- DL manuals

- Labconco

- Air Cleaner

- 3970200

- User Manual

Labconco 3970200 User Manual

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

labconco@labconco.com

HOME PAGE www.labconco.com

To receive important product updates,

complete your product registration card

online at register.labconco.com

User’s Manual

Purifier

®

Vertical Clean Benches

Models

3970200, 3970201, 3970203, 3970204, 3970220, 3970221,

3970223, 3970224, 3970300, 3970301, 3970303, 3970304,

3970320, 3970321, 3970323, 3970324, 3970400, 3970401,

3970403, 3970404, 3970420, 3970421, 3970423, 3970424

Please read the User’s Manual before operating the equipment

.

Summary of 3970200

Page 1

Labconco corporation 8811 prospect avenue kansas city, mo 64132-2696 800-821-5525, 816-333-8811 fax 816-363-0130 e-mail labconco@labconco.Com home page www.Labconco.Com to receive important product updates, complete your product registration card online at register.Labconco.Com user’s manual purifie...

Page 2

Copyright © 2004, 2007 labconco corporation. All rights reserved. The information contained in this manual and the accompanying products are copyrighted and all rights reserved by labconco corporation. Labconco corporation reserves the right to make periodic design changes without obligation to noti...

Page 3

T t a a b b l l e e o o f f c c o o n n t t e e n n t t s s chapter 1: introduction 1 iso class 5 definition 2 about this manual 2 typographical conventions 3 chapter 2: prerequisites 5 support, vibration & movement requirements 6 location and air current requirements 6 airflow specifications 6 elec...

Page 4

Setting the downflow velocity with the speed control adjustment 32 calibrate and operate the airflow monitor 32 initial certification 36 re-certification 36 fluorescent light replacement 36 uv light replacement (if equipped) 37 motorized impeller replacement 37 speed control replacement 39 chapter 7...

Page 5

1 product service 1-800-522-7658 c c h h a a p p t t e e r r 1 1 i i n n t t r r o o d d u u c c t t i i o o n n congratulations on your purchase of a labconco purifier® vertical clean bench. Your enclosure provides product protection. It is the result of labconco’s more than 30 years experience in ...

Page 6: Iso Class 5 Definition

2 chapter 1: introduction product service 1-800-522-7658 iso class 5 definition airborne particulate cleanliness inside any clean bench or enclosure is designated by iso class 5, which is equivalent to 3520 particles 0.5 µm or larger per cubic meter of air per iso standard 14644-1. Iso class 5 clean...

Page 7: Typographical Conventions

3 chapter 1: introduction product service 1-800-522-7658 chapter 4: performance features and safety precautions explains how the purifier vertical clean bench operates and the appropriate precautions you should take when using it. Chapter 5: appropriate applications for your vertical clean bench dis...

Page 8

4 chapter 1: introduction product service 1-800-522-7658 with the information following an exclamation icon may result in injury to the user or permanent damage to the enclosure. • critical information is presented in boldface type in paragraphs that are preceded by the wrench icon. Only a trained c...

Page 9

5 product service 1-800-522-7658 c c h h a a p p t t e e r r 2 2 p p r r e e r r e e q q u u i i s s i i t t e e s s before you install the vertical clean bench, you need to prepare your site for installation. You must be certain that the area is level and of solid construction. In addition, a dedic...

Page 10: Requirements

6 product service 1-800-522-7658 chapter 2: prerequisites support, vibration and movement requirements at a minimum, the supporting structure usually consists of a base cabinet or base stand and chemically-resistant work surface. Location and air current requirements purifier vertical clean benches ...

Page 11: Electrical Requirements

7 chapter 2: prerequisites product service 1-800-522-7658 enclosure width model description downflow velocity (fpm) out- flow exhaust volume (cfm) noise pressure db(a) average outflow face velocity (fpm) 2' 2' vertical clean bench 30 40 50 60 120 165 210 250 53-57 58-60 60-61 62-63 85 115 145 170 3'...

Page 12

8 product service 1-800-522-7658 c c h h a a p p t t e e r r 3 3 g g e e t t t t i i n n g g s s t t a a r r t t e e d d now that the site for your vertical clean bench is properly prepared, you are ready to unpack, inspect, install, and validate your clean bench. Read this chapter to learn how to: ...

Page 13: Unpacking The Clean Bench

9 chapter 3: getting started product service 1-800-522-7658 unpacking the clean bench carefully remove the shrink-wrap or carton on the clean bench and inspect it for damage that may have occurred in transit. If damaged, notify the delivery carrier immediately and retain the entire shipment intact f...

