- DL manuals

- Laars

- Boiler

- NTH1000

- Installation And Operation Instructions Manual

Laars NTH1000 Installation And Operation Instructions Manual

Installation and Operation Instructions

Document 1255B

H2352900B

WARNING

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed

by a qualified installer, service agency, or gas

supplier.

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler and heater installation and maintenance. Improper installation and/or operation

could create carbon monoxide gas in flue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty.

AVERTISSEMENT

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion ou

pour éviter tout dommage matériel, toute blessure

ou la mort.

Ne pas entreposer ni utiliser d’essence ni d’autres

vapeurs ou liquides inflammables dans le

voisinage de cet appareil ou de tout autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions du

fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualifié ou

par le fournisseur de gaz.

Installation and

Operation Instructions for

N

EO

T

HERM

®

LC

Modulating Boiler Water Heater

Model NTH1000

Model NTV1000

1,000 MBTU/h

1,000 MBTU/h

Model NTH1700

Model NTV1700

1,700 MBTU/h

1,700 MBTU/h

Summary of NTH1000

Page 1

Installation and operation instructions document 1255b h2352900b warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in the vicin...

Page 2

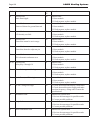

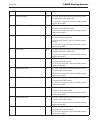

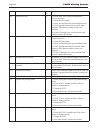

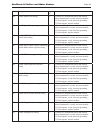

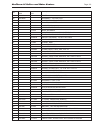

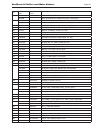

Neotherm lc boilers and water heaters section 1 general information ....................................... 1 1.1 introduction ............................................... 1 1.2 about the touch screen ........................... 1 1.3 safety notes ............................................. 3 1...

Page 3

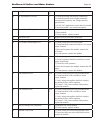

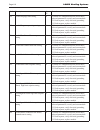

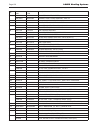

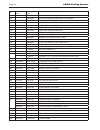

Laars heating systems section 9 – setup and configuration ............................ 44 9.1 reviewoflead/lagcontrolsystem ...... 44 9.1.1 aboutlead/lagoperation ..................... 44 9.1.2 lead/lagmodulationcycle .................... 45 9.1.3 nthlead/lagwithindirect domestichotwater ..............

Page 4

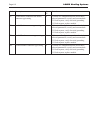

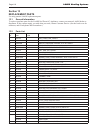

Laars heating systems.

Page 5

Neotherm lc boilers and water heaters page 1 section 1 general information 1.1 introduction this manual includes information which will help you to install, operate, and maintain the neotherm lc 1000 and 1700 systems. Please read this manual completely before proceeding with the installation. If you...

Page 6

Laars heating systems page 2 • each controller and burner work together. Each boiler includes two of these controller/burner combinations. Notice the different terms we are using here. The term boiler refers to the whole appliance – the complete neotherm lc 1000 or 1700. Each boiler includes two sep...

Page 7

Neotherm lc boilers and water heaters page 3 manual includes two longer sections that will help you to work with the control system: • section 8 – “using the touch screen and the gauges.” this section will explain how to “navigate” through the touch screen : how to enter and change values, and so on...

Page 8

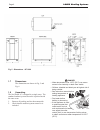

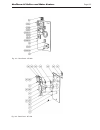

Laars heating systems page 4 1.6 appliance overview pressure and temperature gauge blower 1 (under bezel) automatic gas valves manual gas valve blower 2 touchscreen protective cover (slides downward) power switch ducted air inlet electrical box prv and flow switch outlet temperature sensors inlet te...

Page 9

Neotherm boilers and water heaters page 5 model 1700 pressure and temperature gauge blower 1 (behind bezel) automatic gas valves manual gas valve (on back) blower 2 touchscreen protective cover (slides downward) power switch ducted air inlet electrical box prv and flow switch outlet temperature sens...

Page 10

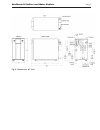

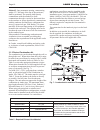

Laars heating systems page 6 fig. 5 - dimensions - nt 1000 1.7 dimensions the dimensions are shown in fig. 5 and fig. 6. 1.8 unpacking the neotherm lc is shipped in a single crate. The standard outdoor/system sensor kit is packed inside the same crate. 1. Remove all packing and tie-down materials. 2...

Page 11

Neotherm lc boilers and water heaters page 7 fig. 6 - dimensions - nt 1700

Page 12

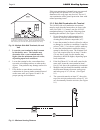

Laars heating systems page 8 section 2 locating the appliance 2.1 locating the appliance the neotherm lc may be installed indoors or outdoors. The unit may only be installed outdoors in a location which will never experience freezing temperatures. Choose a location for the unit which allows clearanc...

