- DL manuals

- Laars

- Boiler

- MAGNATHERM MGH2000

- Installation And Operation Instructions For

Laars MAGNATHERM MGH2000 Installation And Operation Instructions For

Installation and Operation Instructions

Document 1276

H2359200-

WARNING

If the information in these instructions is

not followed exactly, a fire or explosion

may result causing property damage,

personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed

by a qualified installer, service agency, or gas

supplier.

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler and heater installation and maintenance. Improper installation and/or operation

could create carbon monoxide gas in flue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty.

AVERTISSEMENT

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion ou

pour éviter tout dommage matériel, toute blessure

ou la mort.

Ne pas entreposer ni utiliser d’essence ou ni

d’autres vapeurs ou liquides inflammables dans

le à proximité de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous servir

des téléphones dans le bâtiment où vous vous trovez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions du

fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualifié ou

par le fournisseur de gaz.

Installation and

Operation Instructions for

M

AGNA

T

HERM

®

Modulating Boiler Water Heater

Model MGH2000

Model MGV2000

1,999 MBTU/h

1,999 MBTU/h

Model MGH3000

Model MGV3000

3,000 MBTU/h

3,000 MBTU/h

Model MGH4000

Model MGV4000

4,000 MBTU/h

4,000 MBTU/h

Summary of MAGNATHERM MGH2000

Page 1

Installation and operation instructions document 1276 h2359200- warning if the information in these instructions is not followed exactly, a fire or explosion may result causing property damage, personal injury or death. Do not store or use gasoline or other flammable vapors and liquids in the vicini...

Page 2

Laars heating systems section 1 - general information 1.1 introduction ......................................................1 1.2 safety notes .....................................................1 1.3 modelidentification .........................................2 1.4 warranty ........................

Page 3

Laars heating systems section 9 – navigating the touch screen 9.1 the touch screen ..........................................40 9.2 using the touch screen ..................................40 9.3 verificationprocessforsafety-related parameters ......................................................42...

Page 4

Laars heating systems.

Page 5

Magnatherm boilers and water heaters page 1 touch screen open the front panel to access the touch screen section 1 general information 1.1 introduction this manual includes information which will help you to install, operate, and maintain the magnatherm 2000, 3000 and 4000 systems. Please read this ...

Page 6

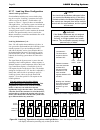

Laars heating systems page 2 model nomenclature 1 2 3 4 5 6 7 8 9 10 11 12 13 m g 1 series m g usage h - hydronic v - volume water size mbtu/h 2 0 0 0 3 0 0 0 4 0 0 0 fuel n - natural p - propane country code x - usa/ canada e - export * options code x - standard j - csd-1 elec system a - 110v, 1Ø b...

Page 7

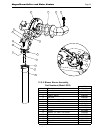

Magnatherm boilers and water heaters page 3 model 2000 manual gas valve blower touch screen heat exchanger condensing unit air intake and filter water outlet water inlet vent power pack perspective from opposite corner. Perspective from front left corner. Shown with front doors and left side panels ...

Page 8

Laars heating systems page 4 manual gas valve blower touch screen model 3000 air intake and filter water outlet water inlet vent power pack condensate trap heat exchanger condensing unit.

Page 9

Magnatherm boilers and water heaters page 5 model 4000 manual gas valve (hidden behind main gas valve) blower touch screen air intake and filter water outlet water inlet vent power pack condensate trap heat exchanger condensing unit.

Page 10: 3.0 Shown

Laars heating systems page 6 e f u front view b a view rear 3.0 shown n q s p m r l g h k j t side view c d condensate trap contact factory optional flanges, vent gas 6”x3.5” touchscreen display air inlet pressure relief valve water outlet ‘knock- down’ height water inlet model a b c d e f g h j k l...

Page 11

Magnatherm boilers and water heaters page 7 section 2 locating the appliance 2.1 locating the appliance the magnatherm may be installed indoors or outdoors. If installing outdoors in a location that may experience freezing temperatures, precautions must be taken to prevent water in the heat exchange...

