- DL manuals

- Lab.gruppen

- Speaker System

- PLM 12K44

- Operation Manual

Lab.gruppen PLM 12K44 Operation Manual

PLM+ SERIES

Powered Loudspeaker Management™

System

Operation Manual

Rev. 3.0.1

Item no. OM–PLM+

PLM+ SERIES

Powered Loudspeaker Management™

System

Rev. 3.0

Quick Start Guide

PLM 20K44

PLM 12K44

PLM 5K44

Item no. QSG-PLM+SERIES

Incorporating technologies from

PLM 20K44

PLM 12K44

PLM 5K44

Incorporating technologies from

Summary of PLM 12K44

Page 1

Plm+ series powered loudspeaker management™ system operation manual rev. 3.0.1 item no. Om–plm+ plm+ series powered loudspeaker management™ system rev. 3.0 quick start guide plm 20k44 plm 12k44 plm 5k44 item no. Qsg-plm+series incorporating technologies from plm 20k44 plm 12k44 plm 5k44 incorporatin...

Page 2

1. Important safety instructions 2 plm+ series operation manual rev 3.0.1 1. Important safety instructions before using the device, be sure to carefully read the safety instructions. Keep this document with the device at all times. 1. Read these instructions. 2. Keep these instructions 3. Heed all w...

Page 3

1. Important safety instructions plm+ series operation manual rev 3.0.1 3 to completely disconnect this equipment from the ac mains, disconnect the power supply cord plug from the ac receptacle. The mains plug of the power supply cord shall remain readily operable. Français: pour démonter complèteme...

Page 4

Table of contents 4 plm+ series operation manual rev 3.0.1 table of contents 1. Important safety instructions 2 1.1. Approvals 2 1.2. Warnings 2 2. Introduction 6 2.1. Welcome 6 2.2. Main features 6 2.3. Additional documentation 8 3. Installation 8 3.1. Unpacking 8 3.2. Mounting 8 3.3. Cooling 10 3....

Page 5

Table of contents plm+ series operation manual rev 3.0.1 5 7.4. Mute enable button 34 7.5. Meter button 34 7.6. Menu button 34 7.7. Exit button 34 7.8. Dynamic buttons, controls and leds 35 7.9. Warning and fault indications 40 7.10. Meter mode 42 7.11. Menu mode 46 8. Back panel interface 60 8.1. S...

Page 6

2. Introduction 6 plm+ series operation manual rev 3.0.1 2. Introduction 2.1. Welcome thank you for choosing the lab.Gruppen plm+ series of powered loudspeaker management systems for your for fast installation and use of this product, your welcome package includes a printed copy of the plm+ series q...

Page 7

2. Introduction plm+ series operation manual rev 3.0.1 7 2.2.2.1. Amplifier gain amplifier gain is set in the digital domain for plm+ series devices, and may be controlled via the lake controller software or front-panel interface. 2.2.2.2. Isvpl™ the inter-sample voltage peak limiter (isvpl) tailors...

Page 8

3. Installation 8 plm+ series operation manual rev 3.0.1 2.3. Additional documentation this document, the plm+ operation manual, serves as the primary reference source for detailed information on the installation and operation of plm+ series powered loudspeaker management systems. It also provides f...

Page 9

3. Installation plm+ series operation manual rev 3.0.1 9 3.2.1. Rear mounting two rear support brackets along with associated mounting hardware are included with the plm+, as shown in figure 3.1; it is recommended that these are used wherever possible. Fit the brackets to the vertical rails at the r...

Page 10

3. Installation 10 plm+ series operation manual rev 3.0.1 3.3. Cooling 3.3.1. Overview direction. Space to allow air to escape. If the plm+ is rack-mounted, never operate the unit with any front or rear rack doors or covers in position. It is recommended to keep the ambient temperature around the pl...

Page 11

3. Installation plm+ series operation manual rev 3.0.1 11 if the mains plug (ac plug) fitted to the mains cable (ac cord) is not appropriate for your country, it can be removed and a locally-sourced one fitted instead, observing the color coding in the table below: table 3.1: ac plug configuration i...

