- DL manuals

- Laars

- Boiler

- NeoThem NTH

- Service Manual

Laars NeoThem NTH Service Manual

Summary of NeoThem NTH

Page 1

Document 1292 modulating boiler model nth sizes 399-850 mbtu/h water heater model ntv sizes 399-850 mbtu/h every reference that you’ll need, to service the commercial n eo t herm ® service manual for n eo t herm.

Page 3

Service manual - neotherm 500 how to use this manual i how to use the troubleshooting information this manual is divided into five main sections: section a - troubleshooting instructions section b - troubleshooting procedures section c - combustion section d - neotherm control system appendix start ...

Page 4

Service manual - neotherm 500 ii finding information in this pdf file this manual includes a lot of detailed information, but none of this is very useful to you unless you can find it. We’d like to help you to find the information you need, quickly and easily. There are four ways to locate informati...

Page 5

Service manual - neotherm 500 iii safety notes please read this section before beginning any troubleshooting procedures. If the information in this manual is not followed exactly, a fire or ex- plosion may result, causing loss of life, personal injury, or property damage. Necessary training - this p...

Page 6

Service manual - neotherm 500 electrical shock hazard electrical shock can cause severe injury, death or property damage. Only a professional technician, trained in electrical safety, should work on this unit. Whenever the troubleshooting procedures make this possible, turn off the power to the unit...

Page 7

Service manual - neotherm 500 table of contents section a - troubleshooting - start here sect. Title ................................................................................Page a1 troubleshooting - start here ............................................... 1 a2 unit will not fire - blower i...

Page 8

Service manual - neotherm 500 table of contents (continued) b15 removing and replacing the high and low gas pressure switches ............................................................. 32 b16 checking the condensate trap water level switch ......... 35 b17 testing the condensate trap level switch...

Page 9

Service manual - neotherm 500 table of contents (continued) section c - possible combustion problems sect. Title page c1 about correct combustion ................................................ 59 c2 combustion adjustment procedure - units with original (white) user interface .........................

Page 10

Service manual - neotherm 500 viii.

Page 11: Troubleshooting - Start Here

1 service manual - neotherm 500 a1 troubleshooting - start here for troubleshooting instructions, see these sections: section symptom page a2 unit will not fire, blower is not running 2 a3 blower runs continuously, no display 4 a4 control unit is in “standby” mode 5 a5 changing control settings, cha...

Page 12

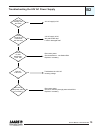

2 service manual - neotherm 500 unit will not fire - blower is not running a2 no yes check 120v ac electrical power. Display is lit? See section b2 - “troubleshooting the 24v ac power supply” no check for correct “call for heat” signal. (5-6 on tb7) see section b22 “checking the blower” see section ...

Page 13

3 service manual - neotherm 500 unit will not fire - blower is not running a2 cont. Check programming in controller - temperature settings, outdoor reset, etc. See table of code numbers in appendix. Problem indication from controller? Yes - code number supplied no see section a4 “control unit is in ...

Page 14

4 service manual - neotherm 500 blower runs continuously, no display a3 in this condition, the blower is running continuously, but the display is completely blank. If unit continues to operate normally - temporary condition if breaker trips again - see section b2 reset 24v breaker switch under trans...

Page 15

5 service manual - neotherm 500 control unit is in “standby” mode in certain situations, the controller on this unit can go into “standby” mode. The boiler pump is running, so the unit sees a “call for heat.” there is no lockout or hold, but something is preventing it from going to “run” mode. A4 no...

Page 16

6 service manual - neotherm 500 a4 cont. Control unit is in “standby” mode (continued) example: high flue temperature trips high stack temp. Sensor. Unit will not run for 20 min., then automatically resets. Controller reacting to a temporary problem? No units with original (white) user interface - s...

Page 17

7 service manual - neotherm 500 changing control settings, change not complete original (white) interface neotherm units were produced using two types of user interfaces. (see section d 1 to identify the kind of interface used on your unit.) these instructions apply to units with the original (white...

