- DL manuals

- La San Marco

- Coffee Maker

- PLUS 5

- Technical Instruction Manual

La San Marco PLUS 5 Technical Instruction Manual

Summary of PLUS 5

Page 1

Pag.1 technical instruction la san marco s.P.A. En english cod. 7770.046 edition october 2009.

Page 2

Pag.2 table of contents introduction and general instructions..................................................................................................................................... 3 instructions for installation ............................................................................

Page 3

Pag.3 introduction and general instructions thoroughly read the instructions contained in this booklet because it gives important information regarding safety for installation, use and maintenance. Keep this booklet in a safe and accessible place for further consultation. This is a commercial applia...

Page 4

Pag.4 general characteristics materials used: - stainless steel for boiler - teflon/copper for hydraulic tubes - aluminium with stainless steel lining for the brewing group - plastic for grinder with conic grinder blades. - other accessories in food plastic which are in contact with the ground coffe...

Page 5

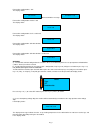

Pag.5 machine keypad key reference plus 5 1 exit ( edit ) / espresso 2 ins ( insert blank ) / black coffee 3 del ( delete character ) / cappuccino 4 scroll / latte macchiato 5 - / choco 6 + / mocha 7 enter / steam 8 esc / hot water 9 info 10 shift /clean exit ins del src - - enter esc.

Page 6

Pag.6 electric - hydraulic connection 200v-1+n-50/60hz 230v-1+n-50/60hz 120v-1+n-50/60hz h2o in (1-5 bar) h2o out water softner water filtre.

Page 7

Pag.7 starting up warning : all parameters that concern the steam boiler will not be displayed in plus 5 easy machines. After having connected the machine to the water and electric networks, turn the switch on (see diagram). The display shows: language english rev.X.Xxx : indicate the software relea...

Page 8

Pag.8 keep key n°10 (shift) pressed and then press key n° 9 ( info), and the machine will set itself to on state. , the display shows: filling - up steam boiler during this stage the steam boiler is being filled up. Warning : the solenoid valve of the steam nozzle automatically opens to release the ...

Page 9

Pag.9 for machine configurations: self. The display shows: select drink alternated with the message: position the cup for machine configurations: waiters’ card the display shows: insert card for machine configurations: self + credit card the display shows: insert card for machine configuration: self...

Page 10

Pag.10 select drink steam not ready the displayed message indicates that the set up heating temperature in the steam boiler has not been reached yet, and therefore milk based dispensing and hot water dispensing are not enabled. In both cases wait until the boiler has reached the set up heating tempe...

Page 11

Pag.11 access the main setting menus with password or smart-card a) access the main setting menus with password to enter the programming environments, a password is required which define the access rights to the different environments. The password must be composed with 5 numbers. To insert the pass...

Page 12

Pag.12 b) access the main setting menus with smart card. ( only for machines with transponder installed ) to enter the programming environments , place one of the following smart cards above the proper reader with the led light on and the machine in off : - waiter smart card - roaster- smart card - ...

Page 13

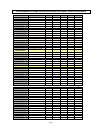

Pag.13 programmable parameters in according with smart card or password waiter roaster owner service technician info - reset reard dose data douse counter a x x x x x douse counter b x x x x x system data group cleaning x x whisk cleaning x x milker cleaning x x grinder cycles x x water filter x x g...

Page 14

Pag.14 system clock programming yy-mm-dd day hh:mm x° x° x° x x clock display x x x auto start -up x x x on - off x x x day off x x x display regulation contrast x x x display mode x x x default colour x x x service clean/rinse cleaning time x x x x cycle cleaning alarm x group cleaning programming ...

Page 15

Pag.15 info-reset a1) read doses data ( doses counter a/b ) enter info reset - system data read doses data read doses data - doses counter b - reset doses counter a - reset doses counter b doses counter a enter doses counter a tx xxxxxx yy xxxxxx zz press the + / - keys to select the count a or b . ...

Page 16

Pag.16 enter total token cashing x.Xx x.Xx : indicates the total token cashing of the machine. The total token will be calculates if the selling price of the token has been set for each dose. Token a : xx token b : xx token c : xx enter xx : indicates the n° of the token a-b-c inserted. Enter total ...