Page 12

4. Product overview 12 plm+ series operation manual rev 3.0.1 4. Product overview 4.1. Front panel overview the front panel presents the following amplifier status indicators: the front panel controls are clustered around a daylight readable lcd 3 , allowing adjustment and monitoring of the majority...

Page 13

4. Product overview plm+ series operation manual rev 3.0.1 13 5 mute enable – select mute enable to allow the dynamic function buttons to operate as mute controls for the module inputs and power output channels. The mute enable bu a subsequent press deselects this mode. If left activated, mute enabl...

Page 14

4. Product overview 14 plm+ series operation manual rev 3.0.1 4.2. Rear panel 3 4 5 1 1 2 3 4 input 1 input 2 input 3 aes/ebu input 1-2 input 3-4 sec prim must be grounded/earthed made in sweden pin 1: scrn 2: pos 3: neg analog with i so- f loat tm 50-60hz 100-240v 2400-2950w ser. N:o removed! Ch 2 ...

Page 15

4. Product overview plm+ series operation manual rev 3.0.1 15 ethernet and power connectors 5 primary network connector – the primary neutrik rj45 ethercon® connection provides integration into an ethernet control network which may include other lake processors and the lake controller software. Netw...

Page 16

5. Operation and performance 16 plm+ series operation manual rev 3.0.1 5. Operation and performance 5.1. Operation precautions make sure that the standby button on the unit’s front panel is either unlit (off), or red (standby), before making any input or output connections. Ensure the ac voltage is ...

Page 17

5. Operation and performance plm+ series operation manual rev 3.0.1 17 desired power can be specified in several domains: burst and peak power; peak and rms voltage; and also the speaker’s aes power rating. By specifying the nominal impedance of the load, the rpm algorithms have all input data requi...

Page 18

5. Operation and performance 18 plm+ series operation manual rev 3.0.1 cafÉ with esp: cafÉ (configuring amplifiers for the environment) is a dedicated software application for windows and osx that provides tools for system planning, specification and commissioning. CafÉ incorporates the equipment sp...

Page 19

Lake-enabled amplifier devices (d series lake, plm+, plm) that have a smaller peak output voltage capability still allow isvpl speaker threshold settings up to 600 v. When a threshold is set above the current maximum capability of a power output channel, the actual isvpl will automatically be set to...

Page 20

5. Operation and performance 20 plm+ series operation manual rev 3.0.1 5.3.3. Power average limiter (pal) the power average limiter active warning (pal active) will be displayed when the power supply’s maximum rated design parameters are reached. When this warning is displayed, gain limiting is bein...

Page 21

5. Operation and performance plm+ series operation manual rev 3.0.1 21 5.3.6. Current average limiter (cal™) the current average limiter (cal) monitors the rms current drawn from each power output channel to ensure that the power output stages are not overloaded. When activated, it regulates the cur...

Page 22

5. Operation and performance 22 plm+ series operation manual rev 3.0.1 limiter (atl) is engaged, reducing power output to avoid amp channel protection (muting). Limiting is removed when temperature falls below the warning threshold. 5.3.8.3. Power supply / dsp a power supply (psu) or dsp temperature...

Page 23

5. Operation and performance plm+ series operation manual rev 3.0.1 23 trigger voltage voltage [v rms] 100 90 80 70 60 50 40 30 20 10 0 0 5 10 15 20 25 30 frequency [khz] fig 5.4: vhf protection frequency sensitivity the attack time of the vhf protection circuitry also changes with frequency, becomi...

Page 24

5. Operation and performance 24 plm+ series operation manual rev 3.0.1 5.3.12. Power supply protection the power supply is very advanced and has several internal control and monitoring functions. Should any of these fail, the power supply will shut down to prevent damage or limit severity of the fai...

Page 25

5. Operation and performance plm+ series operation manual rev 3.0.1 25 5.4.1. Low inrush current high power amplifiers with inadequate inrush current limiting can draw considerable current from the mains at turn–on, sometimes tripping a fast–acting mains breaker. The plm+, however, has very low inru...