Page 12

Laars heating systems page 8 commencing within 12” (300 mm) of the top and one commencing within 12” (300 mm) of the bottom, of the enclosure shall be provided. The openings shall communicate directly, or by ducts, with the outdoors or spaces that freely communicate with the outdoors. When directly ...

Page 13

Magnatherm boilers and water heaters page 9 with the outdoors and shall have a minimum free area of 1 square inch per 3000 btu/hr (734 square mm/kw) of the total input rating of all equipment located in the enclosure. This opening must not be less than the sum of the areas of all vent connectors in ...

Page 14

Laars heating systems page 10 if the system temperatures are unknown at the time of installation, class iic or higher venting material is recommended. The magnatherm is a category iv appliance and may be installed with the standards listed on table 6. The unit’s vent can terminate through the roof, ...

Page 15

Magnatherm boilers and water heaters page 11 category iv appliances. Per the requirements of can/csa-b149.1, only bh vent systems can be connected to these units and such vent systems, either ulc s636 certified stainless steel or other ulc s636 certified bh vent (eg. Plastics) must be installed per ...

Page 16

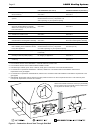

Laars heating systems page 12 *when vent terminal is less than 10 feet (3 m) horizontally from a forced air inlet, the terminal must be at least 3 feet (0.9 m) above the air inlet. (us only) figure 3. Combustion air and vent through side wall u.S. Installations (see note 1) canadian installations (s...

Page 17

Magnatherm boilers and water heaters page 13 objects. 7. If the boiler or water heater uses ducted combustion air from an intake terminal located on the same wall, see see figure 5 and figure 4 for proper spacing and orientation. In the u.S., if the vent termination is located in an area exposed to ...

Page 18

Laars heating systems page 14 3.3.3 vertical vent terminal when the unit is vented through the roof, the vent must extend at least 3 feet (0.9 m) above the point at which it penetrates the roof. It must extend at least 2 feet (0.6 m) higher than any portion of a building within a horizontal distance...

Page 19

Magnatherm boilers and water heaters page 15 3.4 common vent test note -this section does not describe a method for common venting magnatherm’s. It describes what must be done when a unit is removed from a common vent system. Magnatherm’s require special vent systems and fans for common vent. Contac...

Page 20

Laars heating systems page 16 warning do not use open flame to check for leaks. An open flame could lead to explosion, which could result in property damage, serious injury or death. Note - the magnatherm appliance and all other gas appliances sharing the gas supply line must be firing at maximum ca...

Page 21

Magnatherm boilers and water heaters page 17 sched 40 metal pipe capacity for 1.50 specific gravity undiluted propane nominal pipe size @ 11” w.C. Inlet and 0.5” w.C. Pressure drop sch 40 metal pipe capacity for 0.60 specific gravity natural gas nominal pipe size @ 0.30” w.C. Pressure drop nominal: ...

Page 22

Laars heating systems page 18 section 5 water flow requirements 5.1 magnatherm boiler flow and head requirements 5.2 magnatherm water heater flow and head requirements dimensional data sizing data water pipe gas pipe boiler thermal efficiency water heater thermal efficiency water content vent diamet...

Page 23

Magnatherm boilers and water heaters page 19 a boiler installed above radiation level, or as required by the authority having jurisdiction, must be provided with a low water cutoff device either as a part of the boiler or at the time of boiler installation. 6.3 mgh freeze protection magnatherm units...

Page 24

Laars heating systems page 20 different glycol products may provide varying degrees of protection. Glycol products must be maintained properly in a heating system, or they may become ineffective. Consult the glycol specifications, or the glycol manufacturer, for information about specific products, ...

Page 25

Magnatherm boilers and water heaters page 21 figure 7. Hydronic piping — single boiler, multiple temperature zones zoning with circulators water feed controls air vent 4 pipe dia. Max. 4 pipe dia. Max. 4 pipe dia. Max. 4 pipe dia. Max. Low temp. Radiant zone space heating zone circuits space heating...