Page 13

Neotherm lc boilers and water heaters page 9 shall be of the same cross-sectional area as the free area of the openings to which they connect. Method 1: two permanent openings, one commencing within 12” (300 mm) of the top and one commencing within 12” (300 mm) of the bottom, of the enclosure shall ...

Page 14

Laars heating systems page 10 method 2: one permanent opening, commencing within 12” (300 mm) of the top of the enclosure, shall be permitted. The opening shall directly communicate with the outdoors or shall communicate through a vertical or horizontal duct to the outdoors or spaces that directly c...

Page 15

Neotherm lc boilers and water heaters page 11 3.2 venting warning selection of improper vent materials for installations that are installed in closets, or will be operated in high ambient temperature levels, may lead to property damage, personal injury, or death. Warning a 12” or 305 mm section (for...

Page 16

Laars heating systems page 12 it is the responsibility of the appropriately licensed technician installing this neotherm lc to use ulc s636 certified vent material consistent with the requirements as described in the venting and combustion air section. Class i venting systems are suitable for gas-fi...

Page 17

Neotherm lc boilers and water heaters page 13 *when vent terminal is less than 10 feet (3 m) horizontally from a forced air inlet, the terminal must be at least 3 feet (0.9 m) above the air inlet. (us only) fig. 9 - combustion air and vent through side wall u.S. Installations (see note 1) canadian i...

Page 18

Laars heating systems page 14 5. Locate the vent terminal so that it cannot be blocked by snow. The installer may determine that a vent terminal must be higher than the minimum shown in codes, depending upon local conditions. 6. Locate the terminal so the vent exhaust does not settle on building sur...

Page 19

Neotherm lc boilers and water heaters page 15 3.3.3 vertical vent terminal when the unit is vented through the roof, the vent must extend at least 3 feet (0.9 m) above the point at which it penetrates the roof. It must extend at least 2 feet (0.6 m) higher than any portion of a building within a hor...

Page 20

Laars heating systems page 16 3. As much as possible, close all building doors and windows. Also close all doors between the space in which the appliances remaining connected to the common venting system are located and other spaces of the building. Turn on any clothes dryers or other appliances not...

Page 21

Neotherm lc boilers and water heaters page 17 section 4 gas supply and piping 4.1 gas supply and piping gas piping should be supported by suitable hangers or floor stands, not the appliance. Installers should refer to local building and safety codes or, in the absence of such requirements, follow th...

Page 22

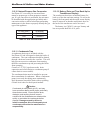

Laars heating systems page 18 sched 40 metal pipe capacity for 1.50 specific gravity undiluted propane nominal pipe size @ 11” w.C. Inlet and 0.5” w.C. Pressure drop size 1/2” 3/4” 1” 1-1/4” 1-1/2” 2” length maximum capacity in thousands of btu per hour 20 200 418 787 1616 2422 4664 40 137 287 541 1...

Page 23

Neotherm lc boilers and water heaters page 19 section 5 pump requirements 5.1 neotherm lc boiler flow and head requirements 5.2 neotherm lc water heater flow and head requirements table 7 - water flow requirements table 8 - neotherm lc water heater flow data temperature rise in °f model 20°f 25°f 30...

Page 24

Laars heating systems page 20 suggested piping diagrams are shown in figures 12 through 16. These diagrams are meant only as guides. Components required by local codes must be properly installed. The neotherm lc’s efficiency is higher with lower return water temperatures. Therefore, to get the best ...

Page 25

Neotherm lc boilers and water heaters page 21 6a.3 nth freeze protection warning glycol must not be used in domestic hot water applications. Refer to section 6b.4 for instructions on freeze protection for ntv units (domestic hot water). Neotherm lc’s may be installed indoors or outdoors. If installe...

Page 26

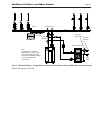

Laars heating systems page 22 fig. 12 - hydronic piping — single boiler, multiple temperature zones zoning with circulators water feed controls air vent 4 pipe dia. Max. 4 pipe dia. Max. 4 pipe dia. Max. 4 pipe dia. Max. Low temp. Radiant zone space heating zone circuits space heating zone circuit s...

Page 27

Neotherm lc boilers and water heaters page 23 fig. 13 - hydronic piping — single boiler, zoning with circulators, indirect dhw tank with zone pumps indirect tank directly off of boiler air vent 4 pipe dia. Max. Expansion tank water feed controls 4 pipe dia. Max. Indirect dhw tank anti-scald mixing v...

Page 28

Laars heating systems page 24 fig. 14 - hydronic piping — single boiler with low temperature zones and indirect dhw tank indirect tank directly off of boiler low temp. Radiant zone low temp. Radiant zone air vent water feed controls expansion tank 4 pipe dia. Max. Indirect dhw tank anti-scald mixing...

