- DL manuals

- Lagler

- Sander

- ELAN

- Operating Instructions Manual

Lagler ELAN Operating Instructions Manual

Summary of ELAN

Page 1

Elan english / englisch edge-, stair- and corner-sanding machine elan www.Laegler.Com operating instructions translation of original operating instructions for the edge-, stair- and corner-sanding machine 00.350.20.002 01.02.2018 *00.350.20.002*.

Page 2

Elan 01.02.2018 english / englisch contents 1 introduction ..................................................................................................................................................................... 5 1.1 features of the machine ................................................

Page 3

Elan 01.02.2018 english / englisch contents 8 regular inspection and maintenance work in accordance with accident prevention regulations ................. 43 9 causes of faults ..............................................................................................................................

Page 4

Elan 01.02.2018 english / englisch parts and assemblies fig. 1 main features of the edge-, stair- and corner-sanding machine elan multiclip guide roller motor cable dust bag handle piece motor attachment switch fan housing 4.

Page 5

Elan 01.02.2018 english / englisch introduction 1 you have purchased a high-quality product from lÄgler ® . We wish you a great deal of success with your elan. All lÄgler ® products are subjected to a thorough inspection before leaving the factory. R e a d t h e s e o p e r a t i n g i n s t r u c t...

Page 6

Elan 01.02.2018 english / englisch introduction 1 1.4 protective devices the following parts of the machine are protective devices and thus must always be kept in perfect condition: attachment = protection against sanding disc, protection against v-belt attachment cover = dust protection, protection...

Page 7

Elan 01.02.2018 english / englisch introduction 1 1.5.3 wearing parts and safety-related parts check the condition of the wearing parts and safety-related parts mentioned below at regular intervals in order to be able to work safely and optimally at all times. Replace the following parts in case of ...

Page 8

Elan 01.02.2018 english / englisch 2 hazard warnings and safety instructions 2.1 hazard warnings warning! Risk of death from suffocation and risk of injury: • never wrap the power cable around your neck or other parts of the body! Risk of death from electrical shock: • the machine may never be used ...

Page 9

Elan 01.02.2018 english / englisch 2 hazard warnings and safety instructions risk of death and risk of property damage from unsecured load: • when transported in a car or the like, the machines and all parts must be secured against sliding! Risk of explosion due to sparks while sanding or a high dus...

Page 10

Elan 01.02.2018 english / englisch 2 hazard warnings and safety instructions risk of fire from the overheating of the cables: • only cables with three wires and wire cross-sections of at least 1.5 mm² (0.0023 sq. In.) may be used as motor cables and power cables! • the maximum cable length in order ...

Page 11

Elan 01.02.2018 english / englisch 2 hazard warnings and safety instructions caution! Risk of injury and risk of property damage from rotating tools and parts of the machine: • for all operating conditions of the machine only one operator is required! As a consequence, for safety reasons only one pe...

Page 12

Elan 01.02.2018 english / englisch 2 hazard warnings and safety instructions health risk caused by noise: • use hearing protection when conducting work that produces noise! Observe the applicable regulations and legal requirements in your country! Risk of property damage: • never use any cleaning pr...

Page 13

Elan 01.02.2018 english / englisch 2 hazard warnings and safety instructions • maintain your machines with care! - keep your machines clean so that you can work better and more safely. - follow the maintenance guidelines and the instructions for replacing tools. - keep the handles dry and free of oi...

Page 14

Elan 01.02.2018 english / englisch technical data technical data 3.1 data on type plate attention! In order to receive the correct spare parts from us, please specify in inquiries and spare part orders always the serial numbers of your machines! The type plate of elan is located on the motor housing...

Page 15

Elan 01.02.2018 english / englisch 3.2 machine data manufacturer eugen lägler gmbh machine type edge-sanding machine machine name elan serial number see type plate (fig. 2) year of manufacture see type plate (fig. 2) motor type universal motor type of current alternating current (ac) voltage 230 v 1...

Page 16

Elan 01.02.2018 english / englisch note on noise emission: the values indicated are emission values and must not represent safe workplace values as well. Although a correlation exists between emission levels and immission levels, it is not always possible to determine whether additional precautionar...

