Summary of Z-Spray JR36R

Page 1

Owners manual jr36r / zs-3620r z-spray.

Page 3: Table Of Contents

Table of contents \ section 1 to the owner page 1.1 read this manual entirely before operating the z-spray………………………..…..1 1.2 product / warranty registration…………….…………………………………..……...1 1.3 l t rich products warranty……………………………………………………………1 1.4 component manufactures’ warranties…………………………………………..…….....

Page 4

Section 1 to the owner 1.1 read this manual entirely before operating the z-spray the information presented herein will prepare you to operate the l.T. Rich z-spray in a safe and knowledgeable manner. Operating the z-spray in a proper manner will provide a safer working environment, create more effi...

Page 5

1.4 component manufactures’ warranty some of the component parts of the z-spray are warranted by their respective manufactures. These parts are: hydro-gear pumps/motors parker wheel motors subaru engine delevan pump the complete manufactures’ warranty information for these components is located in t...

Page 6

The illustrations and data used in the manual were current at the time of printing, but the z-spray may vary slightly due to ongoing engineering changes. L. T. Rich products, inc reserves the right to implement engineering and design changes to the z-spray as may be necessary without prior notificat...

Page 7

Periodically tighten all nuts, bolts and screws and check that all fasteners are properly installed to ensure that the z-spray is in safe operating condition. Never perform maintenance on the z-spray while parking brake is disengaged. 2.5 storage safety rules never store the z-spray in any area acce...

Page 8

3.2 hydraulic system maintenance hydro-gear recommends that the fluid and filter(s) be changed every 500 hours. Use any type of motor oil in a 5w-40 synthetic or equivalent. Hydraulic system requires 25 micron hydraulic filters (part # 80404) or equivalent to be used. Check for hydraulic leaks daily...

Page 9

Inspect wheel and caster assembly every 25 hours for bearing wear, damage, debris, and proper installation. Inspect all bolts, washers, nuts, pins and other mounting hardware of z-spray once a week to ensure that hardware pieces are properly tightened. 3.4 spray system maintenance the z-spray has bo...

Page 10

Check agitator wire on a daily basis. If wire is not present, product will run the risk of building up prior to reaching hopper door and not spreading evenly. Section 4 z-spray operations 4.1 operations upon turning the key on to start the unit, apply full choke. Once unit has started, release first...

Page 11

Creating pressure to these nozzles is done through the throttle valve. Threading the throttle valve in (picture # 1) will create pressure to either the boom nozzles or the hose reel. Threading the throttle valve out (picture # 2) will bring pressure to the tank(s) and create agitation. If threading ...

Page 12

(hose reel chrome valve in closed position) (hose reel chrome valve in open position) periodically check the in-line filter for any debris in the screen. If debris is present, this can create erratic pressure spikes and/or not allow the proper flow through system. After clearing any debris, ensure t...

Page 13

Useful formulas gpm = gpa x mph x w (per nozzle) 5,940 gpm = gal/1,000sq ft x mph x w (per nozzle) 136 gpa = 5,940 x gpm (per nozzle) mph x w gal/1,000sq ft = 136 x gpm (per nozzle) mph x w gpm - gallons per minute gpa - gallons per acre gal/1,000sq ft - gallons per 1,000 square feet mph - miles per...

Page 14

*turbo floodjet tips used only on boom less units* alert!!! Never operate all 3 nozzles at the same time (refer to manual for examples) psi drop size capacity one nozzle in gpm capacity one nozzle in oz./min _______spacing__________ /\ 34” /\ gallons per 1,000 sq. Ft. 3 mph 4 mph 5 mph stf-vs2 10 xc...

Page 15

4.4 spreader operation the jr36r / zs-3630 z-spray unit is equipped with a 120 lb spreader. The hydraulic hopper motor with the spreader control rate knob allows variable spread widths from 3 to 25 feet. This depends on volume/density, particle size and rate of travel, and weather conditions. The pa...

