- DL manuals

- Lagler

- Sander

- TRIO 900.65.00.100

- Operating Instructions Manual

Lagler TRIO 900.65.00.100 Operating Instructions Manual

Summary of TRIO 900.65.00.100

Page 1

Three disc sanding machine trio english / englisch trio www.Laegler.Com 00.900.20.002 01.04.2015 *00.900.20.002* operating instructions translation of original operating instructions for the three disc sanding machine.

Page 2

Trio 01.04.2015 english / englisch contents 1 introduction ..................................................................................................................................................................... 5 1.1 features of the machine ................................................

Page 3

Trio 01.04.2015 english / englisch contents 7.5 changing the v-belt ...................................................................................................................................................... 48 7.5.1 removing the v-belt .......................................................

Page 4

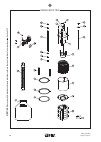

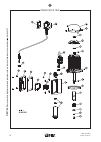

Trio 01.04.2015 english / englisch trio - main components wing nut of cleaning slide dust separator suction hose fig. 1 main components of the three disc sanding machine trio. Handle pressure control sensor on/off switch dust bag box chassis motor cable filter housing switch box handle multiclip for...

Page 5

Trio 01.04.2015 english / englisch introduction 1.1 features of the machine figure 1 depicts the trio with the main components designated. Take your time to become familiar with the machine. 1.2 description of the machine the trio works with three sanding discs that are suspended in a freely rotatin...

Page 6

Trio 01.04.2015 english / englisch introduction 1.3 intended use of the machine the three disc sanding machine trio is suitable for dry sanding of wooden floors or cork floors in a dry environment. Additional milling discs are available for dry work on screed or other subfloors. Application fields •...

Page 7

Trio 01.04.2015 english / englisch introduction 1.5 machine configuration 1.5.1 basic equipment • 1 machine ready for operation • 1 operating instructions • 3 sanding plates for velcro discs, sanding screen and pads • 1 additional weight 9 kg (20 lbs) • 25 dust bags • 1 multiclip for fastening the d...

Page 8

Trio 01.04.2015 english / englisch 1.5.3 wearing parts and safety-related parts check the condition of the wearing parts and safety-related parts mentioned below at regular intervals in order to be able to work safely and optimally at all times. Replace the following parts in case of wear and/or dam...

Page 9

Trio 01.04.2015 english / englisch hazard warnings and safety instructions warning! Risk of death, risk of injury, risk of fire: • be certain to read the hazard warnings and safety instructions before using the machine! • instruct your coworkers and col- leagues accordingly! Otherwise these persons ...

Page 10

Trio 01.04.2015 english / englisch 2 hazard warnings and safety instructions risk of death from unsecured load: • when transported in a car or the like, the machines and all parts must be secured against sliding! Risk of explosion due to sparks while sanding or a high dust concentration in the air: ...

Page 11

Trio 01.04.2015 english / englisch 2 hazard warnings and safety instructions risk of fire from the overheating of the cable. • only the following motor cables and power cables may be used: - machines with motor for mains voltage 220 v or 230 v: cables with three wires and wire cross-sections of at l...

Page 12

Trio 01.04.2015 english / englisch 2 hazard warnings and safety instructions risk of injury and risk of property damage from rotating tools and parts of the machine: • for all operating conditions of the machine only one operator is required. As a consequence, for safety reasons only one person must...

Page 13

Trio 01.04.2015 english / englisch 2 hazard warnings and safety instructions health risk caused by noise: • use hearing protection when conducting work that produces noise! Observe the applicable regulations and legal requirements in your country! Risk of property damage: • remove the sanding plates...

Page 14

Trio 01.04.2015 english / englisch 2 hazard warnings and safety instructions 2.2 general safety instructions • check your machines for damage! Before using the machines, you must inspect the safety devices carefully to ensure that they are working perfectly and as intended. Check whether the moving ...

Page 15

Trio 01.04.2015 english / englisch 2 hazard warnings and safety instructions • do not overload the machines! It works better and more safely in the power range noted. • do not bend too far over the machine! Avoid unnatural postures. Make sure that you stay in a stable position and keep your balance ...

Page 16

Trio 01.04.2015 english / englisch technical data 3.1 data on type plate attention! In order to receive the correct spare parts from us, please specify in inquiries and spare part orders always the serial numbers of your machines! The type plate is located on the switch box of motor (fig. 2). The fo...

Page 17

Trio 01.04.2015 english / englisch technical data 3.2 machine data manufacturer eugen lägler gmbh machine type three disc sanding machine machine name trio serial number see type plate (fig. 2) year of manufacture see type plate (fig. 2) motor type single-phase ac motor voltage 230 v 220 v frequency...

