Installation and operation instructions document 2130 for your safety: this product must be installed and serviced by a professional service technician, qualified in hot water boiler installation and maintenance. Improper installation and/or operation could create carbon monoxide gas in flue gases w...

Laars heating systems page 2 table of contents section 1. General information 1.1 introduction ................................................... 3 1.2 heater identification ..................................... 3 1.3 general flow requirement .......................... 3 section 2. Installation 2.1...

Mighty therm lo-nox page 3 section 1. General information 1.1 introduction this manual provides information for the installation and operation of laars gas-fired hydronic boilers and water heaters. It is strongly recommended that all application and installation procedures be reviewed completely bef...

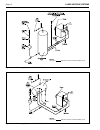

Laars heating systems page 4 section 2. Installation 2.1 heater placement the heater must be placed to provide specific clearances on all sides for maintenance and inspections. There must also be minimum distances maintained from combustible surfaces. These clearances also apply to noncombustible ma...

Mighty therm lo-nox page 5 2.2.1.B forced-air ventilation in the united states: any equipment which exhausts air from the heater room can deplete the combustion air supply or reverse the natural draft action of the venting system. This could cause flue products to accumulate in the heater room. Addi...

Laars heating systems page 6 z223.1 and/or, in canada, can/cga b-149 and any local codes having jurisdiction. When a draft fan is installed, a suitable draft switch must be wired into the boiler control circuit at terminal designated "field interlock" to prevent firing of the boiler unless a positiv...

Mighty therm lo-nox page 7 distance from gas meter or last stage regulator size 0-100' 100-200' 200-300' 500 1½" 2" 2" 715 2" 2" 2½" 1010 2" 2½" 3" 1430 2½" 3" 3" 1825 2½" 3" 3½" note: these figures are for natural gas (.65 sp. Gr.), and are based on 1/2" water column pressure drop. Check supply pre...

Laars heating systems page 8 check heater wiring and pump for correct voltage, frequency and phase. Consult the national electrical code or the canadian electrical code regarding branch circuit requirements for equipment with these motors. 2. The heater should be wired exactly as shown in the wiring...

Mighty therm lo-nox page 9 figure 8 is suggested to make sure the system water is neither too hot nor too cold when a changeover takes place. When a boiler is connected to heating coils located in air handling units (where they may be exposed to refrigerated air circulation), install a flow figure 9...

Laars heating systems page 10 3.2.5 piping system requirements 1. Provide a boiler installed above radiation level with a low water cutoff device either as part of the boiler or at the time of boiler installation. 2. Install manual and/or automatic bleeding devices at high points in the system to el...

Mighty therm lo-nox page 11 3.3.2 piping system requirements 1. Check piping diagrams with local applicable plumbing, heating and building safety codes. 2. All two-temperature systems using temperature valves must have forced recirculation in the low temperature building loop. 3. A check valve insta...

Laars heating systems page 12 figure 12. Hot water supply system with vertical tank. Figure 13. Hot water supply system with horizontal tank. Notes: heavy line indicates heater to tank circulating loop. Notes: heavy line indicates heater to tank circulating loop..

Mighty therm lo-nox page 13 to the heat exchanger. Specifications in table 4 include allowance for 30 feet of piping and 6 elbows between heater and tank. Important: check oil level in pump before starting. Oil pump every three (3) months. Fill bearing assembly to lower level of overflow vent. Add f...

Laars heating systems page 14 certified in accordance with the requirements for relief valves and automatic gas shutoff devices for hot water supply systems, ansi z21.22. (in canada, in accordance with the requirements for the standard for temperature and pressure relief valves and vacuum relief val...

Mighty therm lo-nox page 15 figure 16. Two temperature hot water supply system with vertical tank. Warning hot water can scald! Hot water can produce third degree burns in 6 seconds at 140°f (60°c) and in 30 seconds at 130°f (54°c). Section 4. Operating instructions 4.1 controls - general (see figur...

Laars heating systems page 16 figure 17. Controls location. Figure 18. Operating and safety components. Shut down whenever overheating of water occurs (exceeding the temperature set point of the switch). 4.1.6 flow switch standard on all models: the switch is mounted in the outlet “tee” connection. ...

Mighty therm lo-nox page 17 note: safe lighting and other performance criteria were met with the gas manifold and control assembly provided on the heater when it underwent tests specified in ansi z21.13 and can1-4.3-m85. Before placing the heater in operation, check the automatic safety shutoff devi...

Laars heating systems page 18 4. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the appliance and to replace the heater. 4.5.1 lighting instructions 1. Stop! Read the safety information (1 through 4) above. 2. Turn off all elect...

