Installation and operation instructions document 1080c h2020900c these instructions are to be stored next to the boiler for reference purposes. For your safety: this product must be installed and serviced by a professional service technician, qualified in hydronic boiler installation and maintenance...

Laars heating systems page 2 table of contents section 1. General information 1a. Introduction ................................................... 3 1b. Warranty ....................................................... 3 1c. Heater identification ..................................... 3 1d. Flow requi...

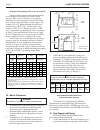

Mini-therm jvi page 3 size 15°f 8°c 20°f 11°c 25°f 14°c flow rate headloss flow rate headloss flow rate headloss gpm l/s ft m gpm l/s ft m gpm l/s ft m 50 5.3 0.3 0.3 0.1 4.0 0.3 0.2 0.1 3.2 0.2 0.1 0.0 75 8.0 0.5 0.6 0.2 6.0 0.4 0.3 0.1 4.8 0.3 0.2 0.1 100 10.7 0.7 1.3 0.4 8.0 0.5 0.7 0.2 6.4 0.4 0...

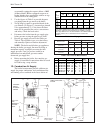

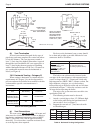

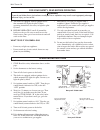

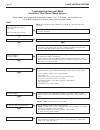

Laars heating systems page 4 figure 1. Closet installation. Top view side view damage from improper flow is not warranted. Failure to insure proper water flow through the heat exchanger of the boiler will void the laars warranty. Flow can be verified by measuring the difference in water temperatures...

Mini-therm jvi page 5 are normally equipped to operate below a 2000' (610m) altitude. Boilers equipped to operate at higher altitudes have appropriate stickers or tags attached next to the rating plate. 2. Use the figures in table 5 to provide adequate gas piping from the gas meter to the boiler. 3....

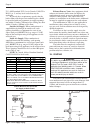

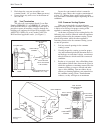

Laars heating systems page 6 u.S. Ansi standard z223.1 or in canada, can/cga- b149.1 or .2, and any local codes that may be applicable. In general, these requirements specify that the boiler rooms which represent confined spaces should be provided with two permanent air supply openings; one within 1...

Mini-therm jvi page 7 minimum 12" (305mm) height above the boiler, is recommended. The vent system should be sloped up toward the chimney 1/4" per foot (20mm per meter). The vent connector must be supported for the design and weight of the material employed, to maintain clearances and prevent physic...

Laars heating systems page 8 (b) vent termination a listed vent terminal designed for the type of pipe being used must complete the vertical run where it exits the chimney. The vent pipe must extend at least 3' (.9m) above the highest point where it passed through the roof. In addition, the vent cap...

Mini-therm jvi page 9 locate the vent terminal so that it cannot be blocked by snow. Most codes requires termination of at least 12" (305mm) above grade, but the installer may determine it should be higher depending on local conditions. 1h-3. Common venting system when an existing boiler is removed ...

Laars heating systems page 10 speed. Do not operate a summer exhaust fan. Close fireplace dampers. 4. Place in operation the appliance being inspected. Follow the lighting instructions. Adjust thermostat so appliance will operate continuously. 5. Test for spillage at the burner opening after five mi...

Mini-therm jvi page 11.

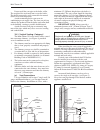

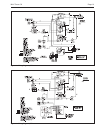

Laars heating systems page 12 1k. Electrical wiring follow these instructions to make the necessary initial electrical connections. 1. Remove the two screws attaching the front cover of the control box. 2. There are five wires coiled in the area on the right side of the control box, supplied with wi...

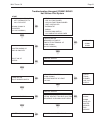

Mini-therm jvi page 13 figure 11. Wiring diagram, jvp. Figure 10. Wiring diagram, jvh..

Laars heating systems page 14 figure 10. Multiple zone wiring. For primary/secondary pumping: connect to "w" in lieu of "a." boiler relay is used for boiler pump and connection to "w" will energize boiler pump when any zone is calling for heat. Wiring with taco zone valves wiring with honeywell zone...