Page 18

8 service manual - neotherm 500 unit is running, but building is still cold a6 yes no clear it air inlet is blocked? Clean air intake inside unit is plugged? Yes no clean, blow out (gas/air mixture is correct, but not enough gas/air mixture is supplied.) dirty fan? Yes no burner and/or heat exchange...

Page 19

9 service manual - neotherm 500 control unit says “run,” but boiler is not firing in this condition, the panel is lighted, so you know the unit has power. The boiler pump is running, so you know the unit is receiving the call for heat. The blower is running, the unit has spark, and the gas valve is ...

Page 20: A10

10 service manual - neotherm 500 on systems using anti-freeze – this can occur if the concentration of anti-freeze is too high. At concen- trations above 35%, localized boiling can occur, and this can produce noise. Unit is noisy a10 on systems using the current user interface – to see if the unit i...

Page 21

11 service manual - neotherm 500 quick check of components in the safety chain this procedure gives you a quick way of checking the safety switches and some of the control functions in the unit. This will allow you to rule out some large sections of the control system, and find the part of the syste...

Page 22

12 service manual - neotherm 500 quick check of components in the safety chain - continued 6. If this unit is set up to use a separate dhw signal – insert a jumper across terminals 5 and 6 on tb-6 on the control board. See fig. B1-3. This will create a permanent “call for dhw” signal. (again, rememb...

Page 23

13 service manual - neotherm 500 10. Check for 24v ac between terminal j6-1 on the control module and any terminal on tb4. See fig. B1-6. If 24v ac is present here, this means that the following safety switches are ok: • high gas pressure switch • low gas pressure switch • condensate trap level swit...

Page 24

14 service manual - neotherm 500 quick check of components in the safety chain - continued b1 cont. Fig. B1-8 - control voltage for the blower j2 12. If the unit is receiving a “call for heat,” and all of the safety switches are ok, the blower should be receiv- ing control voltage through j2 on the ...

Page 25

15 service manual - neotherm 500 troubleshooting the 24v ac power supply b2 24v ac between tb3 and tb4? Yes no 24v ac supply is ok 120v ac to nt unit? No yes troubleshoot the 120v ac incoming voltage. 120v ac at main power switch (3-7 on sw1)? No disconnect power. Check for continuity through power ...

Page 26

16 service manual - neotherm 500 checking the safety chain b3 24v ac is present? (all switches closed) yes no safety chain is ok check for 24v ac between tb8-1 and tb4-1. Check for 24v ac between tb8-2 and tb4-1. 24v ac is present? Yes see procedure b4 - “checking the low water cutoff switch” no che...

Page 27: 2-12

17 service manual - neotherm 500 checking the safety chain - continued b3 cont. 24v ac is present? (other safety switches closed) yes no check for 24v ac at terminal j6-1. With boiler attempting to run, check for 24v ac across two leads on air pressure switch. 24v ac is present? (switch open) yes se...

Page 28

18 service manual - neotherm 500 checking the low water cutoff switch (option) control resets? Yes no check for continuity from base of switch to ground. Has continuity? No isolate the boiler and drain it. Remove the probe. Do not use teflon tape on the threads. (this would interrupt the continuity)...

Page 29

19 service manual - neotherm 500 checking the low water cutoff switch (continued) controller for low water cutoff the low water cutoff switch operates by passing a slight electrical current between from a probe to ground when water is surrounding the probe. If there is no water, there is no current,...

Page 30

20 service manual - neotherm 500 removing and replacing the low water cutoff controls the low water cutoff (lwco) is designed to shut down the unit if there is a low water condition. The control includes two parts: a control box, and a probe which reaches into the water piping. Tools and equipment r...

Page 31

21 service manual - neotherm 500 procedure - replacing the control box 1. To remove the cover, remove the two sheet metal screws on the sides. 2. Disconnect the three wires on the terminal strip, and the violet wire that runs to the connector above the terminal strip. See fig. B6-2. 3. The control b...

