the igniter lead from ignition module. 6. Loosen the nut on the water tight connection through which ignition lead is fed. See fig. 10. ...

16 boot ignitor a b screws cover c igniter/flame sensor 1. Disconnect the heater from its electrical supply. 2. Close fuel supply valves to heater. 3. Pull the boot of the ignition lead up and back from the igniter along the lead to expose the igniter to ignition lead terminal. If the ignition cable...

Adapter inlet bushing ground lead valve grounding and attachment screw injector body adapter gas control valve gas control valve 1. Disconnect the heater from its electrical supply. 2. Close fuel supply valves to heater. 3. Remove dust filter and filter sleeve. 4. Brush or blow off any dust in vicin...

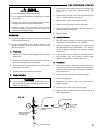

Fuel supply valve (open this valve to use pressure gauge) test kit hose pressure gauge kit 500-20736 gas supply hose gas control valve open 18 fig. 15 gas pressure checks warning fire aand eexplosion h hazard ■ do not disassemble the gas control valve. ■ do not attempt to replace any components on t...

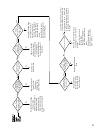

19 read this entire section before beginning to troubleshoot problems. The following troubleshooting flow charts provide systematic procedures for isolating heater problems. The charts are intended for use by a qualified gas heater service person. Do n not s service tthe h heater u unless yyou h hav...

Does ignit er spark? 20 pr ob le m 11 h ea te r d oe s n ot ll ig ht is pr oper v oltage being sent fr om on/off switch t o high limit switch? Is an audible “click” hear d when solenoid valv e is supplied voltage? Check f or v oltage and r esistance of switch and electrical leads betw een switches a...

21 pr ob le m 22 h ea te r l li gh ts bu t ww ill nn ot s ta y l li t is heat er’s dust filt er r easonably clean ? R emo ve ignit er and clean its electr ode with st eel w ool or emer y clo th r emo ve filt er . Clean filt er accor ding t o prescribed filt er cleaning methods in this owner’s manual...

22 pr ob le m 33 h ea te r b ur ne r f fl am e ex te nd s b ey on d o ut er bb ur ne r c on e o or b la ck ss oo t on iin si de oo f c an op y r emo ve air filt er and clean accor ding t o prescribed methods in this owner’s manual. Ye s no is dust filt er clean? Are inner cone, inlet venturi, inject...

Electrical connection and ladder diagram 23 caution: refer to the heater's electrical connection diagram when servicing to avoid wiring errors and heater malfunction. Check for proper operation after servicing. Warning: this heater may start at any time high voltage igniter lead igniter red red grou...

Heater component function burner orifice metering device used to feed gas to combustion cones at a specific flow rate. Double combustion chamber made of special alloy steel. This is where combustion of gas occurs, providing radiant heat used in the warming process. Gas control valve component that h...

Parts identification parts schematic 11 4 5 10 34 6 17 8 26 32 25 37 27 28 22 35 24 23 31 30 7 31b 1 31a 29 3 9 2 12 36 20 16 21 13 41 1 14 19 18 33 39 42 40 38 25.

Parts list 26 model item description i17 i34 1 inner cone 130-09585 130-09557 outer cone 130-09588 130-09556 combustion cone kit with gasket 500-21087 500-21088 2 gasket 130-09586 130-09560 3 plate, burner 130-21953-03 130-22212-03 4 igniter 120-22612 5 cover, igniter mounting 220-22786 6 spacer 130...

Contact your local l.B. White dealer for replacement parts and service or call the l.B. White company, inc. At 1-800-345-7200 for assistance. Be sure that you have your heater model number when calling. 27 l.B. White co., inc. Warrants that the component parts of its equipment are free from defects ...