- DL manuals

- Labconco

- Enclosure

- 69632 Series

- User Manual

Labconco 69632 Series User Manual

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

labconco@labconco.com

HOME PAGE www.labconco.com

To receive important product updates,

complete your product registration card

online at register.labconco.com

User’s Manual

Paramount

®

Ductless Enclosures

Models

69632 Series, 2' Widths

69633 Series, 3' Widths

69634 Series, 4' Widths

69635 Series, 5' Widths

69636 Series, 6' Widths

Please read the User’s Manual before operating the equipment.

Summary of 69632 Series

Page 1

Labconco corporation 8811 prospect avenue kansas city, mo 64132-2696 800-821-5525, 816-333-8811 fax 816-363-0130 e-mail labconco@labconco.Com home page www.Labconco.Com to receive important product updates, complete your product registration card online at register.Labconco.Com user’s manual paramou...

Page 2

Copyright © 2008, 2009, 2010 labconco corporation. All rights reserved. The information contained in this manual and the accompanying products are copyrighted and all rights reserved by labconco corporation. Labconco corporation reserves the right to make periodic design changes without obligation t...

Page 3

T t a a b b l l e e o o f f c c o o n n t t e e n n t t s s chapter 1: introduction 1 chapter 2: prerequisites 3 support and stability requirements 3 location and air current requirements 4 exhaust and blower requirements 4 electrical requirements 6 space requirements 6 chapter 3: getting started 7 ...

Page 4

Maximum visibility 21 simple electrical connection 21 safety precautions 21 misapplications that could result in a hazardous situation 24 chapter 5: using the ductless enclosure 25 information center 25 status area 26 operating the pivoting sash 26 starting the ductless enclosure 26 the paramount to...

Page 5

Chapter 7: accessorizing the ductless enclosure 50 filters 50 work surfaces 51 work surface with deck mounted valves, gooseneck, and cupsink 52 base stands, accessory shelves, seismic supports and hydraulic lift base stands 53 storage cabinets 54 exhaust transitions 55 remote blowers 56 exhaust damp...

Page 6

Product service 1-800-522-7658 1 c c h h a a p p t t e e r r 1 1 : : i i n n t t r r o o d d u u c c t t i i o o n n congratulations on the purchase of a labconco paramount ® ductless enclosure, commonly called a ductless fume hood. Unlike traditional fume hoods, the paramount ductless enclosure is ...

Page 7

Chapter 1: introduction product service 1-800-522-7658 2 even if you are an experienced ductless enclosure user, please review chapter 5: using the ductless enclosure; it describes the paramount ductless enclosure features so that you can use it efficiently and effortlessly. The paramount ductless e...

Page 8

Product service 1-800-522-7658 3 c c h h a a p p t t e e r r 2 2 : : p p r r e e r r e e q q u u i i s s i i t t e e s s before you install the paramount ductless enclosure, you need to prepare your site for installation. A dedicated source of electrical power should be located near the installation...

Page 9

Chapter 2: prerequisites product service 1-800-522-7658 4 location and air current requirements the paramount ductless enclosures have been designed to contain hazards by negating typical cross drafts and turbulence within the opening. However, it is recommended that the enclosure be placed in an ar...

Page 10

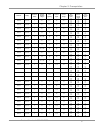

Chapter 2: prerequisites product service 1-800-522-7658 5 model no. Voltage enclosure width internal working height sash opening exterior depth exterior height face velocity (fpm) airflow exhaust volume (cfm) noise pressure (dba) 6963200 100-115v 2' 22.7" 9.4" 29" 43.7" 60 80 100 85 115 145 50 54 59...

Page 11: Electrical Requirements

Chapter 2: prerequisites product service 1-800-522-7658 6 electrical requirements standard duplex electrical receptacles should be nearby for connecting the paramount ductless enclosure and other equipment. The enclosures include iris pass-through ports to allow electrical cords through the back of ...

Page 12

Product service 1-800-522-7658 7 c c h h a a p p t t e e r r 3 3 : : g g e e t t t t i i n n g g s s t t a a r r t t e e d d now that the site for your paramount ductless enclosure is properly prepared, you are ready to unpack, inspect, install, and validate your system. Read this chapter to learn h...