Page 32

22 service manual - neotherm 500 high water temperature limit switch (optional) laars does not provide this switch. It is installed only where required. This is a normally-closed (nc) switch. If the water temperature rises above the pre-set limit, the switch opens. Some types of switches must be res...

Page 33

23 service manual - neotherm 500 testing the flow switch the flow switch uses a set of paddles to sense water flowing through the system. See fig. B9-2. When water is flowing, the switch is normally closed (n.C.). If the water flow stops, the switch opens. After a “no flow” condition, the switch res...

Page 34: B10

24 service manual - neotherm 500 removing and replacing the flow switch the switch assembly includes two parts: a set of paddles that extend into the water pipe, and a control box. See fig. B9-1. Figure b9-2 shows the paddles that extend into the piping to detect the water flow. The paddles are size...

Page 35: B10

25 service manual - neotherm 500 removing and replacing the flow switch (continued) 7. Once you have trimmed the paddles, install them on the switch. See fig. B10-1. Insert the pin to attach the paddles to the center post. 8. Important! When the switch is installed, the ends of the paddles must sit ...

Page 36: B11

26 service manual - neotherm 500 removing and replacing the gas valve the modulating gas valve consists of a valve body that controls the on/off gas flow and a negative pressure regulator. It provides the air/gas ratio control in combination with the venturi to the unit. The easiest way to remove th...

Page 37: B11

27 service manual - neotherm 500 removing and replacing the gas valve (continued) b11 cont. 5. Disconnect the small vacuum hose running to the top of the gas valve. 6. Disconnect the wires to the high gas pressure switch only. (on the unit, this is the pressure switch on the left, on the side closes...

Page 38: B11

28 service manual - neotherm 500 removing and replacing the gas valve (continued) b11 cont. 9. Now you can remove the whole assembly from the machine. Figure b11-6 shows the complete assembly. 10. The next step is to remove the high gas pressure switch. Turn the red handle on the gas valve to the of...

Page 39: B12

29 service manual - neotherm 500 checking the high gas pressure switch b12 the high gas pressure switch is a 24v manual reset switch that acts to cut power to the gas valve if the gas pressure is too high for proper op- eration. The type of switch used is integrally vent limited, and does not requir...

Page 40: B13

30 service manual - neotherm 500 checking the low gas pressure switch the low gas pressure switch is a 24v manual reset switch that acts to cut power to the gas valve if the gas pressure is too low for proper operation. The type of switch used is integrally vent limited, and does not require venting...

Page 41: B14

31 service manual - neotherm 500 testing the low gas pressure switch b14 in the gas train, this switch is located before the gas control valve. Gas will reach this switch whenever the gas shutoff valve to the unit is open. Figure b14-1 shows the gas train. Connect a test gauge to the inlet gas press...

Page 42: B15

32 service manual - neotherm 500 each nt unit includes two switches which sense gas pressure: • the low gas pressure switch is located before the gas valve. It will prevent the unit from firing if there is not enough gas pressure to operate cor- rectly. • the high gas pressure switch is placed after...

Page 43: B15

33 service manual - neotherm 500 removing and replacing the high and low gas pressure switches (continued) b15 cont. Procedure - removing or replacing either switch 1. Turn off power to the machine. Use the main discon- nect switch on the front of the machine, just above the control panel. 2. Remove...

Page 44: B15

34 service manual - neotherm 500 for the low gas pressure switch only - mark the wire on the left using a piece of electri- cal tape. When the switch is assembled, this wire will go to the “n.O.” connection. Wire to n.O. Contact mark this wire with a piece of tape. Fig. B15-4 - low gas pressure swit...

Page 45: B16

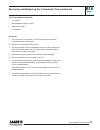

35 service manual - neotherm 500 checking the condensate trap level switch 24v ac present? (switch open) no yes see section b3 - “checking the safety chain ” check for 24v ac across switch. Test switch. See section b17. Replace if necessary. See section b18. Outlet blocked? No yes flush outlet with ...

