- DL manuals

- Lagler

- Sander

- SINGLE

- Operation Maintenance Safety

Lagler SINGLE Operation Maintenance Safety

Summary of SINGLE

Page 1

Single - the single-disc sanding machine single english / englisch operation, maintenance, safety translation of the original operating instructions for the single-disc sanding machine 00.850.20.002 01.02.2013 *00.850.20.002*.

Page 2

Single 01.02.2013 english / englisch single assemblies fig. 1 assemblies of the single single-disc sanding machine cable holder 2-handed safety operating lever (on/off) adjusting lever handle with stepless adjustment of the guide tube drive motor sanding plate motor cover guide tube wheel dust extra...

Page 3

Single 01.02.2013 english / englisch 1 introduction ..................................................................................................................................................................... 4 1.1 features of the machine .......................................................

Page 4

Single 01.02.2013 english / englisch introduction introduction 1.1 features of the machine fig. 1 (page 2) shows the most important assemblies which make up the single. We recommend that you take some time to become familiar with the machine. 1.2 description of the machine the single single-disc san...

Page 5

Single 01.02.2013 english / englisch introduction 1.4 danger warnings please read through the danger warnings carefully and instruct your employees or colleagues accordingly. Failure to comply with this requirement could result in dangerous situations or injury. In order to avoid injury, the machine...

Page 6

Single 01.02.2013 english / englisch technical data technical data 1.5 safety devices the following parts of the machine are safety devices and must accordingly be kept in perfect working order: machine housing = protection from sanding plate and sanding disc dust extraction socket with cap = protec...

Page 7

Single 01.02.2013 english / englisch technical data intended applications sanding wooden and cork floors, work on floor underlays and spreading care products and cleaning agents. Basic equipment machine ready for operation, extension cable 3 x 2.5 sq. Mm - 10 m long, hexagonal socket wrench sizes 5 ...

Page 8

Single 01.02.2013 english / englisch getting started getting started this section describes the procedure for commissioning the single on site. In order to exclude the possibility of damage and malfunc- tions, it is essential to proceed in the sequence outlined below. Before working with the machine...

Page 9

Single 01.02.2013 english / englisch getting started 8 the height of the guide tube can be adjusted, allowing you to work with the single as comfortably as possible. To make this adjustment, pull the adjusting lever towards you (fig. 3). This releases the lock on the guide tube so that it can be mov...

Page 10

Single 01.02.2013 english / englisch getting started for safety reasons, the machine cannot be switched on: • if the guide tube is in a vertical position, since this makes the machine very difficult to control (fig. 11). • unless both start levers on the handle are pulled at the same time. Holding t...

Page 11

Single 01.02.2013 english / englisch working with the single working with the single for more information free of charge, please apply to: within germany - tel.: 0800 / 52 34 537 - fax: 0800 / 48 66 353 within the usa - tel.: 800-848-6635 or - tel.: 0049 - 7135 - 98 90-0 - fax: 0049 - 7135 - 98 90-9...

Page 12

Single 01.02.2013 english / englisch working with the single 4 release the adjusting lever so that the guide tube can engage again. Carefully tilt the machine backwards on the wheels. As you do so, steady the machine with your foot to stop it roll- ing away (fig. 14). Please ensure that the machine ...

Page 13

Single 01.02.2013 english / englisch working with the single 7 carefully tilt the machine back up over the wheels and onto the sanding plate. As you do so, steady the machine with your foot to stop it rolling away (fig. 16). 4.3.2 changing conventional sanding discs note: so that sanding discs that ...

Page 14

Single 01.02.2013 english / englisch working with the single 4.4 adjusting and replacing the cable holder 4.4.1 adjusting the cable holder the cable holder positions can be adjusted individually along the groove on the guide tube of the machine. 1 using a hexagonal socket wrench, slacken the screw i...

Page 15

Single 01.02.2013 english / englisch working with the single 3 open the cap of the dust extraction socket on the machine housing and push the vacuum cleaner hose into the connec- tion piece (fig. 24). 4 switch the vacuum cleaner to auto mode (fig. 25). Auto mode means that the vacuum cleaner switche...

Page 16

Single 01.02.2013 english / englisch transport and storage transport and storage 5.1 dismantling and assembling the machine for transportation, the machine can be dismantled into three parts: the guide tube as one element, the sanding plate and the drive unit (machine housing with motor). All parts ...

Page 17

Single 01.02.2013 english / englisch maintenance and replacement of wearing parts maintenance and replacement of wearing parts periodically, but at the latest when you notice that damage has oc- curred, a variety of maintenance procedures have to be performed. For this work, always use original spar...

Page 18

Single 01.02.2013 english / englisch maintenance and replacement of wearing parts 3 release the adjusting lever so that the guide tube can engage again. Carefully tilt the machine backwards on the wheels. As you do so, steady the machine with your foot to stop it roll- ing away (fig. 32). Please ens...

Page 19

Single 01.02.2013 english / englisch maintenance and replacement of wearing parts 6.3 replacing the wheels always use original lÄgler ® wheels (for part nos. Please see section 11, spare parts ). 1 switch off the machine and pull the extension cable out of the socket. 2 use a suitable pair of circli...