Page 17

Pag.17 b) info reset system data group cleaning xx milker cleaning xx water filter xx group cleaning confirm reset group cleaning 0 enter milker cleaning confirm reset milker cleaning 0 enter +/ - grinder cycles confirm reset grinder cycles 0 enter +/ - water filter confirm reset water filter 0 ente...

Page 18

Pag.18 the following info are displayed only when the clock is programmed machine service xxxx yy - zzzz xxxx : indicates the n° of group cycles left. If the programmed n° of group cycles exceed the display shows: ( - xxxx ) yy : indicates the maintenance month zzzz : indicates the maintenace year i...

Page 19

Pag.19 doses programming please note : to access to the doses programming the machine must be at the set-up temperature. Press the key no 5 (-) and no 6 (+) to select the parameter and then press the key no 8 (enter) to confirm the selection. A ) doses slight adiustment.

Page 20

Pag.20 b) set doses coffee milk hot water disable tx drink type + / - tx drink name xxxxx enter to modify the drink name press the key t1. The display show xxxxx -b-c-d-f-g-h-i-l-m- the heart symbol (cursor) must be located on the character you want to select. To scroll the character use the keys (+...

Page 21

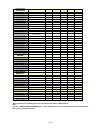

Pag.21 dose parameters coffee drink type coffee+ soluble drink type soluble drink type coffee+ milk drink type milk drink type milk + soluble drink type coffee+ milk + soluble drink type hot water drink type steam product a : pre - x x - - x x - - product a : post - x x - - x x - - product b : pre -...

Page 22

Pag.22 depending on the drink type, the necessary dose parameters will be activated to set the drink. Press the key n°7 (enter) to confirm the modification carried out and shift to the next level. Press the key n°6 (+) and no5 (-) to modify the level mode. Press the key n°8 ( esc) to return to the p...

Page 23

Pag.23 c ) price set-up dose programming - doses sligth adjust - set doses - calibration - instant product calibration price set-up enter doses price tx xxxxxxxxx tx xxxxxxxxx tx xxxxxxxxx tx xxxxxxxxx price set-up - doses price - free drinks - token value c1) doses price price set-up - free drinks ...

Page 24

Pag.24 d ) calibration ( grinder-milker ) steamed milk foamed milk grinder 1 press key t1 press key t2 press key t3 the calibration menù its useful to adjust the milker ( steamed milk-foamed milk ) and the grinders . To activate the milker and the grinder for max.10 seconds press t1- t2- t3- t4 bott...

Page 25

Pag.25 e) instant dispenser calibration enter default density a: xx gr / 100 ml b: xx gr / 100 ml use + / - keys to insert the serving size wrote on the instant product package. Warning: at the first time it’s necessary to do the ( instant product calibration ) before insert the values of the produc...

Page 26

Pag.26.

Page 27

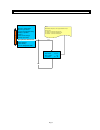

Pag.27 system manager press the key n°7 (enter) to confirm entering the desired environment. Press the key n° 8 (esc) to exit. Enter select - info reset - dose programming system manager system manager - machine configuration - machine parameter - system clock programming - display regulation - serv...

Page 28

Pag.28 machine configuration enter enter machine configuration steam boiler enabled use: + / - keys to enable or disable the steam boiler. Machine configuration milker enabled use: + / - keys to enable or disable the automatic milk frother. Machine configuration pump type rotation use: + / - keys to...

Page 29

Pag.29 machine configuration doses buttons preset ? Please confirm no if one of these configurations is modified : - steam boiler - milker - milk pump - machine type we suggest to select yes and confirm the doses buttons preset. + / - yes no machine configuration doses buttons preset ? Enter enter e...

Page 30

Pag.30 machine parameters please note : some of the following parameters may not be displayed depending to the machine configuration previously programmed. Language + / - enter english german french flemish italian japanese enter serial disable + / - i/o hartwall i/o 9600 rm5 coin box for i/o 18 - 2...

Page 31

Pag.31 rinse after milk dose enable disable + / - pause after milk 3 sec. 3 -10 sec. Waiting time milk dose a - b 15 min. Enter 0 - 60 min. Additional milk 2 sec. 0 - 10 sec. Enter decimal prices 2 + / - 0/2 scale factor 1 + / - enter 0 - 1000 alarm detail enable disable + / - alarms visualized with...