Page 46: B17

36 service manual - neotherm 500 fig. B17-1 - small condensate trap assembly (typical) some operating conditions can cause small particles of mineral material to be formed in the heat exchang- er and collect in the condensate trap. The drain can also be blocked if it is frozen or plugged with debris...

Page 47: B18

37 service manual - neotherm 500 tools and equipment required: * 1/4” socket • small diagonal cutters or knife • water-pump pliers • 11” ty-wrap procedure 1. Turn off power to the system. Use the main disconnect switch mounted above the front panel. 2. Remove the front panel from the unit. 3. You wo...

Page 48: B19

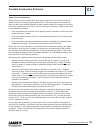

38 service manual - neotherm 500 exhaust vent blocked? Yes no clear the vents. Check the bird screens or terminals. Check for blocked air intake and exhaust vents. Clean with a shop-vac. Dirty fan? Yes no test the air pressure switch. (see section b20.) switch is ok? No replace switch. Yes problem w...

Page 49: B20

39 service manual - neotherm 500 1. The switch is located behind the front panel. Dis- connect the two leads, and connect a volt-ohmme- ter set to check for continuity (reading ohms). 2. Insert a hose “t” in the clear plastic hose that runs to the positive pressure port (closest to the electrical co...

Page 50: B21

40 service manual - neotherm 500 procedure - removing or replacing the switch 1. Turn off power to the machine. Use the main disconnect switch located above the top of the control panel. 2. Remove the covers on top of the unit so you can reach the air pressure switch. 3. Remove the mounting screws o...

Page 51: B22

41 service manual - neotherm 500 yes blower goes to full speed? Replace the sola controller see section d8, d9. Unplug j2. This is the control signal to the blower. No yes check wiring harness. Wires ok? No replace wire harness no has call for heat? At start of test, unit should be ready to run (”st...

Page 52: B23

42 service manual - neotherm 500 fig. B23-1 - gas shutoff valve (typical) the easiest way to remove the blower is to remove it as part of an assembly, including the air/gas chan - nel, front panel of the combustion chamber, and the burner. Once you have done this, you can separate the burner from th...

Page 53: B23

43 service manual - neotherm 500 5. Behind the gas valve, locate the black rubber air intake hose. Loosen the hose clamp on the left end of this hose, and pull the end of the hose away from the end of the venturi. When you have finished this step, the unit will look like fig. B23-3. 6. Disconnect th...

Page 54: B23

44 service manual - neotherm 500 8. Now you can remove the front of the heat exchanger, with the blower and burner still at- tached. Undo the six 10mm nuts around the out- side of the front plate of the heat exchanger. See fig. B23-6. As you remove the part, note the position of the large black gask...

Page 55: B23

45 service manual - neotherm 500 11. The location where you removed the venturi is the air intake for the blower. To clean the blower, blow compressed air through the intake and spin the impeller. 12. To reassemble, reverse the procedure listed above. 13. Replace the gasket on the inner surface of t...

Page 56: B24

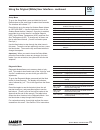

46 service manual - neotherm 500 yes no correct this immediately. Blocked exhaust outlet? Dirty heat exchanger? If you have the current user interface, set the stack temperature limit to 190°f. Actual stack temperature problem? Check the continuity on the wires from the sensor to j9-4, j9-5, and j9-...

Page 57: B25

47 service manual - neotherm 500 the stack temperature limit switch will shut down the nt unit if the stack temperature rises above 195°f. This is a “duplex” sensor - it actually includes two separate thermistors. The control system constantly compares the readings from the thermistors. If there is ...

Page 58: B26

48 service manual - neotherm 500 checking the dhw sensor the system sensor is mounted in the circulating loop, and provides the input for the ch (central heating) function. This type of sensor can fail in either an “open” or “shorted” condition, or may become inaccurate. On a unit with the current u...