Page 29

Neotherm lc boilers and water heaters page 25 fig. 15 - hydronic piping — multiple boilers, multiple temperature zones, reverse return zoning with circulators space heating zone circuits low temp. Radiant zone space heating zone circuit air vent water feed controls expansion tank common piping must ...

Page 30

Laars heating systems page 26 fig. 16 - hydronic piping — multiple boilers, indirect dhw off of one boiler space heating zone circuits space heating zone circuit air vent water feed controls expansion tank common piping must be sized for the combined water flow of all the boilers. High temp. Space h...

Page 31

Neotherm lc boilers and water heaters page 27 6b.2 ntv piping requirements the water piping should be supported by suitable hangers and floor stands. Do not support the piping with this appliance. The hangers used should allow for expansion and contraction of copper pipe. Rigid hangers may transmit ...

Page 32

Laars heating systems page 28 6b.3 ntv cold water make-up the cold water make-up may be connected to the tank or to the inlet of the boiler as shown in figures 17-19. Install back-flow preventers and shut-offs where needed or required by code. 6b.4 ntv freeze protection the ntv unit must never be in...

Page 33

Neotherm lc boilers and water heaters page 29 fig. 19 - dhw piping - two heaters, two vertical tanks notes: 1. Optional cwmu & recirculation line location. 2. Locate the ntv dhw sensor or remote aquastat well in lower 1/3 of tank. 3. Back flow preventer may be required - check local codes. 4. Therma...

Page 34

Laars heating systems page 30 section 7 electrical connections warning the neotherm lc appliance must be electrically grounded in accordance with the requirements of the authority having jurisdiction or, in the absence of such requirements, with the latest edition of the national electrical code, an...

Page 35

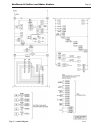

Neotherm lc boilers and water heaters page 31 fig. 20 - electronics panel layout tb5 tb2 tb1 primary controller (upper burner) secondary controller (lower burner) tb7 tb6 tb4 tb3 tb10 tb9.

Page 36

Laars heating systems page 32 the system pump connections are located on terminal block 5 (5-6 on tb5) in the control panel. (see figure 20.) the system pump contacts are rated for 120 vac, 7.4 amps. To use the contacts, power must be supplied on one terminal with the other terminal wired to the rel...

Page 37

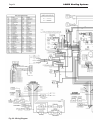

Neotherm lc boilers and water heaters page 33 fig. 21 - ladder diagram.

Page 38

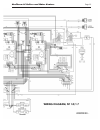

Laars heating systems page 34 fig. 22 - wiring diagram.

Page 39

Neotherm lc boilers and water heaters page 35.

Page 40

Laars heating systems page 36 section 8 using the touch screen and gauges 8.1 the touch screen and gauges there are only a few gauges on the front of the neotherm lc. See fig. 23. Other than the on/off switch, all of the control functions are done using the touch screen. 8.2 using the touch screen t...

Page 41

Neotherm lc boilers and water heaters page 37 login 1 2 3 4 5 6 7 8 9 0 - = q w e r t y i o p [ ] u a s d f g h j k l : * z x c v b n m , . / shift backspace ok clear cancel fig. 26 - keyboard screen the passwords used by this system are “case sensitive” – it matters whether a letter in the password...

Page 42

Laars heating systems page 38 at the bottom of the screen shown in fig. 28, the system is telling you that it wants you to log in. Fig. 28 - login required the screen used to login is similar to the keyboard screen shown in fig. 26. 8.3 while operating - checking lead/lag operating information the l...

Page 43

Neotherm lc boilers and water heaters page 39 2. You can change the setpoints from this screen. When you press the yellow box beside setpoint, the controller presents this screen: fig. 32 - setpoints screen select the setpoint you want to change, then enter the new value 3. If you press the details ...

Page 44

Laars heating systems page 40 8.6 checking individual details the details button on the status summary screen leads to a series of screens that show all of the setup parameters entered for the controller you have selected. Let’s say that the first screen presented in this series is the screen for fr...

Page 45

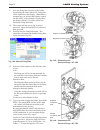

Neotherm lc boilers and water heaters page 41 3. Press the configure button to start a configuration session for the selected controller. See fig. 39. Fig.39-configurationscreen this screen lists all of the configuration groups. (the list is actually longer – scroll down using the bar on the right s...

Page 46

Laars heating systems page 42 fig.43-verificationneeded notes – • once you change one of these safety-related parameters, you must finish the verification process for the group that includes the parameter, or the control system will not let the boiler operate. You can wait to do the verification unt...

Page 47

Neotherm lc boilers and water heaters page 43 fig. 47 - safety parameter reset 7. The reset button is located on the front of the controller. See fig. 44. You must press the reset button within 30 seconds, or the verification will be cancelled..