Page 26

Laars heating systems page 22 figure 8. Hydronic piping — single boiler with low temperature zones and indirect dhw tank indirect tank directly off of boiler low temp. Radiant zone low temp. Radiant zone air vent water feed controls expansion tank 4 pipe dia. Max. Indirect dhw tank anti-scald mixing...

Page 27

Magnatherm boilers and water heaters page 23 figure 9. Hydronic piping — multiple boilers, multiple temperature zones, reverse return. Zoning with circulators space heating zone circuits low temp. Radiant zone space heating zone circuit air vent water feed controls expansion tank common piping must ...

Page 28

Laars heating systems page 24 figure 10. Hydronic piping — multiple boilers, indirect dhw off of one boiler space heating zone circuits space heating zone circuit air vent water feed controls expansion tank common piping must be sized for the combined water flow of all the boilers. High temp. Space ...

Page 29

Magnatherm boilers and water heaters page 25 7.2 mgv suggested piping schematics figure 11 through figure 13 show suggested piping configurations for mgv boilers. These diagrams are only meant as guides. All components or piping required by local code must be installed. 7.3 mgv piping requirements t...

Page 30

Laars heating systems page 26 event of pressure relief. Install a diaphragm-type expansion tank, flow check, and shutoff valves where needed or as required by code. The piping should be installed so that each pump supplies flow only to the heater to which it is attached. 7.4 mgv cold water make-up t...

Page 31

Magnatherm boilers and water heaters page 27 figure 13. Dhw piping - two heaters, two vertical tanks note: this drawing shows suggested piping configuration and valving. Check with local codes and ordinances for additional requirements. Building return supply tprv 2 ball valve (typical) 1 3 cold wat...

Page 32

Laars heating systems page 28 section 8 electrical connections 8.1 installation warnings caution the supply voltage to the magnatherm unit must not be disconnected, except for service or isolation, or unless otherwise instructed by procedures outlined in this manual. To signal a call for heat, use t...

Page 33

Magnatherm boilers and water heaters page 29 three phase single phase 600 480 208 120 240 l1 p br blk l1 blk blk l2 v o r l2 wht r l3 t y bl table 12. Phasevoltagecoloridentification on three phase models a step down transformer (which is protected using an appropriate din rail mounted circuit break...

Page 34

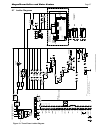

Laars heating systems page 30 figure 14. Electronics panel layout 1 ca0099 vari-prime printed circuit board kit 9 2 km004400 auto-reset high limit control 8 1 e2339800 touch screen alarm silence switch manual reset high limit alarm bell (optional) low water cut-off bas gateway (optional) 7 1 e234610...

Page 35

Magnatherm boilers and water heaters page 31 1 ca0099 vari-prime printed circuit board kit 9 2 km004400 auto-reset high limit control 8 1 e2339800 touch screen alarm silence switch manual reset high limit alarm bell (optional) low water cut-off bas gateway (optional) 7 1 e2346100 6 1 km004300 5 1 a0...

Page 36

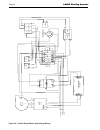

Laars heating systems page 32 figure 15. Wiring diagram, all units page 1 of 2 24v + 24v + 24v neutral 24v neutral 120v (n) 120v + boiler pump system pump 120v + a 120v (n) tt tt alarm alarm dhw sensor remote reset 4-20ma (-) 0-110vdc (-) 0-10vdc (+) outdoor/ system analog (-) analog (+) 0-10v pump ...

Page 37

Magnatherm boilers and water heaters page 33 page 2 of 2 24v + 24v + 24v neutral 24v neutral 120v (n) 120v + boiler pump system pump 120v + a 120v (n) tt tt alarm alarm dhw sensor remote reset 4-20ma (-) 0-110vdc (-) 0-10vdc (+) outdoor/ system analog (-) analog (+) 0-10v pump outdoor/ system tod dh...

Page 38

Laars heating systems page 34 re c ep ta c le gfci w g br convenience 2 a m p l2 l3 blower l1 g diagrams for each voltage w see below for tranformer detail bk + 5 l3 l2 l1 g w /t 3 v/t2 u/ t1 0-10v 16 vfd - 2 17 3 a m p + 24 v y w bk + 12 0v - - bl b a 9 8 7 6 5 4 3 2 1 120v n 120v h 120v n tb2 l1 l...