Page 16

(diffuser, deflector & hopper cable) (hydraulic hopper motor) (rate dial) (diffuser shown on underside of opening) section 5 parts 5.1 part number / pictorial page 13.

Page 17

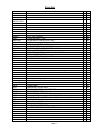

Electric parts part # description qty 80202 pump on-off switch 1 80204-2010 spot spray switch (foot switch only) 1 80205 wiring harness 1 80206 30 amp fuse 1 80207 starter solenoid 1 80208 battery box 1 80120-2010 12 volt battery (*cannot ship, local pickup only*) 1 80214-a tach/hour meter 1 80215 k...

Page 18

Caster parts part # description qty ns-10061-l left side locking caster 1 ns-10061-r right side locking caster 1 80306 dust cap 1 80308 caster bearing 2 80009 castle nut 1 80302 caster bearing seal 2 cp18x112 cotter pin 1 spot spray gun part # description qty 60040 spot spray gun 1 60041 spot spray ...

Page 19

Manifold assembly part # description qty 60049 ½ mpt x ¾ hose bard 90 degree 1 60023 ½ to ¼ bushing 1 60022 ½ fpt tee 1 60058 ¾ mpt x ½ mpt reducing nipple 1 60032 gauge, 60psi 1 60010 directo valve \ aa6b 3 60027 ½ mpt x ½ hb 90 3 60026 ¾ mpt x ½ hb 90 1 60012 throttle valve 1 60042 ¼ to 3/8 barb 9...

Page 20

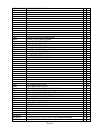

Parts list 80020 junior rear wheel assy 20x8x8 2 ea 80019-mm front zplug wheel assy. 13x6.5x6 2 ea 80200-striker trail tech striker speedometer 1 ea 80202 pump on-off switchch-m-58031-01 1 ea 80204-foot switch assy. Foot spot spray switch assy. 2010fs-01 1 ea 80210 12 volt batteryss11ul1 cca350 ...

Page 21

Hz200blk-06-47 47" boom hose jr36r 1 ea hz200blk-06-62 62" boom hose jr36r 1 ea hz200blk-06-79 79" boom hose jr36r 1 ea igjcfxxx0606-8 jr36r 8" return hose assembly 1 ea 80440 hydraulic spreader motormte 207 1 ea 60035 strainer 50mesh w/ check valve 3 ea 60038 boom elbows3ntl38 3 ea 60061 inline...

Page 22

Section 6 trouble shooting 6.1 troubleshooting engine: not starting. There are a few reasons as to why your engine fails to start. If the engine does not turn over, then the battery could be dead, bad connection to the battery wires, key switch may be bad, 30 amp fuse on the wiring harness (orange w...

Page 23

Granular: there are numerous potential challenges that can happen on the granular side due to the amount of use this portion of the unit sees. If product is not spreading evenly or consistently, then look for a few things with your hopper impeller or hopper diffuser. If there is build up at the end ...

Page 24

Honda engine wiring harness schematics page 21.

Page 25

**optional carrying rack system** (part # 90131) ideal for transporting the ride-on to and from the jobsite rugged stainless steel construction ramps easily fold into an upright position fits any class 4 or 5, 2-inch receiver (must be rated for 600 lbs. Minimum) distance between the rails and bumper...

Page 26: L. T. Rich Products Inc

L. T. Rich products inc . Warranty registration card serial #: company name: company address: city / state: company phone: company fax: company contact: company email: *please circle what most accurately describes your business* commercial sports complex school municipal cemetery home owner other de...

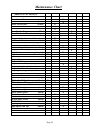

Page 27: Maintenance Chart

Maintenance chart service action(s) daily weekly bi-weekly monthly yearly hours front caster wheels (grease) x front caster yokes (grease) x front tire pressure (22 psi) x rear tire pressure (18 psi) x rear rim nut torque (75lbs) x rear hub castle nut (check cotter pin) x hopper cables (lubricate w/...