Page 13: Unpacking The Enclosure

Chapter 3: getting started product service 1-800-522-7658 8 unpacking the enclosure we recommend that you do not remove the enclosure from its shipping container until it is ready to be placed into its final location. Move the unit by placing a flat, low dolly under the shipping skid, or by using a ...

Page 14

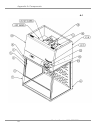

Chapter 3: getting started product service 1-800-522-7658 9 work surface and enclosure installation 1. Level the base cabinets and the work surface. Work surface should be placed flush with the front of the stand or base cabinet as shown in figure 3-1. 2. Identify and position the work surface ensur...

Page 15

Chapter 3: getting started product service 1-800-522-7658 10 figure 3-1 paramount ductless enclosure installation.

Page 16

Chapter 3: getting started product service 1-800-522-7658 11 install carbon filters and/or hepa filters refer to figure 3-2 for a view of the filter loading compartment with the front panel removed. The paramount ductless enclosure ships without filters that must be ordered separately. It is highly ...

Page 17

Chapter 3: getting started product service 1-800-522-7658 12 to install the filters, push the stacked filters to the stop in the rear of each filter compartment. After loading the stacked filters into the compartments, close the gas spring cylinders by pulling the handle down and compressing the fil...

Page 18: Initial Safety-First

Chapter 3: getting started product service 1-800-522-7658 13 initial safety-first ™ vapor sensor warm up period the safety-first ™ vapor sensor includes a 5v, 0.28w integrated heater and any detectable gas that accumulates during shipment must be driven off the organic sensor over an initial 10-30 m...

Page 19: Validate The Enclosure

Chapter 3: getting started product service 1-800-522-7658 14 validate the enclosure to determine the actual face velocity at the sash opening, airflow velocity readings are taken. Each paramount ductless enclosure has been preset at 75-80 fpm. The “average face velocity” is achieved by taking readin...

Page 20

Product service 1-800-522-7658 15 c c h h a a p p t t e e r r 4 4 : : p p e e r r f f o o r r m m a a n n c c e e f f e e a a t t u u r r e e s s a a n n d d s s a a f f e e t t y y p p r r e e c c a a u u t t i i o o n n s s the paramount ductless enclosure is a self-contained filtered enclosure th...

Page 21

Chapter 4: performance features and safety precautions product service 1-800-522-7658 16 figure 4-1 performance features.

Page 22: High Performance Containment

Chapter 4: performance features and safety precautions product service 1-800-522-7658 17 high performance containment the paramount ductless enclosures use patented technology to direct air into and through the contaminated air chamber (u.S. Patent 6,461,233). The containment enhancing and aerodynam...

Page 23: Safety-First™ Vapor Sensor

Chapter 4: performance features and safety precautions product service 1-800-522-7658 18 safety-first™ vapor sensor the safety-first™ vapor sensor detects filter saturation in the exhaust to alert the operator to replace the filters. The early warning provided by the safety-first vapor sensor provid...

Page 24: Audible/visual Alarms

Chapter 4: performance features and safety precautions product service 1-800-522-7658 19 smart-flow™ airflow monitor the smart-flow™ airflow monitor continuously monitors airflow and displays face velocity. An audible/visual alarm alerts the user to low airflow conditions. The smart-flow airflow mon...

Page 25: Ergonomic Sloped Front

Chapter 4: performance features and safety precautions product service 1-800-522-7658 20 ergonomic sloped front the ergonomic slope provides maximum visibility and comfort, reduces glare, thereby minimizing operator fatigue. The space saving design (u.S. Patent no. D538,941) increases effective labo...

Page 26: Maximum Visibility

Chapter 4: performance features and safety precautions product service 1-800-522-7658 21 maximum visibility visibility is maximized on all units with at least 270 degree visibility from both sides and the front pivoting sash. Some 3' and 4' models have 360 degree visibility which is especially usefu...

