- DL manuals

- Labrie

- Trucks

- Top Select

- Operator's Manual

Labrie Top Select Operator's Manual

Summary of Top Select

Page 1

Maintenance manual cool grey 10 c blackc 2935 c top select tm operator manual.

Page 2: Elect

5/1/09 p art n umber : #90405 t op s elect ™ o perator m anual.

Page 4: Table of Contents

Part #: 90405 iii table of contents introduction liability ..................................................................................................... 1 introducing the t op s elect ™ ................................................................ 1 to contact labrie plus ...................

Page 5

Iv part #: 90405 safety features ....................................................................................... 36 global motion sensors (optional) ....................................... 36 troubleshooting and maintenance .................................................... 37 back up alar...

Page 6

Part #: 90405 v dashboard optional indicators ............................................................ 51 tailgate control ..................................................................................... 53 loading bucket control ................................................................

Page 7

Vi part #: 90405 chapter 3 operating the t op s elect ™ daily inspection ..................................................................................... 63 approaching the vehicle ...................................................... 63 visual inspection .........................................

Page 8

Part #: 90405 vii body unloading procedure .................................................................. 88 unloading corrective actions ............................................. 90 emergency unloading action .............................................. 90 maximizer operation ...............

Page 9

Viii part #: 90405.

Page 10: Ntroduction

Part #: 90405 1 i ntroduction l iability labrie environmental group assumes no liability for any incidental, consequential or other liability from the use of this information. All risks and damages, incidental or otherwise, arising from use or misuse of the information contained herein are entirely ...

Page 11: Contact

2 part #: 90405 t o contact l abrie p lus address 3630 stearns drive oshkosh, wi 54904 toll free: 1-800-231-2771 telephone: 1-920-233-2770 general fax:1-920-232-2498 sales fax: 1-920-232-2498 parts, service and warranty (during business hours, 7 am through 7 pm central standard time) technical suppo...

Page 12: Afety

Part #: 90405 3 s afety safety is always of prime importance when operating any type of equipment. All operators working with this unit must be aware of the safety practices and features detailed in this section. S afety is e veryone ’ s b usiness personnel are not to use the equipment if they are n...

Page 13: Mployer

4 part #: 90405 e mployer r esponsibility it is the employer’s responsibility to be familiar with and ensure that operation is in accordance with safety requirements and codes including all applicable regulations, including the occupational safety and health act (osha) and the american national stan...

Page 14: Eneral

Part #: 90405 5 5. The employee has the responsibility to report any damage or malfunction of the vehicle to his employer or his supervisor immediately. The employer will then take the necessary measures prior to the re-operation of the vehicle to insure its safe operation. 6. Do not operate this eq...

Page 15: ’

6 part #: 90405 d on ’ t 1. Do not operate any unit while under the influence of alcohol, narcotics or other intoxicants. 2. Do not talk on a cell phone and/or listen to loud music while driving. Cell phones and a loud radio can be a distraction that can have fatal consequences. 3. Do not wear jewel...

Page 16: Danger

Part #: 90405 7 s afety p recautions 1. Do not operate this vehicle before having read and completely understood this manual and the safety labels on the vehicle. Maintenance personnel must also read and understand the maintenance manual for this vehicle (and the maintenance related information in t...

Page 17: Warning

8 part #: 90405 warning w ear safety glasses , gloves and protective footwear at all times . Warning d o not climb into body compartments using the side bucket . Warning m ake sure that all people or any obstructions are sufficiently cleared from the loading bucket before moving it . F ailure to do ...

Page 18: Ire

Part #: 90405 9 f ire extinguisher the fire extinguisher provided is 5 lbs (minimum capacity). It must be checked regularly by qualified personnel. It is suggested that at least one abc type fire extinguisher be easily accessible from each side of the truck, inside or outside the cab. S afety k its ...

Page 19: Afety

10 part #: 90405 s afety d ecals l ocation d anger , w arning and c aution d ecals see accompanying illustrations for the location and content of safety decals. Note:decals may change depending on the special features installed on the unit, the type of body and the cab configuration. Pay careful att...

Page 20

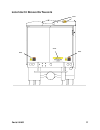

Part #: 90405 11 l ocation o f d ecals o n t ailgate 32307 47266 47266 47274.