Page 48

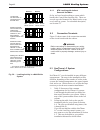

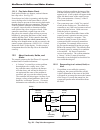

Laars heating systems page 44 section 9 setup and configuration 9.1 review of lead/lag control system 9.1.1 about lead/lag operation the boilers in this series are always set up for lead/ lag operation. In a single-boiler installation, there are two controllers and two burners, as shown in fig. 49. ...

Page 49

Neotherm lc boilers and water heaters page 45 in either kind of installation, a system sensor is usually used to monitor the demand. The input from this sensor is used to control the modulation rates of the operating burners. Boiler burner position control master/slave assignment modbus control addr...

Page 50

Laars heating systems page 46 fig. 50 – lead/lag activity in a multi-boiler system low demand - the first burner* in sequence fires at less than 65% first burner* second burner* third burner* fourth burner* boiler x boiler y demand increases - once the first burner reaches 50%, the second burner* sw...

Page 51

Neotherm lc boilers and water heaters page 47 fig. 51 – connection terminals.

Page 52

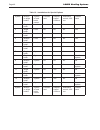

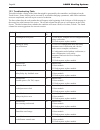

Laars heating systems page 48 system multiple or single boilers system or local boiler control common vent setpoint control 4-20 ma modulation control, 4-20 ma outdoor reset 1 single boiler local no no no no 2 single boiler local no no no yes 3 multiple boiler local no no no no 4 multiple boiler loc...

Page 53

Neotherm lc boilers and water heaters page 49 15 single boiler system no no yes no 16 single boiler system no no yes yes, from system 17 multiple boiler system no no yes no 18 multiple boiler system no no yes yes, from system 19 multiple boiler system yes yes no no 20 multiple boiler system yes yes ...

Page 54

Laars heating systems page 50 system 4 – multiple boilers, local control, outdoor reset job b set up the names for each of the controllers job c make one control the lead/lag master job d on each of the controllers that will act as a slave, disable the lead/lag master job e set up the modbus control...

Page 55

Neotherm lc boilers and water heaters page 51 system 7 – single boiler, system control job i set the parameters used by the lead/lag system job l building automation or multiple boiler control thermostat demand job o set up the combustion on each of the burners job p set the date and time on the sys...

Page 56

Laars heating systems page 52 system 11 – single boiler, system control, 4-20 ma setpoint control job i set the parameters used by the lead/lag system job m building automation or multiple boiler control 4-20 ma setpoint control job o set up the combustion on each of the burners job p set the date a...

Page 57

Neotherm lc boilers and water heaters page 53 system 15 – single boiler, system control, 4-20 ma modulation control job n building automation or multiple boiler control 4-20 ma modulation control job o set up the combustion on each of the burners job p set the date and time on the system system 16 –...

Page 58

Laars heating systems page 54 system 20 – multiple boiler, system control, common vent, 4-20 ma setpoint control, outdoor reset job a note on common venting job b set up the names for each of the controllers job c make one control the lead/lag master job d on each of the controllers that will act as...

Page 59

Neotherm lc boilers and water heaters page 55 9.4 installation jobs note – to install your system, you will not need to do all of the installation jobs listed here. Please refer to section 9.3 for a list of specific installation jobs necessary to install your system. Job a – note for systems using c...

Page 60

Laars heating systems page 56 present the keyboard screen. Use the “bs” (backspace) key to erase the existing name. Enter the new name, then press ok. 6. Now you can rename the other control on boiler 1 – the secondary control. Press the home button in the top left-hand corner to go back to the ‘hom...

Page 61

Neotherm lc boilers and water heaters page 57 job d - disable the lead/lag master function on the lead/lag slaves (this is an individual function – do this for each of the controls, except the one used as the lead/lag master. Use the separate touch screen on each boiler.) at the beginning of this se...

Page 62

Laars heating systems page 58 job e – set up the modbus control addressing (this is an individual function – do this for each of the controls use the separate touch screen on each boiler.) do this on any system with multiple boilers. Note – do not connect the modbus wiring yet. The controls must be ...

Page 63

Neotherm lc boilers and water heaters page 59 primary control on boiler 1 is “1.” if this is not already set to “1”, enter the correct number, then press ok. Warning if the addresses are not assigned properly, the system could fail to operate correctly, or it might operate in an unsafe manner. This ...

Page 64

Laars heating systems page 60 warning if the flap valve identifications are not configured correctly, this could cause the equipment to malfunction. This could lead to personal injury or death, and could damage the equipment. If the configuration is not correct, the control system will present an er...