Page 18

Trio 01.04.2015 english / englisch note on noise emission: the values indicated are emission values and must not represent safe workplace values as well. Although a correlation exists between emission levels and immission levels, it is not always possible to determine whether additional precautionar...

Page 19

Trio 01.04.2015 english / englisch this paragraph contains instructions on how to put your trio machine into operation at the workplace. In order to prevent damage and malfunctions it is necessary to strictly stick to the sequence of steps indicated below. Caution! Risk of injury and risk of propert...

Page 20

Trio 01.04.2015 english / englisch commissioning 4 the changing of sanding media is described in: - section 5.3.1, changing the sanding discs - section 5.3.2, conversion to sanding screens - section 5.3.3, conversion to pads in order to work with milling discs please proceed as described in section ...

Page 21

Trio 01.04.2015 english / englisch 9 if there is no dust bag attached to the dust separator, proceed according to section 5.5, changing the dust bag. 10 close the dust bag box (fig. 11, 1) and lock it by turning the two fasteners back to their downward position (fig. 11, 2). 11 fix the velcro sealin...

Page 22

Trio 01.04.2015 english / englisch 4.2 connecting the power cable warning! Risk of death from electrical shock: • never connect the machine to hazardous electrical power sources! Only use safety sockets! • to protect yourself and the machine against faults in the mains supply use a safety switch prc...

Page 23

Trio 01.04.2015 english / englisch commissioning 4 4.3 switching on the machine caution! Risk of injury and risk of property damage from rotating parts of the machine: • make sure the sanding plates or milling discs are in place correctly ( section 5.2, changing the sanding plates)! • the machine mu...

Page 24

Trio 01.04.2015 english / englisch commissioning 4 machines with three-phase ac motor (mains voltage 400 v) if the motor do not start by pushing the green button on the on/off switch (fig. 19, 1) and the light on the switch box shines (fig. 19, 2), the rotation direction of the motor is wrong. To ch...

Page 25

Trio 01.04.2015 english / englisch commissioning 4 4.4 switching off the machine 1 tilt the machine just slightly backwards using the black handle. 2 push the red button (0) on the on/off switch (fig. 22). 3 keep hold of the machine until the sanding plates or milling discs comes to a complete stand...

Page 26

Trio 01.04.2015 english / englisch 5.1 general information and tips the ideal range of usage for the trio is fine sanding with grits starting at 60 and intermediate finish sanding! The trio’s functionality offers the following advantages: • as opposed to a belt sanding machine, a finer surface is ac...

Page 27

Trio 01.04.2015 english / englisch working with the trio 5.2 changing the sanding plates depending on the different types of work to be done you may have to change the sanding plates. 5.2.1 removing the sanding plates 1 switch off the machine and pull the power plug out of the socket! 2 release the ...

Page 28

Trio 01.04.2015 english / englisch working with the trio 5.2.2 mounting the sanding plates 1 mount the sanding plate of your choice by placing one of the three locking bolts into the hole of one rubber plug (fig. 28, 1) and then fitting the other two bolts into their respective rubber plugs (fig. 28...

Page 29

Trio 01.04.2015 english / englisch fig. 31 do not remove the flexible velcro ring when removing worn-out sanding discs. Fig. 32 remove the sanding discs and the flexible velcro rings. 5.3 changing the sanding media 5.3.1 changing the sanding discs 1 switch off the machine and pull the power plug out...

Page 30

Trio 01.04.2015 english / englisch fig. 35 the sanding screens are fixed quickly and securely to the pad base using the plastic plug. Fig. 34 place the normal pads directly on the sanding plates. Working with the trio 5 5.3.2 conversion to sanding screens 1 switch off the machine and pull the power ...

Page 31

Trio 01.04.2015 english / englisch working with the trio 5 4 remove the three sanding discs and flexible velcro rings (fig. 32) and replace them by pads. 5 fasten the pads with a plastic plug (fig. 36). To remove a pad, grasp beneath it using both hands and pull this evenly off the sanding plate tog...

Page 32

Trio 01.04.2015 english / englisch fig. 42 tighten the counter nut again. Fig. 41 use the torx screwdriver to adjust the adjustment screw. 3 loosen the counter nut (wrench size 13 mm) on the top edge of the milling disc for the holder to be adjusted. Use the torx screwdriver in the shaft of the thre...

Page 33

Trio 01.04.2015 english / englisch working with the trio 5 5.5 changing the dust bag warning! Risk of fire from the formation of sparks while sanding: • note the warning on the dust separator (fig. 43)! • the dust bag must always be removed from the machine directly after sanding (fig. 44, 1)! Place...