Mini-therm jvi page 15 12. Close the water makeup valve and check the strainer in the pressure reducing valve for sediment or debris. Reopen the water makeup valve. 13. Verify system pressure with the boiler pressure gauge before beginning regular operation. 14. Within 3 days of start-up, recheck an...

Laars heating systems page 16 2a. System start-up 1. Verify that the pump system is operating properly: a. Shut off the manual gas valve located outside the boiler. B. Raise the wall thermostat high enough to call for heat. C. The pump should come on immediately. If it does not, test the electrical ...

Mini-therm jvi page 17 • immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions. If you cannot reach your gas supplier, call the fire department. C. Use only your hand to push in or turn the gas control knob. Never use tools. If the knob will not push in o...

Laars heating systems page 18 section 3. 3a. Maintenance 1. Lubricate the water circulating pump per the instructions on the pump. 2. If a strainer is employed in a pressure reducing valve or the piping, clean it every six months. 3. At start-up, and periodically thereafter, the burner and pilot fla...

Mini-therm jvi page 19 3b. Electrical troubleshooting 1. Remove the control box cover on the front of the boiler. 2. Verify that 115 volts is reaching the boiler by testing across the black wire and the white wire on the transformer. 3. Verify 24 volts transformer output by placing the meter leads o...

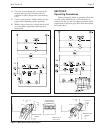

Laars heating systems page 20 # symptom cause remedy 1. Pump not operating no power . . . . . Check circuit breakers and power source. Pump defective . . . . . Replace. Incorrectly wired . . . . . Recheck wiring diagrams. 2. Pilot outage inlet gas pressure too low . . . . . Consult gas utility compa...

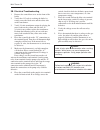

Mini-therm jvi page 21 turn gas on. Pilot burner lights? Main valve opens? System ok igniter warms up and glows red pilot valve opens start • turn gas supply off • set thermostat to call for heat sv9501/sv9601 is powered (24 vac nominal) yes check: • line voltage power • low voltage transformer • li...

Laars heating systems page 22 troubleshooting honeywell s8600 intermittent pilot system (spark ignition) some models are equipped with lockout/retry modules. On l.P.G. Models, trial for ignition last 15 seconds followed by 5 minutes lockout, then the cycle repeats. Start turn off gas supply. Turn th...

Mini-therm jvi page 23 air vent a device used to purge air from the circuit. Should be located at the highest point in the circuit. Branch the section(s) of supply and return piping, including the heat distribution units connected directly to the trunk. Also referred to as a “zone”. By-pass a sectio...

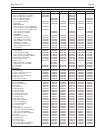

Laars heating systems page 24 part number description model, size 1. Pilot gas system pilot assembly (nat.), hot surface pilot assembly (lp), hot surface pilot assembly (nat.), spark pilot assembly (lp), spark 2. Burner with pilot bracket 3. Main burner 4. Main gas valves valve, hot surface, (nat.) ...

Mini-therm jvi page 25 description model, size 1. Pilot gas system pilot assembly (nat.), hot surface pilot assembly (lp), hot surface pilot assembly (nat.), spark pilot assembly (lp), spark 2. Burner with pilot bracket 3. Main burner 4. Main gas valves valve, hot surface, (nat.) sv9501h315 valve, h...

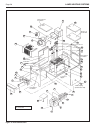

Laars heating systems page 26 33 flue collector insulation 28 43 rear top insulation 1-1/4 tee 1/2" coupling (model 50 & 100) 1/2" close nipple front panel insulation *items 13, 14, 15 and 30 are not shown 18 19 17 24 29 39 42 16 22 21 26 34 2 6 1 11 5 37 4 3 41 40 rear panel insulation 12 36 7 7 8 ...

Mini-therm jvi page 27.

H2020900c waterpik technologies, inc. 6000 condor drive, moorpark, ca 93021 • 805.529.2000 • fax 805.529.5934 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 480 s. Service road west, oakville, ontario, canada l6k 2h4 • 905.844.8233 • fax 905.844.2635 www.Laars.Com litho in ...