Page 21

12 part #: 90405 l ocation o f d ecals i nside c ab (i nter ) right-hand side cab extension temporary handbrake control 43794 43982 43786 43850 47603 47426 32311 43790 43858 47276 43796 or 47394 or 47396 or 43956* 43986 or 47398 or 47400 or 47514* 43798 47440 47284 43792 43972 (not shown) * height d...

Page 22: ), C

Part #: 90405 13 l ocation o f d ecals i nside c ab (i nter ), c ontinued 43864 43866 or 43890

Page 23: (M2)

14 part #: 90405 l ocation o f d ecals i nside c ab (m2) 47426 32311 43790 43850 43786 47296 43972 47603 47276 43858 43944 43798 43856 43986 43952 43868 43794 97838 right-hand side cab extension temporary handbrake control 43792.

Page 24: (M2), C

Part #: 90405 15 l ocation o f d ecals i nside c ab (m2), c ontinued 43864 43866 or 43890 (optional).

Page 25

16 part #: 90405 l ocation o f d ecals o n c onsole 43870 or 43872 (for l-h side driving position) 43868 43900 43952 43876 43888 43874 43906 43880 43862 43878 47451 (optional) 47370 (when equipped with two loading buckets) 47284 43796 or 43956 or 47394 or 47396* 104539 47398 or 47400 or 43986 or 475...

Page 26

Part #: 90405 17 i llustration of d ecals 15489 15490 32307 or 32308 or 32311 9479.

Page 27

18 part #: 90405 43790 43786 43760

Page 28

Part #: 90405 19 43794 43796 43792 43798.

Page 29

20 part #: 90405 43816 43817 43850

Page 30

Part #: 90405 21 43858 43862 43864 43866 43868 43856.

Page 31

22 part #: 90405 43870 43872 43874 43876 43878 43880 43888 43890

Page 32

Part #: 90405 23 43906 43900 43920 43922 chassis with tag axle (optional) chassis with tag axle (optional) 43944.

Page 33

24 part #: 90405 43948 43950 43952 43956.

Page 34

Part #: 90405 25 43958 43972 43982.

Page 35

26 part #: 90405 47264 47262 43986 47260 43798.

Page 36

Part #: 90405 27 47266 47274 47276 47268.

Page 37

28 part #: 90405 47284 47290 47292 47286.

Page 38

Part #: 90405 29 47296 47304 47320 47300

Page 39

30 part #: 90405 47324 47350 47352 47340

Page 40

Part #: 90405 31 47370 47396 47394 47374.

Page 41

32 part #: 90405 47398 47400 47402 47422.

Page 42

Part #: 90405 33 47426 47451 47440 47554 47514.

Page 43

34 part #: 90405 47562 47564 47603 47622 47990

Page 44

Part #: 90405 35 104539 97838 104092 the value depends on the truck model..

Page 45: Afety

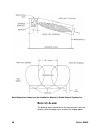

36 part #: 90405 s afety features g lobal m otion s ensors ( optional ) this optional safety system is used to detect objects located behind the truck. This system is turned on by placing the transmission in reverse. The main components of this system are a control box , located in the cab, sensors,...

Page 46: Warning

Part #: 90405 37 the sensors are installed on the rear bumper and adjusted in order to obtain low coverage to ground. To adjust the sensors, refer to the installation manual of the manufacturer. Troubleshooting and maintenance refer to the troubleshooting guide of gobal sensor systems inc. Warning s...

Page 47

38 part #: 90405 note:illustrations taken from the installation manual of global sensor systems inc. B ack u p a larm the back up alarm sounds when the transmission is put into reverse, when the body raises or when the tailgate opens..

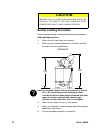

Page 48: Setting The Body Safety Prop

Part #: 90405 39 b ody s afety p rop the body safety prop ensures that the body will not lower when you are working beneath it. Setting the body safety prop 1. Start the engine. 2. Make sure there is enough clearance before raising the body. 3. Raise the body until the safety prop is free to tilt un...

Page 49: Warning

40 part #: 90405 6. Lower the body until it rests on the safety prop. 7. Apply the lockout/tagout procedure before performing maintenance under the body. T ailgate s afety p rop setting the tailgate safety prop to set the tailgate safety prop, apply the following procedure: 1. Make sure there is no ...

Page 50

Part #: 90405 41 6. Set the safety prop and install the safety pin. 7. Lower the tailgate onto the safety prop. 8. Reverse the above instructions in order to store the safety prop. Safety pin.