Page 39

Magnatherm boilers and water heaters page 35 l1 contactor a2 a1 t2 t1 bk bk r r bk l2 w 1 2 5 4 6 3 w bk/o g y bl bk - - + 24v y w bk + 120v bl 3 amp w /t 3 v/t2 u/ t1 0-10v 1 4 vfd l2 l1 n pe l1 l3 l2 blower bk convenience r ec ep ta c le gfci 2 amp n g w g h l1 l1 circuit breaker l2 l2 g g n n h h...

Page 40

Laars heating systems page 36 2 5 4 6 1 3 bl + 120v - - + 24v y w bk 4 a m p hv lv 5 6 3 2 1 4 3 2 1 4 5 6 transformer ph1500pp 3 amp l3 l2 l1 blower w bk t1 t2 a1 a2 contactor l1 l2 bk w w bk vfd l2 l1 n w /t 3 v/t2 u/ t1 0-10v 1 4 pe w g br convenience r ec ep ta c le gfci 2 a m p n g h 10 amp 2 a...

Page 41

Magnatherm boilers and water heaters page 37 condensate r1 4 78 com 1 com 2 12 3 6 5 display ac b j3 m b1 120 vac 24 vac j5-1 interlock t3 t2 t1 l3 l2 l1 v fd bl ower m o to r 1 (+) (-) 2 2 43 1 2 43 1 2 43 1 vtb5 vtb4 vtb1 24 va c po w er variprime co m n/c n/o (opt ional) en cl os ur e 3 1 2 vtb2 ...

Page 42

Laars heating systems page 38 cond en sa te r1 4 78 com 1 c om 2 12 3 6 5 d is pl a y c b a j3 mb1 110 va c 24 va c j5-1 in terlo c k (+) (-) 12 43 2 1 43 2 1 43 2 1 3 1 2 vt b2 vt b6 vt b3 vt b5 vt b4 vt b1 24 vac pow er vari pri me com n/ c n/ o (o pt io nal ) enclosure 4 hsi r-4 pi lo t j1-3 fl a...

Page 43

Magnatherm boilers and water heaters page 39 c o n d en sa te r1 5 4 78 com 1 com 2 12 3 6 di splay ac b j3 m b1 120 vac 24 vac j5-1 in terlock 1 (+) (-) 2 2 43 1 2 43 1 2 43 1 enclosure 3 1 2 vtb2 vtb6 vtb3 vtb5 vtb4 vtb1 24vac po w er variprime com n/ c n/ o (o ptio na l) 4 hs i r-4 pi lo t j1-3 f...

Page 44

Laars heating systems page 40 touch screen open the front panel to access the touch screen section 9 navigating the touch screen 9.1 the touch screen the touch screen is visible behind a protective cover and can be accessed by unlocking and opening the front door. See figure 22. 9.2 using the touch ...

Page 45

Magnatherm boilers and water heaters page 41 screen menu icons there are several icons at the top of the touch screen menus (and most of the other screens) that will help you move around the system: home upper left-hand corner return to home page camera upper left-hand corner screen-shot of current ...

Page 46

Laars heating systems page 42 menu 4. Login required the screen used to login is similar to the keyboard screen. It may be difficult for some operators to press the keys on this screen. In this case, use the back of a plastic pen, or a stylus, or a pencil eraser. (do not use sharp metal tools – thes...

Page 47

Magnatherm boilers and water heaters page 43 figure 24. Reset button on controller 4. The system will present a listing for each group of parameters that need verification see menu 7. Menu 7. Safetyparameterconfirmation 5. For each group, check the list carefully. Press yes if all of the parameters ...

Page 48

Laars heating systems page 44 menu 10. Status summary screen notice the four buttons at the bottom of each status summary screen: • configure – allows an installer to change some of the setup parameters used by the system. A password may be required. • operation – used to adjust the setpoints, chang...

Page 49

Magnatherm boilers and water heaters page 45 9.6 setting the date and time on the system display the display includes an internal clock, which keeps track of the date and time. This setting is important, because log entries for lockouts and alerts include time listings. If the date and time setting ...