Page 34

Trio 01.04.2015 english / englisch fig. 47 pull the cover foil from the adhesive strip (1) and seal the dust bag (2). The dust bag must be deposited in a closed and non-combustible container! Fig. 48 make sure the dust bag is in the correct position: - print towards you (a), - adhesive strip towards...

Page 35

Trio 01.04.2015 english / englisch transport and storage transport and storage warning! Risk of injury and risk of property damage: when transported in a car or the like, the machines and all parts must be secured against sliding! Risk of fire from formation of sparks while sanding: always transport...

Page 36

Trio 01.04.2015 english / englisch 4 pull the suction hose from the neck of the upper part of the separator (fig. 53). 5 loosen the two cross grip fasteners at the side by which chassis is attached to machine housing (fig. 54, 1) and move the chassis backwards (fig. 54, 2). Transport and storage 6 f...

Page 37

Trio 01.04.2015 english / englisch fig. 57 insert the cable plug of the sensor into the switch. Make sure that the nose of the cable plug is inserted into the groove of the socket! Fig. 56 hook the switch into holder on the chassis. Fig. 58 lock the cable plug of the sensor by turning the ring nut. ...

Page 38

Trio 01.04.2015 english / englisch 6.3 storage warning! Risk of fire from formation of sparks while sanding: always store the machine without dust bag! If the machine is to be stored for a longer period, make sure it is stored in a dry, frost-free room which is not subject to great fluctuations in t...

Page 39

Trio 01.04.2015 english / englisch maintenance work and replacement of wearing parts maintenance work and replacement of wearing parts warning! Risk of death from electrical shock and risk of injury from rotating parts of the machine: • all extensive maintenance work, especially on the electrical eq...

Page 40

Trio 01.04.2015 english / englisch maintenance work and replacement of wearing parts certain maintenance jobs ought to be performed from time to time, at the latest, however, when damage is established or the red led of the pressure control sensor lights up. Use only lÄgler ® original spare parts. P...

Page 41

Trio 01.04.2015 english / englisch fig. 61 move the cleaning slide up and down while continuously turning the wing nut. Fig. 62 push the cleaning slide as deep as possible into the dust separator (1). Insert the power plug into the mains socket (2). You can now switch the machine back on again (3). ...

Page 42

Trio 01.04.2015 english / englisch fig. 66 place a board between the closed dust bag box and the chassis. Maintenance work and replacement of wearing parts fig. 64 hook the on/off switch into the transport holder on motor switch box. 7 fig. 65 pull the suction hose from the neck of the upper part of...

Page 43

Trio 01.04.2015 english / englisch fig. 67 remove the four cap nuts and washers on top of the dust separator. Fig. 68 lift off the upper part of the separator. Fig. 69 lift the filter cartridge out of the filter housing. Maintenance work and replacement of wearing parts fig. 70 make sure the seal si...

Page 44

Trio 01.04.2015 english / englisch 4 put the washers on the screws which project out of the upper part of the separator and put the cap nuts back on (fig. 73, 2). Only place these on loosely, don’t tighten them. 5 now it is time to push the cleaning slide all the way down to centre the system (fig. ...

Page 45

Trio 01.04.2015 english / englisch maintenance work and replacement of wearing parts fig. 75 remove the eight screws and pull off the cover. 7 fig. 76 turn the counter nut back to the casing wall. Fig. 77 turn the clamping nut back to the counter nut. Fig. 78 push the tooth belt tensioner back (1) a...

Page 46

Trio 01.04.2015 english / englisch maintenance work and replacement of wearing parts fig. 79 with the tensioner pulled back (1), insert the tooth belt with the geared side facing and engaging the pinion gearing with the flat side of belt skirting the pulleys (2). Fig. 80 when the tooth belt tensione...

Page 47

Trio 01.04.2015 english / englisch maintenance work and replacement of wearing parts 7 fig. 83 twist the counter nut to the clamping nut. Fig. 84 carefully fasten the two nuts. Fig. 85 replace the cover and fix it in place using the eight screws. 4 twist the counter nut to the clamping nut (fig. 83)...

Page 48

Trio 01.04.2015 english / englisch maintenance work and replacement of wearing parts 7 fig. 88 hook the on/off switch into the transport holder on motor switch box. Fig. 87 loosen the ring nut (1) and remove the cable plug from the switch (2). Fig. 86 bring the machine back into vertical position. F...

Page 49

Trio 01.04.2015 english / englisch maintenance work and replacement of wearing parts fig. 92 release the tension of the v-belt by carefully applying the cranked closed-mouth wrench and moving the belt tensioner as shown. 7 fig. 91 remove the v-belt guard fixing screw (1) and remove the v-belt guard ...