Page 65

Neotherm lc boilers and water heaters page 61 table 14 – number of controls number of boilers number of controls 2 4 3 6 4 8 for example, if your system has three boilers, there would be a total of six controllers (two for each boiler), so you would enter “6” for number of controls. 5. Press the lin...

Page 66

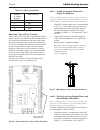

Laars heating systems page 62 fig. 74 – reset button on controller the control system allows 30 seconds to press the reset button. Do not press the reset button yet! You will need to do this in a moment. At this point, we just want to alert you to something: in order to be able to reach the controll...

Page 67

Neotherm lc boilers and water heaters page 63 job g – disconnect unused touch screens once a lead/lag system is set up and operating, the monitoring functions will all be handled from one touch screen – the one connected to the controller operating as the lead/lag master. If the extra displays remai...

Page 68

Laars heating systems page 64 boiler 1 (lead/lag master) boiler 2 secondary primary tb9, pin 7 connect to tb9, pin 1 tb9, pin 8 connect to tb9, pin 2 tb9, pin 9 connect to tb9, pin 3 tb9, pin 10 connect to tb9, pin 4 tb9, pin 11 connect to tb9, pin 5 tb9, pin 12 connect to tb9, pin 6 3. Repeat the p...

Page 69

Neotherm lc boilers and water heaters page 65 dhw time of day setpoint - separate time-of-day setpoint for domestic hot water (see the material on “about the ‘time of day’ function at the end of this section) modbus port - always use mb1 4. To see the other settings related to the lead/ lag function...

Page 70

Laars heating systems page 66 20 ma water temperature - if a 4 – 20 ma input is used to adjust the setpoint, this entry sets the high limit of the control range. (in the example shown here, an input of 20 ma would result in a setpoint of 120°f.) 7. Press the left-arrow or right-arrow until you see t...

Page 71

Neotherm lc boilers and water heaters page 67 low water temp. - if the outdoor temperature reaches the max. Outdoor temp. Or higher, the system will use the low water temp value as the new setpoint. In the example shown in fig. 86, the max. Outdoor temp. Is set to 70°f. If the outdoor temperature re...

Page 72

Laars heating systems page 68 about the “time of day” function if the “time of day” function is enabled, the control system can be set to maintain different temperatures for central heat and domestic hot water (other than the normal setpoints) in the system at certain times of the day. Normally this...

Page 73

Neotherm lc boilers and water heaters page 69 2. Set the outdoor reset and warm weather shutdown parameters as desired. How to get there – outdoor reset screen and warm weather shutdown screen home page lead/ lag screen lead/ lag screen lead/ lag master configuration screen select the outdoor reset ...

Page 74

Laars heating systems page 70 when outdoor reset is enabled, and the outdoor temperature falls between the maximum and minimum outdoor temperatures (70° and 32° in the example above), the setpoint will be adjusted down by about 1° for every 2° increase in the outdoor temperature. For example, if the...

Page 75

Neotherm lc boilers and water heaters page 71 fig.95–leadlagcentralheatconfiguration 3. Change the 4 ma water temperature to match the lowest water temperature setting on the building automation system or multiple boiler control. 4. Change the 20ma water temperature to match the highest water temper...

Page 76

Laars heating systems page 72 warning improper adjustment may lead to poor combustion quality, increasing the amount of carbon monoxide produced. Excess carbon monoxide levels may lead to personal injury or death. Primary burner primary controller gas valve gas valve secondary controller secondary b...

Page 77

Neotherm lc boilers and water heaters page 73 required tools: screwdrivers, torx bits, combustion analyzer in the rest of this section we will explain the setup procedure in more detail. 1. On the gas valve for the primary burner on the boiler, locate the adjustments for the high fire co 2 and low f...

Page 78

Laars heating systems page 74 9. You can change the fan speed of the burner by adjusting the value entered for firing rate on the right side of the display. (remember, a moment ago you selected the primary control for this boiler, so this change will only affect the primary burner.) press the yellow...

Page 79

Neotherm lc boilers and water heaters page 75 turn the high fire adjustment screw counter- clockwise. To lower the high fire co 2 level, turn the screw clockwise. (make the adjustment in small steps of 1/8 turn to avoid “overshooting” the correct setting. The valve is built with a bit of “backlash.”...

Page 80

Laars heating systems page 76 • turn off the call for heat, and set both burners to run at 1200 rpm for low fire. Turn on the call for heat, and check the performance again. 20. If the co 2 doesn’t track between the correct limits, there is a possibility that one of the burners has not been set up c...

Page 81

Neotherm lc boilers and water heaters page 77 4. Select date and time. Figure 107 shows the setup screen. Fig. 110 – date and time 9.5 setup for domestic hot water on a lead/lag system there are three ways that a neotherm lc system can be set up to provide domestic hot water. Two of them involve the...