Page 27

Chapter 4: performance features and safety precautions product service 1-800-522-7658 22 9. Avoid cross drafts and limit traffic in front of the enclosure. Air disturbances created may draw contaminants out of the enclosure. 10. A qualified certification technician should test the enclosure before i...

Page 28

Chapter 4: performance features and safety precautions product service 1-800-522-7658 23 23. Use the smallest possible quantity of chemical(s) within the enclosure and never exceed the amount which can be effectively adsorbed by the filters before breakthrough. 24. Leave the blower on for at least o...

Page 29: Hazardous Situation

Chapter 4: performance features and safety precautions product service 1-800-522-7658 24 misapplications that could result in a hazardous situation there is one scenario where the paramount’s misapplication could be a part of a hazardous condition. That situation is where; 1. The inlet concentration...

Page 30: Information Center

Product service 1-800-522-7658 25 c c h h a a p p t t e e r r 5 5 : : u u s s i i n n g g t t h h e e d d u u c c t t l l e e s s s s e e n n c c l l o o s s u u r r e e information center the information center is an lcd display located on the control panel. The center’s display is divided into thr...

Page 31: Status Area

Chapter 5: using the ductless enclosure product service 1-800-522-7658 26 status area the lcd displays the paramount ductless enclosure’s condition during operation such as the filter types, face velocity, and bar graph to display the remaining filter life in hours. This line can display any of the ...

Page 32: The Paramount Touchpad

Chapter 5: using the ductless enclosure product service 1-800-522-7658 27 the paramount touchpad the touchpad of the paramount ductless enclosure is shown below. Take a moment to get familiar with the buttons, their location and function. Also familiarize yourself with the display located on the fro...

Page 33

Chapter 5: using the ductless enclosure product service 1-800-522-7658 28 all program screens.

Page 34

Chapter 5: using the ductless enclosure product service 1-800-522-7658 29 main setup screens.

Page 35

Chapter 5: using the ductless enclosure product service 1-800-522-7658 30 filter setup program screens.

Page 36

Chapter 5: using the ductless enclosure product service 1-800-522-7658 31 calibration program screens.

Page 37

Chapter 5: using the ductless enclosure product service 1-800-522-7658 32 diagnostic program screens pressure sensor diagnostic notes: x20 cal example represents a pressure of 134 with the impeller off and 212 with the motor speed at 157 producing 90 fpm for this calibration example. With smart flow...

Page 38: User Selectable Features

Chapter 5: using the ductless enclosure product service 1-800-522-7658 33 user selectable features the paramount ductless enclosure offers the user unsurpassed flexibility and convenience. To access the menu, press the “menu” button. The lcd display panel will show the first level menu. To select fr...

Page 39: Blower Operation

Chapter 5: using the ductless enclosure product service 1-800-522-7658 34 light lamp timer and blower timer both timers allow you to decide whether the fluorescent lamp or blower will operate continuously or for a limited time period that you select. This may be desired for energy-savings as well as...

Page 40

Chapter 5: using the ductless enclosure product service 1-800-522-7658 35 filter setup display options this menu selection determines which filters are loaded and displayed in the lower and upper positions. One of seven filter types must be selected for each filter position. The filter check time an...

Page 41

Chapter 5: using the ductless enclosure product service 1-800-522-7658 36 if a check airflow activates the most common causes of a check airflow alarm are: • blockage of the inlet perforated baffle or exhaust outlet. • loading or blockage of the filters resulting in low airflow. • motorized impeller...

Page 42

Chapter 5: using the ductless enclosure product service 1-800-522-7658 37 work techniques • keep all materials a minimum of 4 inches (100 mm) from the inside of the lower air foil, and perform all contaminated operations as far to the rear of the work area as possible. • segregate all clean and cont...

Page 43

Product service 1-800-522-7658 38 c c h h a a p p t t e e r r 6 6 : : m m a a i i n n t t a a i i n n i i n n g g t t h h e e d d u u c c t t l l e e s s s s e e n n c c l l o o s s u u r r e e replacing the carbon filters, hepa filters, and fluorescent light is the primary routine maintenance requi...