Page 51: Rior

42 part #: 90405 c amera s ystem ( optional ) optional monitor and cameras can be installed inside the cab and throughout the vehicle. The t op s elect ™ can be equipped with up to two (2) cameras. The operator can choose between the camera on the tailgate, the one located on street side mirror. The...

Page 52: Leanliness

Part #: 90405 43 c leanliness cleanliness is part of safety. Clean all the truck’s lights and safety decals, so the operator, the surrounding pedestrians and vehicles will be aware of the truck at all times. Rake dirt out of the body once it has been unloaded. Some units are equipped with clean out ...

Page 53: Hut

44 part #: 90405 s hut d own p rocedure if the truck is parked for an extended period of time, follow the chassis manufacturer’s shutdown procedure as well as maintenance requirements and ensure the following procedure: 1. Park on a hard and level ground. 2. Apply the parking brake. 3. Make sure tha...

Page 54: Warning

Part #: 90405 45 d riving s peed if the cab of the vehicle has been modified by labrie environ- mental group (right-hand side driving position) for door-to-door waste collection, the maximum speed limit while driving at the right-hand side is, if permitted, 20 mph. (32 km/h). Therefore, it is recomm...

Page 55

46 part #: 90405 7. Adjust mirrors properly. 8. Check the accelerator pedal and the temporary handbrake (if equipped). 9. Release the parking brake. You are now set for waste collection. Right-hand side driving position left-hand side driving position camera view (optional) right-hand side mirror fi...

Page 56: Ontrols

Part #: 90405 47 c ontrols and i ndicators the t op s elect ™ has a series of controls and indicators that allow easier operation of the different functions installed on the vehicle. Such controls and indicators are mainly located in the cab and the following is a description of each one of them. B ...

Page 57: Ump

48 part #: 90405 always stop the vehicle using the footbrake, then apply the temporary handbrake (for short stops) or the parking brake (for longer stops) before leaving the vehicle. A medium application of pressure on the footbrake is normally sufficient to stop the truck. If the brakes are always ...

Page 58: Mergency

Part #: 90405 49 e mergency s top c ontrol in case of emergency, disengage the pump switch (refer to “pump switch” ). The pump will shut off and all control joysticks will be inoperable. If a system is not working properly, advise the maintenance personnel. Never work on the equipment without perfor...

Page 59

50 part #: 90405 2. Apply the temporary handbrake. To disable the auto-neutral function: 1. Release the temporary handbrake. 2. Step on the foot brake. The transmission will shift back to drive. If the transmission does not shift to neutral when releasing the temporary handbrake: 1. Apply the footbr...

Page 60: Ver

Part #: 90405 51 o ver s peed p rotection m ode all units equipped with an allison electronic transmission (md or hd) are equipped with an over speed protection. The pump will disengage if the engine rpm goes above 1800 rpm. The pump system will com back on as soon as the rpm falls under 900 rpm. No...

Page 61

52 part #: 90405 temperature indicator (optional) air pressure indicator transmission temperature (optional) alternator indicator (optional) speedometer oil pressure (optional).

Page 62: Ailgate

Part #: 90405 53 t ailgate c ontrol located on the console, the tailgate control lever has a spring ac- tivated sleeve which locks the handle to prevent any accidental opening of the tailgate. The sleeve needs to be pulled up before moving the lever to open or close the tailgate. When the tailgate i...

Page 63: Oading

54 part #: 90405 l oading b ucket c ontrol the loading bucket control joystick is located inside the cab. Note:this joystick can also be located between the cab and the body, depending on the chassis model. When there is a loading bucket joystick outside the cab, it is automatically equipped with a ...

Page 64: Loading Bucket Rear Control

Part #: 90405 55 loading bucket rear control for operator convenience, a rear control joystick is available as an option for the loading bucket. If your t op s elect ™ is equipped with this device, you can empty the loading bucket from the back of the truck as well as from the front. Warning m ake s...

Page 65: Loading Bucket Selector

56 part #: 90405 loading bucket selector some t op s elect ™ units are equipped with two loading buckets. In order to prevent both roofs from colliding with each other, it is necessary to select one of the loading buckets, using the selector switch located on the console. Caution m ake sure that bot...

Page 66: Oist

Part #: 90405 57 h oist c ontrol the body hoist control lever is located on the cab console. The lever has a spring activated sleeve which locks the handle to pre- vent any accidental body hoist operation. This lever has to be moved to the left or right in order to raise or lower the body. When the ...