Page 50

Laars heating systems page 46 9.7 configurationmenus menu 18. Home screen to navigate to the configuration menu screen, first touch the controller icon on the home screen to access the status summary screen, menu 19. Status summary screen from the status summary screen, touch the ‘configure’ button ...

Page 51

Magnatherm boilers and water heaters page 47 a factory supplied outdoor air temperature sensor is used with the outdoor reset and warm weather shutdown features. Wiring for single boiler operation, the outdoor sensor will be connected to tb1-21a and 22a. For lead lag operation of multiple boilers, t...

Page 52

Laars heating systems page 48 the controller in the magnatherm energizes the appropriate pump contacts when it receives a call for heat. Once the call for heat is satisfied, the pumps will remain on for the defined pump overrun time. The boiler, system, and dhw pump terminals are found on the main c...

Page 53

Magnatherm boilers and water heaters page 49 9.7.14 burner control ignition the pilot test hold function allows the installer to set the pilot flame to the required pressures listed in table 14, without turning on the main valve. With a call for heat enabled the unit will start the normal sequence o...

Page 54

Laars heating systems page 50 figure 25. Lead / lag operation, 2 boilers. Low demand - the first boiler in sequence fires at less than 65% first boiler second boiler demand increases - once the first boiler reaches 65%, the second boiler switches on, and both modulate together between 20% and 65% ne...

Page 55

Magnatherm boilers and water heaters page 51 figure 27. Lead / lag operation, 3 or more boilers low demand - the first boiler in sequence fires at less than 65% 1 2 3 4 demand increases - once the first boiler reaches 50%, the second boiler switches on, and both modulate together between 29% and 65%...

Page 56

Laars heating systems page 52 select ‘configure’. In the configuration menu, scroll down and select ‘lead lag slave configuration’. Identify each unit (including the lead/lag master) as a slave by turning on “slave enable.” you will be prompted to sign in. This can be done by pressing the ‘lock’ sym...

Page 57

Magnatherm boilers and water heaters page 53 9.7.18leadlagmasterconfiguration then set up the master controller by going to the lead lag master boiler and opening up the lead lag master configuration in that boilers configuration menu. Select master enable select ok and then back out to the main men...

Page 58

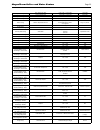

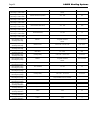

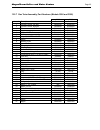

Laars heating systems page 54 section 9.8 - parameter defaults & ranges config group ch config- central heat ch config- central heat ch config- central heat ch config- setpoint ch config- setpoint ch config- setpoint ch config- setpoint ch config- setpoint ch config- setpoint ch config- setpoint ch ...

Page 59

Magnatherm boilers and water heaters page 55 section 9.8 - parameter defaults & ranges config group ch config- central heat ch config- central heat ch config- central heat ch config- setpoint ch config- setpoint ch config- setpoint ch config- setpoint ch config- setpoint ch config- setpoint ch confi...

Page 60

Laars heating systems page 56 section 9.8 - parameter defaults & ranges config group ch config- central heat ch config- central heat ch config- central heat ch config- setpoint ch config- setpoint ch config- setpoint ch config- setpoint ch config- setpoint ch config- setpoint ch config- setpoint ch ...

Page 61

Magnatherm boilers and water heaters page 57 figure 28. Bas connections menu 21. Enabling com2 menu 9.9 connections to a building automation system magnatherm boilers can be controlled and monitored through the included modbus ports. The modbus wiring must be completed according to the diagrams show...

Page 62

Laars heating systems page 58 9.10 vari-prime vari-prime is a variable pump control that is standard equipment on all mgh boilers. Pump speed is controlled to maintain a user-chosen temperature rise between the inlet and outlet of the magnatherm. General pcb operation 1. The desired delta t can be s...

Page 63

Magnatherm boilers and water heaters page 59 9.11 – combustion setup procedure in this section, we will explain how to set up the gas valve so the boiler will run efficiently at both the high fire and low fire conditions. Required tools: screwdrivers, torx bits, allen wrench set, combustion analyzer...

