- DL manuals

- L.T. Rich Products

- Tiller

- Z-Plug

- Owner's Manual

L.T. Rich Products Z-Plug Owner's Manual

Summary of Z-Plug

Page 1

Owners manual z-plug (4 wheel unit).

Page 3: Table Of Contents

Table of contents section 1 to the owner page 1.1 read this manual entirely before operating the z-plug………………………..….1 1.2 product / warranty registration…………….………………………………………...1 1.3 l t rich products warranty…………………………………………………..………1 1.4 component manufactures’ warranties………………………………………………..2 1.5 c...

Page 4: L. T. Rich Products Inc

L. T. Rich products inc . Warranty registration card serial #: company name: company address: city / state / zip: company phone: company fax: company contact: company email: *please circle what most accurately describes your business* commercial sports complex school municipal cemetery home owner ot...

Page 5

Section 1 to the owner 1.1 read this manual entirely before operating the z-plug the information presented herein will prepare you to operate the l.T. Rich z-plug in a safe and knowledgeable manner. Operating the z-plug in a proper manner will provide a safer working environment, create more efficie...

Page 6

1.4 component manufactures’ warranty some of the component parts of the z-plug are warranted by their respective manufactures. These parts are: hydro-gear pumps/motors parker wheel motors vanguard commercial engines delevan pump (if applicable) the complete manufactures’ warranty information for the...

Page 7

Although these instructions have been complied through extensive field experience and engineering data, some information presented herein may be generated in the nature due to unknown and/or varying operating conditions. However, these instructions, combined with your increased experience with the z...

Page 8

2.4 maintenance safety rules never perform maintenance on the z-plug when children are present. Never allow anyone near the operation controls while performing service or maintenance to the z-plug. Keep z-plug engine area free of accumulated debris, fuel, or excess grease and oil to prevent fire haz...

Page 9

(not required to remove hydro shield) (remove hydro shield to access drain hose) (remove hydro shield for easier access) (pull drain hose out from between hydro’s) (remove bolts from the engine shield brackets) (remove oil filter and replace with new) (install and secure engine shield back on to fra...

Page 10

Fuel recommendations: fuel must meet these requirements clean, fresh, unleaded gasoline. A minimum of 87 octane/87 aki (91 ron). Gasoline with up to 10% ethanol (gasohol) or up to 15% mtbe (methyl tertiary butyl ether) is acceptable *full maintenance information can be located in the engine manual p...

Page 11

Inspect wheel and caster assembly every 25 hours for bearing wear, damage, debris, and proper installation. Inspect idler arm bushing every 50 hours for wear. These bushings are wear items and will have to be replaced periodically. Inspect all bolts, washers, nuts, pins and other mounting hardware o...

Page 12

The z-plug unit has the ability to mount a 120 lb hopper spreader unit to the frame. Just like our z-spray spreader systems, maintenance is a key requirement to allow successful applications. Here are a few things to maintain on this system. Lubricate (silicone spray) hopper and diffuser cables on a...

Page 13

Section 4 aerator operations 4.1 overview the z-plug can cover 80,000 square feet per hour and produce up to 3 ½” cores. The full floating tine head can maneuver around trees and beds while engaged. The 2,000 lb hydraulic cylinder picks up the head in less than 2.5 seconds for turning around or gett...

Page 14

Pull the pin from the aerator front frame neck (it will be attached to the front frame of the traction unit) and dismount the ball swivel from the pin (pull neck downward). Lower front neck of the aerator head and position yourself back on the traction unit. Drive away from the aerator head by turni...

Page 15

5.2 spray calibration/tip chart/liquid quantities the z-plug spray system comes standard with lavender colored air injected tips which will apply liquid material @ .32 (1/3) gallons per 1,000 sq. Ft. @ 5 m.P.H and 4—45 psi. Each tip has a 5 psi shut-off screen to prevent drip. Your machine is capabl...

Page 16

The diffuser adjustment allows the user to adjust the intensity of the spread pattern. A small turn shifts the product placement on the impeller. This in turn balances the spread pattern heavier to the left (back side ramp) or heavier to the right (front side ramp). Adjustment is very sensitive, so ...

Page 17

*spray/spread calibration decal charts are available from the parts department (units shipped from july 2010 and current have this decal installed on the backside of the knee pad). Part # is 30705* section 6 parts 6.1 part number / pictorial electric parts part # description qty 80202 pump on-off sw...

Page 18

Hydraulic parts/idler bracket parts part # description qty 80003 idler pulley 1 80004 idler pulley bracket weldment 1 80304 idler pulley bracket bushings 2 80112 idler spring 1 80413-bx53 drive belt 1 80413-b54 drive belt (may 2011 to current) 1 hhesc5-12221 idler bracket bolt 1 fw-sae-12 idler brac...