Page 82

Laars heating systems page 78 fig.113–lead/lagmasterconfiguration entries on this screen allow you to set the ch setpoint and dhw setpoint. 4. Press the button for advanced settings. This leads to a “ring” of related screens, and you can scroll through the list by pressing one of the left- or right-...

Page 83

Neotherm lc boilers and water heaters page 79 4. Select that line by pressing it. If you want to change the dhw priority, the system will ask you to log in using the installer-level password. For this kind of installation, the entry should be “dhw> ch.” 5. Go to the line for “dhw priority vs lead la...

Page 84

Laars heating systems page 80 9.6 gateway connections to a building automation system neotherm lc boilers can be controlled and monitored through the included modbus ports. The modbus wiring should be completed according to the instructions in this manual. If alternate communication protocols are de...

Page 85

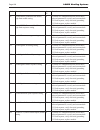

Neotherm lc boilers and water heaters page 81 9.8 installer parameters this is a list of all of the parameters which can be accessed using the installer password. Label description how to reach 4 ma water temperature if a 4 – 20 ma input is used to adjust the setpoint, this entry sets the low limit ...

Page 86

Laars heating systems page 82 label description how to reach ch (central heat) has priority over ll (lead/ lag) this controls whether a local central heat demand has priority over the control asserted by the ll master, when this controller is enabled as a slave. If lead/lag enabled – lead/lag master...

Page 87

Neotherm lc boilers and water heaters page 83 label description how to reach ch (central heat) setpoint this setpoint is used when the time-of-day input is off. If the outdoor reset function is active, this setpoint provides one coordinate for the outdoor reset curve. See the section for the ch outd...

Page 88

Laars heating systems page 84 label description how to reach dhw (domestic hot water) pump control the dhw pump (pump c) can be turned on manually, or it can be set to operate automatically. If it is turned on then it remains on until changed back to auto. In auto mode it operates according to the d...

Page 89

Neotherm lc boilers and water heaters page 85 label description how to reach lead lag d gain this is part of the damping function (“derivative”) used when the controller interprets the input from the system sensor. Lead/lag master button configure button screen> advanced settings button/ left- or ri...

Page 90

Laars heating systems page 86 label description how to reach lead lag on hysteresis when the lead/lag function is enabled, the control system will not fire the boilers until the temperature at the system sensor drops to the lead/lag ch setpoint minus a hysteresis value (normally about 10°f). If lead...

Page 91

Neotherm lc boilers and water heaters page 87 label description how to reach modbus address each controller must have a unique modbus address. Setup button screen> control setup button/ change address button number of controllers in flap valve system each controller needs to know how many flap valve...

Page 92

Laars heating systems page 88 11. Shut down the entire system and vent all radiation units and high points in the system piping, as described in step 4. 12. Close the make-up water valve. Check the strainer in the pressure reducing valve for sediment or debris from the make-up water line. Reopen the...

Page 93

Neotherm lc boilers and water heaters page 89 caution if any odor of gas is detected, or if the gas burner does not appear to be functioning in a normal manner, close the main gas shutoff valve. Do not shut off the power switch. Contact your heating contractor, gas company, or factory representative...

Page 94

Laars heating systems page 90 section 11 maintenance warning disconnect all power to the unit before attempting any service procedures. Contact with electricity can result in severe injury or death. 11.1 system maintenance do the following once a year: 1. Lubricate the system pump, if required, per ...

Page 95

Neotherm lc boilers and water heaters page 91 power supply to the boiler. Turn off all manual gas valves connecting the boiler to the main gas supply line. Remove the front door of the boiler to gain access to the gas valve and venturi. Disconnect the four flange bolts connecting the gas manifold pi...

Page 96

Laars heating systems page 92 11.2.7 blower the combustion air blower is a high-pressure centrifugal blower with a variable speed motor. The speed of the motor is determined by the control logic. 120 volts are supplied to the blower at all times. If it is necessary to replace the blower, turn off th...

Page 97

Neotherm lc boilers and water heaters page 93 11.2.10 natural/propane gas conversion neotherm lc’s can easily be converted from natural to propane gas or from propane to natural gas. If a gas conversion is performed, the unit must be identified with the appropriate gas labels and a conversion sticke...

Page 98

Laars heating systems page 94 section 12 troubleshooting 12.1 potential setup and synchronization problems because the neotherm lc uses a sophisticated control system, it can constantly perform a series of self-checks. For example, as a burner is lighted, the controller checks each stage of the purg...

Page 99

Neotherm lc boilers and water heaters page 95 12.1.2 flap valve status check each boiler includes two burners, and each burner has a flap valve. See fig. 123. If one burner in a boiler is operating, and the other is not, the flap valve for the burner that is off will remain closed to prevent air fro...

