Available in either l.P. Gas vapor withdrawal or natural gas configurations. Models output (btuh) fuel hw220 220,000 congratulations! You have purchased the finest agricultural building heater available. Your new l.B. White heater incorporates the benefits from the most experienced manufacturer of h...

Warning fire and explosion hazard ■ not for home or recreational vehicle use. ■ installation of this heater in a home or recreational vehicle may result in a fire or explosion. ■ fire or explosions can cause property damage or loss of life. For your safety if you smell gas: 1. Open windows. 2. Don't...

This owner's manual includes all options and accessories commonly used on this heater. However, depending on the configuration purchased, some options and accessories may not be included. When calling for technical service assistance, or for other s p e c i f i c i n fo r m a t i o n , a l way s h a...

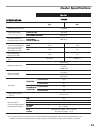

4 4 heater specifications specifications hw220 propane natural gas gas maximum input (btuh) 220,000 exhaust fan 550 cfm shuttered air inlet 220 sq. In. 100 sq. In. Max. 13.5 11.0 min. 11.0 7.0 5.0 3.1 10.19 lbs. 220 cu. Ft. Ball bearing 1/2 h.P. 1,100 rpm 115/60/1 230/60/1 17.1 6.7 6.2 2.6 35 x 25 x...

5 5 lp gas and natural gas have man-made odorants added specifically for detection of fuel gas leaks. If a gas leak occurs, you should be able to smell the fuel gas. That’s your signal to go into immediate action ! ■ do not take any action that could ignite the fuel gas. Do not operate any electrica...

1. Do not attempt to install, repair, or service this heater or the gas supply line unless you have continuing expert training and knowledge of gas heaters. Qualifications for service and installation of this equipment are as follows: a. To be a qualified gas heater service person, you must have suf...

Direct fired heaters discharge combustion by-products with the heated air in to the area being heated. These include co, co 2 , no, no 2 , and ethylene. These gases can result in harm to the worker or the plants. This greenhouse heater has been specifically developed for very low levels of these com...

-- after all connections are checked and any leaks are stopped, turn on the main burner. -- stand clear while the main burner ignites to prevent injury caused from hidden leaks that could cause flashback. -- with the main burner in operation, check all connections, hose connections, fittings and joi...

Indoor ventilation requirements this heater requires a properly sized, motorized air inlet shutter and exhaust fan for indoor installation. These components, along with specific instructions, are provided in indoor ventilation kit # 25985. Air inlet locate the air inlet directly beneath the heater a...

As shipped, the heater is configured for mounting to an optional mounting bracket kit, part number 23652, which is installed on freestanding supports or mounted directly to the structure’s wall. Separate installation instructions accompany the kit. The heater may also be suspended by chain to the gr...

1. T to connect the series tap plug thermostat kit: a. Connect the power cord of the heater to the fe m a l e s i d e o f t h e p l u g o n t h e e n d o f t h e thermostat cord. B. Plug the male side of the series tap plug on the thermostat cord into a three-wire (grounded) electrical outlet within...

Follow steps 1 - 6 on initial start-up after heater installation by a qualified gas heater service person. For normal start- up, simply turn thermostat above room temperature. The heater will start. 1. Open all manual fuel supply valves and check for gas leaks using approved leak detectors. The gas ...

1 13 1. Before cleaning, shut off all gas supply valves and disconnect electrical supply. 2. At least once a year give the heater a thorough cleaning, preferably before the beginning of the fall heating season. At that time, remove the fan and motor assembly and brush or blow off the fan wheel. Addi...

1 14 1. Remove the motor mounting plate screws and pull the fan and motor assembly from the housing. 2. Loosen the square head set screw(s) on the fan wheel. 3. Pull the fan wheel from the motor shaft. Use a wheel puller if necessary. 4. Remove the four (4) nuts securing the motor to the mounting pl...

1 15 air proving switch switch w/ paddle leads nuts paddle oblong hole housing side panel 1. Remove two sheet metal screws holding air proving s w i t c h a s s e m b l y to b l owe r h o u s i n g . Re m ove assembly by turning switch assembly 90 degrees so the switch paddle can be pulled through o...