Page 26

5. Operation and performance 26 plm+ series operation manual rev 3.0.1 • if there are one or two “spurs” with 70v loudspeakers connected; if two in parallel is default, it will warn if one is missing. • if there is a short circuit in the load. • if there is an open circuit (all loudspeakers missing)...

Page 27

5. Operation and performance plm+ series operation manual rev 3.0.1 27 note: manual configuration of loadpilot is implemented in cafÉ versions 1.1.0. And later. For detailed information on manual configuration of loadpilot, please refer to the integrated guide in the software program and to the cafÉ...

Page 28

6. Signal flow and lake® processing 28 plm+ series operation manual rev 3.0.1 6. Signal flow and lake® processing 6.1. Signal flow the figures below depict the audio signal flow for a plm+ series device. It is worth noting that this sophisticated device provides seven points in the signal chain wher...

Page 29

6. Signal flow and lake® processing plm+ series operation manual rev 3.0.1 29 6.2. Level adjustments & mute points 1 input router stage input selection and mute 2 input mixer stage router on /off connection to mixer and gain settings 3 module input stage mute (n/a for lm series mesa mode) and gain s...

Page 30

6. Signal flow and lake® processing 30 plm+ series operation manual rev 3.0.1 6.3. Lake processing and control as outlined in section 2.2.3, this device integrates seamlessly into the lake processing environment, providing all features, functionality and connectivity associated with all lake process...

Page 31

6. Signal flow and lake® processing plm+ series operation manual rev 3.0.1 31 6.5. Loudspeaker processor overview the lake processing system within plm+ series devices may be configured with up to four processing modules containing a total of up to twelve processing module outputs, that can be route...

Page 32

7. Front panel interface 32 plm+ series operation manual rev 3.0.1 7. Front panel interface an overview of the front panel interface is provided in section 4.1. This chapter describes each cluster of controls as shown in the diagram below. 3 1 2 4 5 6 7 8 9 12 11 10 2 1 7.1. Overview the front panel...

Page 33

7. Front panel interface plm+ series operation manual rev 3.0.1 33 7.1.3. Selecting a module in the lake controller software via the front panel it is sometimes useful to identify which module icon/s in the lake controller software are associated with a particular hardware frame. To highlight the mo...

Page 34

7. Front panel interface 34 plm+ series operation manual rev 3.0.1 7.4. Mute enable button the dynamic function buttons to the immediate left and right of the lcd are used as mute buttons only when the mute enable button 5 is activated (flashing). When mute enable is activated the mute enable button...

Page 35

7. Front panel interface plm+ series operation manual rev 3.0.1 35 7.8. Dynamic buttons, controls and leds figure 7.3: lcd with dynamic buttons, controls and leds 7.8.1. Communication led a this bright white led signifies selection in the lake controller, or controller communication providing visual...

Page 36

7. Front panel interface 36 plm+ series operation manual rev 3.0.1 7.8.3. Rotary encoder c the rotary encoder is used to adjust parameters in conjunction with the selection made via the dynamic function buttons and lcd menus. The ring around the rotary encoder illuminates when a selected parameter i...

Page 37

7. Front panel interface plm+ series operation manual rev 3.0.1 37 7.8.4.1. Mute functions the plm+ provides mute functions at several different points in its audio chain. Please refer to section 6.1 for further information. The four types of mute are: 1. Plm+ input router mute 2. Module input mute ...

Page 38

7. Front panel interface 38 plm+ series operation manual rev 3.0.1 note: fault condition led indications take priority over mute status indications. If a fault condition occurs, the led will indicate the fault by flashing and will note the mute status. When a frame fault is active the audio on all c...

Page 39

7. Front panel interface plm+ series operation manual rev 3.0.1 39 7.8.5. Led fault, warning and clip indication b d a tricolor led is embedded inside each of the eight dynamic function buttons. The leds convey a variety of status indications including faults and warnings, signal clip indications, m...

Page 40

7. Front panel interface 40 plm+ series operation manual rev 3.0.1 7.8.5.2. Warning or fault indications if certain parameters within the plm+ approach or exceed preset limits, a warning condition or fault condition may arise. One or more leds provide a visual indication of the problem, along with a...

