- DL manuals

- L.T. Rich Products

- Tiller

- Z-Spray

- Owner's Manual

L.T. Rich Products Z-Spray Owner's Manual

Summary of Z-Spray

Page 1

Owners manual z-spray (60 gallon z-max / 30 gallon intermediate/junior).

Page 3: Table Of Contents

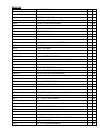

Table of contents section 1 to the owner page 1.1 read this manual entirely before operating the z-spray………………………..…..1 1.2 product / warranty registration…………….…………………………………..……...1 1.3 l t rich products warranty……………………………………………………………1 1.4 component manufactures’ warranties…………………………………………..……..2 ...

Page 4: L. T. Rich Products Inc

L. T. Rich products inc . Warranty registration card serial #: company name: company address: city / state / zip: company phone: company fax: company contact: company email: *please circle what most accurately describes your business* commercial sports complex school municipal cemetery home owner ot...

Page 5

Section 1 to the owner 1.1 read this manual entirely before operating the z-spray the information presented herein will prepare you to operate the l.T. Rich z-spray in a safe and knowledgeable manner. Operating the z-spray in a proper manner will provide a safer working environment, create more effi...

Page 6

1.4 component manufactures’ warranty some of the component parts of the z-spray may be warranted by their respective manufactures. These parts are: hydro-gear pumps/motors ( www.Hydro-gear.Com ) parker wheel motors ( www.Parker.Com ) vanguard commercial engines ( www.Briggsandstratton.Com ) delavan ...

Page 7

The illustrations and data used in the manual were current at the time of printing, but the z-spray may vary slightly due to ongoing engineering changes. L. T. Rich products, inc reserves the right to implement engineering and design changes to the z-spray as may be necessary without prior notificat...

Page 8

Periodically tighten all nuts, bolts and screws and check that all fasteners are properly installed to ensure that the z-spray is in safe operating condition. Never perform maintenance on the z-spray while parking brake is disengaged. **refueling your z-spray** use only approved gasoline container. ...

Page 9

Oil recommendations: briggs & stratton recommends the use of certified oils for best performance. Other high-quality detergent oil are acceptable if classified for service sf, sg, sh, sj or higher. Do not use special additives. Outdoor temperatures determine the proper oil viscosity for the engine. ...

Page 10

3.3 traction unit maintenance the z-spray has 5 grease fittings that require periodic greasing. These locations can be found on the wheel assembly (1 on each front wheel assembly), on the caster assembly (1 on each front caster assembly), and the drive belt idler (1 on idler arm). Inspect wheel and ...

Page 11

Check spray system in-line filter gasket weekly. Improper gasket placement, missing gasket or filter not tightened down can create loss in pump pressure. Check spray tips for any clogging of materials or foreign objects. Clean out tank on daily basis for proper storing. 3.5 spreader maintenance the ...

Page 12

This attachment is used mostly for your non-turf friendly products such as round up and other total kill products, but can also be used for selective products. ~ foam marking kit (part # 80907-60 or 80930-foam) – this attachment allows a unit to mark the turf and make the operator aware of where the...

Page 13

Turning on the spray system can be done one of two ways. Your first option would be the on/off switch located on the control panel (left picture). This would be located on the lower/right side of the control panel. The second way to turn the spray system on is the foot switch located on the left sid...

Page 14

Using the spreader system, there are 3 cables to operate the hopper door (far left cable), the diffuser (middle cable) and the deflector shield (lower right cable). By pulling on the far left hopper door cable, this will open the door and allow product to fall on the spinner. Adjustments as to how w...

Page 15

*note: liquid is pulled from the larger ¾” hose and returned to the ½” hose with this valving setup, you have the option of pulling product from both tanks simultaneously or independently. The picture above left shows the right side valves on and the left side valves off. Periodically check the in-l...

Page 16

Your machine is capable of using tips from ¼ to 1 gallon in size. See chart for your desired drop rate. The following are some general guidelines for sprayer calibration (note: this chart only applies if using air injected tips. Using other tips will require different calculations). Please refer to ...

Page 17

(hopper, diffuser and deflector cables) (hydraulic hopper motor) (hopper rate dial) (diffuser shown on underside of opening) your machine is equipped with a 220 lb. Or 120 lb. Spyker model spreader. The hydraulic spreader motor with the spreader motor control has the ability to vary spread widths fr...

Page 18

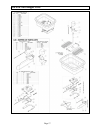

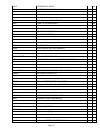

Section 6 parts 6.1 part number / pictorial wheel parts (front and rear) part # description qty 80019-a front 16” wheel assembly 1 80019-b front wheel spacers 2 80309 front wheel cone bearings 2 80311 front wheel bearing cup (for replacement only) 2 80021 rear wheel assembly for max & inter. (not pi...