Page 59: B28

49 service manual - neotherm 500 a typical installation for the inlet water temperature sensor is shown in fig. B28-1. The sensor is connected to j8 4-5 on the control module. This sensor uses an electronic device called a “thermistor.” for instructions on testing the sensor, see section b32. To res...

Page 60: B30

50 service manual - neotherm 500 fig. B30-1 - outlet water temperature sensor (typical) the outlet water temperature switch allows the control system to monitor the temperature of the water as it leaves the nt unit. A typical installation for the outlet water temperature sensor is shown in fig. B30-...

Page 61: B31

51 service manual - neotherm 500 4. The outlet water temperature sensor is mounted in the shoulder of the heat exchanger assembly, just above the point where the water outlet pipe is at- tached to the heat exchanger. (the outlet pipe is marked with a label on top of the unit.) remove the top panels ...

Page 62: B33

52 service manual - neotherm 500 servicing the transformer fig. B34-1 - transformer installation (typical) the transformer changes the 120v ac input power into 24v ac for use by the controls in the nt unit. The transformer includes an integral 4 amp circuit breaker, and is mounted on the machine fra...

Page 63: B34

53 service manual - neotherm 500 tools and equipment required: • volt-ohmmeter • phillips head screwdriver (size #1) • deep socket for transformer mounting nuts test procedure: it is simplest to test the transformer by checking the voltages at other points on the nt unit. 1. Turn on power to the uni...

Page 64: B35

54 service manual - neotherm 500 if the system pressure exceeds the relief valve setting, the pressure relief valve is designed to open and release the excess pressure and water. Note - this type of valve is designed to relieve a limited number of times during its life cycle, so it is not a good ide...

Page 65: B36

55 service manual - neotherm 500 the ignitor assembly is a two-rod system that con- sists of a ground rod and a spark rod. Adjustment procedure: 1. Shut off the 120v power supply to the unit. 2. Turn off all manual gas valves connecting the unit to the main gas supply line. 3. Remove the front door ...

Page 66: B37

56 service manual - neotherm 500 the flame sensor is a single-rod system, and is mounted in the front cover of the heat exchanger. Over time, this sensor can become tarnished or coated. (this will hap- pen more quickly if the nt unit has been operating often at a low firing rate.) the flame sensor h...

Page 67: B38

57 service manual - neotherm 500 a problem with the circulator pump could appear as a #79 error (outlet high limit). It could also appear as a #63 error (lci - limit control input) if the safety chain includes a flow switch. The sola controller also can display error #51 - pump fault. No no check fo...

Page 68

58 service manual - neotherm 500

Page 69

59 service manual - neotherm 500 possible combustion problems about correct combustion when the unit is firing, the gas valve must always supply the correct amount of gas to match the amount of air going through the burner. The ratio of gas to air remains con - stant, but the control module adjusts ...

Page 70

60 service manual - neotherm 500 combustion adjustment procedure - units with original (white) user interface warning improper adjustment may lead to poor combustion quality, increasing the amount of carbon monoxide produced. Excessive carbon monox - ide levels may lead to personal injury or death. ...

Page 71

61 service manual - neotherm 500 2. Once you have completed the high fire combustion test, measure the co 2 / o 2 in the flue products at low fire. How to get there: use the down arrow to set the “rate” to “20%.” the nt unit is now forced to low fire for 5 minutes. The co 2 readings should be betwee...

Page 72

62 service manual - neotherm 500 combustion adjustment procedure - units with current user interface warning improper adjustment of the high fire and low fire settings may lead to poor combustion, increasing the amount of carbon monoxide produced. Excessive carbon monoxide levels may lead to persona...

Page 73

63 service manual - neotherm 500 2. Next, measure the co 2 and o 2 in the flue products at low fire. The neotherm can be forced to remain in low fire during the setup. How to get there: from the “home” screen, press “i” to go to “info/ install.” choose “test,” then go to “forced rate.” select “set l...