Page 100

Laars heating systems page 96 correct the cause of the problem, and press the button on the screen to clear the hold. 2. If a serious problem continues, the system will declare a lockout. A brief explanation of the cause of the lockout will appear in an orange bar across the bottom of the screen. If...

Page 101

Neotherm lc boilers and water heaters page 97 fig. 128 – alert log screen to get more information on a particular alert, touch the entry for that alert on the screen..

Page 102

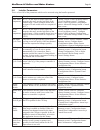

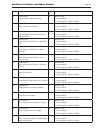

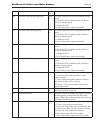

Laars heating systems page 98 12.3 troubleshooting table this table includes a listing of the faults that might be generated by the controllers, and displayed on the touch screen. Some of these can be corrected by an installer changing a parameter, while other conditions are more complicated, and wi...

Page 103

Neotherm lc boilers and water heaters page 99 code description l or h procedure 11 internal fault: invalid burner control state flag l internal fault 1. Reset module 2. If fault repeats, replace module. 12 internal fault: safety relay drive cap short h internal fault 1. Reset module 2. If fault repe...

Page 104

Laars heating systems page 100 code description l or h procedure 26 internal fault: static flame ripple h internal fault 1. Reset module 2. If fault repeats, replace module. 27 internal fault: flame rod shorted to ground detected h internal fault 1. Reset module 2. If fault repeats, replace module. ...

Page 105

Neotherm lc boilers and water heaters page 101 code description l or h procedure 53 ac input phases reversed l 1. Check the module and display connections. 2. Check the module power supply and make sure that both frequency and voltage meet the specifications. 3. On 24 vac applications, assure that j...

Page 106

Laars heating systems page 102 code description l or h procedure 79 outlet high limit h or l 1. Check wiring and correct any possible errors. 2. Replace the outlet high limit. 3. If previous steps are correct and fault persists, replace the module. 80 dhw (domestic hot water) high limit h or l 1. Ch...

Page 107

Neotherm lc boilers and water heaters page 103 code description l or h procedure 97 internal fault: a2d mismatch. L internal fault. 1. Reset module. 2. If fault repeats, replace module. 98 internal fault: exceeded vsnsr voltage tolerance l internal fault. 1. Reset module. 2. If fault repeats, replac...

Page 108

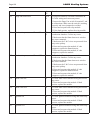

Laars heating systems page 104 code description l or h procedure 108 flame lost in run l 1. Check main valve wiring and operation - correct any errors. 2. Check the fuel supply. 3. Check fuel pressure and repeat turndown tests. 4. Check ignition transformer electrode, flame detector, flame detector ...

Page 109

Neotherm lc boilers and water heaters page 105 code description l or h procedure 129 fan speed failed during preignition h or l 1. Check wiring and correct any potential wiring errors. 2. Check the vfds (variable-speed fan drive) ability to change speeds. 3. Change the vfd 4. If the fault persists, ...

Page 110

Laars heating systems page 106 code description l or h procedure 155 purge fan switch off h or l 1. Purge fan switch is off when it should be on. 2. Check wiring and correct any errors. 3. Inspect the purge fan switch j6 terminal 3 and its connections. Make sure the switch is working correctly and i...

Page 111

Neotherm lc boilers and water heaters page 107 code description l or h procedure 164 block intake on l 1. Check wiring and correct any errors. 2. Inspect the block intake switch to make sure it is working correctly. 3. Reset and sequence the module. 4. During standby and purge, measure the voltage a...

Page 112

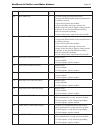

Laars heating systems page 108 code description l or h procedure 187 invalid dhw (domestic hot water) high limit enable setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace...

Page 113

Neotherm lc boilers and water heaters page 109 code description l or h procedure 200 invalid lightoff rate setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace module. 201 ...

Page 114

Laars heating systems page 110 code description l or h procedure 214 invalid prepurge time setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace module. 215 invalid purge ra...

Page 115

Neotherm lc boilers and water heaters page 111 code description l or h procedure 225 invalid flame threshold setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace module. 22...

Page 116

Laars heating systems page 112 code description l or h procedure 237 invalid dhw (domestic hot water) connector type setting l 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace mo...

Page 117

Neotherm lc boilers and water heaters page 113 12.4 diagnostic tests and input/ output indicators two kinds of screens are grouped together in this section: • detailed indications of the input and output signals • diagnostic tests of the pumps and burner modulation note that these functions apply to...

Page 118

Laars heating systems page 114 12.5 lead/lag slave diagnostics the control system includes a diagnostic screen that lists some information on the lead/lag slaves in the system. See fig. 134. How to get there – home page lead lag screen lead lag screen lead lag slave status screen fig. 134 - lead/lag...