Page 67: Aximizer

58 part #: 90405 m aximizer c ontrol (o ptional ) when the unit is equipped with a maximizer, the maximizer control joystick is located inside the cab. Note:this joystick can also be located between the cab and the body, depending on the chassis model. As soon as the maximizer joystick is activated,...

Page 68: Ight

Part #: 90405 59 l ight c ontrols work lights switch (optional) when installed, this switch activates and deactivates the work lights. • shift the switch up to illuminate the work lights. • shift the switch down to turn off the work lights. Flashing lights switch (optional) this switch activates and...

Page 69: Arning

60 part #: 90405 w arning l ights neutral light indicator (green) located on the dashboard, this light turns on when the transmission is in neutral position. Temporary handbrake light (red) located on the dashboard, this light turns on when the temporary handbrake (or service brake) is applied..

Page 70: Pto Light (Red)

Part #: 90405 61 pto light (red) located next to the pump switch, this light turns on when the hydraulic pump is engaged. Auto-neutral light (red) located on the console, the auto-neutral light turns on when the auto-neutral system is engaged. Tailgate, roof or body raised warning light (red) locate...

Page 71

62 part #: 90405 tailgate fully opened light (optional) this light (if equipped) turns on when the tailgate is fully open, so you can raise the body for dumping. Body raise allowed indicator (optional) this warning light turns on when the air suspension has been dropped. Always drop the air suspensi...

Page 72: Perating

Part #: 90405 63 o perating the t op s elect ™ the different methods, procedures and necessary actions to operate the t op s elect ™ are presented in this section.. Before operating the t op s elect ™, the operator must be completely familiar with all safety procedures, location, operation and funct...

Page 73: Visual Inspection

64 part #: 90405 visual inspection before starting the vehicle, the operator must perform a visual inspection of the truck. Ensure the engine is not running and the parking brake is set. 1. Ensure the cleanliness of lamps, safety labels, camera lenses, mirors, windows, and the vehicle in general. 2....

Page 74

Part #: 90405 65 • hydraulic system is off. See “pump switch” on page 48. 2. Start the vehicle as stated in the chassis manufacturer manual. 3. Switch on the pump (switch on the control console) to engage the hydraulic system (the air pressure has to be at a minimum of 70 psi). See “pump switch” on ...

Page 75: Cab Door Opening Procedure

66 part #: 90405 cab door opening procedure this section applies only to cabs that have been modified by labrie environmental group. To open the curb side door: 1. Unlock and open the curb side cab door. 2. Inside the folding door, locate the sliding lock. 3. Pull up the sliding lock lever (see illu...

Page 76: Body Inspection Procedure

Part #: 90405 67 8. Lock the folding door using the latch located behind the cab. 9. To release, use the release mechanism located inside the cab. Body inspection procedure exit the cab to continue your inspection. Bring a rag along to clean all accessible lights, stickers, camera lens, etc. Look fo...

Page 77

68 part #: 90405 5. Check the chassis area, fuel tank and air tanks (air tanks must be drained every day), wheels for leaks, cracks or other type of problems. 6. At the front of the unit, check lights, mirrors and pump (if not pto mounted). 7. Go around and check lights, clean camera, labels, lights...

Page 78: Inspection Sheet Example

Part #: 90405 69 inspection sheet example the following is an example of an inspection sheet. The operator must follow the inspection sheet provided by his employer. If the employer doesn’t have an inspection sheet, ask their permission before using this example..

Page 79: Oading

70 part #: 90405 l oading and u nloading planning your route it is important to plan your route in order to be efficient. Planning your route will shorten your collection time and prevent from being caught in a traffic jam. Remember that the t op s elect ™ was designed exclusively to pick up recycla...

Page 80: Curb Side Extension

Part #: 90405 71 6. Step off the vehicle. To step out, keep a good hold on the vehicle until you have assured yourself of a good stand on solid ground. 7. Load the bucket (refer to “bucket loading procedure” on page 74). 8. Step back in the vehicle, press the brake pedal and toggle the temporary han...

Page 81: Loading Bucket

72 part #: 90405 7. Release the temporary handbrake or parking brake. 8. Engage the transmission shifter to drive. 9. Drive to the next pick up point. Loading bucket loading bucket specifications 16-inch loading bucket: • volume: 2.23 yd³ • maximum weight: 1000 lbs (453 kg) 18-inch loading bucket: •...