Page 14

10 product service 1-800-522-7658 chapter 3: getting started the work surface should be at least as wide and deep as the enclosure to properly support it. The front of the clean bench should be aligned within 0.30" (8 mm) of the front of the work surface. Mounting holes are provided in the labconco ...

Page 15

11 chapter 3: getting started product service 1-800-522-7658 figure 3-1 vertical clean bench installation.

Page 16: Source to The Vertical Clean

12 product service 1-800-522-7658 chapter 3: getting started verifying hepa filter integrity the hepa filter is shipped installed with the gasket on the downstream side. The hepa filter is leak checked at labconco. A second leak check is recommended before using the enclosure and at least annually t...

Page 17: With The Speed Control

13 chapter 3: getting started product service 1-800-522-7658 setting the downflow velocity with the speed control adjustment adjustment of the speed control gives the correct downflow velocity and is located behind the front panel. The downflow velocity should be from 30-65 fpm for class 100 (iso cl...

Page 18: To The Work Surface

14 product service 1-800-522-7658 chapter 3: getting started the downflow test grid consists of 15 test points, 5 points in 3 rows. The back row of the grid is 6" from the rear of the work area. The middle and front rows are 6.57" apart from the back to the front. The first and last column of the do...

Page 19

15 product service 1-800-522-7658 c c h h a a p p t t e e r r 4 4 p p e e r r f f o o r r m m a a n n c c e e f f e e a a t t u u r r e e s s a a n n d d s s a a f f e e t t y y p p r r e e c c a a u u t t i i o o n n s s the purifier vertical clean bench is designed to provide product protection on...

Page 20

16 chapter 4: performance features and safety precautions product service 1-800-522-7658 figure 4-1 10 6 9 located behind 4 2 1 8 located behind control panel 5 12.

Page 21

17 chapter 4: performance features and safety precautions product service 1-800-522-7658 figure 4-2 vertical clean bench airflow diagram figure 4-2 vertical clean bench airflow diagram 19 13 6 airflow switch with adjustment screw 15 optional uv light (not shown) 4 7 11 18 1 17.

Page 22

18 chapter 4: performance features and safety precautions product service 1-800-522-7658 figure 4-3 optional uv sash closure 16.

Page 23

19 chapter 4: performance features and safety precautions product service 1-800-522-7658 1. Aerodynamic lower air foil allows air to sweep the work surface and promote iso class 5 air conditions inside the enclosure. See figure 4-1. 2. Ergonomic slope of 10 degrees provides maximum visibility and co...

Page 24: Safety Precautions

20 chapter 4: performance features and safety precautions product service 1-800-522-7658 11. Filter clamping bolt evenly seals the hepa filter to the frame of the enclosure. See figure 4-1 and 4-2. 12. Control panel . The control panel, which is located above the sash, contains the filter pressure g...

Page 25

21 chapter 4: performance features and safety precautions product service 1-800-522-7658 2. Use good housekeeping in the clean bench at all times. Clean up spills immediately. Periodically clean clean bench interior. 3. Do not overload the work surface with apparatus or work material. 4. The purifie...

Page 26

22 chapter 4: performance features and safety precautions product service 1-800-522-7658 15. The surface of the hepa filter is fragile and should not be touched. Care must be taken to avoid puncturing the hepa filter during maintenance. If you suspect that a hepa filter has been damaged do not use t...

Page 27

23 product service 1-800-522-7658 c c h h a a p p t t e e r r 5 5 a a p p p p r r o o p p r r i i a a t t e e a a p p p p l l i i c c a a t t i i o o n n s s f f o o r r y y o o u u r r v v e e r r t t i i c c a a l l c c l l e e a a n n b b e e n n c c h h now that the installation of your vertical...

Page 28: Suitable Applications

24 chapter 5: appropriate applications for your vertical clean bench product service 1-800-522-7658 • wear a long sleeved lab coat, rubber gloves and protective eyewear. Wear a protective mask if appropriate. Consult your safety officer for additional personal protective equipment recommendations. •...

Page 29: Hepa Filter Applications,

25 chapter 5: appropriate applications for your vertical clean bench product service 1-800-522-7658 listed below are suitable applications for hepa filters. Hepa filter applications, suitability and guidelines • procedures traditionally performed on an open bench where a clean class 5 air environmen...

Page 30

26 product service 1-800-522-7658 c c h h a a p p t t e e r r 6 6 m m a a i i n n t t a a i i n n i i n n g g y y o o u u r r v v e e r r t t i i c c a a l l c c l l e e a a n n b b e e n n c c h h monitoring airflow and changing the filters are the primary maintenance required. Certification and re...

