Summary of STRADA EE

Page 1

En s t r a d a e e.

Page 2

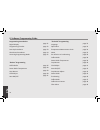

En chapters 1. General warnings and safety specifications 2. Definition of available models 3. Installation 4. Machine operation and coffee preparation 5. Dispensing steam and hot water 6. Maintenance and periodic cleaning operations 7. De-commissioning and demolition 8. Mandatory maintenance and ch...

Page 3

En 3 1. General warnings and safety specifications 1) this operating manual is an integral and essential part of the product and must be supplied to users. Users are asked to read the enclosed warnings and cautions carefully, as they provide valuable information concerning safety during installation...

Page 4

En 4 • do not unplug the device from the power outlet by pulling on the power supply cable; • do not expose the device to atmospheric agents (rain, sun, etc.); • do not allow children or untrained people to use this device; • do not clean the control panel with a wet cloth since it is not watertight...

Page 5

En 5 2. Definition of available models this operating manual refers exclusively to the following models, of our own manufacture: strada, model ee 3 groups 1 main switch 2 pressure gauge (steam boiler) 3 pressure gauge (coffee boiler) 4 brew groups 5 encoder 6 tea water button 7 digital display 8 ste...

Page 6

En 6 1) general description the machine is built in 2 and 3 coffee group versions and is essentially composed of the following parts: • steam boiler (produces steam and hot water); • coffee (“saturated”) boiler; • brewing groups; • exterior cover; • water pump. 2) description of the various parts • ...

Page 7

En 7 • testing: hydraulic test at 18 bar performed on ready-to-use small boilers, at our factory. • brewing groups they consist of a precision casting made of stainless steel. The brewing group accepts the portafilter used to hold the ground coffee; the espresso flows through the brewing group, thro...

Page 8

En 8 3. Installation la figura affianco descrive come collegare ogni filo alla spina. Rispettare anche le norme federali, statali o locali vigenti. Modello/serie gruppo v/hz potenza nominale (w) input nominale (a) potenza caldaia caffe’ potenza caldaia vapore potenza totale dimensione cavo alimentaz...

Page 9

En 9 1) accessories check the package to make sure that the following accessories are included: • a number of 1-dose and 2-dose portafilters orresponding to the number of groups; • replacement 1-dose and 2-dose filters (one of each); • 1 tamper; • 1 blind filter; • cleaning detergent, for the groups...

Page 10

En 10 to verify if this is actually matching our suggested ranges. Once the test has been performed, learn which treatment system is most appropriate for your particular water supply by filling out the online water calculator on our website: la marzocco water calculator (http://www.Lamarzocco. Com/w...

Page 11

En 11 this is the power supply for the water pump motor. The internal electronics will switch the pump motor on when needed. • 3-core cable with 1.5 mm2 cross section or 3-core awg 16 (for ul version) secured to espresso machine via a strain relief connector. 4) waste water drain connection the espr...

Page 12

En 12 1) starting the espresso machine a) filling the boilers with water once the installation procedures have been completed, it is necessary to fill the boiler tanks with water. Complete the following procedure to properly fill the boiler tanks: • coffee boiler the water flows inside the coffee bo...

Page 13

En 13 in normal operating conditions, the coffee boiler pressure transducer, while brewing, can read anywhere from 0-12 bar when brewing. The steam boiler pressure is visible through a pressure gauge placed inside the machine, behind the control and the 1st group. When the steam boiler reaches opera...

Page 14

En 14 away any calcium deposits. This remedy is valid also in case the valve remains open in the drain position (i.E. The pressure cannot increase to 8 bar approx.). 7) general notes for coffee preparation the portafilters must remain heated since they are at the lowest position of the group itself,...

Page 15

En 15 5. Dispensing steam and hot water 1) steaming milk or other liquids in order to allow for any condensed water in the wand to be released always allow some steam to be discharged by turning on the valve before inserting the steam wand into the pitcher of liquid to be heated. Dip one of the 2 st...

Page 16

En 16 1) cleaning groups and drain wells - put a tablespoon of detergent powder for coffee machines into the blind filter, supplied with the machine, and tighten it onto the group you want to clean by using a normal filter holder. - turn the paddle valve on and off approximately 10 times (10 seconds...