Page 74

64 service manual - neotherm 500 troubleshooting combustion problems during adjiustment, can reach target figures in table? Cannot reac h gas inle t pressure ok? Ye s no gas supply problem. Check with gas company. Interior of burner is clean? No clean burner and heat exchanger. See section c5. Can r...

Page 75

65 service manual - neotherm 500 cleaning the burner and heat exchanger the buildup of black carbon soot on the external surfaces of the heat exchanger can be caused by one or more of the following: incomplete combustion, combustion air problems, venting problems, and short- cycling. Soot buildup or...

Page 76

66 service manual - neotherm 500 disassembly procedure: 1. Turn off power to the machine. Use the main discon - nect switch on the front of the machine, just above the control panel. 2. Remove the front panel. 3. Shut off the gas at the gas shutoff valve on the right side of the machine (yellow hand...

Page 77

67 service manual - neotherm 500 cleaning the burner and heat exchanger (continued) c5 cont. 6. Disconnect the wires to the blower. See fig. C5-5. There are two connectors. The power wires run to the front connector, and the control wires connect to the rear. 7. The next job is to separate the front...

Page 78

68 service manual - neotherm 500 8. Now you can remove the front of the heat exchang - er, with the blower and burner still attached. Undo the six 10mm nuts around the outside of the front plate of the heat exchanger. See fig. C5-7. As you remove the part, note the position of the large black gasket...

Page 79

69 service manual - neotherm 500 10. Separate the blower from the assembly by remov - ing the four 13mm screws. As you disassemble the parts, note the position of the black gasket. 11. Separate the air-gas channel from the front plate for the heat exchanger. Remove the five #25 torx® screws. Remove ...

Page 80

70 service manual - neotherm 500 fig. C5-10 - correct way to clean the flame sensor cleaning the burner and heat exchanger (continued) fig. C5-11 - inside of heat exchanger (new unit) refractory material c5 cont. Cleaning procedure: 1. The flame sensor is mounted in the front cover of the heat excha...

Page 81

71 service manual - neotherm 500 fig. C5-12 - dirty heat exchanger fig. C5-13 - very dirty heat exchanger fig. C5-14 - drain hose connected under the heat exchanger cleaning the burner and heat exchanger (continued) refractory material stainless steel coils (dirty) c5 cont. The heat exchanger in fig...

Page 82

72 service manual - neotherm 500 4. Clean the heat exchanger by brushing away any soot with the toilet brush, and collecting the dust using a vacuum cleaner. Use the vacuum to remove any mineral granules. Caution! Do not use a stiff brush with wire bristles. This can scratch the tubes on the heat ex...

Page 83

73 service manual - neotherm 500 identifying the user interface on your unit there are two main parts to the control system on a neotherm unit: • the “controller” - this is the control module that contains the computer that actually operates the unit. The controller is located inside the cabinet of ...

Page 84

74 service manual - neotherm 500 using the original (white) user interface this interface was used on all neotherm models produced through 2012. There are a few features on this interface that you should know about - • when the neotherm unit is first turned on, the interface will go through a self-t...

Page 85

75 service manual - neotherm 500 setup menu to go to the setup mode, press and hold the up and down buttons at the same time for about three seconds. The interface will indicate “°f.” press next to go to the setup for outdoor reset (shown as “lbt hod lod”). Use the up button to turn on the outdoor r...

Page 86

76 service manual - neotherm 500 reacting to lockouts on the original (white) user interface the system responds to three kinds of trouble indications: • a ”lockout” is caused by a serious problem that might involve a safety issue. Once the controller enters a lockout, the burner will shut down, and...

Page 87

77 service manual - neotherm 500 removing and replacing the original (white) user interface please check the troubleshooting instructions in section a before replacing the user interface. Here is the removal/ replacement procedure: 1. Turn off all power to the neotherm unit, and shut off all manual ...

Page 88

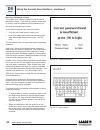

78 service manual - neotherm 500 using the current user interface this interface is used on all neotherm models produced since 2012. The table below lists the functions of the various parts of the user inter- face. In a moment, we will explain how to use the buttons to reach the different sections o...