Page 44

Chapter 6: maintaining the ductless enclosure product service 1-800-522-7658 39 quarterly (or more often as required) • note the airflow velocity on the display. Determine the actual airflow face velocity through the sash opening of the enclosure where the average reading should be at the specified ...

Page 45

Chapter 6: maintaining the ductless enclosure product service 1-800-522-7658 40 there are five means of determining when its time to change the carbon filters (not shown in the order of preference). Odor - a person’s sensitivity to odor, tolerance of odor and their comfort level under odoriferous co...

Page 46

Chapter 6: maintaining the ductless enclosure product service 1-800-522-7658 41 inserted between the stacked filters to sample the lower filter or inserted through the holes in the blower exhaust cover to sample both filters. Connect the syringe to the detector tube while the system is running and p...

Page 47: Hepa Filter Leak Test

Chapter 6: maintaining the ductless enclosure product service 1-800-522-7658 42 install carbon filters and/or hepa filters refer to the instructions in chapter 3 on filter installation during startup. Set filter life and filter check timers refer to the instructions in chapter 3 on setting the filte...

Page 48

Chapter 6: maintaining the ductless enclosure product service 1-800-522-7658 43 procedure for the ati 2g photometer 1. Turn on the photometer and allow it to operate for a minimum of 5 minutes. Leave the valve in the “clear” setting. 2. Press the “enter” keypad. Press the “ref” keypad. 3. The displa...

Page 49: Initial Certification

Chapter 6: maintaining the ductless enclosure product service 1-800-522-7658 44 change the airflow face velocity (if necessary) the paramount has been tested and shipped at a face velocity of 75-80 fpm. If necessary, refer to the instructions in chapter 3 to change the face velocity. Refer to the “c...

Page 50

Chapter 6: maintaining the ductless enclosure product service 1-800-522-7658 45 figure 6-1 light replacement fluorescent light replacement 1. Disconnect the power. 2. Locate the small light reflector located under the control panel shown in figure 6-1. 3. Remove the light reflector by removing two p...

Page 51

Chapter 6: maintaining the ductless enclosure product service 1-800-522-7658 46 figure 6-2 light replacement.

Page 52

Chapter 6: maintaining the ductless enclosure product service 1-800-522-7658 47 motorized impeller replacement the motorized impeller (ecm) must be replaced as a complete unit; it has over 50,000 hours of useful life as tested. See appendix a for replacement parts diagram. See figure 6-3 for a view ...

Page 53

Chapter 6: maintaining the ductless enclosure product service 1-800-522-7658 48 main control board replacement if the main control board is replaced, the paramount must be calibrated per the menu screens in chapter 5. See appendix a: replacement parts, and reference figure 6-4. 1. Consult the wiring...

Page 54

Chapter 6: maintaining the ductless enclosure product service 1-800-522-7658 49 organic sensor board replacement if the organic sensor board is replaced, the paramount must be calibrated for the “organic sensor.” contact labconco product service. See appendix a: replacement parts and reference figur...

Page 55

Product service 1-800-522-7658 50 c c h h a a p p t t e e r r 7 7 : : a a c c c c e e s s s s o o r r i i z z i i n n g g t t h h e e d d u u c c t t l l e e s s s s e e n n c c l l o o s s u u r r e e there are several ways to accessorize and/or modify the ductless enclosure for your individual req...

Page 56

Chapter 7: accessorizing the ductless enclosure product service 1-800-522-7658 51 2. Work surfaces an optional work surface is available to attach to the ductless enclosure. The black epoxy work surfaces are contoured to fit the dimensions of the ductless enclosures to contain spills. The stainless ...

Page 57

Chapter 7: accessorizing the ductless enclosure product service 1-800-522-7658 52 3. Work surface with deck mounted valves, gooseneck, and cupsink the work surfaces supplied with deck mounted valves allow the convenience of water, air, and vacuum along with a cupsink and cold water gooseneck fixture...

Page 58

Chapter 7: accessorizing the ductless enclosure product service 1-800-522-7658 53 4. Base stands, accessory shelves, seismic supports, and hydraulic lift base stands the following base stands, hydraulic lift base stands, accessory shelves, and seismic supports may be used with the accessory work sur...

