- DL manuals

- La San Marco

- Coffee Maker

- 95 Series

- Use And Maintenance Manual

La San Marco 95 Series Use And Maintenance Manual

Summary of 95 Series

Page 1

Uso e manutenzione macchine caffÈ espresso - serie 95 use and maintenance manual espresso coffee machines - 95 series manuel d’instructions pour l’emploi et l’entretien machines À cafÉ express - serie 95 bedienungs- und wartungsanleitung espressomaschinen - serie 95 it gb fr de.

Page 2: Contents

Manual code 7770.009 revision 04/2006 29 contents e n g l is h recommendations (reference, use, warranty) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 technical characteristics of different models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 machine charac...

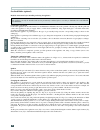

Page 3: Recommendations

E n g l is h recommendations 30 reference this manual provides machine users and routine maintenance personnel with all the information necessary for a safe and efficient operation of the machine. This manual is an integral part of the machine and contains all the information required for its operat...

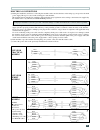

Page 4: Technical Characteristics

E n g l is h technical characteristics of different models 31 • the machines are prearranged for the following voltages: 400v - 3n three-phase ( elements) 230v - 3 three-phase ( elements) 230v single-phase • only practical models 110/230v single phase. • pump incorporated in practical and sprint mod...

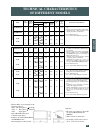

Page 5: Machine Characteristics

Machine characteristics 32 a u t o m a t ic m o d . . S e m ia u t o m a t ic m o d . E n g l is h.

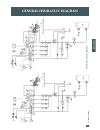

Page 6: General Hydraulic Diagram

General hydraulic diagram 33 e n g l is h v er si o n w it h s ta b il iz ed t em p er at u re n o rm al v er si o n.

Page 7: Water Supply Diagram

Water supply diagram 34 e n g l is h c o n n ec ti o n f o r m o d el s w it h int erna l pum p c o n n ec ti o n f o r m o d el s w it h ext erna l pum p.

Page 8: Legend

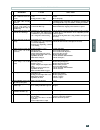

Legend 35 e n g l is h 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 17a 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44a 44b grounds collecting plate with grill automatic level control valve automatic level control valve boiler discharge valve displacement meter valve d...

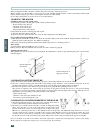

Page 9: Installation Of Machine

36 e n g l is h installation of machine f o r t h e i n s t a l l e r the machine is delivered packed. After having removed the packing, make sure that the machine is complete and in good condition. If in doubt, contact the qualified and authorized la san marco s.P.A. Personnel. Dispose the packing ...

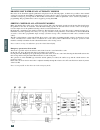

Page 10

37 e n g l is h only for practical models only for sprint models other models notes: connection not possible for mod. 95-26. *the power absorbed by the heating elements can be reduced to 2/3 by eliminating one of the two black cables. 110v/230v single phase blue brown ye/gr 1 heating element blue br...

Page 11

38 e n g l is h i n s t r u c t i o n s f o r a u t h o r i z e d i n s t a l l e r gas fired boiler (optional) read the instructions before installing and using the appliance. Attention this appliance can only be installed and used in permanently ventilated places according to uni-cig 7129 and uni-...

Page 12

After having verified the proper operation, replace the settings tag on the appliance with the one for the new type of gas that is provided with the standard kit containing the newly installed gas nozzle. Safety devices on appliance (manually reset) the appliance is provided with two safety devices ...

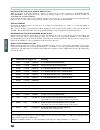

Page 13

Version with probe on boiler lid + – – + version with probe on upper part of boiler 40 e n g l is h f o r t h e i n s t a l l e r before starting the machine, check the condition and perfect efficiency of the safety devices. Before starting to use the machine, it is necessary to become familiar with...

Page 14: Machine Operating

41 e n g l is h f o r t h e u s e r before starting the machine, check the condition and perfect efficiency of the safety devices. Before starting to use the machine, it is necessary to become familiar with the machine controls, particularly with the push buttons and the emergency procedures, follow...