Page 89

79 service manual - neotherm 500 home display when the boiler is operating normally, the controller will display the home display. See fig. D5-2. The screen display area has three sections: • the upper section of this screen displays the most important operating information for the unit. In the exam...

Page 90

80 service manual - neotherm 500 quick start this menu gives you an easy way to check or change the most common set- tings on the unit: • ch setpoint • dhw setpoint • outdoor reset (note - on some units you cannot disable this function) • low water temperature • maximum outdoor temperature • minimum...

Page 91

81 service manual - neotherm 500 you will notice that the system did not ask you for a password, so this is one of the values that can be changed by anyone. Entering a time the controller uses several different timing functions, and you can change some of these. (in the example shown in fig. D5-5, w...

Page 92

82 service manual - neotherm 500 entering a password or name the system uses a different type of screen to enter a password or name. If you want to change a setup value or function, and the system requires a password, you can enter it using the login screen. There are two ways you can reach this scr...

Page 93

83 service manual - neotherm 500 fig. D5-8 - enable/ disable screen fig. D5-9 – changing lcd contrast turning a function on and off some of the values can be enabled or disabled. Figure d5-8 shows one example. • use the up- and down-arrows to highlight the line you want, then press the round ok butt...

Page 94

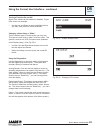

84 service manual - neotherm 500 reacting to lockouts on the current user interface the system responds to three kinds of trouble indica- tions: • a”lockout” is caused by a serious problem that might involve a safety issue. Once the controller enters a lockout, the burner will shut down, and will no...

Page 95

85 service manual - neotherm 500 removing and replacing the current user interface fig. D7-1 - current user interface tools and equipment required: * soft cloth (clean towel, etc.) • small phillips-head screwdriver (size #1) procedure 1. Turn off power to the system. Use the main discon- nect switch...

Page 96

86 service manual - neotherm 500 7. Place the new circuit board in position and replace the screws. 8. Plug in the two ribbon cable connectors. 9. Plug in connectors x01 and x07. 10. Replace the front panel assembly. 11. Turn on power to the unit. Removing and replacing the current user interface (c...

Page 97

87 service manual - neotherm 500 removing and replacing the sola controller all of the nt units use the sola controller. This procedure explains how to remove and replace this controller. Notice that, as installed in the nt unit, the sola controller is mounted “upside down.” this does not affect the...

Page 98

88 service manual - neotherm 500 on the right side of the controller (reading top to bottom): • disconnect connector cp6 from j6 • disconnect connector cp5 from j5 • disconnect connector cp4a from j4 (upper part) • disconnect connector cp4b from j4 (lower part) at the lower center of the controller:...

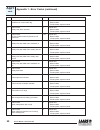

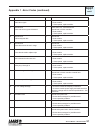

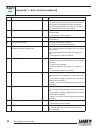

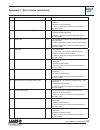

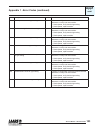

Page 99: App1

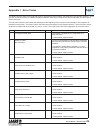

89 service manual - neotherm 500 app1 appendix 1 - error codes this table includes a listing of the faults that might be generated by the controllers, and displayed on the operator interface. Some of these can be corrected by an installer changing a parameter, while other conditions are more complic...

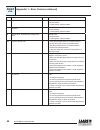

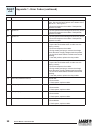

Page 100: App1

90 service manual - neotherm 500 appendix 1 - error codes (continued) app1 cont. Code description l or h procedure 11 internal fault: invalid burner control state flag l internal fault 1. Reset module 2. If fault repeats, replace module. 12 internal fault: safety relay drive cap short h internal fau...

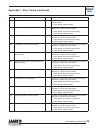

Page 101: App1

91 service manual - neotherm 500 appendix 1 - error codes (continued) code description l or h procedure 26 internal fault: static flame ripple h internal fault 1. Reset module 2. If fault repeats, replace module. 27 internal fault: flame rod short to ground detected h check flame rod - see section b...