Page 17

En 17 1/2 a litre of water inside a heat-resistant container and boil. - place the diffuser screen(s) and diffuser screw(s) in the solution and leave them fully submerged for about 30 minutes. Rinse thoroughly with clean water. Install and run hot water through each group several times with the scre...

Page 18

En 18 7. De-commissioning and demolition 1) de-commissioning and demolition start by setting the main switch to the “0” or off position. Disconnecting from the power outlet disconnect the espresso machine from the electrical network by switching off the associated circuit breaker or circuit protecti...

Page 19

En 19 8. Mandatory maintenance and check-up operations ▪ replace group gaskets ▪ replace diffuser screens ▪ clean auto-fill probe ▪ check vacuum breaker for proper operation ▪ inspect water inlet valve ▪ inspect drain system for leaks or clogs ▪ check flow rate for each group ▪ check brew temperatur...

Page 20

En 20 9. Software programming guide programming introduction digital display programming encoder start up procedures shut down procedures accessing programming mode “barista” programming coffee boiler steam boiler temperature cup warmer clock adjust auto on/off “technical” programming language open ...

Page 21

En 21 strada programming introduction description • this espresso machine has a cpu and many configurable settings. • additionally, there are many feedback controls employed in this espresso machine to troubleshoot problems should they occur. • the following is a brief introduction to the controls a...

Page 22

En 22 the encoder knob is always located on the left of group one. By turning it to the right it is possible to increase the value. By turning it left, it is possible to decrease the value and by pushing it down, it is possible to scroll through the software menu, enter functions or confirm first in...

Page 23

En 23 display operating procedure description the following is the procedure for turning on the power to the espresso machine. • please follow the procedures carefully to avoid any damage to the espresso machine. • proceed checking for water connection to the espresso machine. • proceed making sure ...

Page 24

En 24 display operating procedure description the following is the procedure for safely turning off the espresso machine. Press and hold the encoder knob for 3 seconds. The display changes to the following: this is the off setting used in the normal operating conditions. During servicing or other co...

Page 25

En 25 display operating procedure description accessing programming mode • to change the values of any parameter the operator must first enter into the programming mode. • there are two levels within the programming mode that allow the programming of specific parameters. • the two programming levels...

Page 26

En 26 display operating procedure description while the espresso machine is on, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Rotate the encoder knob to select enabled or disabled , press the e...

Page 27

En 27 display operating procedure description while the espresso machine is on, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Rotate ...

Page 28

En 28 display operating procedure description the steam boiler contains water at elevated temperatures. Water temperature over 52°c can cause severe burns instantly or death from scalding danger while the espresso machine is on, press and hold the encoder knob. After approximately 10 seconds the fol...

Page 29

En 29 display operating procedure description while the espresso machine is on, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Rotate ...

Page 30

En 30 display operating procedure description while the espresso machine is on, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears.. Press the encoder knob until the following display appears. The fi...

Page 31

En 31 display operating procedure description while the espresso machine is on, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. If the ...

Page 32

En 32 display operating procedure “technical” programming language • this parameter allows the technician to change the language of the display. While the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder kno...

Page 33

En 33 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. This p...

Page 34

En 34 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Rotate...

Page 35

En 35 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Rotate...

Page 36

En 36 display operating procedure description pre-infusion or pre-brewing while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the follo...

Page 37

En 37 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Press ...

Page 38

En 38 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Rotate...

Page 39

En 39 display operating procedure description the steam boiler contains water at elevated temperatures. Water temperature over 52°c can cause severe burns instantly or death from scalding. Danger while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the f...

Page 40

En 40 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Rotate...

Page 41

En 41 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. The fi...

Page 42

En 42 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. If the...

Page 43

En 43 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Use th...

Page 44

En 44 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Move l...

Page 45

En 45 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Rotate...

Page 46

En 46 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Rotate...

Page 47

En 47 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Use th...

Page 48

En 48 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. This p...

Page 49

En 49 display operating procedure description while the espresso machine is off, press and hold the encoder knob. After approximately 10 seconds the following display appears. Releasing the encoder knob the following display appears. Press the encoder knob until the following display appears. Ruotar...

Page 50

Printed on environmentally friendly munken paper.