Page 50

Trio 01.04.2015 english / englisch maintenance work and replacement of wearing parts 7 fig. 98 insert the closed mouth wrench below the clamping roll (1), move the belt tensioner (2) and insert the v-belt into the pulleys (3 + 4). Fig. 96 loop the new v-belt around the motor pulley (1) and insert th...

Page 51

Trio 01.04.2015 english / englisch fig. 100 insert the v-belt guard into the slot at the motor, push it towards the motor (1) and tighten it with the screw (2). Maintenance work and replacement of wearing parts 7 caution! Risk of injury: during mounting of the v-belt take care of your fingers danger...

Page 52

Trio 01.04.2015 english / englisch maintenance work and replacement of wearing parts 7 fig. 104 position the new sealing felt at one side first before fixing it completely in place. Fig. 105 press the sealing felt carefully all over, especially at the edges and around the cutaways for the sanding pl...

Page 53

Trio 01.04.2015 english / englisch fig. 107 replacing the rubber plugs. Make sure of the correct insertion position! Maintenance work and replacement of wearing parts 7 10 tighten all eight screws equally tight. 11 remount the sanding plates or milling discs as described in section 5.2.2, mounting t...

Page 54

Trio 01.04.2015 english / englisch regular inspection and maintenance work fig. 108 the inspection label on the motor confirms the electrical and mechanical safety of the machine and indicates when the next maintenance check is due. Regular inspection and maintenance work in accordance with accident...

Page 55

Trio 01.04.2015 english / englisch note: • all lÄgler ® machines and electrical e q u i p m e n t a r e s u b j e c t e d t o a n electrical inspection as well as a thorough visual and functional test before they leave the factory. • a recurring inspection of the machines and electrical equipment mu...

Page 56

Trio 01.04.2015 english / englisch warning! Risk of death from electrical shock: work on the electrical equipment is to be conducted exclusively by a qualified e l e c t r i c i a n ! T h e m a c h i n e m u s t b e switched off and the power plug removed from the socket during this work! The circui...

Page 57

Trio 01.04.2015 english / englisch • the temperature switch in the motor has switched off the machine because - the power cables have a total length of more than 20 m (790”), - the power cables have wire cross-sections which are too small: at mains voltage 220 v or 230 v are the wire cross-sections ...

Page 58

Trio 01.04.2015 english / englisch 9.3 the machine runs but has no or very little sanding power capacity • sanding plates: the sanding medium is incorrect or dull and must be replaced. Section 5.3, changing the sanding media • milling discs: the indexable inserts are dull or damaged and must be turn...

Page 59

Trio 01.04.2015 english / englisch 9.4 the machine vibrates intensely and runs noisily • sanding plates: the sanding media are not centred or not fixed properly to the sanding plates. This must be corrected correspondingly. Section 5.3, changing the sanding media • milling discs: the indexable inser...

Page 60

Trio 01.04.2015 english / englisch 9.5 the machine runs but creates a great deal of dust • the filter cartridge in the dust separator must be cleaned. Section 7.2, cleaning the filter cartridge • the cleaning slide of the dust separator must be pushed back into the dust separator until the limit sto...

Page 61

Trio 01.04.2015 english / englisch 9.6 sanding problems (waves, strips, grooves) • the floor was not vacuumed before sanding. The floor must be vacuumed thoroughly always directly before each sanding step. • the sanding medium is damaged or incorrect and must be replaced. Section 5.3, changing the s...

Page 62

Trio 01.04.2015 english / englisch notes 62.

Page 63

Trio 01.04.2015 english / englisch notes 63.

Page 64

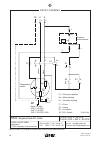

Trio 01.04.2015 english / englisch eugen lÄgler gmbh kappelrain 2 d-74363 güglingen-frauenzimmern k1 1 2 14 3 13 ha hi f1 3 p > 3 k1 a1 a2 c b 40 f m m 1 ~ 2 1 1 3 4 l1 n pe 2 h1 4 1 5 6 2 10.06.1996 s1 s2 m1 red black yellow temperature switch on off motor 1.8 kw 230 v / 50 cps 230 v / 60 cps 220 v...

Page 65

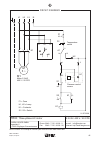

Trio 01.04.2015 english / englisch eugen lÄgler gmbh kappelrain 2 d-74363 güglingen-frauenzimmern l2 k1 13 14 3 p > k1 m 3 ~ 2 3 n h1 4 1 5 6 2 01.07.2008 l3 l2 l1 k1 a1 11 12 14 l3 l1 a1 11 12 14 a1 11 12 14 1 h2 f2 m1 s1 s2 on f1 6.3 a temperature switch motor 2.2 kw 400 v / 50 cps off pressure co...