Page 32

Pag.32 temperature measure unit c° f° + / - enter esc celsius or centigrade fahrenheit coffee temperature 90° c + / - steam temperature 125° c + / - enter 75 - 95 c° esc esc 110 - 126 c° enter keyboard sound disable enable + / - esc installation date yy / mm / dd press + / - to modify the machine in...

Page 33

Pag.33 system clock set-up system clock programming yy - mm - dd day hh:mm -- / -- / -- --- / -- : -- press the key +/- to program the date ( yy-mm-dd) and the time ( day hh:mm ) enter clock display disable enable + / - the clock will not be dispayed auto start-up enter on off xx:xx xx:xx enter day ...

Page 34

Pag.34 display regulation press the key n°6 (+) and n°5 (-) to adjust the display contrast. Display regulation contrast xx enter display regulation display mode press + & - enter press the key n°6 (+) and n°5 (-) to change the dsplay in normal mode or reverse mode. Display regulation default color p...

Page 35

Pag.35 service system manager - machine configuration - machine parameters - system clock programming - display regulation - smart card manager - change password - group manual movements - test actuactors - boiler draining - alarm history - preset configuration data service enter service - clean/rin...

Page 36

Pag.36 cycle cleaning alarm clean/rinse - cleaning time - group cleaning program - group auto rinsing - mixer cleaning program - mixer auto rinsing - milker cleaning program - milker auto rinsing cycle cleaning alarm variable value : + / - 0 - 1000 press the keys + / - to program after how many cups...

Page 37

Pag.37 mixer cleaning program clean/rinse - cleaning time - cycle cleaning alarm - group cleaning program - group auto rinsing - mixer auto rinsing - milker cleaning program - milker auto rinsing mixer cleaning program enter mixer auto rinsing clean/rinse - cleaning time - cycle cleaning alarm - gro...

Page 38

Pag.38 milker auto rinsing clean/rinse - cleaning time - cycle cleaning alarm - group cleaning program - group auto rinsing - mixer cleaning program - mixer auto rinsing - milker cleaning program milker auto rinsing enter milker rinsing stand by machine + / - stand by machine t.O. After milk 10 min ...

Page 39

Pag.39 enter maintenance set-up - water filter - grinders - group cycles machine service machine service variable value : + / - inspection month off maintenance cycle xxxxx + / - 0ff - 65000 service frequency 1-per year 1per year -4 enter press + / - to program after how many cycles the display will...

Page 40

Pag.40 smart card manager please note: a -the smart card manager is displayed only for coffee machine with transponder installed. B -to create a new card (technician – service – owner – roaster and waiter ) its necessary use an external pc tool..

Page 41

Pag.41.

Page 42

Pag.42 change password system manager - machine configuration - machine parameters - system clock programming - display regulation - service - smart card manager - group manual movements - test actuactors - boiler draining - alarm history - preset configuration data change password enter change pass...

Page 43

Pag.43 group manual movements group manual movements higher motor xxx motor expeller lower motor xxx enter where: xxx indicates the pulses of the upper and lower motor. Press the key : n° 1 and n° 2 to move the upper piston n° 3 and n° 4 to move the expeller motor n° 5 and n°6 to move the lower pist...

Page 44

Pag.44 test actuators system manager - machine configuration - machine parameters - system clock programming - display regulation - service - smart card manager - change password - group manual movements - boiler draining - alarm history - preset configuration data test actuators test actuators - ac...

Page 45

Pag.45 test actuators - actuators 1 - actuators 3 - milk pump - mixer a - dispenser a - mixer b - dispenser b - exhaust fan - electronic fan actuators 2 actuators 2 enter press a dose keys between t1 to t6 to activate the actuator that you wish to check. Press the same dose key to stop the activated...

Page 46

Pag.46 test actuators - actuators 1 - actuators 2 - actuators 3 - milk pump - dispenser a - mixer b - dispenser b - exhaust fan - electronic fan mixer a mixer a enter esc mixer test a 0 keep pressed the + key to increase the speed of the mixer a motor . Keep pressed the – key to decrase the speed. 0...

Page 47

Pag.47 warning: a) you can activate more than one actuator at the same time. B) once a time-out of 5 seconds has elapsed, the activated actuators will be automatically interrupted. C) the “milk pump speed” parameter will be displayed only for machine with milk pump installed..

