Warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. What to do if you smell gas •...

Laars heating systems page 2 section 1. General information 1.1 introduction ...................................................... 3 1.2 model identification .......................................... 4 1.3 warranty .......................................................... 4 1.4 dimensions ..........

Mighty therm 2 (200, 300, 400) page 3 section 1. General information using this manual – because the mighty therm2 boilers and mighty therm2 water heaters are identical appliances, with the exception of materials of manufacture, labels and ultimate use application, this manual provides information f...

Laars heating systems page 4 1.2 model identification consult the rating plate on the unit. The following information describes the model number structure. Model character designation 1-3 model series designation m t 2 = mighty therm2 4 usage h = hydronic v = volume water 5-8 size 0 2 0 0 = 199,900 ...

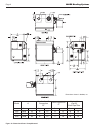

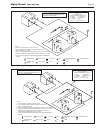

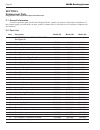

Mighty therm 2 (200, 300, 400) page 5 figure 1a. Dimensional data - non pump mounted. *air and vent connections may be on top or back of the mighty therm2, and are field convertible. Model a combustion air connection b* vent connection c* horizontal (cat iii) vent pipe size in. Cm in. Cm in. Cm in. ...

Laars heating systems page 6 figure 1b. Dimensional data - pump mounted. *air and vent connections may be on top or back of the mighty therm2, and are field convertible. Model a combustion air connection b* vent connection c* horizontal (cat iii) vent pipe size in. Cm in. Cm in. Cm in. Cm 200 20.5 5...

Mighty therm 2 (200, 300, 400) page 7 control replacement, etc.). When vented vertically, the mighty therm2 must be located as close as practical to a chimney or outside wall. If the vent terminal and/or combustion air terminal terminate through a wall, and there is potential for snow accumulation i...

Laars heating systems page 8 section 2. Venting and combustion air warning for indoor installations, as an additional measure of safety, national combustion co. Strongly recommends installation of suitable carbon monoxide detectors in the vicinity of this appliance and in any adjacent occupied space...

Mighty therm 2 (200, 300, 400) page 9 2.1.2 intake combustion air the combustion air can be taken through the wall, or through the roof. When taken from the wall, it must be taken from out-of-doors by means of the laars horizontal wall terminal ( see table 1 ). When taken from the roof, a field-supp...

Laars heating systems page 10 warning operation of appliances with a blocked common vent may lead to serious injury or death. Safety devices must be implemented to prevent blocked common vent operation. If safe operation of all appliances connected to a common vent cannot be assured, including preve...

Mighty therm 2 (200, 300, 400) page 11 u.S. Installations (see note 1) canadian installations (see note 2) a= clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm) deck, or balcony b= clearance to window or door that may direct vent only: 12 inches (30 cm) be opened other than d...

Laars heating systems page 12 gravity inlets or other openings. Whenever possible, locations under windows or near doors should be avoided. 4. Locate the vent terminal so that it cannot be blocked by snow. The installer may determine that a vent terminal must be higher than the minimum shown in code...

Mighty therm 2 (200, 300, 400) page 13 2. Product approved side wall horizontal vented gas fueled equipment installed in a room or structure separate from the dwelling, building or structure used in whole or in part for residential purposes. (c) manufacturer requirements – gas equipment venting syst...

Laars heating systems page 14 spaces of the building. Turn on clothes dryers and any appliance not connected to the common venting system. Turn on any exhaust fans, such as range hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer exhaust fan. Close fireplace ...

Mighty therm 2 (200, 300, 400) page 15 model (size) outdoor vent and air terminal kit 200 ca003001 300 ca003002 400 ca003003 table 6. Vent / air kits for outdoor units. Section 3. Gas supply and piping 3.1 gas supply and piping gas piping should be supported by suitable hangers or floor stands, not ...

Laars heating systems page 16 note: the mighty therm2 appliance and all other gas appliances sharing the gas supply line must be firing at maximum capacity to properly measure the inlet supply pressure. The pressure can be measured at the supply pressure port on the gas valve. Low gas pressure could...

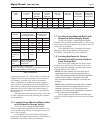

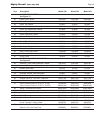

Mighty therm 2 (200, 300, 400) page 17 model (size) 20°f 25°f 30°f 35°f flow gpm h/l feet flow gpm h/l feet flow gpm h/l feet flow gpm h/l feet 200 17 1.6 14 1.0 11 0.7 10 0.5 300 26 3.5 20 2.3 17 1.6 15 1.2 400 34 6.3 27 4.0 23 2.8 19 2.1 metric equivalent model (size) 11°c 14°c 17°c 19°c flow lpm ...

Laars heating systems page 18 figure 5. Hydronic piping — multiple boilers, low temperature system. Figure 6. Hydronic piping — one boiler, multi-temperature system..

Mighty therm 2 (200, 300, 400) page 19 figure 7. Hydronic piping — primary-secondary, reverse-return. Figure 8. Hydronic piping — primary-secondary, reverse-return, low temperature..

Laars heating systems page 20 section 4b. Water connections — mighty therm2 water heater 4b.1 water system piping — water heater hot water piping should be supported by suitable hangers or floor stands. Do not support piping with this appliance. Due to expansion and contraction of copper pipe, consi...

Mighty therm 2 (200, 300, 400) page 21 when the system requires water for heating at temperatures higher than required for other uses, an anti-scald mixing or tempering valve shall be installed to temper the water for those uses in order to reduce scald hazard potential. 4b.5 freeze protection — wat...

Laars heating systems page 22 figure 9. Water heater piping — one heater, one tank. Notes: 5. Caution: pump sizing must be based upon water hardness at job site 1. Optional cwmu & recirc. Line location. 2. Locate pennant dhw sensor or remote aquastat well in lower 1/3 of tank. 3. Back flow preventer...