Page 41

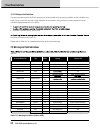

7. Front panel interface plm+ series operation manual rev 3.0.1 41 table 7.6: fault conditions (red led) on screen warning text type led no. Warning event log text amp ch. Mute channel 5-8 fault/clip mute amp channel mute temp flt:ch channel 5-8 amp temp fault temp fault: amp channel check ac mains ...

Page 42

7. Front panel interface 42 plm+ series operation manual rev 3.0.1 7.10. Meter mode 7.10.1. Home view the default view when powering on the device is meter mode > home view as shown in figure 7.7. Figure 7.7: meter mode > home view home view provides a summary of module i/o gain level and limiter ga...

Page 43

7. Front panel interface plm+ series operation manual rev 3.0.1 43 note: output limiter (gain reduction) meters take into account the sum of plm+ isvpl and lake limitermax. 10 l to which each module output is routed. When mode or bridge mode, as shown in figure 7.8 for further information on bridge ...

Page 44

7. Front panel interface 44 plm+ series operation manual rev 3.0.1 6 loadpilot status: 1. High freq pilot tone enabled/disabled, 2. Low freq pilot tone enabled/disabled, status 7 loadpilot status: 1. High freq pilot tone enabled/disabled, 2. Low freq pilot tone enabled/disabled, status 8 loadpilot s...

Page 45

7. Front panel interface plm+ series operation manual rev 3.0.1 45 7.10.4. Input meters view input view enables inspection of the source selected to each input router; input signal level before the input mixer (i.E. Prior to the home view module input meters); module input mixer routing; as well as ...

Page 46

7. Front panel interface 46 plm+ series operation manual rev 3.0.1 5 output 1: output label - output gain meter - lx: sum of lake max-peak and max-rms gain reduction 6 output 2: output label - output gain meter - lx: sum of lake max-peak and max-rms gain reduction 7 output 3: output label - output g...

Page 47

7. Front panel interface plm+ series operation manual rev 3.0.1 47 7.11.1.1. Parameters with individual values and group totals the following parameters display two values: • module > gain • module > delay • module > limiters > maxrms level • module > limiters > maxpeak level the module parameter ca...

Page 48

7. Front panel interface 48 plm+ series operation manual rev 3.0.1 • load monitor (see section 7.11.8) • configure no. Of cabinets in parallel • loadsmart verification • estimated no. Of cabinets 7.11.2. Module submenu only module output channels for routed power channels are displayed. This applies...

Page 49

7. Front panel interface plm+ series operation manual rev 3.0.1 49 7.11.2.2. Gain menu > module > gain figure 7.16: module gain edit screen press the illuminated button next to the module input/s and/or output/s for adjustment, and use the rotary encoder to change the value(s). Multiple gain values ...

Page 50

7. Front panel interface 50 plm+ series operation manual rev 3.0.1 7.11.2.5. Amp gain menu > module > amp gain by default, all outputs are selected; use the rotary encoder to change the gain of all power outputs or press the associated output button to deselect one or more outputs. Amp gain adjusts ...

Page 51

7. Front panel interface plm+ series operation manual rev 3.0.1 51 maxrms level (maxrmslvl) this sets the maximum rms signal level at the module outputs. It is adjustable from -30 dbu to +30 dbu in 0.1 db increments, subject to user-defined level limits. The group total is displayed (in brackets) fo...

Page 52

7. Front panel interface 52 plm+ series operation manual rev 3.0.1 7.11.3. I/o configuration menu > i/o config figure 7.17: i/o configuration sub menu this menu provides configuration options for input routing, along with settings for aes termination and iso-float as described in the following secti...

Page 53

7. Front panel interface plm+ series operation manual rev 3.0.1 53 with a router selected on the front panel, press the middle button on the left of the lcd to activate this parameter for editing. Use the illuminated rotary encoder to scroll through the following options: • auto select (default) • f...

Page 54

7. Front panel interface 54 plm+ series operation manual rev 3.0.1 the plm+ device at the end of a distribution line should be set to terminated; all other plm+ devices should be set to unterminated. If an aes3 distribution amplifier (da) is being used to distribute the digital audio signals, with o...