Page 119

Neotherm lc boilers and water heaters page 115 12.8 control snapshot the software allows you to take a “snapshot” of the current state of the controller, including setup information and operating information. This information can be helpful during troubleshooting. How to get there – home page setup ...

Page 120

Laars heating systems page 116 burner ignition sequence here is the start-up sequence following a lead lag (ll) central heating request: 1. The thermostat used for the ll central heat function calls for heat. On a system set up for lead/lag operation, this will be the system sensor. (the setpoint or...

Page 121

Neotherm lc boilers and water heaters page 117 during the initiate period: • all of the checks made under synchronization, plus: • locks out if a/c line power errors occur. • locks out if four-minute initiate period has been exceeded. During the standby period: • all of the checks made under synchro...

Page 122

Laars heating systems page 118 section 13 replacement parts use only genuine laars replacement parts. 13.1 general information to order or purchase parts for the laars neotherm lc appliance, contact your nearest laars dealer or distributor. If they cannot supply you with what you need, contact custo...

Page 123

Neotherm lc boilers and water heaters page 119 key no. Part no. - 1000 part no. - 1700 description 35 10j3019 cover 36 s2116600 grommet, 1 1/2” pipe, flex 37 10j3031 plate, retainer, gasket, hx 38 10j3030 gasket, hx outlet 39 17j1205 support, hx 40 17j1231 cross brace, front 41 17j1010 base, weldmen...

Page 124

Laars heating systems page 120 key no. Part no. - 1000 part no. - 1700 description 82 r2073812 r2073812 gasket, d-shape, rubber, r2073903 r2073903 gasket, strip, foam, adhesive, 3/8 x 1/8 83 10j1231 17j1231 cross brace, front hx, base 84 r10j1221 r17j1221 panel, side, assy with gaske ts 85 r2074405 ...

Page 125

Neotherm lc boilers and water heaters page 121 key no. Part no. - 1000 part no. - 1700 description 118 10j4050 pipe, water inlet assy(nth) 10j4080 pipe, water inlet, stainless steel, assy (ntv) 119 70-236 70-236 pipe plug, malleable iron, black, 1/8 npt (nth) p2042300 p2042300 pipe plug, stainless s...

Page 126

Laars heating systems page 122 key no. Part no. - 1000 part no. - 1700 description 162 p0012300 nipple close 1/4 npt (csd-1) 164 v2018600 adapter, 4mm hose barb x m5-.8 w/ washer 165 p2032400 bushing, reducer, 1/4x1/8 npt black iron 166 rp2050100 flange kit, gas valve 168 s0064900 bushing nylon 7/8”...

Page 127

Neotherm lc boilers and water heaters page 123 key no. Part no. - 1000 part no. - 1700 description 207 r10j7008 r10j7008 panel assy, control, sliding (with decals) 10j7019 10j7019 label, high voltage connections, tb1, tb2 & tb5 10j7021 10j7021 label, low voltage connections, tb3, tb4 10j7025 10j7025...

Page 128

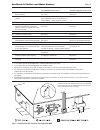

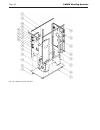

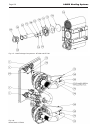

Laars heating systems page 124 fig. 140 - machine frame - nt1000 13.3 parts illustrations.

Page 129

Neotherm lc boilers and water heaters page 125 fig. 141 - rear panel - nt1000 fig. 142 - rear panel - nt1700

Page 130

Laars heating systems page 126 fig. 143 - machine frame - nt1700

Page 131

Neotherm lc boilers and water heaters page 127 fig. 144 - front panels and covers - nt1000 and nt1700

Page 132

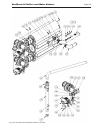

Laars heating systems page 128 fig. 145 - burners and combustion chamber - nt1000

Page 133

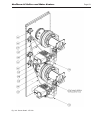

Neotherm lc boilers and water heaters page 129 fig. 146 - burners and combustion chamber - nt1700

Page 134

Laars heating systems page 130 fig. 147 - heat exchanger components - nt1000 and nt1700 fig. 148 - burner detail - nt1000

Page 135

Neotherm lc boilers and water heaters page 131 fig. 149 - burner detail - nt1700

Page 136

Laars heating systems page 132 fig. 150 - electronic components fig. 151 - condensate trap - nt1000

Page 137

Neotherm lc boilers and water heaters page 133 fig. 152 - condensate trap - nt1700 fig. 153 - flow switch - nt1000 and nt1700

Page 138

Laars heating systems page 134 this page intentionally left blank..

Page 139

Neotherm lc boilers and water heaters page 135 this page intentionally left blank..

Page 140

H2352900b 800.900.9276 • fax 800.559.1583 (customer service and product support) 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com printed in u.S.A. © laars heating systems 1...