Page 102: App1

92 service manual - neotherm 500 appendix 1 - error codes (continued) code description l or h procedure 53 ac input phases reversed l 1. Check the module and display connections. 2. Check the module power supply and make sure that both frequency and voltage meet the specifications. 3. On 24 vac appl...

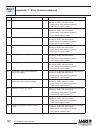

Page 103: App1

93 service manual - neotherm 500 appendix 1 - error codes (continued) code description l or h procedure 79 outlet high limit h or l 1. Check wiring and correct any possible errors. See section b7. 2. Replace the outlet high limit. 3. If previous steps are correct and fault persists, re - place the m...

Page 104: App1

94 service manual - neotherm 500 appendix 1 - error codes (continued) code description l or h procedure 97 internal fault: a2d mismatch. L internal fault. 1. Reset module. 2. If fault repeats, replace module. 98 internal fault: exceeded vsnsr voltage tolerance l internal fault. 1. Reset module. 2. I...

Page 105: App1

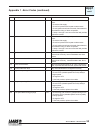

95 service manual - neotherm 500 appendix 1 - error codes (continued) code description l or h procedure 108 flame lost in run l 1. Check main valve wiring and operation - correct any errors. 2. Check the fuel supply. 3. Check fuel pressure and repeat turndown tests. 4. Check ignition transformer ele...

Page 106: App1

96 service manual - neotherm 500 appendix 1 - error codes (continued) code description l or h procedure 129 fan speed failed during preignition h or l 1. Check wiring and correct any potential wiring errors. See section b22. 2. Check the vfd’s (variable-speed fan drive) ability to change speeds. 3. ...

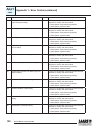

Page 107: App1

97 service manual - neotherm 500 appendix 1 - error codes (continued) code description l or h procedure 153 combustion pressure off h or l 1. Check wiring and correct any errors. 2. Inspect the combustion pressure switch to make sure it is working correctly. 3. Reset and sequence the relay module. 4...

Page 108: App1

98 service manual - neotherm 500 code description l or h procedure 159 main valve off l 1. Check the main valve terminal wiring and correct any errors. Be sure the on/off switch on the bottom of the valve is on. See fig. B11-7. 2. Reset and sequence the module. If fault persists, replace the module....

Page 109: App1

99 service manual - neotherm 500 code description l or h procedure 178 safety relay on at safe start check l internal fault. 1. Reset module. 2. If fault repeats, replace module. 184 invalid blower/ hsi output setting l 1. Return to configuration mode and recheck selected parameters, reverify and re...

Page 110: App1

100 service manual - neotherm 500 appendix 1 - error codes (continued) code description l or h procedure 196 invalid ignition source setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault rep...

Page 111: App1

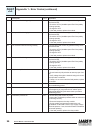

101 service manual - neotherm 500 appendix 1 - error codes (continued) code description l or h procedure 210 invalid postpurge time setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repe...

Page 112: App1

102 service manual - neotherm 500 appendix 1 - error codes (continued) code description l or h procedure 221 unconfigured dhw (domestic hot water) high limit setpoint setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify ele...

Page 113: App1

103 service manual - neotherm 500 appendix 1 - error codes (continued) code description l or h procedure 232 invalid pressure sensor type setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If faul...

Page 114: App2

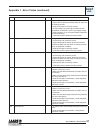

104 service manual - neotherm 500 appendix 2 - ignition and firing sequence app2 this is the basic operating sequence of the appliance whether there is a dhw, or hydronic call for heat. 1. The unit receives a call for heat. 2. The controller does a check of the safety chain. 3. The blower starts and...

Page 115: App3

105 service manual - neotherm 500 appendix 3 - wiring diagram app3.

Page 116

106 service manual - neotherm 500

Page 118

Customer service and product support: 800.900.9276 • fax 800.559.1583 headquarters: 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com litho in u.S.A. © laars heating systems ...