Page 55

7. Front panel interface plm+ series operation manual rev 3.0.1 55 1 toggle the source from which you want to route the channels (module, analog, aes) (note: that this also may affect the destination, as only aes3 and analog can be routed to dante. 2 toggle up among the available source channels 3 t...

Page 56

7. Front panel interface 56 plm+ series operation manual rev 3.0.1 7.11.5.1. Frame info menu > frame > frame info firmware version (fw version) further internal version numbers are displayed on right side of screen; bundle, dsp, fpga and safe image version. Serial number (serial no.) the printed ser...

Page 57

7. Front panel interface plm+ series operation manual rev 3.0.1 57 7.11.5.3. Breaker emulation limiter menu > frame > bel conf the breaker emulation limiter (bel) provides ampere selection (5-32 a) and breaker type selection (conservative, fast and universal). Select by pressing the adjacent button ...

Page 58

7. Front panel interface 58 plm+ series operation manual rev 3.0.1 7.11.6. Front panel display controls menu > frame > front contrast to adjust the front panel lcd contrast, select this option then use the rotary encoder to change the value. Dimming to adjust the front panel lcd & led brightness, se...

Page 59

7. Front panel interface plm+ series operation manual rev 3.0.1 59 7.11.8.1. Configure # of cabinets in parallel this option allows selection of the number of speaker cabinets connected to each plm+ output channel. Select individual or multiple outputs and use the rotary encoder to set the value fro...

Page 60

8. Back panel interface 60 plm+ series operation manual rev 3.0.1 8. Back panel interface an overview of the back panel interface is provided in section 4.2. This chapter describes each cluster of connections as shown in figure 8.1. Input 1 input 2 input 3 aes/ebu input 1-2 input 3-4 sec prim must b...

Page 61

8. Back panel interface plm+ series operation manual rev 3.0.1 61 8.1.2. Speakon connectors power outputs are available simultaneously on a single 8-pole connector (plm 20k44 and plm 12k44 only) and on two 4-pole connectors. The four-pole connectors carry outputs for channels 1&2 and 3&4 respectivel...

Page 62

8. Back panel interface 62 plm+ series operation manual rev 3.0.1 3+ 2- 4+ 2+ 1- 1+ 4- 3- 1+ 2 - 3+ 4 - nl4 plm+ output channels 1 & 2 nl4 plm+ output channels 3 & 4 nl8 plm+ output channels 1 - 4 8.1.3. Binding post connectors ch 2 ch 1 ch 4 ch 3 speaker outputs class 3 wiring bridge bridge ch 2 ch...

Page 63

8. Back panel interface plm+ series operation manual rev 3.0.1 63 connect the ‘+’ loudspeaker terminals to the red binding posts and the ‘ – ‘ terminals to the black binding posts. There are three methods of connecting speaker cables to the binding posts. 1. Solder 4 mm banana-plugs to the ends of t...

Page 64

8. Back panel interface 64 plm+ series operation manual rev 3.0.1 8.2.3. Unbalanced operation balanced connections are recommended where possible. However, if it is necessary to drive the device from equipment with an unbalanced output, wire the inputs as shown in figure 8.10. 1 2 3 cold hot scrn co...

Page 65

8. Back panel interface plm+ series operation manual rev 3.0.1 65 8.3. Aes3 digital inputs 8.3.1. Aes3 xlr connector aes3 digital audio input is via two xlr3f connectors. Connectors are provided for inputs 1 & 2 and inputs 3 & 4. Wiring of this connector follows the same standard as for analog xlr c...

Page 66

8. Back panel interface 66 plm+ series operation manual rev 3.0.1 table 8.14: rj45 wiring & pin out description figure 8.15: rj45 wiring & pin out diagram when the device is connected to an active network, the yellow link led illuminates above the connector in use. Data activity on the network is in...

Page 67

8. Back panel interface plm+ series operation manual rev 3.0.1 67 8.5. Power inlet 8.5.1 power connector a neutrik nac3 series powercon connector rated at 32 a is fitted to the rear of the plm+ for ac mains input. The power cable (ac cord) supplied with the plm+ has the mating connector ready-fitted...