Outlet pressure t inlet pressure tap on off attention ■ the following explains a typical procedure to be followed in checking gas pressures. ■ the gas pressures will vary depending upon fuel type. ■ consult the dataplate on the heater or page 4 in this manual for specific pressures to be used in con...

1 17 1. Remove the sensor from its mounting bracket. Clean the sensor’s rod with emery cloth or steel wool to buildup of dirt to help maintain proper flame sense. See fig. 17. 2. Check the flame sensor’s insulative base for any cracks. If cracks are found, replace the sensor. Fig. 17 ■ for proper fl...

Troubleshooting instructions read this entire section before beginning to troubleshoot problems. The fo l l ow i n g t ro u b l e s h o ot i n g g u i d e p rov i d e s s y s te m a t i c procedures for isolating equipment problems. This guide is intended for use by a qualified gas heater service pe...

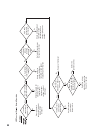

19 problem led constant on l e d l ig h t n o t o n normal operation is pr oper v o ltage supplied t o heat er? Check data plat e f o r electrical supply req uirments. Pr o v ide pr oper v oltage, contact electrician. Ye s no ye s ye s ye s def e ctiv e wire or electrical connection. R eapir or repl...

20 problem l e d f la s h in g o n e t im e f la s h p a tt e rn b e g in s im m e d ia te ly a ft e r c o n d it io n o c c u rs . Is air pr o ving switch stuck closed or shor ted ? Check continuity . Is air flo w switch arm binding in f a n housing? F ree the switch . Det ermine casue of flapper b...

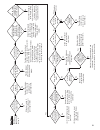

2 21 t w o t im e s flash patt ern begins 12 seconds af te r condition occur s. (patt ern indicat es lac k of air pr o ving in fan section of unit.) are air -pr o ving switch contacts stuck open? (p er fo rm continuity check .) does fan mo tor star t up fo r prepurge during initial call fo r heat? I...

2 22 t h re e t im e s ignition failure heat er does no t light or s ta y lit. Is lp tank full and pr operly sized and are all gas supply v a lv es t o heat er open? Fill tank or resize if necessar y. Open all gas supply v alv es ye s no is pr oper gas pressure supplied to heat er? Ye s are 2 4 v ol...

2 23 f iv e t im e s rapid on/of f cy cling of the burner . See flame sensor relat ed pr oblems in three time flash patt ern. S ix t im e s lo w micr oam p output fr om flame sensor . The heat er will continue t o operat e as normal. Flame sense is lo w and that flame f ailure or im pr oper operatio...

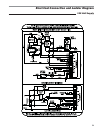

2 24 electrical connection and ladder diagram 115 volt supply 120 vol t.

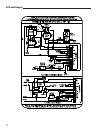

2 25 230 volt supply 120 vol t.

2 26 heater component function air proving switch safety device used to insure that the proper air flow is being achieved before the gas valve is opened. Burner cast iron component used to channel gas and provide an area at which the fuel may ignite. Burner orifice brass metering device used to feed...

2 27 28 30 37 38 39 21 20 19 16 17 6 5 7 8 9 10 11 12 4 3 2 1 14 31 32 33 34 35 26 27 29 36 22 25 13 18 15 24 23 parts identification parts schematic.

2 28 parts identification parts list item description part number 1 regulator lp gas 06553 natural gas 24414 2 valve, manual shut off with nipple 03399 3 hose, 1/2 x 10 ft., rigid x swivel 20714 4 adapter, hose, 1/2 npt x 1/2 nps 25873 5 kit, sediment trap 00815 6 screws (2) 572502 7 bracket with sc...

Contact your local l.B. White dealer for replacement parts and service or call the l.B. White co., inc. At (800) 345-7200 for assistance. Be sure that you have your heater model number and configuration number when calling. L.B. White co., inc. Warrants that the component parts of its heater are fre...