Page 31: Routine Maintenance Schedule

27 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 routine maintenance schedule weekly • wipe down the interior surfaces of the enclosure with a disinfectant or cleaner, depending upon the usage of the unit and allow to dry. • using a damp cloth, clean the exterior su...

Page 32

28 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 installations and usage, the hepa filters will last two to five years before requiring replacement. Replace hepa filters when downflow velocity drops below the recommended 30-65 fpm velocity and the speed control is a...

Page 33

29 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 figure 6-1 hepa filter changing diagram & filter leak test diagram speed control adjustment screw front panel gasket gasket side down as shown hepa filter hepa filter sealing surface prefilter filter clamp bolt.

Page 34: Hepa Filter Leak Test

30 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 hepa filter leak test purpose after installing the new hepa filter, the hepa filter should be leak checked. This test is performed to determine the integrity of the hepa filter, the filter housing, and the filter seal...

Page 35

31 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 4. Using the “^” or “ ν ” keypads, respectively, increase or decrease the numerical value until it equals 30 (2'), 20 (3'). 15 (4') for the purifier vertical clean bench enclosure at 55 fpm downflow velocity. 5. Press...

Page 36: With The Speed Control

32 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 setting the downflow velocity with the speed control adjustment 1. Remove the front panel by loosening the (2) phillips screws on top that secure the front panel. 2. The speed control is located on the electrical suba...

Page 37

33 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 the “silence alarm” button is pressed, the audio alarm will be silenced, but the red “alert” led will remain on. The alarm is silenced indefinitely unless an airflow change is detected. If safe airflow is later detect...

Page 38

34 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 6. Over time the hepa filter will load and eventually slow the downflow velocity. Once the alarm condition is met, simply increase the speed control as outlined in chapter 6 or replace the hepa filter if the speed con...

Page 39

35 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 figure 6-2 guardian airflow monitor with airflow switch light reflector speed control airflow monitor led circuit board airflow switch with adjustment screw control panel green “safe” led silence alarm button with tes...

Page 40: Initial Certification

36 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 initial certification the purifier vertical clean bench has been certified at the factory for an average downflow velocity of 40-55 fpm along with the hepa filter leak test. The purifier vertical clean bench should be...

Page 41: Uv Light Replacement (If

37 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 uv light replacement (if equipped) 1. Disconnect the power. 2. Locate the uv lamp located inside the enclosure. 3. Rotate and remove the old uv lamp. 4. Reinstall the new uv lamp. 5. Power the unit up and try the new ...

Page 42

38 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 figure 6-3 motorized impeller replacement 2' model motorized impeller wire access hole impeller mounting bracket hardware front panel mounting screws for motorized impeller hepa filter capacitor mounted here on electr...

Page 43: Speed Control Replacement

39 chapter 6: maintaining your vertical clean bench product service 1-800-522-7658 speed control replacement 1. Remove the bracket that the speed control is attached to. See figures 6-1, and 6-2. 2. Remove the two screws holding the speed control using a phillips screwdriver. Refer to appendix a for...

Page 44

40 product service 1-800-522-7658 c c h h a a p p t t e e r r 7 7 a a c c c c e e s s s s o o r r i i z z i i n n g g a a n n d d m m o o d d i i f f y y i i n n g g y y o o u u r r v v e e r r t t i i c c a a l l c c l l e e a a n n b b e e n n c c h h there are several ways to accessorize and modi...

Page 45

41 chapter 7: accessorizing and modifying your vertical clean bench product service 1-800-522-7658 2. Guardian™ airflow monitor the guardian airflow monitor allows you to continuously monitor airflow through the clean bench. The guardian monitor can be placed on any purifier vertical clean bench. De...

Page 46

42 chapter 7: accessorizing and modifying your vertical clean bench product service 1-800-522-7658 4. Storage cabinets and stands solvent acid size/description dual doors right hinge left hinge dual doors right hinge left hinge 48" 9902000 - - 9901000 - - 36" 9902100 - - 9901100 - - 30" 9902200 - - ...

Page 47

43 chapter 7: accessorizing and modifying your vertical clean bench product service 1-800-522-7658 5. Iv bar kits for pharmacy applications, iv bar kits support intravenous bottles and bags. 3721000 2' iv bar kit 3721001 3' iv bar kit 3721002 4' iv bar kit.

Page 48

44 product service 1-800-522-7658 c c h h a a p p t t e e r r 8 8 t t r r o o u u b b l l e e s s h h o o o o t t i i n n g g a a n n d d s s e e r r v v i i c c e e r r o o p p e e r r a a t t i i n n g g l l o o g g refer to the following table if your vertical clean bench fails to operate properl...

