- DL manuals

- L.T. Rich Products

- Snow Blower

- Snowrator Zx4

- Owner's Manual

L.T. Rich Products Snowrator Zx4 Owner's Manual

Summary of Snowrator Zx4

Page 1

Owners manual snowrator zx4 920 hendricks drive lebanon, in 46052 (877) 482-2040 www.Snowrator.Com.

Page 3: Table Of Contents

Table of contents section 1 to the owner page 1.1 read this manual entirely before operating the snowrator……………………..…..1 1.2 product / warranty registration…………….…………………………………..……...1 1.3 l t rich products warranty……………………………………………………………1 1.4 component manufactures’ warranties…………………………………………..……..2...

Page 4

Section 1 to the owner 1.1 read this manual entirely before operating the snowrator the information presented herein will prepare you to operate the l.T. Rich snowrator in a safe and knowledgeable manner. Operating the snowrator in a proper manner will provide a safer working environment, create mor...

Page 5

1.4 component manufactures’ warranty some of the component parts of the snowrator are warranted by their respective manufactures. These parts are: hydro-gear pump parker wheel motors honda engine delevan liquid pump the complete manufactures’ warranty information for these components is located in t...

Page 6

The illustrations and data used in the manual were current at the time of printing, but the snowrator may vary slightly due to ongoing engineering changes. L. T. Rich products, inc reserves the right to implement engineering and design changes to the snowrator as may be necessary without prior notif...

Page 7

Periodically tighten all nuts, bolts and screws and check that all fasteners are properly installed to ensure that the snowrator is in safe operating condition. 2.5 storage safety rules never store the snowrator in any area accessible by children. Never store the snowrator with fuel in the tank insi...

Page 8

3.2 hydraulic system maintenance hydro-gear recommends that the fluid and filter(s) be changed every 500 hours. Use any type of motor oil in a 5w-40 synthetic or equivalent. Hydraulic system requires 25 micron hydraulic filters (part # 80404) or equivalent to be used. Check for hydraulic leaks daily...

Page 9

Page 6.

Page 10

Page 7.

Page 11

Page 8.

Page 12

Page 9.

Page 13

Page 10

Page 14

3.3 traction unit maintenance inspect wheels every 25 hours for damage, debris, and proper installation. Inspect all bolts, washers, nuts, pins and other mounting hardware of snowrator once a week to ensure that hardware pieces are properly tightened. 3.4 snowrator system maintenance the snowrator h...

Page 15

Be sure that guides (4) are not damaged to allow the hopper door to slide freely check agitator wire on a daily basis. If wire is not present, product will run the risk of building up prior to reaching hopper door and not spreading evenly. Section 4 snowrator operations 4.1 operations upon turning t...

Page 16

The blade control joystick valve has 5 positions of operation. Pulling back on the joystick valve will raise the blade to the up position (off the ground for transport of transition). Pulling the joystick valve to the left tilts the blade to the left allowing to angle the snow to the left. Pulling t...

Page 17

4.2 spraying operations the snowrator spray system has a liquid storage tank of 20 gallons that can disperse a host of liquid and/or wettable powder. To get maximum life and performance out of the spray system, it is recommended that the tank, nozzles and hoses be flushed of all products after each ...

Page 18

4.3 spreader operation (optional) the snowrator unit has an optional 120 lb. Spreader that can be mounted to the machine. This electric hopper motor with the spreader control rate knob allows variable spread widths from 3 to 25 feet. This depends on volume/density, particle size and rate of travel, ...

Page 19

Section 5 parts 5.1 part number / pictorial (serial # sr4320-2015-001 to sr3620-2016-085) page 16.

Page 20

5.1 part number / pictorial (serial # sr3620-2016-086 to current) page 17.

Page 21

Spot spray gun part # description qty 60040 spot spray gun 1 60041 spot spray tip 1 60029 ¼” mpt x 3/8” barb 1 page 18.

Page 22

5.2 parts list parts list 80202 pump on-off switchch-m-58031-01 1 ea 80210 12 volt batteryss11u1l cca350 1 ea 80215 key switch4f463 1 ea 80214-a tach/hour meter 1 ea 80352-36r jr 36r wheel hub-4 hole (r only) 4 ea 80404 hydraulic filteraa0513 1 ea 60010 directo valve aa6b 1 ea 60012 throttle...

Page 23

80205-36r jr36r ignition harness 1 ea 86036 36" jr36r hydro hose 1 ea 86024 23" jr36r hydro hose 1 ea 10058 bulkhead, 1/2" (hole requirement 1 1/4") 2 ea 60078 1/2 cpvc mip adapter 2 ea egb716-black 7/16 trim lok edging 3 ft 80620 jr36r wheel motor right 2 ea 80621 jr36r wheel motor left 2 ea 80402-...

Page 24

Swivel one end, goodyear insta grip hose 86070 return hose assembly 11" crimped jic female swivel both ends, goodyear insta grip hose 1 ea qd-ff-f-04-npf04-s f. Firg 14npt 5 ea qd-ff-m-04-npf04-s m. Firg 14 npt 5 ea 80707-plow plow spring century # 614 2 ea 80213 switch, on/off, with light, sr 1 ea ...

Page 25

Section 6 trouble shooting 6.1 troubleshooting engine: not starting. There are a few reasons as to why your engine fails to start. If the engine does not turn over, then the battery could be dead, bad connection to the battery wires, key switch may be bad, 30 amp fuse on the wiring harness (orange...

Page 26

Granular: there are numerous potential challenges that can happen on the granular side due to the amount of use this portion of the unit sees. If product is not spreading evenly or consistently, then look for a few things with your hopper impeller or hopper diffuser. If there is build up at the en...

Page 27

Honda engine wiring harness schematics page 24.

Page 28

Page 25.

Page 29: L. T. Rich Products Inc

L. T. Rich products inc . Warranty registration card serial #: company name: company address: city / state: company phone: company fax: company contact: company email: *please circle what most accurately describes your business* commercial sports complex school municipal cemetery home owner other de...

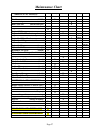

Page 30: Maintenance Chart

Maintenance chart service action(s) daily weekly bi-weekly monthly yearly hours tire pressure (18 psi) x rim nut torque (75lbs) x hub castle nut (check cotter pin) x engine oil (check) x engine oil change 50 hrs engine air filter check (change if needed) x replace engine air pre-filter check (change...