Page 48

Pag.48 boiler draining solenoide valve open boiler draining t1 coffee t2 steam press the key t1 or t2 to interrupt the procedure esc press the key t1 to start coffee boiler draining ( the solenoide valve of the group and by-pass will be activated ) press the key t2 to start steam boiler draining ( t...

Page 49

Pag.49 alarm history alarm history 1 x - yyyyy jj z yy-mm-dd hh:mm alarm history 1 x - yyyyy jj z yy-mm-dd hh:mm enter + / - esc 1 - 10 : is the sequence number of the alarm x : is the alarm number yyyyy : is the description of the alarm jj : is the code of the alarm z : is the number of times the a...

Page 50

Pag.50 preset parameters preset configuration data service enter power off and power on enter after 5 second the display shows preset configuration data technician factory +/ - service warning : - with the service preset will be reseted only the service accessible parameters. - with the technician p...

Page 51

Pag.51 cleaning process abort if you want to interrupt the cleaning procedure for group or whisk or milk frother follow the procedure: ( only with the technician or service password ) g roup c lea ning o ff o n / o ff m ilker c leaning w hisk c leaning a bort cleaning ente r n o yes + / - insert the...

Page 52

Pag.52 trouble shooting 1) n°10 time out pulses, upper piston motor. H. Motor puls 10 this alarm is visualised on display by code 10 causes: the upper motor encoder has not received pulses for 3 seconds, since the motor is not running result: the machine is switched off. Check the following: 1. Wron...

Page 53

Pag.53 5) n° 15 alarm of too much coffee in the brewing chamber. Too much coffee 15 this alarm is visualised on display by code 15 causes: the upper piston has positioned itself where the wet seal of the piston gasket in the brewing chamber is not guaranteed. Result: the machine is switched off. Sol...

Page 54

Pag.54 8) n° 34 steam boiler time-out temperature alarm . Select drink steam not ready this alarm is visualised on display by code 34 cause: the steam boiler temperature has reached the minimum value of 105°c result: boiler heating is interrupted and the buttons of coffee-based, milk-based and filte...

Page 55

Pag.55 11) n° 38 steam boiler temperature alarm. Steam temperat. 38 this alarm is visualised on display by code 38 first case : the temperature inside the steam boiler has reached the limit value of 129°c (264.2°f) or more. Result: boiler heating is interrupted and all dose buttons are disabled. Sol...

Page 56

Pag.56 13) n° 60 corrupted data alarm. Corrupted data alarm 60 this alarm is visualised on display by code 60 first case: this alarm is visualised during machine functioning cause: incorrect operating data in machine memory. Result: machine shutdown. Solution: carry out the following controls. 1) ve...

Page 57

Pag.57 17) n°81 modem gsm alarm ( only for machine with gsm modem kit ) gsm : off 81 this alarm is visualised on display by code 81 solution: check the following : a) check the power supply of the gsm modem installed in the coffee machine. B) check that the serial cable is properly connected in the ...

Page 58

Pag.58 22) n° 93-tools maintenance alarm. Grinder mainte. 93 this alarm is visualised on display by code 93 cause: the tools have reached the set up working time (see service chapter ) result: none. Solution: replace the tools and cancel the alarm following the procedure explained in the info reset ...

Page 59

Pag.59 special functions for machine calibration 1) calibrating the coffee dispensing pressure (pump pressure). To calibrate the coffee dispensing pressure use the device code a 0128 ( pic. A ). The procedure is the following : - replace the upper piston with the one equipped with pressure gauge (pi...

Page 60

Pag.60 if the adjusting range is not wide enough to get the needed grinding degree, you can do the following: remove the hoppers and/or product containers remove the top cover from the machine (unscrew the 2 rear and 2 front screws) unscrew the 2 screws ( pic.A ) and move the grinding regulator righ...

Page 61

Pag.61 recommendations for a correct preventive maintenance the aim of this schedule is to prevent as far as possible equipment from breaking down, through the periodical check-up and replacement of components subject to fair wear and tear, thus reducing service calls and relevant cost in working ho...

Page 62

Pag.62 suggestions: use the test actuators menu to check all loads of the machine: grinder/s, solenoid valves, contactor and heating element. Check alarm history menu, if you find any alarm check and solve the problem. Test actuators and alarm history menu are part of the system manager menu. Please...