Page 17

Elan 01.02.2018 english / englisch commissioning commissioning this section describes how to put the elan into service on site. In order to prevent damage and malfunctions, you should proceed in the order of steps mentioned below. Before starting to work with the machine, you must be properly instru...

Page 18

Elan 01.02.2018 english / englisch 4.2 connecting the power cable warning! Risk of death from electrical shock: • never connect the machine on hazardous electrical power sources! Only use safety sockets! • to protect yourself and the machine against faults in the mains supply use a safety switch prc...

Page 19

Elan 01.02.2018 english / englisch commissioning 4 4.3 switching on the machine caution! Risk of injury and risk of property damage from rotating parts of the machine: • always tip the machine backwards slightly (fig. 10) before switching on the machine so that the sanding disc is raised off the flo...

Page 20

Elan 01.02.2018 english / englisch 4.4 switching off the machine caution! Risk of injury and risk of property damage from rotating parts of the machine: always tip the machine backwards slightly (fig. 10) before switching off the machine so that the sanding disc is raised off the floor! 1 tip the ma...

Page 21

Elan 01.02.2018 english / englisch working with the elan 5.1 general application tips warning! Risk of death from electrical shock: the machine may never be used for wet processing opera- tions of any kind! Attention! • bear in mind that the elan operates at very high cutting speeds! For this reason...

Page 22

Elan 01.02.2018 english / englisch working with the elan 5 • after replacing the sanding disc, start working in poorly lit areas of the room in order to remove the initial aggressiveness of the sanding medium. • always vacuum the floor or stairs thoroughly before the first sanding operation and afte...

Page 23

Elan 01.02.2018 english / englisch working with the elan fig. 18 remove the conventional sanding disc by loosening the tensioning nut with the closed mouth wrench. Fig. 19 remove the nut and the paper tensioning disc from the sanding plate. Fig. 20 mount a new sanding disc and assemble again. 5 5.2....

Page 24

Elan 01.02.2018 english / englisch working with the elan fig. 21 after removing the sanding disc pull off the velcro negative and clean the sanding plate. Fig. 22 place the new sanding plate covering on the fastening rivets correctly lined up and press down over the entire surface and in the cone on...

Page 25

Elan 01.02.2018 english / englisch working with the elan 5 5 then place the other attachment on the machine by inserting the v-belt into the motor pulley first and then place the attachment on the machine (fig. 25). 6 then screw the hexagonal nuts (wrench size 13 mm) onto the threaded studs. Make su...

Page 26

Elan 01.02.2018 english / englisch 5.5 emptying the dust bag warning! Risk of fire from the formation of sparks while sanding: • note the warning on the motor housing (fig. 29)! • the dust bag must always be removed from the machine directly after sanding and emptied into a non-combustible container...

Page 27

Elan 01.02.2018 english / englisch 4 pick up the machine and shake the dust residue from the machine into the dust bag (fig. 30). 5 undo the multiclip fastener (fig. 31) and the cord of the dust bag (fig. 32). 6 keep the opening of the dust bag closed and carefully pull it off from the pipe muff (fi...

Page 28

Elan 01.02.2018 english / englisch transport and storage transport and storage warning! Risk of death and risk of property damage from unse- cured load: when transported in a motor vehicle or the like, the machines and all parts must be secured against sliding! Risk of fire from spontaneous combusti...

Page 29

Elan 01.02.2018 english / englisch maintenance work and replacement of wearing parts maintenance work and replacement of wearing parts warning! Risk of death from electrical shock and risk of injury from rotating parts of the machine: • all extensive maintenance work, especially on the elec- trical ...

Page 30

Elan 01.02.2018 english / englisch maintenance work and replacement of wearing parts 7 7.1 cleaning and care warning! Risk of fire from the formation of sparks while sanding or from spontaneous combustion: • there is a high risk of fire when sanding woods with a large amount of resin, oiled or waxed...

Page 31

Elan 01.02.2018 english / englisch maintenance work and replacement of wearing parts 7 fig. 35 undo the two nuts with which the attachment is fastened. Fig. 36 tighten the two nuts again while using your thumb to press the attachment forward in order to maintain the belt under tension. A and b shoul...

