Installation and operation instructions document 3164d h2311900d installation and operation instructions for pennant ™ pool heater model pncp u.S. Reg. 2,765,423 warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury...

Laars heating systems page 2 section 1. General information 1.1 introduction ..................................................... 3 1.2 model identification ......................................... 3 1.3 warranty ......................................................... 4 1.4 dimensions .............

Pennant pool heater page 3 section 1. General information in the commonwealth of massachusetts, this appliance must be installed by a licensed plumber or gas fitter. Warning the pennant pool heater must be installed in accordance with the procedures detailed in this manual, or the laars heating syst...

Laars heating systems page 4 13 revision 2 = second version 14 heat exchanger b = glass-lined ci / copper / brz trim (std. Pncp) k = bronze / copper p = glass-lined cast iron / cu-nickel / brz trim s = bronze / cu-nickel 15 option code x = standard unit j = csd-1, fm, iri, il l = mn and lds (indoor ...

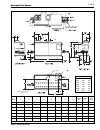

Pennant pool heater page 5 figure 1. Dimensional data. Air vent horiz. Conn. Conn. Vent size a b c d e f g h w* v* pipe 500 33½ 85 15¾ 40 5¾ 15 29¾ 76 32¾ 83 7¾ 20 8¾ 22 46 117 6 15 8 20 6 15 750 45½ 116 21¾ 55 5¾ 15 29¾ 76 32¾ 83 7¾ 20 8¾ 22 58 147 6 15 10 25 8 20 1000 57½ 146 28¾ 73 5¾ 15 29¾ 76 3...

Laars heating systems page 6 required recommended appliance clearance from service access surface combustible material clearance inches cm inches cm left side 1 2.5 24 61 right side 1 2.5 24 61 top 1 2.5 12 30 back 1 2.5 ** 12** 30** front 1 2.5 36 91 vertical (category 1) 6* 15.2* vent horizontal p...

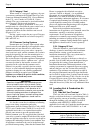

Pennant pool heater page 7 figure 2. Combustion air and vent through roof. Term description pipe single-wall galvanized steel pipe, 24 gauge minimum (either insulated or non-insulated) joint permanent duct tape or aluminum tape sealing table 4. Required combustion air piping material. (5.5 square cm...

Laars heating systems page 8 2.2.2 category i vent when vented as a category i appliance, the vent system must conform to the national fuel gas code (american national standard z223.1-latest edition) in the u.S., or in canada, to csa b149.1 (latest edition). The vent system must be sized and install...

Pennant pool heater page 9 figure 3. Combustion air and vent through side wall. *when vent terminal is less than 10 feet (3m) horizontally from a forced air inlet, the terminal must be at least 3 feet (0.9m) above the air inlet. Local applicable codes (see figure 3). Consider the following when inst...

Laars heating systems page 10 outdoor vent outdoor size terminal combustion air terminal 500 20254703 d2007900 750 20254705 d2007900 1000 20254705 d2008000 1250 d2007700 d2008000 1500 d2007700 d2008000 1750 d2007800 d2008000 2000 d2007800 d2008200 table 6. Vent terminals for outdoor units cannot be ...

Pennant pool heater page 11 distance from gas meter size and or last stage regulator gas type 0-100' 0-31m 100-200' 31-61m 200-300' 61-91m 500 natural 1-1/2" 3.8cm 2" 5.1cm 2" 5.1cm 500 propane 1" 2.5cm 1-1/2" 3.8cm 1-1/2" 3.8cm 750 natural 2" 5.1cm 2" 5.1cm 2-1/2" 6.4cm 750 propane 1-1/2" 3.8cm 1-1...

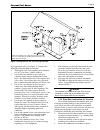

Laars heating systems page 12 temperature at or above 120°f (49°c) (see figure 5). This keeps cold return water from causing condensing on the outside of the pennant heat exchanger. Important note: since heater outlet temperatures can reach 150°f (66°c) in some cases, copper or cpvc are recommended ...

Pennant pool heater page 13 4.2 automatic chlorinators a concentration of chlorine in the heater can be very destructive; therefore the following rules about the installation and operation of such devices must be followed: 1. The chlorinator should be installed so it introduces the gas or solution d...

Laars heating systems page 14 spade (fork) terminal. From the other side of the main power switch connect to the main terminal block using a ¼" female insulated quick connect. This will be the same position where the jumper had terminated (see figure 7). Connect n2 and ground to the main terminal bl...

Pennant pool heater page 15 button. The setpoint will be displayed. Press the up arrow or down arrow buttons until the desired setpoint is displayed. Press the enter button and the setpoint will be activated. The display will return to indicating the present pool loop temperature. The boiler operati...

Laars heating systems page 16 section 6. Operating instructions 6.1 sequence of operation the amber “ready” light on the front panel indicates that the control system is energized. Upon a call for heat from the pool temperature control, the green “heat” indicator on the front panel will light. The g...

Pennant pool heater page 17 if a call for heat is prevented from being satisfied either by a safety interlock or due to an ignition lockout, the red “service” indicator on the front panel will light. To reset the standard ignition module, toggle the pennant power switch off, and then on again. (to r...

