Installation, operation and maintenance instructions document 2051e h0147500e installation, operation and maintenance instructions for mighty therm volume water heaters model vw-pw sizes 175-400 for your safety: this product must be installed and serviced by a professional service technician, qualif...

Laars heating systems page 2 table of contents section 1. General information 1.1 introduction .................................................... 3 1.2 warranty ........................................................ 3 1.3 technical assistance ..................................... 3 section 2. In...

Mighty therm volume water heaters page 3 section 1. General information 1.1 introduction this manual provides installation, operating, and maintenance instructions for models vw and pw volume water heaters, sizes 175 through 400. Review all application and installation procedures completely before p...

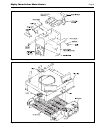

Laars heating systems page 4 number for the drafthood is on the heater rating plate. Follow this procedure to make the conversion: a. Remove the top filler plate, stamped “hot”, by slipping a fine-blade screwdriver into the slot at the rear of the plate and gently prying it up (see figure 2). B. Rem...

Mighty therm volume water heaters page 5 d. Disengage the flue transition ring from the stack extension and place it on top of the collector assembly as shown in figure 4. E. Slide the adapter plate over the bottom of the stack extension as shown in figure 5. Fit the stack extension down over the fl...

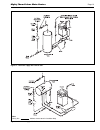

Laars heating systems page 6 figure 11. Standard base for combustible floor. Figure 13. Typical roof mounting with standard combustible mount base. Figure 12. Typical roof mounting. Figure 10. Outdoor location installation. Figure 9. Incorrect outdoor installation. Concrete slab must extend out a mi...

Mighty therm volume water heaters page 7 method 1: two permanent openings, one commencing within 12" (30 cm) of the top and one commencing within 12" (30 cm) of the bottom of the enclosure shall be provided. The openings shall communicate directly, or by ducts, with the outdoors or spaces that freel...

Laars heating systems page 8 supply or reverse the natural draft action of the venting system. This could cause flue products to build up in the heater room. More air must be supplied to make up for the decrease. 2.5 venting of combustion products 2.5.1 general information when installed indoors, th...

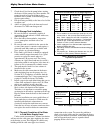

Mighty therm volume water heaters page 9 figure 15. Heat exchanger reversal. Figure 16. Flue collector holddown clamps..

Laars heating systems page 10 9. Remove the four screws that fastens the metal channels covering the capillary tube on the right side of the jacket, and lay the channels aside. 10. In the control compartment, find the manual reset high-limit switch box (see figure 15) and loosen the screw on the top...

Mighty therm volume water heaters page 11 40. On indoor installations (sizes 175-250), insert the draft hood switch plug into the receptacle on the left side of the heater. 2.6.2 water chemistry 20. Lift out the heat exchanger assembly, turn it 180 degrees, and reseat the unit in the heater with the...

Laars heating systems page 12 heat flow pressure* water temp exch. Water rate drop rise model passes category gpm l/s ft. M ° f ° c 175 2 soft 22 1.4 5.8 1.8 13 7 normal 34 2.1 11.2 3.4 8 4 hard 46 2.9 19.1 5.8 6 3 4 soft 11 0.7 4.9 1.5 25 14 normal 17 1.1 9.3 2.8 16 9 hard 23 1.5 15.9 4.8 12 7 250 ...

Mighty therm volume water heaters page 13 figure 22. Hot water supply with horizontal tank. Note: heavy line indicates heater-to-tank circulation loop. Figure 21. Hot water supply with vertical tank..

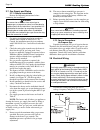

Laars heating systems page 14 valve is directed to an open drain and protected from freezing. 2. Install a properly sized thermal expansion tank on the cold water supply line. 2.6.7 pressure relief valve the pressure relief valve must be installed in the tapped opening provided in the boiler header ...

Mighty therm volume water heaters page 15 7. Check the oil level in the pump before starting the heater. Oil the pump every three months. Oil pumps located in excessively hot or dusty locations once a month. Self-lubricating pumps do not require oiling. 8. Fill the bearing assembly to the lower leve...

Laars heating systems page 16 10. The correct burner manifold gas pressure is stamped on the rating plate. The regulator on the gas valve is preset at the factory, and does not normally need adjustment. 11. Before operating the heater, test the complete gas supply system and all connections for leak...