Page 49

45 chapter 8: troubleshooting product service 1-800-522-7658 problem cause corrective action blower won’t operate. Unit not plugged into outlet. Plug the enclosure into appropriate electrical service. Circuit breaker(s) or ground fault interrupter. Reset circuit breaker. Blower wiring is disconnecte...

Page 50

46 chapter 8: troubleshooting product service 1-800-522-7658 problem cause corrective action airflow monitor malfunction (continued) wrong alarm set point. Airflow monitor was not properly adjusted. Repeat calibration steps outlined in this manual in chapter 6. Constant audible alarm. Check airflow ...

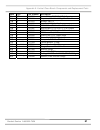

Page 51: Service Operating Record Log

47 chapter 8: troubleshooting product service 1-800-522-7658 service operating record log customer name model number date installed serial number unit location date comments.

Page 52

48 product service 1-800-522-7658 a a p p p p e e n n d d i i x x a a v v e e r r t t i i c c a a l l c c l l e e a a n n b b e e n n c c h h c c o o m m p p o o n n e e n n t t s s a a n n d d r r e e p p l l a a c c e e m m e e n n t t p p a a r r t t s s the components that are available for your...

Page 53

49 appendix a: vertical clean bench components and replacement parts product service 1-800-522-7658 item qty. Part number description 1 1 3911000 glass, side 2a 1 3911900 glass, sash 2' 2b 1 3911901 glass, sash 3' 2c 1 3911902 glass, sash 4' 3a 1 3938900 sash assembly, 2' 3b 1 3938901 sash assembly,...

Page 54

50 appendix a: vertical clean bench components and replacement parts product service 1-800-522-7658 item qty. Part number description 17a 1 3937900 wiring harness main, 115v, 2' 17b 1 3937901 wiring harness main, 230v, 2' 17c 1 3938000 wiring harness, 115v, 3' and 4' 17d 1 3938001 wiring harness, 23...

Page 55

51 appendix a: vertical clean bench components and replacement parts product service 1-800-522-7658 item qty. Part number description 30 10 1893712 screw, #10 x .75 ph phil. Thd. Forming 31a 2 1881196 capscrew, 3/8 –16 x 6.0 lg. Hx. Hd. 31b 4 1911018 washer, flat 3/8 31c 2 1906925 nut, hex 3/8 nylon...

Page 56

52 appendix a: vertical clean bench components and replacement parts product service 1-800-522-7658 figure a-1 replacement parts, purifier vertical clean benches 26 fluorescent 24 25 27 uv 23 15 14 40 7 13 18 35, 36 not shown 28 31 32 20 29 30 11 16 9 10 1 6 3 2 4 5 17 19 12, not shown 22.

Page 57

53 product service 1-800-522-7658 a a p p p p e e n n d d i i x x b b d d i i m m e e n n s s i i o o n n s s see the following dimensions for the purifier vertical clean benches..

Page 58

54 appendix b: dimensions product service 1-800-522-7658 figure b-1 purifier vertical clean bench.

Page 59

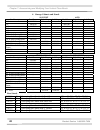

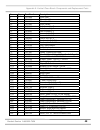

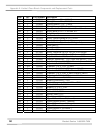

55 product service 1-800-522-7658 a a p p p p e e n n d d i i x x c c v v e e r r t t i i c c a a l l c c l l e e a a n n b b e e n n c c h h s s p p e e c c i i f f i i c c a a t t i i o o n n s s this appendix contains technical information about all the purifier vertical clean benches including e...

Page 60

56 appendix c: vertical clean bench specifications product service 1-800-522-7658 c-1.

Page 61

57 appendix c: vertical clean bench specifications product service 1-800-522-7658 c-2.

Page 62

58 appendix c: vertical clean bench specifications product service 1-800-522-7658 c-3.

Page 63

59 appendix c: vertical clean bench specifications product service 1-800-522-7658 c-4.

Page 64

60 product service 1-800-522-7658 a a p p p p e e n n d d i i x x d d r r e e f f e e r r e e n n c c e e s s many excellent reference texts and booklets are currently available. The following is a brief listing: bryan, d., and r.C. Marback. 1984. Laminar-airflow equipment certification: what the ph...

Page 65: Declaration of Conformity

61 product service 1-800-522-7658 declaration of conformity application council directive(s): 73/23/eec, 89/336/eec standard(s) to which conformity is declared: en61010, en55022, en50082-1 manufacturer’s name: labconco corporation manufacturer’s address: 8811 prospect avenue kansas city, mo 64132 us...