Page 66

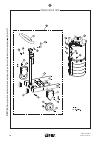

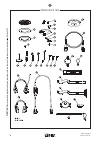

Trio 01.04.2015 english / englisch spare parts trio 66 a ttention: please specify in inquiries and spare part orders always the serial numbers of your machines ( section 3.1 )! 11.

Page 67

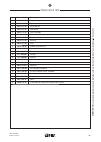

Trio 01.04.2015 english / englisch spare parts trio item part number description 1 900.70.05.100 frame, complete 2 900.70.25.105 bumper felt 3 900.70.80.105 protective rubber 4 900.70.36.100 wheel, complete 6 900.70.34.100 wheel holder 7 900.70.32.105 wheel 8 0125.1008.000 washer 9 7380.1008.055 scr...

Page 68

Trio 01.04.2015 english / englisch spare parts trio 68 a ttention: please specify in inquiries and spare part orders always the serial numbers of your machines ( section 3.1 )! 11.

Page 69

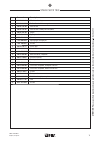

Trio 01.04.2015 english / englisch spare parts trio item part number description 1 900.16.10.100 separator upper part 2 900.16.21.100 opener, complete 3 900.16.23.100 sealing brush 4 900.16.45.105 filter brush 5 900.16.18.105 filter cartridge 6 900.16.19.100 protective cover 7 900.16.17.100 cover lo...

Page 70

Trio 01.04.2015 english / englisch spare parts trio 70 a ttention: please specify in inquiries and spare part orders always the serial numbers of your machines ( section 3.1 )! 11.

Page 71

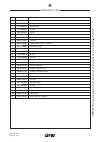

Trio 01.04.2015 english / englisch spare parts trio item part number description 1 900.01.10.200 machine housing 2 900.01.42.100 self-adhesive velcro negative 3 900.01.50.100 velcro seal 900.01.50.105 velcro seal trio by the roll (50 m) 4 900.01.60.100 angle 5 0127.1012.000 spring washer 6 0912.1012...

Page 72

Trio 01.04.2015 english / englisch spare parts trio 72 a ttention: please specify in inquiries and spare part orders always the serial numbers of your machines ( section 3.1 )! 11.

Page 73

Trio 01.04.2015 english / englisch spare parts trio item part number description 1 900.07.10.200 inner housing 2 900.07.20.100 pick up 3 3212.0060.202 ball bearing 4 0471.0060.000 circlip 5 7991.1008.025 screw 10 6797.1010.000 washer 11 0933.1010.065 screw 12 000.10.10.061 washer 14 900.67.00.200 to...

Page 74

Trio 01.04.2015 english / englisch spare parts trio 74 a ttention: please specify in inquiries and spare part orders always the serial numbers of your machines ( section 3.1 )! 11.

Page 75

Trio 01.04.2015 english / englisch spare parts trio item part number description 900.65.00.100 motor, 230 v / 50 cps / 1.8 kw 901.65.00.100 motor, 230 v / 60 cps / 1.8 kw 902.65.00.100 motor, 220 v / 60 cps / 1.8 kw, usa 905.65.00.100 motor, 400 v / 50 cps / 2.2 kw, three-phase current 1 0471.0020.0...

Page 76

Trio 01.04.2015 english / englisch spare parts trio 76 a ttention: please specify in inquiries and spare part orders always the serial numbers of your machines ( section 3.1 )! 11.

Page 77

Trio 01.04.2015 english / englisch spare parts trio item part number description 900.02.10.200 sanding plate, complete 1 900.02.12.305 velcro ring 200 mm 2 900.02.13.205 velcro ring flexible 200/125 mm diameter 5 900.02.23.205 plastic pin 900.02.40.100 milling disc trio, complete 7 900.02.42.105 fas...

Page 78

Trio 01.04.2015 english / englisch notes 78.

Page 79

Trio 01.04.2015 english / englisch service passport service passport please enter the serial number and the year of manufacture of your machine (see type plate) on the rear side of these operating instructions! Otherwise the service passport will not be valid! This service passport is a document. Ma...

Page 80: Trio

Eu declaration of conformity copyright © eugen lägler gmbh, 2015 – all rights reserved – t ranslation of original operating instructions trio – 9 / 01.04.201 5 – printed on chlorine-free bleached paper . Part number 00.900.20.002 no guarantee is provided for the contents of these operating instructi...