Page 32

Elan 01.02.2018 english / englisch fig. 37 remove the two nuts and washers with which the attachment is fastened and the attachment from the machine. Fig. 38 with a few light hammer taps, the three screws are loosened and then unscrewed. Use a screwdriver with a continuous blade only. Fig. 39 remove...

Page 33

Elan 01.02.2018 english / englisch fig. 41 pay attention to centered insertion of the sanding plate bearing piece during assembly! Fig. 42 insert and tighten the three screws. Maintenance work and replacement of wearing parts 7 fig. 43 unscrew the axle clockwise (left-hand thread). 3 rotate the hole...

Page 34

Elan 01.02.2018 english / englisch maintenance work and replacement of wearing parts 7 fig. 44 a new motor pulley. B run-in motor pulley that must be replaced. A b fig. 45 remove the fan cover. Fig. 46 use two pairs of pliers to unscrew the motor pulley from the motor shaft. Fig. 47 rotate the new m...

Page 35

Elan 01.02.2018 english / englisch fig. 48 use the two pairs of pliers to tighten down the motor pulley. Maintenance work and replacement of wearing parts 7 fig. 49 place the fan cover on the machine. 7 use the two pairs of pliers to tighten down the motor pulley (fig. 48). 8 place the fan cover on ...

Page 36

Elan 01.02.2018 english / englisch fig. 52 fold the tension clamp toward the right (1) and remove the carbon brush (2). Fig. 53 with the tension clamp being held back (1), insert the new carbon brush (2). Maintenance work and replacement of wearing parts 7 fig. 50 unscrew the two covers on the casin...

Page 37

Elan 01.02.2018 english / englisch maintenance work and replacement of wearing parts 7 7.7 checking the dust suction system in order to guarantee optimal dust suction for your safety and for the safety of other persons, the following items must be taken into account: • use only original lÄgler ® dus...

Page 38

Elan 01.02.2018 english / englisch maintenance work and replacement of wearing parts 7 fig. 59 steep machine setting for rough sanding tasks. Fig. 57 flat machine setting for fine sanding tasks. Fig. 55 setting of the guide rollers for short attachment and corner attachment. Fig. 56 setting of the g...

Page 39

Elan 01.02.2018 english / englisch fig. 64 proper adjustment of the guide rollers: the machine sands centrically. Fig. 62 for a flatter machine setting rotate the guide roller axis counterclockwise (1 + 2). Thereby the fan housing is lowered (3). Fig. 61 loosen the lock nuts of the guide rollers. Fi...

Page 40

Elan 01.02.2018 english / englisch 7 maintenance work and replacement of wearing parts fig. 65 improper adjustment of the guide rollers: the sanding zone of the machine is too much to the right. Fig. 66 the sanding zone of the machine is too much to the right means, the left guide roller (a) is lift...

Page 41

Elan 01.02.2018 english / englisch 7 maintenance work and replacement of wearing parts fig. 69 remove the screw, the two washers and the nut (1) and remove the wheel from the wheel fork (2). 7.9 replacing the wheels and the guide rollers attention! • blocked wheels or guide rollers restrict the mobi...

Page 42

Elan 01.02.2018 english / englisch 7 maintenance work and replacement of wearing parts 3 rotate the vertical guide roller axis completely out of the fan housing. Note: a light film of oil on the thread of the new guide roller makes the adjustment work easier. 4 rotate the vertical axis of the new gu...

Page 43

Elan 01.02.2018 english / englisch regular inspection and maintenance work in accordance with accident prevention regulations regular inspection and maintenance work the electrical operating equipment and machine parts must be inspected at least once a year by a qualifi ed electrician with respect t...

Page 44

Elan 01.02.2018 english / englisch regular inspection and maintenance work 8 excerpt from the german accident prevention regulations “dguv vorschrift 3” (november 2013) § 5 inspections (1) the employer must ensure that the proper condition of the electrical systems and equipment is inspected 1. Befo...

Page 45

Elan 01.02.2018 english / englisch 9 causes of faults causes of faults warning! Risk of death from electrical shock: work on the electrical equipment is to be conducted exclusively by a qualified elec- trician (circuit diagrams in section 10)! The machine must be switched off and the power plug remo...

Page 46

Elan 01.02.2018 english / englisch 9.2 the machine attempts to start up but is not able to do so • at low temperatures: the machine is too cold and must be heated up to room temperature in a warm room. • cables which are too long or too thin are used for the electrical connection: - the power cables...

