Installation and operation instructions document 1170f h2300300f installation and operation instructions for rheos tm modulating boiler model rhch modulating water heater model rhcv u.S. Patent no. 6,644,393 canada patent pending warning if the information in this manual is not followed exactly, a f...

Laars heating systems page 2 table of contents section 1. General information 1.1 introduction ........................................................ 3 1.2 model identification ............................................ 3 1.3 warranty ............................................................ ...

Rheos boiler and water heater page 3 section 1. General information using this manual – because the rheos boilers and rheos water heaters are identical appliances, with the exception of materials of manufacture, labels and ultimate use application, this manual provides information for the proper ins...

Laars heating systems page 4 (9) fuel n = natural gas p = liquid propane (10) altitude a = universal altitude (0' to 10,000') (0m to 3050m) (11) location c = indoor and outdoor (for non-condensing units) i = indoor (for condensing units) (12) firing mode f = modulating (13) revision 1 = first versio...

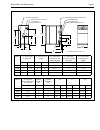

Rheos boiler and water heater page 5 3.75 10 65.75 167 55 140 c b d 7.75 20 "s" water outlet "w" water inlet non-pump-mounted unit "p" water inlet pump-mounted unit 13 33 48 122 17.25 44 30.5 77 53 135 "g" gas connection "a" air inlet with air filter "v" flue vent (cat. Iv) outlet 34.5 88 figure 1. ...

Laars heating systems page 6 1.5 outdoor installations attach the appropriate termination and appliance adaptor to the vent outlet (see table 1). Units are shipped with a louvered cover over the ducted air connection. Do not remove this cover, and/or add any piping to the ducted air connection. The ...

Rheos boiler and water heater page 7 section 2. Venting and combustion air 2.1 combustion air rheos boilers and water heaters must have provisions for combustion and ventilation air in accordance with section 5.3, air for combustion and ventilation, of the national fuel gas code, ansi z223.1, or sec...

Laars heating systems page 8 figure 3. Combustion air and vent through side wall. U.S. Installations (see note 1) canadian installations (see note 2) a= clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm) deck, or balcony b= clearance to window or door that may be 4 feet (1.2 ...

Rheos boiler and water heater page 9 model horizontal combustion horizontal vent air terminal terminal 1200 20260701 d2004500 1600 20260703 d2004500 2000 20260703 d2004600 2400 20260703 d2006200 table 4. Horizontal vent and air terminals for indoor installations. Term description pipe single-wall ga...

Laars heating systems page 10 model and distance from gas meter or last stage regulator gas type 0-50 feet 0-15m 50-100 feet 15-31m 100-200 feet 31-61m 200-300 feet 61-91m 1200 natural 2" 5.1cm 2-1/2" 6.4cm 2-1/2" 6.4cm 3" 7.6cm 1200 propane 1-1/2" 3.8cm 2" 5.1cm 2" 5.1cm 2-1/2" 6.4cm 1600 natural 2...

Rheos boiler and water heater page 11 above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment. The sign shall read, in print size no less than one-half (½) inch in size, “gas vent directly below. Keep clear of all obstructions...

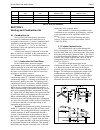

Laars heating systems page 12 system boiler circ. Pump system pump thermometer globe valve check valve pressure reducing valve w/ fast fill bypass expansion tank with air scoop and auto air vent pump legend valve temperature sensor 3-way valve purge valve c cold water make-up optional pump mounted u...

Rheos boiler and water heater page 13 thermometer globe valve check valve pressure reducing valve w/ fast fill bypass expansion tank with air scoop and auto air vent pump legend valve temperature sensor 3-way valve purge valve install air vents at high points in system piping & sizing of expansion t...

Laars heating systems page 14 optional pump mounted unit avaliable boiler circ. Pump cold water make-up system pump system return system supply c thermometer globe valve check valve pressure reducing valve w/ fast fill bypass expansion tank with air scoop and auto air vent pump legend valve temperat...

Rheos boiler and water heater page 15 2.3.4 vertical combustion air terminal when combustion air is taken from the roof, a field-supplied rain cap or an elbow arrangement must be used to prevent entry of rain water (see figure 2). The opening on the end of the terminal must be at least 12" (30cm) ab...

Laars heating systems page 16 thermometer globe valve check valve pressure reducing valve w/ fast fill bypass expansion tank with air scoop and auto air vent pump legend valve temperature sensor 3-way valve notes: 7. Caution: pump sizing must be based upon water hardness at job site caution: this dr...

Rheos boiler and water heater page 17 caution: this drawing shows suggested piping configuration and valving check with local codes and ordinances for additional requirements thermometer globe valve check valve pressure reducing valve w/ fast fill bypass expansion tank with air scoop and auto air ve...