Page 19

Aerator head parts (36” head) part # description qty 80701 aerator tine (60ea on 46” aerator head assembly) 48 80709 pillow block bearing 4 80714-b aerator ½ disk plate (20ea on 46” aerator head assembly) 16 80913 rear tray weights (part # 80914 for 46” head) 3 80703 lift collar 2 80704-b aerator li...

Page 20

Foot plate parts part # description qty 83067 compression springs 3 hhcsc5-38114 bolt 5 nnc-38 nut 5 fw-sae-38 flat washer 10 80181 foot pan tray (mild steel) 1 80029-rev foot plate (mild steel) 1 (*if parts needed for pivot point*) part # description qty fw-sae-38 flat washer 6 hhcsc5-38112 bolt 2 ...

Page 21

Locking caster system parts part # description qty 80022-13 13” linkage rod 1 80022-24.5 24.5 linkage rod 2 80023 ball joint 2 nnc-516 nylon nut 4 fw-sae-516 flat washer 8 hhccsc5-38112 stop bolt 1 83049 spring 4 lwss-516 lock washer 6 zhnfss-516 hex nut 6 collar516 5/16” collar 2 8022-16 16” linkag...

Page 22

120 lb hopper parts part # description qty 70042 120 lb hopper tub 1 80440-rev hydraulic hopper motor 1 70046 hydraulic hopper bracket 1 70334 hopper screen 2 70019 hopper rate dial 1 70022 rate dial holder 1 70037 hopper bottom bearing 1 70041 rate gate linkage 1 70047 hopper bottom plate 1 70040 r...

Page 23

Parts list 80112 - boom spring century# 80914-s 1 30675 - joy stick foam gripeezer # 100130 2 30700 - decal z-spray control panel 1 80019-mm - new style (single bolt) 13” front caster wheel assy. 2 80019-b - spacer hss-34 4 80021 - rear wheel assembly z-maxcarlise# 15-640-419gk 2 80025 - joy s...

Page 24

804449-b - lift valve 1 lever (80448 prince valve 20012 to 2013) 1 80449-electric – electric parker lift valve (2013 to current) 1 80204-thumb – electric lift valve thumb switch (2013 to current) 2 80432 - aux pump fitting (2)6400-04-04 2 80419 - wheel motor fitting (4)6801-08-10-4 4 80420 - 1/2...

Page 25

Tnut51618 - 5/16-18 t nut 4 hhcsc5-51612 - 5/16-18 x 1/2 hex cap screw gr 5 zinc 3 hhcsc5-12212 - 1/2-13 x 2-1/2 hex cap screw gr 5 zinc 8 cb-12112 - 1/2-13 x 1-1/2 carraige bolt 4 fw-sae-34 - 3/4 sae flat washer zinc 1 fwss-12 - 1/2 s/s flat washer 5 fwss-38lod - 3/8 x 1 s/s flat washer 8 fw-sae-51...

Page 26: L. T. Rich Products Inc

L. T. Rich products inc . Warranty registration card serial #: company name: company address: city / state / zip: company phone: company fax: company contact: company email: *please circle what most accurately describes your business* commercial sports complex school municipal cemetery home owner ot...

Page 27

Troubleshooting engine: not starting. There are a few reasons as to why your engine fails to start. If the engine does not turn over, then the battery could be dead, bad connection to the battery wires, key switch may be bad, 30 amp fuse on the wiring harness (orange wire) may be blown or the starte...

Page 28

Granular: there are numerous potential challenges that can happen on the granular side due to the amount of use this portion of the unit sees. If product is not spreading evenly or consistently, then look for a few things with your hopper impeller or hopper diffuser. If there is build up at the end ...

Page 29

Charging issues: 20 amp regulated alternator the 20 amp regulated alternator system provides ac current through two output leads to the regulator-rectifier. The regulator-rectifier converts the ac current to dc, and regulates current to the battery. The charging rate will vary with engine rpm and te...

Page 30

Dc output charging wire test a simple test can be used to test the dc output charging wire circuit. If a wiring problem exists it can be corrected before testing regulator-rectifier. Leave stator wire harness disconnected from regulator-rectifier. Equipment key switch must be in off position. 1. Ins...

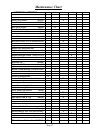

Page 31: Maintenance Chart

Maintenance chart service action(s) daily weekly bi-weekly monthly yearly hours front caster wheels (grease) x front caster yokes (grease) x front tire pressure (22 psi) x rear tire pressure (18 psi) x rear rim nut torque (75lbs) x rear hub castle nut (check cotter pin) x idler pulley arm (grease) x...