Mighty therm 2 (200, 300, 400) page 23 figure 11. Water heater piping — one heater, multiple tanks. Caution: this drawing shows suggested piping configuration and valving, check with local codes and ordinances for additional requirements. Notes: 5. Caution: pump sizing must be based upon water hardn...

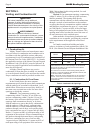

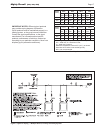

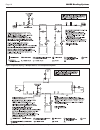

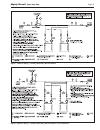

Laars heating systems page 24 figure 15. Wiring diagram, boiler or water heater. - + st.1 6v pump status switch st.2 6v + - no c nc 1 p sensor p2 1 2 bl y y y r no c tb1 l1 pump pump load must not exceed 5 amps. Bl r bk field wiring off on 1 2 3 4 5 3.6 2.0 0.4 switched 120 vac to pump 120 vac l dhw...

Mighty therm 2 (200, 300, 400) page 25 stage 2 stage 1 ctl bd gas valve gas valve ign ctl val flow sw prsw burner ign ctl psw ign ctl th cntrl bd field interlock t t cntrl bd 2 4 cntrl bd 24v- cntrl bd pump status sw fusible link model 200 only manual reset high limit vent stk pr sw +24 ign ctl 24v ...

Laars heating systems page 26 section 6. Operating instructions 6.1 filling the boiler system 1. Ensure the system is fully connected. Close all bleeding devices and open make-up water valve. Allow system to fill slowly. 2. If make-up water pump is employed, adjust pressure switch on pumping system ...

Mighty therm 2 (200, 300, 400) page 27 leds state description 1. Power 2. Heat – on = call for heat; flashes for boiler sensor error 3. Dhw – on = call for dhw; flashes for outdoor sensor error 4. Wwsd – on = outdoor reset and wwsd active and control in wwsd; flashes for outdoor sensor error, operat...

Laars heating systems page 28 differential/2. 2. Target max - the boiler target maximum is the point at which the stages will start to turn off to maintain a maximum water temperature. The boiler maximum water temperature is set by setting dip switch #4: boiler maximum 210°f (off) / 190°f (on). To e...

Mighty therm 2 (200, 300, 400) page 29 blower off. 6.6 operating the burner and set-up 6.6.1 set-up for 0 to 2500 feet altitude the setup must be checked before the unit is put in operation. Problems such as failure to start, rough ignition, strong exhaust odors, etc. Can be due to improper setup. D...

Laars heating systems page 30 section 7. Maintenance 7.1 system maintenance 1. Lubricate the system water-circulating pump, if required, per the instructions on the pump. 2. If a strainer is employed in a pressure reducing valve or the piping, clean it every six months. 3. Inspect the venting system...

Mighty therm 2 (200, 300, 400) page 31 h. Pump (if required) i. Relays j. Flow switch k. Gas train l. Control components 7.2.1 burners close main manual gas valve before proceeding. Checking the burners for debris - remove the ignitor/ burner access panel and ignitor, and inspect the burners through...

Laars heating systems page 32 off the 120-volt power to the appliance. Isolate the boiler or water heater from the system by closing the isolation valves. Caution water may be hot enough to scald. Allow water to cool before proceeding. Attention l’eau peut être chaude au point de vous brûler. Laisse...

Mighty therm 2 (200, 300, 400) page 33 section 8. Trouble shooting 8.1 resolving lockouts there are many causes of lockouts. The three most common causes are: (1) inadequate gas supply, (2) poor combustion, (3) ignitor failure. 1. Inadequate gas supply: before proceeding, ensure that the gas supply ...

Laars heating systems page 34 item description model 200 model 300 model 400 combustion chamber components seefigure20 1 base assembly 2c1000 3c1000 4c1000 2 support, tile notch 2c2019 3c2019 4c2019 3 chamber, refractory, heat exchanger t2108802 t2108803 t2108804 4 assembly, front panel, combustion ...

Mighty therm 2 (200, 300, 400) page 35 jacket components seefigure21 40 panel, front, jacket r2c3320 r3c3320 r4c3320 41 panel, rear, jacket 2c3220 3c3220 4c3220 42 panel, top, jacket 2c3021 3c3021 4c3021 43 panel, jacket, control access 2f3019 3f3019 4f3019 44 panel, hx side access, jacket 2c3620 2c...

Laars heating systems page 36 gas train components seefigure23 80 weldment, gas manifold, main l0063702 l0063703 l0063704 81 manifold, gas, on/off l0063414 l0063416 l0063418 82 manifold, gas, 2 stage left bank l0063404 l0063413 l0063414 83 manifold, gas, 2 stage right bank l0063402 l0063403 l0063405...

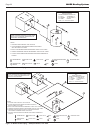

Mighty therm 2 (200, 300, 400) page 37 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 22 23 24 25 26 27 28 29 30 31 31 31 31 31 32 20 21 19 figure 20. Combustion chamber components..

Laars heating systems page 38 figure 21. Jacket components. 40 41 42 48 51 43 44 45 46 47 49 50 52 53 54 54 55.

Mighty therm 2 (200, 300, 400) page 39 60 62 63 63 64 64 73 65 66 67 70 68 72 69b 69a 61 71 figure 22. Heat exchanger components..

Laars heating systems page 40 80 81 85 84 84 86 87 on/off 80 82 83 85 86 86 2 stage figure 23. Gas train components..

Mighty therm 2 (200, 300, 400) page 41 102 104 106 97 figure 24. Control panel components..

Laars heating systems page 42 h2358000a 800.900.9276 • fax 800.559.1583 (customerservice,serviceadvisors) 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com litho in u.S.A. © ...