Page 64

Laars heating systems page 60 model gas type high fire co 2 low fire co 2 pressure differential 2,000 natural 9.0% ± 0.2 0.25% lower than high fire co 2 0.5” to 1.2” wc* propane 10.0% ± 0.2 0.25% lower than high fire co 2 0.5” to 1.2” wc* 3,000 natural 9.0% ± 0.2 0.25% lower than high fire co 2 0.5”...

Page 65

Magnatherm boilers and water heaters page 61 8. Magnatherm is equipped with a zero governing, negative regulator valve. The valve throttle should be adjusted only at high fire, and the offset adjustment is only to be done at low fire. From the “home” screen touch the control icon, then touch “operat...

Page 66

Laars heating systems page 62 12. Close the make-up water valve. Check the strainer in the pressure reducing valve for sediment or debris from the make-up water line. Reopen the make-up water valve. 13. Check the gauge for correct water pressure, and also check the water level in the system. If the ...

Page 67

Magnatherm boilers and water heaters page 63 caution if any odor of gas is detected, or if the gas burner does not appear to be functioning in a normal manner, close the main gas shutoff valve. Do not shut off the power switch. Contact your heating contractor, gas company, or factory representative....

Page 68

Laars heating systems page 64 section 11 maintenance warning disconnect all power to the unit before attempting any service procedures. Contact with electricity can result in severe injury or death. 11.1 system maintenance do the following once a year: 1. Lubricate all the pumps in the system, per t...

Page 69

Magnatherm boilers and water heaters page 65 connecting the boiler to the main gas supply line. Remove the front doors of the boiler, and the top panels, to gain access to the gas valve and fuel/air mixer. Disconnect the four flange bolts connecting the gas manifold pipe to the gas valve. Remove the...

Page 70

Laars heating systems page 66 the following; incomplete combustion, combustion air problems, venting problems or heater short cycling. Soot buildup or other debris on the heat exchanger may restrict the flue passages. If black carbon soot buildup on the heat exchanger is suspected, disconnect the el...

Page 71

Magnatherm boilers and water heaters page 67 section 12 troubleshooting 12.1 lockouts, holds, and alerts the control system on the magnatherm responds to three kinds of trouble indications: • lockout: a “lockout” is caused by a serious problem that might involve a safety issue. Once the controller e...

Page 72

Laars heating systems page 68 3. Press the long yellow alert or yellow lockout bar (the long bar will be a long grey ‘history’ bar if not currently in alert or lockout). Menu 29. Ok, lockouts, alerts, or silence. Choose which history list you would like to see. Ok: brings you back to the status summ...

Page 73

Magnatherm boilers and water heaters page 69 12.2 troubleshooting table this table includes a listing of the fault codes that may be displayed. Some of these can be corrected by changing a parameter, while other conditions are more complicated, and will require a service technician. The first column...

Page 74

Laars heating systems page 70 code description lockout or hold procedure 11 internal fault: invalid burner control state flag l internal fault 1. Reset module 2. If fault repeats, replace module. 12 internal fault: safety relay drive cap short h internal fault 1. Reset module 2. If fault repeats, re...

Page 75

Magnatherm boilers and water heaters page 71 code description lockout or hold procedure 26 internal fault: static flame ripple h internal fault 1. Reset module 2. If fault repeats, replace module. 27 internal fault: flame rod shorted to ground detected h internal fault 1. Reset module 2. If fault re...

Page 76

Laars heating systems page 72 code description lockout or hold procedure 53 ac input phases reversed l 1. Check the module and display connections. 2. Check the module power supply and make sure that both frequency and voltage meet the specifications. 3. On 24 vac applications, assure that j4 termin...

Page 77

Magnatherm boilers and water heaters page 73 code description lockout or hold procedure 79 outlet high limit h or l 1. Check wiring and correct any possible errors. 2. Replace the outlet high limit. 3. If previous steps are correct and fault persists, replace the module. 80 dhw (domestic hot water) ...

