- DL manuals

- L.B. White

- Heater

- Pilot Light Ignition

- Installation And Service Manual

L.B. White Pilot Light Ignition Installation And Service Manual

Summary of Pilot Light Ignition

Page 1

Pilot light ignition installation and service guide agricultural animal confinement building heaters 150-22003.

Page 2

Foreword the purpose of this service guide is to provide detailed instructions and information for the installation, maintenance, troubleshooting and repair of l.B. White pilot ignition agricultural heaters. By consulting specific sections within the guide, you will become acquainted with components...

Page 3

Warning fire and explosion hazard ■ not for home or recreational vehicle use. ■ installation of this heater in a home or recreational vehicle may result in a fire or explosion. ■ fire or explosions can cause property damage or loss of life. For your safety if you smell gas: ■ open windows. ■ don't t...

Page 4

Table of contents section 1 general information section/page basic unit description and application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.1 key markings; purpose and location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.1 heater spec...

Page 5

Basic unit description and application pilot ignition agricultural building heaters are direct-fired, non-vented heaters used in the heating of animal confinement buildings (examples: swine, chicken, and turkey). These heaters utilize a system that ignites the gas by a conventional pilot flame rathe...

Page 6

Heater specifications general information 1.2-1 1 august 1999 specifications maximum input (btuh) 60,000 115,000 170,000 40,000 minimum input (btuh) n/a n/a n/a 15,000 250 cfm 600 cfm 760 cfm 220 cfm 10.5 in. 7.0 in. 11.0 in. 7.0 in. 11.0 in. 7.0 in. W.C. W.C. W.C. W.C. W.C. W.C. 10.0 in. W.C. 4.0 i...

Page 7

Heater specifications general information august 1999 specifications maximum input (btuh) 200,000 250,000 minimum input (btuh) n/a 160,000 760 cfm 1100 cfm 11.5 in. 7.0 in. W.C. W.C. 10.0 in. 4.0 in. W.C. W.C. 11.5 in. 4.5 in. W.C. W.C. 11.5 in. 4.5 in. W.C. W.C. 11 in. 4.0 in. W.C. W.C. 9.26 200 11...

Page 8

Safety precautions general information 1.3-1 1 august 1999 lp ggas aand nnatural ggas hhave m man-m made oodorants aadded sspecifically ffor ddetection oof ffuel ggas lleaks. If aa ggas lleak ooccurs, yyou sshould bbe aable tto ssmell tthe ffuel ggas. That’s yyour s signal tto g go iinto iimmediate ...

Page 9

Safety precautions general information 1. Do not attempt to install, repair, or service this heater or the gas supply line unless you have continuing expert training and knowledge of gas heaters. Qualifications for service and installation of this equipment are as follows: a. To be a qualified gas h...

Page 10

Safety precautions general information three-prong receptacle. Failure to use a properly grounded receptacle can result in electrical shock, personal injury, or death. 14. If gas flow is interrupted and flame goes out, do not relight the heater until you are sure that all gas that may have accumulat...

Page 11

General information installation instructions 1. Read all safety precautions and follow l. B. White recommendations when installing this heater. If during the installation or relocating of heater, you suspect that a part is damaged or defective, call a qualified service agency for repair or replacem...

Page 12

A b c d e f g h 300' 40' 20' 50' 50' 50' 30' 30' 50' 20' 50' 2.2-1 1 august 1999 fig. 1 lp tank first stage regulator (tank pressure reduced to 5 psig) second stage regulator, 5 psig inlet heater general iinformation pipe sizing is critical to the proper operation of any gas heating system. However,...

Page 13

2.2-2 2 pipe sizing installation instructions example (refer to fig 2) important: if exact length is not on chart, use next longer length. Select the size of pipe that shows at least as much capacity as needed for each piping section. A. Section a to b of pipe must supply the complete gas load of 1,...

Page 14

Tank sizing installation instructions attention ■ the following is supplied for informational purposes only. ■ consult your lp gas supplier for specific requirements. A tank is propane storage container ranging in size from 150 gallons to 10,000 gallons or larger. For agricultural heating applicatio...

Page 15

2.4-1 1 august 1999 tank location and installation installation instructions attention ■ the following is supplied for informational purposes only. ■ tank installation shall only be accomplished by a qualified lp gas installation person. ■ state and local codes must be observed at all times. ■ in ab...

Page 16

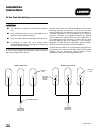

Lp gas tank manifolding installation instructions 2.5-1 1 august 1999 attention ■ the following is supplied for informational purposes only. ■ tank manifolding shall only be accomplished by a qualified lp gas installation person. ■ local and state codes must be observed at all times. ■ in absence of...

Page 17

Manual shut-off valve, hose and regulator assembly installation instructions 1. Always use approved pipe thread compound suitable for use with l.P. Gas or natural gas on the threaded connections. 2. Assemble the components together according to the figure. This view is to show general assembly of th...

Page 18

2.7-1 1 august 1999 sediment trap installation instructions assemble the tee, nipples and cap together and tighten securely. The sediment trap assembly must always be mounted in a vertical position. Make sure pipe thread compound that is resistant to both l.P. Gas and natural gas is used in making a...

Page 19

2.8-1 1 august 1999 electrical requirements installation instructions attention ■ the following is supplied for informational purposes only. ■ all electrical wiring shall be accomplished by a qualified electrician. ■ local and state codes must be observed at all times. ■ in absence of local or state...

Page 20

Models 3 346/348, 3 377/379, 4 408/410 1. Disconnect the heater from its electrical supply and close all fuel supply valves to the inlet of the heater. 2. Locate the two wires labeled “power supply to thermostat” and “power return from the thermostat” within the heater’s electrical junction box. 3. ...

Page 21

Remote thermostat installation instructions 2.9-2 2 models 3 346/348, 3 377/379, 4 408/410 ((cont.) 9. Reconnect the heater to its electrical supply and open the fuel supply valves to the inlet of the heater. 10. Light the pilot. Turn the thermostat up above room temperature so the motor starts and ...