Laars heating systems page 18 note: this appliance must be installed in a closed pressure system with a minimum of 12 psi (82.7kpa) static pressure at the boiler. Hot water piping should be supported by suitable hangers or floor stands. Do not support piping with this appliance. Due to expansion and...

Rheos boiler and water heater page 19 increase the head loss requirement by 20%. Important notes : different glycol products may provide varying degrees of protection. Glycol products must be maintained properly in a heating system, or they may become ineffective. Consult the glycol specifications, ...

Laars heating systems page 20 note: a listed temperature and pressure relief valve listed as complying with the standard for relief valves and automatic gas shutoff devices for hot water supply systems, 1). Ansi z21.22 latest edition, or 2). Csa 4.4, of suitable discharge capacity must be installed ...

Rheos boiler and water heater page 21 section 5. Electrical connections warning the appliance must be electrically grounded in accordance with the requirements of the authority having jurisdiction or, in the absence of such requirements, with the latest edition of the national electrical code, ansi/...

Laars heating systems page 22 figure 15. Control parameter graph. Through the heater is 25°f, the outlet temperature will be 175°f (150°f+25°f). Therefore, set the manual reset high limit to 195°f (175°f + 20°f). Example, metric units: if the tank temperature is set to 60°c, set the heater’s tempera...

Rheos boiler and water heater page 23 figure 16. Control parameter possible interference. Figure 17. Control parameter possible interference..

Laars heating systems page 24 5.5.1 temperature setpoint the temperature setpoint is the point at which the temperature control relay will be de-energized and the unit’s call for heat will end. The temperature setpoint is adjusted with the setpoint dial on the a350 control (see figure 13). The tempe...

Rheos boiler and water heater page 25 sluggish with the control set to medium, the “fast” setting may be an improvement. The “fast” setting will only be used when the rate of change at the sensor is very rapid. In most cases, this setting is too fast for the rheos. 5.6 external control connections r...

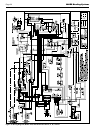

Laars heating systems page 26 figure 18. Wiring diagram, model 1200, standard and codes a, c, d, f and g..

Rheos boiler and water heater page 27 figure 19. Wiring diagram, models 1600, 2000 and 2400, standard and codes a, c, d, f and g..

Laars heating systems page 28 figure 20. Wiring diagram, model 1200, codes b and e..

Rheos boiler and water heater page 29 figure 21. Wiring diagram, models 1600, 2000 and 2400, codes b and e..

Laars heating systems page 30 figure 22. Wiring diagram, model 1200, pump-mounted, standard and codes a, c, d, f and g..

Rheos boiler and water heater page 31 figure 23. Wiring diagram, models 1600, 2000 and 2400, pump-mounted, standard and codes a, c, d, f and g..

Laars heating systems page 32 figure 24. Wiring diagram, model 1200, pump-mounted, codes b and e..

Rheos boiler and water heater page 33 figure 25. Wiring diagram, models 1600, 2000 and 2400, pump-mounted, codes b and e..

Laars heating systems page 34 figure 26. Wiring schematic, model 1200, standard and codes a, c, d, f and g. Figure 27. Wiring schematic, models 1600, 2000 and 2400, standard and codes a, c, d, f and g. Schematic wiring diagram schematic wiring diagram.

Rheos boiler and water heater page 35 figure 29. Wiring schematic, models 1600, 2000 and 2400, codes b and e. Schematic wiring diagram figure 28. Wiring schematic, model 1200, codes b and e. Schematic wiring diagram.

Laars heating systems page 36 figure 31. Wiring schematic, models 1600, 2000 and 2400, pump-mounted standard and codes a, c, d, f and g. Schematic wiring diagram figure 30. Wiring schematic, model 1200, pump-mount - ed, standard and codes a, c, d, f and g. Schematic wiring diagram.

Rheos boiler and water heater page 37 figure 33. Wiring schematic, models 1600, 2000 and 2400, pump-mounted codes b and e. Schematic wiring diagram figure 32. Wiring schematic, model 1200, pump-mount - ed, codes b and e. Schematic wiring diagram.

Laars heating systems page 38 section 6. Operating instructions 6.1 filling the boiler system 1. Ensure the system is fully connected. Close all bleeding devices and open make-up water valve. Allow system to fill slowly. 2. If make-up water pump is employed, adjust pressure switch on pumping system ...

Rheos boiler and water heater page 39 6. Switch on the appliance power switch located on the front of the unit. 7. The rheos will enter the start sequence. The blower and pump come on for pre-purge, then the ignitor warm-up sequence starts and after all safety devices are verified, the gas valve ope...