Mighty therm volume water heaters page 17 warnings vent pipes, drafthoods, and heater tops get hot! These surfaces can cause serious burns. Do not touch these surfaces while the heater is in operation. Adding a vent cap reduces the temperature on the top. For your safety, when starting the heater, k...

Laars heating systems page 18 figure 26. Typical example of wiring schematic, system 1. Ignition system no. 1 - standing pilot on/off or mechanical modulation volume water heaters (325-400) version b natural or propane gas pump included on pw models, field supplied on vw models.

Mighty therm volume water heaters page 19 figure 27. Typical example of wiring schematic, system 12. Ignition system no. 12 - electronic ignition on/off or mechanical modulation volume water heaters (325-400) version b natural or propane gas pump included on pw models, field supplied on vw models.

Laars heating systems page 20 hot water in the application. After a setting has been chosen for the tank temperature control, set the heater temperature control 10°f (6°c) higher. The heater’s temperature control senses the inlet water temperature to the heater. The heater’s manual reset high limit ...

Mighty therm volume water heaters page 21 electronic pilot standing pilot figure 29. Flame patterns. Example, metric units: if the heater’s temperature control is set to 55°c, and the temperature rise through the heater is 14°c, the outlet temperature will be 69°c (55°c + 14°c). Set the automatic re...

Laars heating systems page 22 3.5 hi-limit switch checkout after running the heater for a long enough period, bring the water temperature within the range of the hi-limit switch and slowly back off the high limit setting until the heater shuts off. The main burners should reignite when the hi-limit ...

Mighty therm volume water heaters page 23 if the gas valve is found to be defective, replace it by following these instructions. 1. Turn off electrical power to the heater. 2. Turn off the main gas supply at the manual gas cock outside the heater jacket or at the meter. 3. Remove the front access do...

Laars heating systems page 24 4.3 heat exchanger 4.3.1 inspecting the heat exchanger to check the scale buildup, periodically inspect the tube having the highest temperature as follows: 1. Open the drain valve on the left side of the heater. 2. Remove the hex-head plug located on the right side of t...

Mighty therm volume water heaters page 25 5. Attach one end of the manometer hose to the fitting on the gas valve and the other end to the manometer. 6. Open gas supply valve to the heater to test. 7. With the main burners firing, the manometer reading should be between 6.5 and 9 inches w.C. For nat...

Laars heating systems page 26 testing the transformer requires an ac voltmeter with a 50 volt (v) range. Test the transformer using the following procedures: 1. Clip a lead from the voltmeter to the yellow wire terminal on the transformer. 2. Touch the other lead to the red wire terminal (see figure...

Mighty therm volume water heaters page 27 5.2.4 testing the manual reset hi-limit switch to test the manual reset hi-limit switch (see figure 36): 1. Touch the other lead of the voltmeter to both terminals of the manual reset hi-limit switch. The voltmeter should read 24 to 28vac at both terminals. ...

Laars heating systems page 28 5.2.7 testing the fuse to test the fuse: 1. Clip a lead of the voltmeter to the grounding terminal. 2. Touch the other voltmeter lead to the 24vac terminal on the ignition control. 3. If there is no voltage, replace the fuse. A blown fuse is usually an indication of a s...

Mighty therm volume water heaters page 29 thermocouple thermocouple adapter gas valve millivolt meter pilot figure 41. Testing the pilot thermocouple. 2. Clip one lead of a millivolt meter on the center post of the tube and the other lead on the copper pilot thermocouple shield. Turn the gas valve c...

Laars heating systems page 30 2. If everything appears all right, measure flame sensing current by connecting a direct current (dc) microamp meter between terminal no. 12 and the gnd (burner) terminal on the ignition control (see figure 42). Note: separate the microamp meter leads from each other an...

Mighty therm volume water heaters page 31 nat. Stdg pilot, (model 250) .................. V0073300 nat. Stdg pilot, (model 325-400) ........... V0049900 lp iid, o/o,mm (models 175 thru 400) v0073600 lp iid, 2-stage (models 175 thru 250) .. V0073100 lp iid, 2-stage (models 325 and 400) ... V0073200 l...

H0147500e 800.900.9276 • fax 800.559.1583 (customer service, service advisors) 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 (applications engineering) 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com litho in u.S.A. © ...