H0071400w installation and operation instructions for mini-therm ii residential gas-fired hydronic boilers model jv sizes 50-225 for your safety: this product must be installed and serviced by a professional service technician, qualified in hot water boiler installation and maintenance. Improper ins...

Laars heating systems page 2 table of contents section 1. General information 1a. Introduction ................................................... 3 1b. Warranty ....................................................... 3 1c. Field assembly ............................................. 3 1d. Flow requ...

Mini-therm ii hydronic boiler page 3 section 1. General information warning the jv hydronic boiler must be installed in accordance with the procedures detailed in this manual, or the laars warranty will be voided. The installation must conform to the requirements of the local jurisdiction having aut...

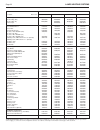

Laars heating systems page 4 size 15°f 8°c 20°f 11°c 25°f 14°c flow rate headloss flow rate headloss flow rate headloss gpm l/s ft m gpm l/s ft m gpm l/s ft m 50 5.3 0.3 0.3 0.1 4.0 0.3 0.2 0.1 3.2 0.2 0.1 0.0 75 8.0 0.5 0.6 0.2 6.0 0.4 0.3 0.1 4.8 0.3 0.2 0.1 100 10.7 0.7 1.3 0.4 8.0 0.5 0.7 0.2 6....

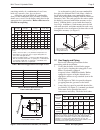

Mini-therm ii hydronic boiler page 5 distance from gas meter boiler size 50 75 100 125 160 225 pipe size 0-50' 1/2 3/4 3/4 3/4 1 1 0-15m 50-100' 3/4 3/4 3/4 1 1 1-1/4 15-30m 100-200' 3/4 1 1 1 1-1/4 1-1/4 30-60m figure 2. Closet and alcove installation (see table 3). Consisting entirely of a combina...

Laars heating systems page 6 boiler size outside air area in sq. In.* inside air area in sq. In.* (sq cm) 50 15 97 100 645 75 20 129 100 645 100 25 161 100 645 125 32 206 125 807 160 40 258 160 1032 225 60 387 225 1452 *area indicated is for one of two openings; one at floor level and one at the cei...

Mini-therm ii hydronic boiler page 7 outside air supply: when combustion air is supplied directly through an outside wall, each opening should have a minimum free area of one square inch per 4,000 btu/h (1.2kw) input of the total input rating of all appliances in the enclosed area. Inside air supply...

Laars heating systems page 8 1h-1. Common venting system when an existing boiler is removed from a common venting system, the common venting system is likely to be too large for proper venting of the appliances remaining connected to it. At the time of removal of an existing boiler, the following st...

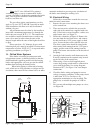

Mini-therm ii hydronic boiler page 9 air scoop jv boiler zone pumps (must be sized properly) flo checks flo checks (installed at proper places) 12" max boiler pump feed water inlet figure 6. Typical plumbing installations. Air scoop jv boiler bypass valve (ball valve) zone pump feed water inlet air ...

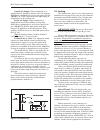

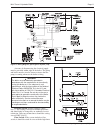

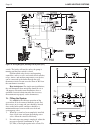

Laars heating systems page 10 figure 7. By-pass piping. Figure 8. Field wiring connections. Note: on jv sizes 160 and 225 a primary/ secondary piping system is recommended. In this system, a circulator is dedicated to pumping the boiler only. This circulator should be sized for the boiler head loss ...

Mini-therm ii hydronic boiler page 11 a means of disconnecting the electrical supply must be provided within sight of the boiler. The pump and boiler must be wired as shown to insure that the pump is running whenever the boiler is firing. Warning the boiler must be electrically grounded in accordanc...

Laars heating systems page 12 switch. The boiler will not fire unless the pump is running and the flow switch is closed. Field installed safety devices and operating controllers, such as a valve end switch, draft switches, relays, timers, and outdoor temperature reset devices, can be connected to th...

Mini-therm ii hydronic boiler page 13 figure 10. Multiple zone wiring. For primary/secondary pumping: connect to "w" in lieu of "a." boiler relay is used for boiler pump and connection to "w" will energize boiler pump when any zone is calling for heat. Wiring with taco zone valves wiring with honeyw...

Laars heating systems page 14 vr8304 vr8300 table 6. Gas valve selection. Pressure regulator is also installed in the line, adjust it to the same pressure. 3. Close all gate valves. Purge one circuit at a time as follows: a. Open one circuit drain valve and let water drain out for at least 5 minutes...

Mini-therm ii hydronic boiler page 15 3. Before lighting smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is heavier than air and will settle on the floor. What to do if you smell gas • do not try to light any appliance. • do not touch any electric swi...

Laars heating systems page 16 6. On each affected burner, slowly close the air shutter until a normal flame is observed then re- tighten its associated locking screw. 7. Turn the boiler off. 8. Perform system start-up in accordance with section 2a of this manual. 9. Observe flame pattern on all burn...

Mini-therm ii hydronic boiler page 17 10. Low water cutoffs should be inspected and flushed periodically. Note: the warranty does not cover damage caused by lack of required maintenance, lack of water flow, or improper operating practices. Fouling on the external surfaces of the heat exchanger is ca...

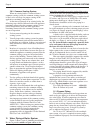

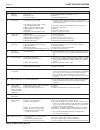

Laars heating systems page 18 table 8. Troubleshooting analysis. # symptom cause remedy 1. Pump not a. No power a. Check circuit breakers and power source. Operating b. Pump defective b. Replace. C. Incorrectly wired c. Recheck wiring diagrams. 2. Pilot outage a. Inlet gas pressure too low a. Consul...

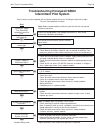

Mini-therm ii hydronic boiler page 19 troubleshooting honeywell s8600 intermittent pilot system some heaters may be equipped with an ignition module that shuts off pilot gas if pilot fails to light. To reset, interrupt power to heater note: before troubleshooting, familiarize yourself with the start...

Laars heating systems page 20 air vent another device used to purge air from the circuit. Should be located at the highest point in the circuit. Branch the section(s) of supply and return piping, including the heat distribution units (see below), connected directly to the trunk. Also referred to as ...

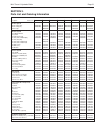

Mini-therm ii hydronic boiler page 21 part number description model, size jvs-50 jvt-50 jvs-75 jvt-75 jvs-100 jvt-100 jvs-125 jvt-125 pilot gas system pilot assembly (nat.) w0030600 w0040900 w0030600 w0040900 w0030600 w0040900 w0030600 w0040900 pilot assembly (lp) w0039600 w0040901 w0039600 w0040901...

Laars heating systems page 22 to obtain or order parts: check with your nearest laars dealer or distributor. They have many of the commonly needed parts in stock. If your dealer cannot supply you, contact the service department at laars. See address and telephone information on back page of this doc...

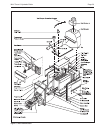

Mini-therm ii hydronic boiler page 23 figure 13 - parts identification figure 13. Parts identification..

H0071400w waterpik technologies, inc. 6000 condor drive, moorpark, ca 93021 • 805.529.2000 • fax 805.529.5934 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 480 s. Service road west, oakville, ontario, canada l6k 2h4 • 905.844.8233 • fax 905.844.2635 www.Laars.Com litho in ...