Page 20

Single 01.02.2013 english / englisch regular maintenance and testing regular maintenance and testing in accordance with accident prevention regulations the electrical operating equipment and machine components must be checked for their electrical and mechanical safety at least once a year by a speci...

Page 21

Single 01.02.2013 english / englisch troubleshooting machine fails to start up the machine fails to start up • the guide tube is in the vertical position. • to start the machine, pull both start levers towards you at the same time . • check the power supply, connect if applicable (is the exten- sion...

Page 22

Single 01.02.2013 english / englisch general safety remarks the machine is creating excessive noise and vibrations • check the sanding disc for damage. • check that the sanding disc is positioned in the centre of the sanding plate. • check the flexible underlay between the sanding plate and sanding ...

Page 23

Single 01.02.2013 english / englisch general safety remarks keep children and unauthorised persons at a distance do not allow children or any unauthorised persons to touch the machine or the cable, keep them away from the work area. Keep the machine in a safe place machines that are not in use shoul...

Page 24

Single 01.02.2013 english / englisch general safety remarks never leave setting tools in the machine before switching on, always check that you have removed all span- ners and setting tools. Avoid unintentional start-up ensure that the on/off switch is not activated when connecting the machine to th...

Page 25

Single 01.02.2013 english / englisch notes 25.

Page 26

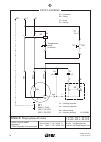

Single 01.02.2013 english / englisch f1 6.3 a on temperature switch (in motor) yellow black blue red m1 motor 1.2 kw 230 v / 50 cps 230 v / 60 cps single: s ingle-phase ac motor e-mail: info@laegler.Com internet: http://www.Laegler.Com 1.2 kw / 230 v / 50 cps 1.2 kw / 230 v / 60 cps phone: 0049 - 71...

Page 27

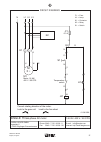

Single 01.02.2013 english / englisch -f1 6.3 a temperature switch m1 motor 1.6 kw 400 v / 50 cps 1.6 kw / 400 v / 50 cps e-mail: info@laegler.Com internet: http://www.Laegler.Com single: three -phase ac motor correct rotating direction of the motor: look to the gear unit look to the fan wheel f1 = f...

Page 28

Single 01.02.2013 english / englisch spare parts 28 11.

Page 29

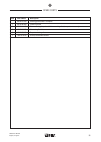

Single 01.02.2013 english / englisch spare parts item part number description 1 850.01.80.200 dust extraction socket 2 000.65.43.252 motor cable 3 x 2.5 mm² 3 000.65.71.040 integrated socket 4 7500.1003.010 screw 5 850.05.09.105 wheel 6 0125.1012.000 washer 7 0471.0012.000 circlip 8 850.01.02.105 bu...

Page 30

Single 01.02.2013 english / englisch spare parts 30 11.

Page 31

Single 01.02.2013 english / englisch spare parts item part number description 1 0912.1006.016 screw 2 0125.1006.000 washer 3 850.20.28.105 cable holder 4 850.20.29.100 sliding block 5 7984.1008.030 screw 6 900.70.25.105 bumper felt 31 11.

Page 32

Single 01.02.2013 english / englisch spare parts 32 11.

Page 33

Single 01.02.2013 english / englisch spare parts item part number description 1 000.65.10.041 running capacitor 40 µf 2 000.65.10.061 starting capacitor 60 µf 3 850.65.00.200 motor, 230 v / 50 cps / 1.2 kw 4 000.65.80.061 fuse, 6.3 a 5 000.65.82.010 fuse holder 6 000.65.20.012 contactor 7 000.65.20....

Page 34

Single 01.02.2013 english / englisch spare parts 34 11.

Page 35

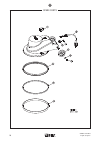

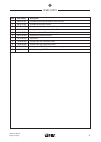

Single 01.02.2013 english / englisch spare parts item part number description 850.02.10.100 sanding plate single complete 1 850.02.06.200 centering dome 2 850.02.11.100 velcro coating, for pad and velcro sanding disc (two parts necessary) 3 850.02.13.105 velcro ring flexible 6 850.02.05.100 paper te...

Page 36

Single 01.02.2013 english / englisch spare parts 36 11.

Page 37

Single 01.02.2013 english / englisch spare parts item part number description 1 000.01.10.011 foldable earmuff type musimuff with fm radio 2 000.01.10.021 foldable earmuff type pocket 3 000.93.11.061 hexagonal socket screw wrench 6 mm 4 000.93.12.052 hexagonal socket screw wrench 5 x 150 mm 5 000.65...

Page 38

Single 01.02.2013 english / englisch notes 38.

Page 39

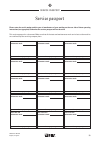

Single 01.02.2013 english / englisch service passport 12 service passport please enter the serial number and the year of manufacture of your machine on the rear side of these operating instructions (see type plate)! Otherwise the service passport will not be valid! This service passport is a documen...

Page 40: Single

Eu declaration of conformity 13 güglingen-frauenzimmern, february 1, 2013 dipl.-ing. (fh) volker wörner, design engineer person responsible for documents eugen lägler gmbh, kappelrain 2 d-74363 güglingen-frauenzimmern eu declaration of conformity for machines (eu directive 2006/42/ec) the manufactur...