Laars heating systems page 40 section 7. Maintenance warning disconnect all power to the appliance before attempting any service to the appliance. Contact with electricity can result in severe injury or death. 7.1 system maintenance 1. Lubricate the system water-circulating pump, if required, per th...

Rheos boiler and water heater page 41 determined the actuator is working properly, the gas valve body may need to be replaced. To remove the gas valve body, shut off 120-volt power and the gas shutoff valve. Remove the front and right-side panels from the unit. Disconnect the union between the valve...

Laars heating systems page 42 7.2.8 ignitor / flame sensor assembly the ignitor is a 110v “hot surface” type. It is energized whenever there is a call for heat and switched off when ignition is established and the flame has been sensed. To replace the ignitor, shut off the 120-volt power to the appl...

Rheos boiler and water heater page 43 figure 36. Gas trains. Safety gas valve modulating gas valve actuator modulating gas valve body manual gas valve manual gas valve gas orifice low gas pressure switch high gas pressure switch standard and control pack c gas train pressure switch air inlet transit...

Laars heating systems page 44 determined the actuator is working properly, the gas valve body may need to be replaced. To remove the gas valve body, shut off 120v power and the gas shutoff valve. Remove the right side and front panels. Remove the valve actuator. Unscrew the valve body from the gas t...

Rheos boiler and water heater page 45 section 8. Trouble shooting 8.1 sequence of operation the rheos appliance is a cold start appliance that should start only on a call for heat from a tank aquastat, room thermostat, zone valve end switch or other space temperature control device. 1. Upon a call f...

Laars heating systems page 46 8.3.3 defective burner - occurs on startup or at burner shutdown a defective burner can cause a delayed ignition. If the gas supply pressure is proper, the gas valve is functioning properly, the burner should be inspected. There should be no distortion or perforations i...

Rheos boiler and water heater page 47 9.2 parts list combustion components see figure 39 1200 1600 2000 2400 1 combustion chamber assembly r2010800 r2016300 r2016400 r2001000 2 base assembly r2001100 r2001100 r2001100 r2001100 3 panel, front cover, base frame r2001200 r2001200 r2001200 r2001200 4 pa...

Laars heating systems page 48 1200 1600 2000 2400 39 pressure switch, low gas r2004100 r2004100 r2004100 r2004100 40 tubing/fittings (gas train repair kit) r2020700 r2020700 r2020700 r2020700 41 air filter box assembly (with gasket and hardware) nat r2020800 r2020900 r2004400 r2004400 41 air filter ...

Rheos boiler and water heater page 49 1200 1600 2000 2400 88 panel, diagnostic lights r2007300 r2007300 r2007300 r2007300 89 bracket, mounting, diagnostic panel r2007400 r2007400 r2007400 r2007400 90 standoff r2007500 r2007500 r2007500 r2007500 91 hardware kit, control panel r2007600 r2007600 r20076...

Laars heating systems page 50 figure 39. Combustion components. 12 13 10 9 17 14 14 20 19 19 19 19 19 19 6 7 8 5 4 18 or 19 18 or 19 19 19 1 - complete combustion component assembly 2 (assembly) 3 14 15 16 14 21 18 or 19 14 11 - hardware kit, combustion chamber.

Rheos boiler and water heater page 51 figure 40. Gas train/combustion air components. 47 48 48 55 56 52 48 41 42 43 44 45 46 49 50 54 48 48 51.

Laars heating systems page 52 figure 41. Gas train components. 26 28 or 30 29 or 30 31 31 36 or 37 39 38 40 standard and control pack c gas train 57 53 26 28 or 30 29 or 30 31 31 35 36 or 37 39 38 40 control packs b and e gas train control packs a and d gas train 57 53 for sizes 2000 natural gas and...

Rheos boiler and water heater page 53 figure 42. Electrical components..

Laars heating systems page 54 figure 43. Heat exchanger / water path components. 93 100 98 103 104 97 101 106 110 94 106 or 108 107 107 or 109 95 105 106 106 106 96.

Rheos boiler and water heater page 55 figure 44. Jacket components. 116 117 118 119 120 121 122 123 124 125 126 127 128 128 126 129 130 131 131 132 - jacket hardware kit 136 - jacket retro-fit kit (standard) 137 - jacket retro-fit kit (mounted pump) 115 133 134 135.

Laars heating systems page 56 tables listing table 1 terminals for outdoor installation......................6 table 2 clearances ........................................................6 table 3 vent / air pipe sizes ..........................................7 table 4 horizontal vent and air termin...

Rheos boiler and water heater page 57.

Laars heating systems page 58.

Rheos boiler and water heater page 59.

H2300300f ® 800.900.9276 • fax 800.559.1583 (customer service, service advisors) 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 (applications engineering) 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com litho in u.S.A. ...