Page 47

Elan 01.02.2018 english / englisch 9.4 the machine vibrates intensely and runs noisily • the sanding medium does not have the proper tension. The tension must be corrected. Section 5.2, replacing the sanding disc • the sanding medium is damaged or incorrect and must be replaced. Section 5.2, replaci...

Page 48

Elan 01.02.2018 english / englisch • the movement of the machine while sanding is incorrect: - move the elan with short or long attachment in circular motions clockwise! - move the elan with corner attachment in circular motions counterclockwise! Section 5.1, general application tips • too much pres...

Page 49

Elan 01.02.2018 english / englisch 9 causes of faults • the v-belt is dirty, damaged or worn-out and must be replaced. Section 7.3, replacing the v-belt • a pulley is dirty, damaged or worn-out and must be cleaned or replaced. Section 7.4, replacing the attachment pulley section 7.5, replacing the m...

Page 50

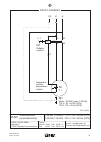

Elan 01.02.2018 english / englisch 10 z1 funkentstörfilter (interference-free capacitor) temperatur- schalter emperature (t switch) q1 schalter (switch) 01.04.2008 1,2 kw (1.2 kw) / 230 v / 50 + 60 hz (cps) e-mail: info@laegler.Com internet: http://www.Laegler.Com telefon phone: 0049 - 7135 - 98 90 ...

Page 51

Elan 01.02.2018 english / englisch 10 01.01.2014 q1 schalter (switch) temperatur- schalter emperature (t switch) 1,05 kw (1.05 kw) / 110 v / 50 + 60 hz (cps) 1,05 kw (1.05 kw) / 120 v / 50 + 60 hz (cps) universalmotor (universal motor) telefon phone: 0049 - 7135 - 98 90 - 0 fax: 0049 - 7135 - 98 90 ...

Page 52

Elan 01.02.2018 english / englisch spare parts elan 52 a ttention: please specify in inquiries and spare part orders always the serial numbers of your machines ( section 3.1 )! 11.

Page 53

Elan 01.02.2018 english / englisch spare parts elan item part number description 1 350.05.00.100 handle elan, complete 352.05.00.100 handle elan usa, complete 2 350.05.15.100 cover, complete 3 350.05.10.100 casing tube, complete 4 0439.1008.800 nut, left-handed thread 5 350.65.02.100 fan blade 6 000...

Page 54

Elan 01.02.2018 english / englisch spare parts elan 54 a ttention: please specify in inquiries and spare part orders always the serial numbers of your machines ( section 3.1 )! 11.

Page 55

Elan 01.02.2018 english / englisch spare parts elan item part number description 350.03.50.100 short attachment elan, complete 2 7500.1004.812 screw 3 350.03.25.100 wall-protecting roller, complete 4 000.70.10.045 v-belt 5 350.03.02.100 cover, short 6 000.10.12.051 screw 7 350.03.52.100 sanding plat...

Page 56

Elan 01.02.2018 english / englisch spare parts elan 56 a ttention: please specify in inquiries and spare part orders always the serial numbers of your machines ( section 3.1 )! 11.

Page 57

Elan 01.02.2018 english / englisch spare parts elan item part number description 1 350.00.80.105 dust bag elan 2 000.01.40.110 multiclip 3 000.01.20.010 respiratory protection mask p3 4 000.65.53.151 extension cable 3 x 1.5 mm² (3 x 0.0023 sq.In.), 10 m (394”) long 5 000.95.21.103 closed mouth wrenc...

Page 58

Elan 01.02.2018 english / englisch notes 58.

Page 59

Elan 01.02.2018 english / englisch 12 service passport service passport please enter the serial number and the year of manufacture of your machine (see type plate) on the rear side of these operating instructions! Otherwise the service passport will not be valid! This service passport is a document....

Page 60: Www.Laegler.Com

Copyright © eugen lägler gmbh, 2018 – all rights reserved – t ranslation of original operating instructions elan – 8 / 01.02.201 8 – printed on paper without the use of chlorines. Part number 00.350.20.002 w e are unable to accept any guarantee for these operating instructions or liability for damag...