Page 78

Laars heating systems page 74 code description lockout or hold procedure 97 internal fault: a2d mismatch. L internal fault. 1. Reset module. 2. If fault repeats, replace module. 98 internal fault: exceeded vsnsr voltage tolerance l internal fault. 1. Reset module. 2. If fault repeats, replace module...

Page 79

Magnatherm boilers and water heaters page 75 code description lockout or hold procedure 108 flame lost in run l 1. Check main valve wiring and operation - correct any errors. 2. Check the fuel supply. 3. Check fuel pressure and repeat turndown tests. 4. Check ignition transformer electrode, flame de...

Page 80

Laars heating systems page 76 code description lockout or hold procedure 129 fan speed failed during preignition h or l 1. Check wiring and correct any potential wiring errors. 2. Check the vfds (variable-speed fan drive) ability to change speeds. 3. Change the vfd 4. If the fault persists, replace ...

Page 81

Magnatherm boilers and water heaters page 77 code description lockout or hold procedure 155 purge fan switch off h or l 1. Purge fan switch is off when it should be on. 2. Check wiring and correct any errors. 3. Inspect the purge fan switch j6 terminal 3 and its connections. Make sure the switch is ...

Page 82

Laars heating systems page 78 code description lockout or hold procedure 164 block intake on l 1. Check wiring and correct any errors. 2. Inspect the block intake switch to make sure it is working correctly. 3. Reset and sequence the module. 4. During standby and purge, measure the voltage across th...

Page 83

Magnatherm boilers and water heaters page 79 code description lockout or hold procedure 187 invalid dhw (domestic hot water) high limit enable setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If...

Page 84

Laars heating systems page 80 code description lockout or hold procedure 200 invalid lightoff rate setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace module. 201 invalid ...

Page 85

Magnatherm boilers and water heaters page 81 code description lockout or hold procedure 214 invalid prepurge time setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace modul...

Page 86

Laars heating systems page 82 code description lockout or hold procedure 225 invalid flame threshold setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace module. 226 invali...

Page 87

Magnatherm boilers and water heaters page 83 code description lockout or hold procedure 237 invalid dhw (domestic hot water) connector type setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fa...

Page 88

Laars heating systems page 84 menu 36. Analog i/o screen 4. Press the button for diagnostic tests. The modulation test allows you to change the rate at which the burner fires, and watch the results. See menu 37 menu 37. Modulation test 5. Press the pump test button. The pump test shows detailed info...

Page 89

Magnatherm boilers and water heaters page 85 to use this function, select the parameter you want to track from the pull-down list. The system will present a graph that tracks that variable. To see the graph for the currently-selected function, press the view button. Menu 42. Trend analysis graph the...

Page 90

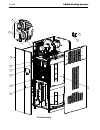

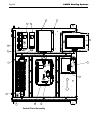

Laars heating systems page 86 25 detail e 26 detail d 24 detail a 9 e 3 11 12 13 5 15 4 7 10 6 10 3 3 15 24 16 26 25 19 22 18 1 17 20 21 8 9 d 14 23 shown for ref only 2 a ac distribution box g 1 3.0 30n3000 scale: none intended size: software sheet 1 of 1 rev. Dwg. No: title: c s frame & jacket ass...

Page 91

Magnatherm boilers and water heaters page 87 frame and jacket assembly 2000 3000 4000 item # description part no. Part no. Part no. 1 base assembly 20n1000 30n1000 40n1000 2 filter a2121700 a2121700 a2121700 2a filter assembly (includes filter) 20n2600 30n2600 40n2600 3 stanchion 20n3001 30n3001 40n...

Page 92

Laars heating systems page 88 intended size: 1 2 tolerances are: 1/8" s 1 magnatherm, 3.0 al 9/11/13 revisions rev. Change: appr engr appr ecn pre approvals draft check release, added sheet 2. Previous rev was "1" .010 - 30n0000 final assembly, vcb title: sheet 1 of 2 13-094n-08 rev. 1 software d dw...