Page 59

Chapter 7: accessorizing the ductless enclosure product service 1-800-522-7658 54 5. Storage cabinets the following storage cabinets may be used with the accessory work surfaces to support the paramount ductless enclosures. Solvent acid size/description dual doors right hinge left hinge dual doors r...

Page 60

Chapter 7: accessorizing the ductless enclosure product service 1-800-522-7658 55 6. Exhaust transitions canopy exhaust transitions connect each motorized impeller for ducting to the outside. The canopy exhaust transition is available for 6" nominal duct (6' paramount requiring two). The canopy exha...

Page 61

Chapter 7: accessorizing the ductless enclosure product service 1-800-522-7658 56 7. Remote blowers – used to exhaust to the outside only. 6" nominal id inlet blower has a 1/4 hp direct drive motor and corrosion-resistant epoxy-coated steel housing and wheel with blower inlet of 6.00" id. Outlet dim...

Page 62

Chapter 7: accessorizing the ductless enclosure product service 1-800-522-7658 57 8. Exhaust dampers exhaust dampers allow adjustments required to maintain proper airflow for roof-mounted blowers or house exhaust systems. Catalog # description 3924000 6" epoxy coated steel in-line adjustable damper ...

Page 63

Chapter 7: accessorizing the ductless enclosure product service 1-800-522-7658 58 11. Sash closures all paramount ductless enclosures have a standard sash opening at the bottom consisting of 9.4" or 12". Sometimes it is necessary to close the lower sash opening during operating procedures. The sash ...

Page 64

Product service 1-800-522-7658 59 c c h h a a p p t t e e r r 8 8 : : t t r r o o u u b b l l e e s s h h o o o o t t i i n n g g refer to the following table if your ductless enclosure fails to operate properly. If the suggested corrective actions do not solve your problem, contact labconco for add...

Page 65

Chapter 8: troubleshooting product service 1-800-522-7658 60 problem cause corrective action organic sensor alarms intermittently and display reads “replace filters-s”, s = organic sensor organic sensor has detected filter breakthrough and only 5-10% of filter life remains. Replace filters with a sp...

Page 66

Chapter 8: troubleshooting product service 1-800-522-7658 61 problem cause corrective action lamp not installed properly. Inspect lamp installation. Lamp wiring disconnected. Inspect lamp wiring. Defective lamp. Replace lamp. Light switch is defective. Replace membrane switch on control panel. Light...

Page 67

Product service 1-800-522-7658 62 a a p p p p e e n n d d i i x x a a : : r r e e p p l l a a c c e e m m e e n n t t p p a a r r t t s s the components that are available for your ductless enclosure are listed. The parts shown are the most commonly requested. If other parts are required, please con...

Page 68

Appendix a: replacement parts product service 1-800-522-7658 63 item quantity part no. Description 9a 1 6964700 front panel, 2' 9b 1 6964701 front panel, 3' 9c 1 6964702 front panel, 4' 9d 1 6964703 front panel, 5' 9e 1 6964704 front panel, 6' 9f 1 6964101 label, front panel 10 1 6964100 membrane sw...

Page 69

Appendix a: components product service 1-800-522-7658 64 a-1.

Page 70

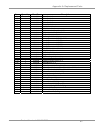

Product service 1-800-522-7658 65 a a p p p p e e n n d d i i x x b b : : p p a a r r a a m m o o u u n n t t d d i i m m e e n n s s i i o o n n s s models paramount description a b c d e f 6963200, -20 2' short 24.0 22.7 23.4 29.0 43.7 9.4 6963300, -20 3' short 36.0 22.7 23.4 29.0 43.7 9.4 6963301...

Page 71

Product service 1-800-522-7658 66 a a p p p p e e n n d d i i x x c c : : s s p p e e c c i i f f i i c c a a t t i i o o n n s s this appendix contains technical information about all the paramount ductless enclosures including electrical specifications and environmental operating conditions. Elect...