Page 19

Hydraulic parts/idler bracket parts part # description qty 80003-premium idler pulley 1 82020-a idler pulley bracket weldment 1 80304 idler pulley bracket bushings 2 80112 idler spring 1 80413-b44 drive belt (b44) 1 hhesc5-12221 idler bracket bolt 1 fw-sae-12 idler bracket washer 2 nnc-12 idler brac...

Page 20

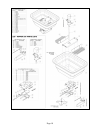

Spot spray gun part # qty description 60040 1 ea spot spray gun 60041 1 ea spot spray tip 60029 1 ea ¼” mpt x 3/8” barb page 16.

Page 21

120 lb & 220 lb hopper parts page 17.

Page 22

Page 18.

Page 23

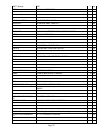

Z-max/intermediate/junior manifold assembly page 19.

Page 24

Z-max/intermediate/junior liquid valve assembly page 20

Page 25

Intermediate/junior boom assembly page 21.

Page 26

Z-max boom assembly page 22.

Page 27

Parts list 30675 joy stick grip 2 ea 30676 brake handle grip 1 ea 60009 1/4" chrome valve90fmb14 1 ea 60010 directo valve aa6b 3 ea 60017 3/4'mpt x 3/4'fpt 90 st el3se34 1 ea 60020 3/4' mpt close nipple3m34 2 ea 60026 3/4'mpt x 1/2' hb 903el3412 3 ea 60029 1/4' mpt to 3/8' barb 3a 1438 1 e...

Page 28

30712 strainer cap decal 1 ea 80302 caster bearing sealsl-122 2 ea 70023-e 12" 220 new hopper shaft 1 ea 60106 cox hose reel 1 ea 80411-15 15mm hydro pulley new style 1 ea 86006 220 hopper hose 6.875 zmax/int 1 ea 60027 1/2'mpt x 1/2' hb 903el12 3 ea 80112 boom spring/belt tension 3 ea 30678 spe...

Page 29

30677-sprayer pad 1 ea 30706 serial number decal 1 ea 80461-hose 11" engine oil drain hose 1 ea hz200blk-08-18 1/2" x 18" boom hose 2 ea 80313 mte hopper motor cap 1 ea ltr60galhyddn 18" hydro drain hose 1 ea 60130-left 30 gallon zmax tank left 1 ea 60130-right 30 gallon zmax tank right 1 ea 60130-1...

Page 30

80527 exhaust clampu125 zinc 2 ea 80421 3/8' 90 deg hydro pump fitting(6)6801-06-06-4 5 ea 80205-2014+ 2014+ ignition harness 1 ea gcp3jcfxjcfx90080808- 42 42" 1/2 jicx jic 90 2 ea hz200blk-08x500 goodyear horizon 1/2' 200 wp black rls 6 ea 30404 60 gal. Footplate vibration isolator 2 ea ltbc-33...

Page 31

Section 7 trouble shooting 7.1 troubleshooting engine: not starting. There are a few reasons as to why your engine fails to start. If the engine does not turn over, then the battery could be dead, bad connection to the battery wires, key switch may be bad, 30 amp fuse on the wiring harness (orange w...

Page 32

Granular: there are numerous potential challenges that can happen on the granular side due to the amount of use this portion of the unit sees. If product is not spreading evenly or consistently, then look for a few things with your hopper impeller or hopper diffuser. If there is build up at the end ...

Page 33

Charging issues: 20 amp regulated alternator the 20 amp regulated alternator system provides ac current through two output leads to the regulator-rectifier. The regulator-rectifier converts the ac current to dc, and regulates current to the battery. The charging rate will vary with engine rpm and te...

Page 34

Dc output charging wire test a simple test can be used to test the dc output charging wire circuit. If a wiring problem exists it can be corrected before testing regulator-rectifier. Leave stator wire harness disconnected from regulator-rectifier. Equipment key switch must be in off position. 1. Ins...

Page 35

Wiring harness page 31.

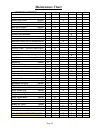

Page 36: Maintenance Chart

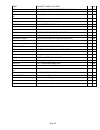

Maintenance chart service action(s) daily weekly bi-weekly monthly yearly hours front caster wheels (grease) x front caster yokes (grease) x front tire pressure (22 psi) x front tire bearing “preload” x rear tire pressure (18 psi) x rear rim nut torque (75lbs) x rear hub castle nut (check cotter pin...