Mighty therm lo-nox page 19 3. If a strainer is used in a pressure reducing valve or in the piping, clean it every 6 months in accordance with the manufacturer's instructions. 4. At startup and every 6 months after, using the burners view port, look at the burner flame for proper performance. The bu...

Laars heating systems page 20 6. Disconnect the flange and the adapter tee from the heat exchanger inlet and outlet. 7. Remove temperature-sensing probes from inlet and outlet header. 8. Remove the heat exchanger from the heater. The heat exchangers are heavy and require minimum two people to remove...

Mighty therm lo-nox page 21 5. After the call for heat is satisfied the ignition control closes the gas valves and operates the blower for a thirty (30) second post purge cycle. This clears the combustion chamber of combustion products. The ignition is attempted three times. If ignition is not succe...

Laars heating systems page 22 figure 21. Troubleshooting chart..

Mighty therm lo-nox page 23 6.3 mechanical components 6.3.1 pressure relief valves leaking intermittently or steadily possible cause remedy a. Static pressure in system exceeds a. Calculate height of water in system above heater. Install setting of relief valve. New valve with psi setting 25% above ...

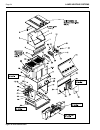

Laars heating systems page 24 figure 22. Parts identification..

Mighty therm lo-nox page 25 section 7. Parts descriptions and order numbers key description size size size size size no 500 715 1010 1430 1825 7.1 jacket and combustion chamber components 1 top panel assembly (indoor) 10535701 10535703 10535705 10535707 10535709 2 spacer, flue collector - - 10540800...

Laars heating systems page 26 key description size size size size size no 500 715 1010 1430 1825 32 baffle heat exchanger front/rear 20020101 20020103 20020105 20020107 20020109 (2) (2) (4) (4) (4) 33 baffle, heat exchanger (10-tube) 10667701 10667703 10667705 10667707 10667709 (9) (18) (18) (36) (1...

Mighty therm lo-nox page 27 figure 23. Tile assemblies. When ordering tiles: assembly number is for all tiles. Part numbers shown for the front of unit are the same for the rear tiles. Check dimensions of old tile as shown here to confirm part number..

Laars heating systems page 28 figure 24. Base / tile support assembly. Key description size size size size size no 500 715 1010 1430 1825 1 base, lower section 10602001 10602003 10602005 10602007 10602009 2 base, upper section 10602101 10602103 10602105 10602107 10602109 3 tile rail, left support 10...

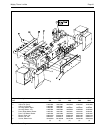

Mighty therm lo-nox page 29 figure 25. Control panel and electrical components. Key description size size size size size no 500 715 1010 1430 1825 1 ignition control, electronic e2101300 e2101300 e2101300 e2101300 e2101300 2 transformer, 115v/24v e0086100 e0086100 e0086100 e0086100 e0086100 3 switch...

Laars heating systems page 30 figure 26. Gas train components. 500 / 715 on / off or 2-stage 1010, 1430, 1825 on / off only 1010, 1430, 1825 2-stage only key description size size size size size no 500 715 1010 1430 1825 1 valve, gas, combination, dual v0077200 v0077200 — — — 2 valve, gas, manual — ...

Mighty therm lo-nox page 31 figure 27. Burner tray. Key description size size size size size no 500 715 1010 1430 1825 1 housing, inlet air, blower 10953500 10953500 10953500 10953500 10953500 2 orifice, air (dual) 10953902 10953903 10953905 10953907 10953909 orifice, air (single) 10953901 10953901 ...

Laars heating systems page 32 key description size size size size size no 500 715 1010 1430 1825 7 air duct 10953000 10953000 10953000 10953000 10953000 (2) (2) (2) (2) (2) 8 gasket, cover 30-268 30-268 30-268 30-268 30-268 9 cover, air mixture, plenum 10956401 10956403 10956405 10956407 10956409 10...

Mighty therm lo-nox page 33 key description size size size size size no 500 715 1010 1430 1825 7.6 outdoor jacket 1 top panel 10660701 10660703 10660705 10660707 10660709 2 rear windshield 10658101 10658103 10658105 10658107 10658109 3 upper rear louver shield 10657101 10657103 10657105 10657107 106...

Laars heating systems page 34 key description size size size size size no 500 715 1010 1430 1825 9 lower rear shield -inner 10659901 10659903 10659905 10659907 10659909 10 rear base extension 10658501 10658503 10658505 10658507 10658509 11 left front end panel 10936300 10936300 10936300 10936300 109...

Mighty therm lo-nox page 35.

Waterpik technologies, inc. 6000 condor drive, moorpark, ca 93021 • 805.529.2000 • fax 805.529.5934 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 480 s. Service road west, oakville, ontario, canada l6k 2h4 • 905.844.8233 • fax 905.844.2635 www.Laars.Com litho in u.S.A. © l...