Page 72

Product service 1-800-522-7658 67 a a p p p p e e n n d d i i x x d d : : q q u u i i c c k k c c h h a a r r t t model no.’s 6963200, -20 6963300, -20 6963301, -02, -21, -22 6963400, -20 6963401, -02, -03, -21, -22, -23 6963501, -03, -21, -23 6963601, -03, -21, -23 model size 2' 3' 3' 4' 4' 5' 6' s...

Page 73

Product service 1-800-522-7658 68 a a p p p p e e n n d d i i x x e e : : e e s s t t i i m m a a t t e e d d f f i i l l t t e e r r l l i i f f e e c c a a l l c c u u l l a a t t i i o o n n the following examples are useful for estimating filter life so the filter life timers can be set properly...

Page 74

Appendix e: accessories product service 1-800-522-7658 69 2' (2 filters) 3' (4 filters) 4' & 5' (6 filters) 6' (8 filters) inlet concentration evap. Rate (ml/min) organic chemical spgr mw organic vapor adsorbed filter capacity estimated filter life estimated check life adsorbed weight adsorbed volum...

Page 75

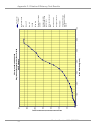

Product service 1-800-522-7658 70 a a p p p p e e n n d d i i x x f f : : f f i i l l t t r r a a t t i i o o n n e e f f f f i i c c i i e e n n c c y y t t e e s s t t r r e e s s u u l l t t s s ductless enclosures require filtration efficiency testing to validate performance. Independent testing...

Page 76

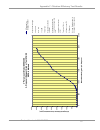

Appendix f: filtration efficiency test results product service 1-800-522-7658 71 3 ' para mount model # 6 96 330 0 a c e tone ( r ea gent grade ) te st 9 /10/08 s e fa 9 meth od 0 0.5 1 1.5 2 2.5 3 0 2 0 4 0 6 0 8 0 100 12 0 140 16 0 180 m a ss a d s o rb ed ( g ra m s) a ce to n e acet on e exhau s...

Page 77

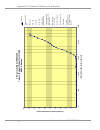

Appendix f: filtration efficiency test results product service 1-800-522-7658 72 0 20 40 60 80 10 0 12 0 14 0 0 1 00 2 00 300 40 0 50 0 6 00 7 00 m ass a d so rb ed (g ra ms) ethyl alc ohol ex haust conce ntr ation (ppm) eth yl al co h ol o r e tha nol 3' par am o u n t m o d e l # 696 33 00 et h yl...

Page 78

Appendix f: filtration efficiency test results product service 1-800-522-7658 73 3 ' paramount mode l # 696 330 0 2- propanol ( r e a ge nt grade) te st 9 /16 /08 sefa 9 met h od 0 50 10 0 15 0 20 0 25 0 30 0 35 0 40 0 45 0 0 5 00 1 00 0 1 50 0 2 000 25 00 30 00 m a ss a d s o rb ed ( g ra m s) 2- p...

Page 79

Appendix f: filtration efficiency test results product service 1-800-522-7658 74 3 ' para mount model # 696 33 00 tol uene (rea gen t g rade ) te st 9 /23/ 08 sef a 9 meth o d 0 10 20 30 40 50 60 70 80 90 10 0 0 50 0 10 00 15 00 20 00 25 00 m ass a d so rb ed ( g ra ms) t o luene tolue ne e xh aus t...

Page 80

Appendix f: filtration efficiency test results product service 1-800-522-7658 75 0 0. 5 1 1. 5 2 2. 5 3 3. 5 4 4. 5 0 5 00 10 00 15 00 20 00 25 00 30 00 ma ss a d so rb ed ( g rams ) hcl - ma ss ca lc u lat ed as 10 0% hcl hcl ex ha ust conce ntr atio n (p pm ) hcl m a ss c al cul at ed as 10 0% hcl...

Page 81

Product service 1-800-522-7658 76 declaration of conformity application council directive(s): 73/23/eec, 89/336/eec, 2002/95/ec (rohs), 2002/96/ec (weee), 2004/108/ec standard(s) to which conformity is declared: en61010-1, en61326-1, en55022, en61000-3-2/3 manufacturer’s name: labconco corporation m...