Page 93

Magnatherm boilers and water heaters page 89 intended size: 1 2 tolerances are: 1/8" s 1 magnatherm, 3.0 al 9/11/13 revisions rev. Change: appr engr appr ecn pre approvals draft check release, added sheet 2. Previous rev was "1" .010 - 30n0000 final assembly, vcb title: sheet 1 of 2 13-094n-08 rev. ...

Page 94

Laars heating systems page 90 frame and jacket assembly 2000 3000 4000 item # description part no. Part no. Part no. 1 base assembly 20n1000 30n1000 40n1000 2 filter a2121700 a2121700 a2121700 2a filter assembly (includes filter) 20n2600 30n2600 40n2600 3 stanchion 20n3001 30n3001 40n3001 4 panel, l...

Page 95

Magnatherm boilers and water heaters page 91 6 3 2 1 2 8 13 12 15 14 7 17 16 10 frame and jacket assembly 2000 3000 4000 item # description part no. Part no. Part no. 1 base assembly 20n1000 30n1000 40n1000 2 filter a2121700 a2121700 a2121700 2a filter assembly (includes filter) 20n2600 30n2600 40n2...

Page 96

Laars heating systems page 92 frame and jacket assembly 2000 3000 4000 item # description part no. Part no. Part no. 1 base assembly 20n1000 30n1000 40n1000 2 filter a2121700 a2121700 a2121700 2a filter assembly (includes filter) 20n2600 30n2600 40n2600 3 stanchion 20n3001 30n3001 40n3001 4 panel, l...

Page 97

Magnatherm boilers and water heaters page 93 frame and jacket assembly 2000 3000 4000 item # description part no. Part no. Part no. 1 base assembly 20n1000 30n1000 40n1000 2 filter a2121700 a2121700 a2121700 2a filter assembly (includes filter) 20n2600 30n2600 40n2600 3 stanchion 20n3001 30n3001 40n...

Page 98

Laars heating systems page 94 cjt 11/1/12 intended size: 1 2 .010 tolerances are: 1/8" software 1 approvals al 11-5-13 jm 11-07-13 revisions rev. Change: appr engr appr ecn dwg. No: d from 1 to 2; previous rev was "3" - 13-094n-20 sm 11-5-13 30n6020 check p2090500, p2090600, p2090700; incrs qty 70-2...

Page 99

Magnatherm boilers and water heaters page 95 13.2.7 gas train assembly, part numbers (models 2000 and 3000) frame and jacket assembly 2000 3000 4000 item # description part no. Part no. Part no. 1 base assembly 20n1000 30n1000 40n1000 2 filter a2121700 a2121700 a2121700 2a filter assembly (includes ...

Page 100

Laars heating systems page 96 io manual/qty. N o it p i r c s e d . O n t r a p item no. Bom table 1 70-236 pipe plug, malleable iron, black, 1/8 npt 8 1 w2000300 valve, manual, bronze, 1/8 mnpt x 1/8 fnpt 7 2 s2123500 washer, sealing, 1/8 bspp fitting, dungs 6 2 p2089600 adapter, female to male, 1/...

Page 101

Magnatherm boilers and water heaters page 97 13.2.8 gas train assembly, part numbers (model 4000) frame and jacket assembly 2000 3000 4000 item # description part no. Part no. Part no. 1 base assembly 20n1000 30n1000 40n1000 2 filter a2121700 a2121700 a2121700 2a filter assembly (includes filter) 20...

Page 102

Laars heating systems page 98 sheet 1 of 1 engr dwg. No: software intended size: 1 2 rev. Approvals draft f2000500; delete f2000600. Drawing number was appr engr appr ecn draft check bom configurations were two. - al 11-12-13 revisions rev. Change: appr xn7080 magnatherm title: 1 decimals .Xx .010 f...

Page 103

Magnatherm boilers and water heaters page 99 13.2.9 control panel assembly, part numbers frame and jacket assembly 2000 3000 4000 item # description part no. Part no. Part no. 1 base assembly 20n1000 30n1000 40n1000 2 filter a2121700 a2121700 a2121700 2a filter assembly (includes filter) 20n2600 30n...

Page 104

H2359200- 800.900.9276 • fax 800.559.1583 (customer service and product support) 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com printed in u.S.A. © laars heating systems 1...