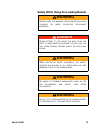

Page 82: Warning

Part #: 90405 73 safety while using the loading bucket warning a lways keep the warning lights and / or four way flashers on when collecting recyclable materials . Danger n ever attempt to get inside the body from the roof to make more room inside the body or for any other reason . S evere injury or...

Page 83: Bucket Loading Procedure

74 part #: 90405 bucket loading procedure before loading the body, read the following loading procedure. Body loading procedure: 1. Make sure all the partitions are secured. 2. Make sure the overhead clearance is sufficient and that the roof is clear of any obstacles. Note:for standard chassis, the ...

Page 84: Loading Bucket Safety Pins

Part #: 90405 75 6. Raise the bucket using the bucket joystick (refer to “loading bucket control” on page 54). Note:if the joystick is equipped with a deadman button, push and maintain this button to operate the loading bucket. Loading bucket safety pins the loading bucket can be locked and secured ...

Page 85

76 part #: 90405 to install loading bucket safety pins: 1. Make sure the body is completely empty. 2. Make sure the loading bucket is empty. 3. Engage the hydraulic system. 4. Lift the bucket until it reaches the end of its stroke. 5. Open the tailgate and install its safety prop (refer to “tailgate...

Page 86

Part #: 90405 77 • insert the pins in their corresponding holes so they are both in locked position. • make sure both pins are firmly held in place. Note:the rear loading bucket safety pin is located near the curb side tailgate hinge. The front loading bucket safety pin is located near the upper cor...

Page 87

78 part #: 90405 operator has to cross body partition(s) using partition door(s). 8. When service is completed, remove the safety pins and completely lower the loading bucket. Body partition door.

Page 88

Part #: 90405 79 loading bucket partition adjustment the loading bucket is equipped with “readily movable” partitions. The bottom lock is held by a vertical pin going through the bottom of the bucket while two side pins hold them at the top. Loading bucket partitions adjustment procedure: 1. Pull th...

Page 89: Body Partitions Adjustment

80 part #: 90405 note: multiple partitions configuration requires the body to be divided according to the number of partitions in the bucket (up to seven partitions). Note:align the body and loading bucket partitions so that no cross contamination can occur when unloading the side bucket. Body parti...

Page 90

Part #: 90405 81 5. Slide off the partition’s top locking pin. 6. Release floor locking pins using the manual release system located in the body. Upper locking mechanism 1- pull the lever (manual operation) block the lever locking mechanism locking mechanism in unlocked position.

Page 91

82 part #: 90405 note:if the partition needs to be moved a long distance, it may be necessary to disconnect the partition pneumatic hose (located on the roof) and plug it into another pneumatic coupler. Each partition (if more than one) has its own pneumatic hose. There may be more than one coupler ...

Page 92: Loading Corrective Actions

Part #: 90405 83 loading corrective actions if the loading bucket does not cycle: 1. Ensure the hydraulic system is engaged (pto switch to on). 2. Check bucket selector switch (for units equipped with two buckets). 3. Use another loading bucket joystick (if more than one installed). 4. Is the loadin...

Page 93: Oading

84 part #: 90405 l oading r oller c arts t op s elect ™ loading bucket can also load roller carts, using an optional automatic latching system. In order to secure roller carts to the loading system, an optional automatic latching system located at the bottom of the bucket will grab the roller cart a...

Page 94

Part #: 90405 85 roller cart latching procedure to latch a roller cart on the loading bucket: note:some units are equipped with more than one latch in order to allow multiple roller cart collection. American style roller cart upper latching support lower latching mechanism ?.

Page 95

86 part #: 90405 1. Push the automatic latching system pin, which is located between the cab and the body. 2. Turn the pin counterclockwise about a ¼ turn. This activates the automatic latching system. 3. Bring the roller cart against the loading bucket. 4. Slowly raise the bucket(s) and make sure a...

Page 96: Caution

Part #: 90405 87 6. Once the roller cart(s) have been emptied, lower the loading bucket. The lower latch will unlock as soon as the cart reaches the ground.. Caution a lways be cautious and watch for an improprely attached cart that c ould fall off . Danger n ever try to “ shake ” the loading bucket...

Page 97: Ody

88 part #: 90405 b ody u nloading p rocedure 1. Drive the vehicle to the desired site. 2. Ensure the vehicle is on safe, stable and level ground. 3. Check for overhead clearance before opening the tailgate and raising the body. 4. Remove tailgate safety pin. 5. Fully raise the tailgate. 6. Raise the...