Page 15

42 e n g l is h f o r t h e u s e r drawing hot water on all automatic models hot water can be drawn through the push button strip shown in the following figure, in which it is possible to have manual servings by pressing the button 40 (for a maximum of 1.5 liters; the flow can be stopped by pressin...

Page 16: Additional Notes For

43 e n g l is h f o r t h e u s e r these models are provided with a panel with a button strip and a lighted display installed on the lower part of the working area (91, in the figure on page 45). The services that can be obtained from this panel are: - programming: clock, on, off, holidays, regener...

Page 17

44 e n g l is h f o r t h e u s e r machine start and stop control from clock when the display on the panel 91 shows “auto”, it means that it is in the condition of “machine off as programmed”. If the display shows the “time of day and day of the week”, it means that it is in the condition of “machi...

Page 18

45 e n g l is h f o r t h e u s e r 1st unit 2nd unit display of boiler water temperature and pressure on display 48 this display normally shows the temperature of the water in the boiler in °c. To check the corresponding pressure, just press the button 43 beside the display (for not more than 5 sec...

Page 19: Additional Notes

46 e n g l is h f o r t h e u s e r these models are prearranged for connection with external electronic units (e.G., personal computer) used for controlling the work performed by the machine. The systems adopted are outlined below, while the general operation of the machine is as described for the ...

Page 20

47 e n g l is h f o r t h e u s e r memobox 2 operation (display - programming unit) explanation of buttons p (1) - advances data reading (2) - increments selected digit † (3) - decrements selected digit s (4) - selects digit to modify r (5) - memorizes selected data / reset / pass display of data w...

Page 21

48 e n g l is h f o r t h e u s e r operation with waiters control in the rs 232 and memobox 2 systems the electronic control unit is supplied with seven waiter’s keys and one owner reset key that enable the operation of the espresso machine, the cycle counts and resetting. Display of number of cycl...

Page 22: Additional Notes

49 e n g l is h f o r t h e u s e r additional notes for 95-31, 95-32, 95-33 and 95-36 models options electric cup warmer the on-off button 60 is used to increase the temperature of the cup shelf; it can be switched on and off at will. Water softener the water conditioner is an essential item for th...

Page 23: Routine Maintenance

50 e n g l is h f o r t h e u s e r routine maintenance boiler water drain if it becomes necessary to empty the boiler, cut off power to the machine by turning the main switch 30 to position “zero” or, in the case of gas-heated machines, put off the flame by closing the gas supply valve 49. Remove t...

Page 24: Emergency Situations

51 e n g l is h f o r t h e u s e r emergency situations a careful operator in good psychophysical condition is the best guarantee of safety. The operator must keep a safe distance from water or steam outlets, since, in normal conditions of operation, they are scalding hot. In case of fire, powder e...

Page 25: Coffee And For Hot Water

52 e n g l is h f o r t h e p r o g r a m m e r programming the doses for espresso coffee and for hot water only for automatic models entering the programming mode turn the main switch 30 to position “zero” (machine switched off). Holding the key 33 of the first unit pressed, turn the main switch 30...

Page 26: Temperature And Pressure

53 e n g l is h f o r t h e p r o g r a m m e r programming the boiler working temperature and pressure only for automatic 95-26 and 95-36 models these models are provided with a triac electronic device which allows the adjustment of the boiler water temperature and pressure. To access this program,...

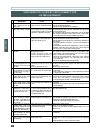

Page 27

54 e n g l is h main defects caused by the incorrect use of the equipment f o r t h e u s e r 1 the boiler fills with water, with venting from the safety valve • leak in one of the boiler filler pipes or in one of the unit circuits • check the automatic level circuit • check the manual fill button •...

Page 28

55 e n g l is h f o r t h e u s e r 14 a whistling noise is heard after coffee has been de- livered • malfunction of the expansion valve • pump pressure too high • replace the seal and the spring in the valve and reset it to 12 bar • reset the pump 15 the filter cup detaches itself while coffee is b...

Page 29

34072 gradisca d'isonzo (go) italia via padre e figlio venuti, 10 tel. ++39 0481 967111 - fax ++39 0481 960166 www.Lasanmarco.Com g ra fic he f ila co rd a / ud in e.