Service manual for 9600 cb & hwg hwg-m2 series cb-m2 series hwg-m2-250 cb-m2-250 hwg-m2-200 cb-m2-200 hwg-m2-175 cb-m2-175 hwg-m2-150 cb-m2-150 hot water generator condensing boiler for natural or for natural or propane gas propane gas for your safety: this product must be installed and serviced by ...

Page 2 laars heating systems table of contents section 1. General information 1a. Introduction ................................................... 3 1b. Start up procedures ..................................... 9 1c. Checkout procedures ................................... 9 1d. Cleaning the combusti...

9600 cb & hwg service manual page 3 section 1. General information 1a. Introduction the heatmaker 9600 cb condensing boilers and the heatmaker 9600 hwg non-automatic circulating tank water heaters have a dual heat exchanger (h-x) design. The primary h-x is a copper coil type which operates in a non-...

Page 4 laars heating systems (a) cold water inlet from tank or system (b) economizer outlet (10°f rise above inlet) (c) combustion coil inlet 130-140°f typical (d) combustion coil outlet (e) hot water outlet to tank or system 160 - 170°f typical (160° f thermostat) figure 2a. Water flow through a he...

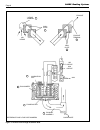

9600 cb & hwg service manual page 5 legend 1 mixing valve 2 internal pump 3 mixer tube 4 flue outlet 5 combustion fan 6 air pressure switch 7 burner 8 secondary heat exchanger 9 primary heat exchanger 10 return (from primary loop) 11 gas valve 12 flow (to primary loop) a secondary heat exchanger inl...

Page 6 laars heating systems figure 3. Air/fuel flow through heatmaker 9600. 43 intake terminal 50 wall plate air intake 45 wall plate 44 exhaust terminal exhaust air orifice gas orifice gas 1 combustion coil 2 economizer 7 flameholder 46 exhaust assembly condensate reference page 8 for part numbers.

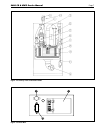

9600 cb & hwg service manual page 7 figure 4. Cut away view of heatmaker 9600. Figure 5. Control box..

Page 8 laars heating systems figure 6. Control components * specify serial number # part description part # 1 combustion coil (primary h-x) hwg 2400-086 combustion coil (primary h-x) cb 2400-284 2 economizer coil (secondary h-x) 10-078 3 upper head 10-034 4 inner shroud 10-112 5 outer shroud 10-124 ...

9600 cb & hwg service manual page 9 1b. Start up procedures 1. Make sure that the system is properly filled, com- pletely purged of air and system valves are open. 2. Open system gas cock(s) and gas control knob on gas valve (if closed). 3. Set the room thermostat, aquastat or storage tank aquastat ...

Page 10 laars heating systems 1d. Cleaning the combustion chamber coil note: in normal operation this procedure is seldom required. Should it prove necessary, the following procedure is used to access the coil for cleaning. 1. Turn off gas and electrical power to unit. 2. Remove upper and lower fron...

9600 cb & hwg service manual page 11 1h. Stack switch the stack switch is a normally open single pole switch which is operated by the pressure difference across the air orifice. It is set to close when a static pressure difference of 1 in. W.C. Is generated by the combustion air blower. Its function...

Page 12 laars heating systems gallon of water from it. Turn off electrical power and disconnect wires from operating control. Remove operating control from diverting valve body and replace with new control. Connect wires to control and open isolation valves. Bleed air from the diverting valve petcoc...

9600 cb & hwg service manual page 13 boiling noises can occur because of air in the secondary loop of a heating system (9600 cb applications) or because of pump failures in either the 9600 cb or 9600 hwg. Another boiling noise which occurs primarily on 9600 hwg units can result from liming of the pr...

Page 14 laars heating systems will require resetting. If a lockout occurs for any of the reasons stated in this section the “valve/flame” light on the boiler control will flash. Tripouts of the manual reset safety limit can be caused by a failure of the thermostat in the diverting valve, short cycli...

9600 cb & hwg service manual page 15 section 2. Troubleshooting (detailed flow charts on page 16-22) if the burner “locks out” for any reason, the cause of failure will be displayed by the flashing of one of the lights. 2a. Code green “power” - light flashing - control failure, no light, no power re...

Page 16 laars heating systems purge - see page 18 valve/flame see page 21 1. Limit circuit open see page 17 2. No call for heat/ hot water replace boiler control 2400-224 replace transformer and run boiler through a few cycles have qualified electrician repair fault in wiring to the boiler check for...

9600 cb & hwg service manual page 17 1 2 3 4 5 6 7 8 9 red red cn6 "control" 1. Switch boiler off 2. Unplug 9 pin "control" plug 3. Check for continuity at back of "control" plug between red wires (boiler temp below 170f) limit circuit appears ok - recycle boiler a few times after plugging in "contr...

Page 18 laars heating systems reset boiler control by switching power of for 15 seconds and then on again with a call for heat / hot water after approx. Two seconds green light comes on and blower starts after five minutes red "purge" light flashes stack switch contacts not closing check for flue bl...

9600 cb & hwg service manual page 19 no continuity ( ohms) 1. Switch off boiler switch 2. Remove both tubes from stack switch and disconnect electrical wires 3. Check for continuity across switch terminals 1. Attach tubes disconnected from stack switch to u-tube manometer 2. Switch on boiler to oper...

Page 20 laars heating systems with a call for heat reset boiler control by switching off boiler switch for 15 secs. After two seconds green power light comes on. Refer to general trouble shooting section page 16 connect manometer to "pressure tap" on gas valve - pressure during blower operation with...

9600 cb & hwg service manual page 21 reset boiler by switching power off for 15 seconds - when "valve/flame" lite lights is there 24 vac between orange and yel- low wires on gas valve and/or does gas valve click? Turn on valves, fill lp tank on lp unit - if req'd - reset boiler by switching power of...

Page 22 laars heating systems yes checking internal pump (you must complete page 16 first) switch power on, green power light lights call for heat exists (there is 24 volts on pins #7 & #9 on 'control' plug - cn6) there is 120 vac at 'circulator' plug-cn5 turn up t'stat or aquastat or correct stat p...

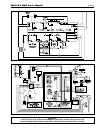

9600 cb & hwg service manual page 23 figure 9. 9600 ladder diagram. Figure 10. 9600 wiring diagram. Caution label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing!.

Quick reference trouble shooter a. Short cycling: 1. 9600 hwg - tank aquastat set too high 2. 9600 cb and 9600 hwg - units shuts down before reaching limit. Continuously restarts without resetting a. Limit out of calibration b. Wrong air/gas orifices for input or fuel (refer to heatmaker 9600 gas or...