Page 98: Warning

Part #: 90405 89 11. Release the second partition and repeat the procedure. 12. Perform the same procedure for all partitions. 13. When unloading is completed, lower the body and lock the partitions back in place. 14. The operator has to go inside the body to make sure that all partitions are locked...

Page 99: Unloading Corrective Actions

90 part #: 90405 unloading corrective actions if the body does not raise: 1. Make sure the hydraulic system is engaged (pto switch on). 2. Check fuses inside the console. 3. Make sure the air pressure has reached 70 psi. 4. Contact your maintenance facility if there is no change. 5. The tag axle (if...

Page 100: Aximizer

Part #: 90405 91 m aximizer o peration follow these instructions in order to gain maximum performance of the maximizer option. Initial set up for body partitions set the bucket partitions and maximizer to obtain your best- known volume distribution before starting recyclable collection (e.G. 60% pap...

Page 101: Unloading Rear Compartment

92 part #: 90405 maximizer cycles until both compartments are fully loaded and no more room is available. Unloading rear compartment to unload rear compartment: 1. Drive the vehicle to the desired site. 2. Ensure the vehicle is on safe, stable and level ground. 3. Check for overhead clearance before...

Page 102: Important

Part #: 90405 93 4. Remove tailgate safety pin. 5. Fully raise the tailgate. 6. Raise the body. The material will slide out. Note:as you raise the body, you can throttle up the engine to raise it completely up faster. Do not accelerate the engine for the last section of the hoist to prevent a sharp ...

Page 103: Unloading Front Compartment

94 part #: 90405 unloading front compartment to unload front compartment: 1. Drive the vehicle to the desired site. 2. Ensure the vehicle is on safe, stable and level ground. 3. Check for overhead clearance before opening the tailgate and raising the body. Caution t he overhead clearance varies acco...

Page 104

Part #: 90405 95 4. Remove tailgate safety pin. 5. Fully raise the tailgate. 6. Raise the body. Note:as you raise the body, you can throttle up the engine to get it completely up faster. Do not accelerate the engine for the last section of the hoist to prevent a sharp stop at the end of the cylinder...

Page 105: The

96 part #: 90405 10. When the unloading is completed, lower the body and relock the maximizer swing door. From the back of the unit, make sure the swing door is properly locked. 11. Close the tailgate and secure the safety pin. E nd of the d ay c leaning body weekly cleaning after dumping the conten...

Page 106: Caution

Part #: 90405 97 8. Using a shovel or a broom, remove as much material as possible. 9. Clean the rest using pressurized water. 10. Once the first partition is clean, release its locks in order to evacuate the water (refer to “body partitions adjustment” on page 80). 11. Clean the second section. Rel...

Page 107: Chassis Weekly Cleaning

98 part #: 90405 chassis weekly cleaning chassis weekly cleaning procedure: 1. Start the engine. 2. Raise the body until the safety prop is free to tilt under the body. 3. Release the safety prop using the prop handle (refer to “setting the body safety prop” on page 39). 4. Apply the lockout/tagout ...

Page 108

Part #: 90405 99 8. Move the maximizer towards the tailgate in order to retract the cylinder. 9. Stop the hydraulic pump and the engine. 10. Open the maximizer access door. 11. Clean the section located between the cab and the maximizer using pressurized water. 12. Open the cylinder access traps (3)...

Page 109: Ydraulic

100 part #: 90405 h ydraulic o il l eak in case of an hydraulic oil leak: 1. Disengage the hydraulic system and stop the truck engine. 2. Close the valve located on the hydraulic tank. 3. Identify the cause of the leak. 4. Call your maintenance facility and report your findings. 5. Before you restar...

Page 110: Caution

Part #: 90405 101 when the pump system has no clutch: caution i n the case of hydraulic system leak , disconnect the drive shaft located between the pump and the engine before driving the vehicle to be repaired ..

Page 111

102 part #: 90405.

Page 112

Cool grey 10 c blackc 2935 c 3630 stearns drive, oshkosh, wi 54904 toll free: 1-800-231-2771 telephone: 1-920-233-2770 general fax: 1-920-232-2496 sales fax: 1-920-232-2498 mailing address: p.O. Box 2785 oshkosh, wi 54903-2785 parts, service and warranty (during business hours 7:00 am to 7:00 pm cen...