Page 68

9. Appendix 68 plm+ series operation manual rev 3.0.1 9. Appendix 9.1. Faults and warnings overview category/type name on screen text description action frame warning ctrl offline on the network check network cabling/ network if controller expected on the network warning aes clock slipping clock sli...

Page 69

9. Appendix plm+ series operation manual rev 3.0.1 69 category/type name on screen text description action psu warning under voltage limit uvl active the under voltage limiter is active as the mains supply is approaching the lower end of the device´s operational voltage. Output power is decreased to...

Page 70

9. Appendix 70 plm+ series operation manual rev 3.0.1 category/type name on screen text description action warning more speakers ovr spkr count loadsmart detected more speakers than expected check load and warning uncertain about load uncertain load loadsmart uncertain about load check load and warn...

Page 71

9. Appendix plm+ series operation manual rev 3.0.1 71 9.2. Maintenance during normal operation this devices provides trouble-free service. If the lcd or front panel display requires cleaning, use a soft cloth only; do not use solvent cleaners. T turning the unit back on. In extreme cases it may be n...

Page 72

9. Appendix 72 plm+ series operation manual rev 3.0.1 9.3.2. Input and router defaults autoselect: on input sensitivity: +26 dbu dante: disabled aes3: terminated iso-float: enabled router 1: priority 1 = dante receiver (ch.1) priority 2 = dante receiver (ch.5) priority 3 = aes1 (ch.1) priority 4 = a...

Page 73

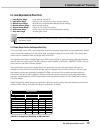

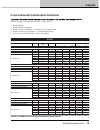

9. Appendix plm+ series operation manual rev 3.0.1 73 9.4. Current draw and thermal dissipation specifications different operating conditions for each plm+ series device. 1. Standby mode 2. Power on (idle - no signal) 3. Power on (normal operation - pink noise 1/8 of rated power) 4. Power on (heavy ...

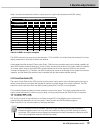

Page 74

9. Appendix 74 plm+ series operation manual rev 3.0.1 plm 12k44 level load rated power per channel line current power factor measured power (w) thermal dissipation (a) (%) in out dissipated btu/hr kcal/hr mains voltage 100 vac, 30 a standby 0.3 43 12 0 12 40 10 power on, idling 2.3 98 219 0 219 749 ...

Page 75

9. Appendix plm+ series operation manual rev 3.0.1 75 plm 20k44 level load rated power per channel line current power factor measured power (w) thermal dissipation (a) (%) in out dissipated btu/hr kcal/hr mains voltage 100 vac, 30 a standby 0.3 52 17 0 17 58 15 power on, idling 2.4 97 235 0 235 802 ...

Page 76

9. Appendix 76 plm+ series operation manual rev 3.0.1 9.5. Glossary of terms, acronyms and abbreviations term description floating such as that found in the plm+ - do mimic the characteristics of transformer-coupled designs to a high degree. Frame lake terminology for a physical unit containing a la...

Page 77

9. Appendix plm+ series operation manual rev 3.0.1 77 table 9.5: glossary of terms, acronyms and abbreviations term description online a device on an ethernet network which is fully operational and communicating with the rest of the network is said to be online. Pal drawn by the psu from the ac main...

Page 78

9. Appendix 78 plm+ series operation manual rev 3.0.1 10. Application guide this chapter describes the practical application and use of plm+ series devices. 10.1. Rack i/o panels for fast and simple system connection, pre-wired racks using connection panels can be used. With an i/o at one position, ...

Page 79

10. Application guide plm+ series operation manual rev 3.0.1 79 10.2.4. Module output gain factory and user gain are provided for each module output. These two stages provide a level of security and control for the system designer (factory) and a further level of adjustment for the user (user), both...

Page 80

10. Application guide 80 plm+ series operation manual rev 3.0.1 10.3.2. Minimize noise to help provide the best volume to noise ratio, use an aes or dante digital input signal wherever possible. If using analog inputs, ensure that unused or unnecessarily high headroom is not introduced at the input ...