Laars heating systems page 18 heater minimum filter model pump flow rate pncp 500 240 gpm pncp 750 360 gpm table 9. Minimum filter pump flow rates for spas. Again and the burner will start. The appliance will return to its previous mode of operation. Note: models 1250, 1500, 1750 and 2000 have two i...

Pennant pool heater page 19 the service light will turn out, and the heater will resume normal operation. Please note that if the heater is equipped with a low water cut off there will be a brief delay while the lwco completes a self- check. 6.6 spring and fall operation stand-by service turn the th...

Laars heating systems page 20 section 7. Maintenance 7.1 system maintenance 1. Lubricate the system water-circulating pump, if required, per the instructions on the pump. 2. Inspect the venting system for obstruction or leakage at least once a year. Periodically clean the inlet air filter and the sc...

Pennant pool heater page 21 the appliance. Remove the cover from the switch to access the mounting screws. Remove the screws, and pull the switch off the control panel. Remove the capillary and bulb from the thermal well located in the header. Replace in reverse order. 7.2.6 temperature control the ...

Laars heating systems page 22 section 8. Trouble shooting 8.1 resolving lockouts there are many causes of lockouts. The three most common causes are: (1) inadequate gas supply, (2) poor combustion, (3) ignitor failure. 1. Inadequate gas supply: before proceeding, ensure that the gas supply has not b...

Pennant pool heater page 23 8.4 high gas consumption appliances operating with an improper air/fuel ratio are very inefficient and consequently, have very high gas consumption. Because efficiency is high when the co 2 is high (or o 2 is low), appliances operating with low co 2 or high o 2 (especiall...

Laars heating systems page 24 item description size size size size size size size 500 750 1000 1250 1500 1750 2000 sheet met al components see figure 10 1 panel, jacket, side left 5c3420 5c3420 5c3420 5c3420 5c3420 5c3420 5c3420 2 panel, jacket, side right 5c3526 5c3526 5c3526 5c3526 5c3526 5c3526 5...

Pennant pool heater page 25 19 chamber , rear 5c2006 7c2006 10c2006 12c2006 15c2006 17c2006 20c2006 20 chamber assembly , lef t, bottom 5c2601 5c2601 5c2601 5c2601 5c2601 5c2601 5c2601 21 chamber assembly , right, bottom 5c2201 5c2201 5c2201 5c2201 5c2201 5c2201 5c2201 22 chamber , t o p 5c2001 7c20...

Laars heating systems page 26 (1) (1) (1) (1) (1) (1) 37a t ile, rear , right side t2016600 t2016600 t2018100 t2016600 t2018100 t2016600 (1) (1) (1) (1) (1) (1) 37b t ile, rear , center t2017200 t2017200 t2017200 t2017200 (1) (1) (2) (2) 38 t ile, bottom t2015500 (1) 39 t ile, bottom, left side t201...

Pennant pool heater page 27 56 gasket, pump adapter not used on current production (was s0024600) 57 pump adapter , glass-lined cast iron not used on current production (was 10364200) pump adapter , bronze 10364201 10364201 10364201 10364201 10364201 10364201 10364201 58 baffle, dif fuser , pump inl...

Laars heating systems page 28 size size size size size size size item description 500 750 1000 1250 1500 1750 2000 gas t rain component s see figure 10 76 manifold, gas supply 5c6700 7c6700 10c6700 12c6700 15c6700 17c6700 20c6700 77 v alve, ball v2003100 v2003100 r2003700 r201 1600 r201 1600 r201 16...

Pennant pool heater page 29 burner manifold, 3 burners, left l2012800 l2012800 l2012800 l2012800 l2012800 (1) (2) (3) (1) (2) burner manifold, 4 burners, right l2012700 l2012700 l2012700 l2012700 (1) (1) (1) (2) burner manifold, 4 burners, left l2012600 l2012600 l2012600 l2012600 (2) (2) (2) (4) 82 ...

Laars heating systems page 30 figure 10. Sheet metal components..

Pennant pool heater page 31 figure 11. Internal components..

Laars heating systems page 32 figure 12. Heat exchanger components. A enlargement from previous page.

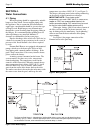

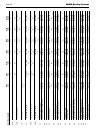

Pennant pool heater page 33 figure 13. Pennant 500 - 1000 ladder diagram. Section 10. Wiring diagrams.

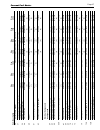

Laars heating systems page 34 figure 14. Pennant 1250 - 2000 ladder diagram..

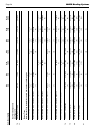

Pennant pool heater page 35 figure 15. Pennant 500 - 1000 wiring schematic..

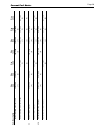

Laars heating systems page 36 figure 16. Pennant 1250 - 1500 wiring schematic..

Pennant pool heater page 37 figure 17. Pennant 1750 - 2000 wiring schematic..

Laars heating systems page 38 figure 18. Field wiring..

Pennant pool heater page 39.

H231 1900d 800.900.9276 • fax 800.559.1583 (customer service, service advisors & technical support) 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 (applications engineering) 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.C...