Page 81

10. Application guide plm+ series operation manual rev 3.0.1 81 the improvement in noise performance (at the cost of losing headroom and compression features) is only 0.6 db; it is therefore not recommended to optimize performance in this manner. 10.3.3.2. Analog input gain structure examples figure...

Page 82

10. Application guide 82 plm+ series operation manual rev 3.0.1 figure 10.6 illustrates how moderate noise with extreme spl can be achieved. Spl is extremely high in this example as maximum headroom is available at the input and within the processing stage. This makes it possible to increase the ave...

Page 83

10. Application guide plm+ series operation manual rev 3.0.1 83 10.5. Digital audio connections whenever possible, it is preferable to connect a digital rather that analog input signal to the device. This is particularly relevant if the source signal is already in the digital domain, such as the sou...

Page 84

10. Application guide 84 plm+ series operation manual rev 3.0.1 10.5.3. Connections and cabling 10.5.3.1. Aes input connectors two aes-3 input signals (each carrying two audio channels) are connected to the xlr3f connectors labelled input 1-2 and input 3-4 in the aes/ebu (aes-3) input section on the...

Page 85

10. Application guide plm+ series operation manual rev 3.0.1 85 it is recommended that all cables be tested for error-free performance at lengths 20% to 25% greater than lengths 10.5.4. External signal distribution hardware 10.5.4.1. Distribution amplifiers format is one input and six outputs. Digit...

Page 86

10. Application guide 86 plm+ series operation manual rev 3.0.1 10.6. Digital clock configuration 10.6.1. Digital clock overview clocking system. The digital clock can generate various independent internal sample rates, or can sync to an incoming aes3 signal. Figure 10.7 shows the various sample rat...

Page 87

10. Application guide plm+ series operation manual rev 3.0.1 87 for automatic detection, the most appropriate clock matching the selected base-rate is automatically selected according to the following priorities. 1. Aes1 (input 1+2) 2. Internal clock when using automatic detection, the aes3 digital ...

Page 88

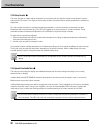

11. Technical specifications 11. Technical specifications 4 4 k 0 2 m l p 4 4 k 2 1 m l p 4 4 k 5 m l p 5000 w w 0 0 0 0 2 w 0 0 0 2 1 900 w w 0 0 4 4 w 0 0 0 3 1250 w w 0 0 0 5 w 0 0 0 3 1250 w w 0 0 4 4 w 0 0 0 3 1250 w w 0 0 3 2 w 0 0 9 1 700 w w 0 5 1 1 w 0 5 9 1300 w w 0 0 3 3 w 0 0 0 3 1250 w ...

Page 89

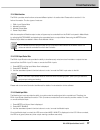

11. Technical specifications plm+ series operation manual rev 3.0.1 89 4 4 k 0 2 m l p 4 4 k 2 1 m l p 4 4 k 5 m l p amplifier gain b d 1 . 0 e z i s p e t s , b d 4 4 - 2 2 b d 5 2 . 0 e z i s p e t s , b d 0 o t f n i - r o t a u n e t t a l a ti g i d rear-panel interface d e c n a l a b y ll a c...

Page 90

12. Warranty and support 90 plm+ series operation manual rev 3.0.1 12. Warranty and support 12.1. General this product is manufactured by lab.Gruppen, and it is warranted to be free from any defects caused by components or factory workmanship, under normal use and service, for a period of ten (10) y...

Page 91

12. Warranty and support plm+ series operation manual rev 3.0.1 91 12.3.2. Factory service in the event a lab.Gruppen product requires factory service, you may contact lab.Gruppen’s service department for return instructions and a return authorization number. Please note for product return: 1. Use t...

Page 92

Intercooler, class td and lake are national and/or international registered trademarks of lab.Gruppen ab. Plm+, powered loudspeaker management, r.Smps, loadlibrary, loadsmart, speakersafe, isvpl, bel, uvl and cal are trademarks of lab.Gruppen ab. Dolby is a registered trademark of dolby laboratories...