- DL manuals

- Laguna

- Saw

- 14-Twelve

- Manual

Laguna 14-Twelve Manual

Summary of 14-Twelve

Page 1

14-twelve © 2013 laguna tools, inc. All rights reserved. Part no. Mband1412-175 laguna tools 17101 murphy ave. Irvine, california 92614 ph: 800.234.1976 www.Lagunatools.Com bandsaw manual.

Page 2: Dear Woodworker,

2 thank you for your purchase and welcome to the laguna tools group of discriminating woodworkers. I understand that you have a choice of where to purchase your machines and appreciate the confidence you have in our products. Every machine sold by laguna tools has been carefully designed and well th...

Page 3: Safety Rules

3 warning: for your own safety, read instruction manual before operating bandsaw 1. Wear eye protection. 2. Do not remove jammed cut off pieces until blade has stopped. 3. Maintain proper adjustment of blade tension, blade guides and thrust bearings. 4. Adjust upper guide to just clear workpiece. 5....

Page 4

4 operation is dusty. Everyday eyeglasses only have impact-resistant lenses; they are not safety glasses. 12. Secure work. Use clamps or a vise to hold work when practical. It's safer than using your hand, and it frees both hands to operate tool. 13. Don't overreach. Keep proper footing and balance ...

Page 5: Grounding Instructions

5 1. All grounded, cord-connected tools: in the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. The ...

Page 6

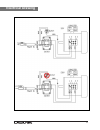

6 this tool. If the tool must be reconnected for use on a different type of electric circuit, the reconnection should be made by qualified service personnel; and after reconnection, the tool should comply with all local codes and ordinances. Fig. 1 3. Grounded, cord-connected tools intended for use ...

Page 7: Table of Contents

7 page number safety rules 3 warranty 8 noise emission 9 specification sheet 9 receiving your machine 10 introduction to your machine 10 parts of the bandsaw 13 where to locate your machine 17 unpacking your machine 17 assembly and set up 18 testing the bandsaw 26 using the bandsaw 36 maintenance an...

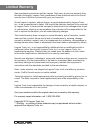

Page 8: Limited Warranty

8 new woodworking machines sold by laguna tools carry a one-year warranty from the date of shipping. Laguna tools guarantees all new machines sold to be free of manufacturers’ defective workmanship, parts, and materials. We will repair or replace, without charge, any parts determined by laguna tools...

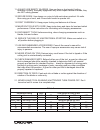

Page 9: Noise Emission

9 motor voltage/hp breaker 15 amp throat 13 5/8" (346mm) table cast iron 16" x 21 1/2" (406.4mm x 546mm) table tilt - 7 degrees + 45 degrees miter slot 3/8" x 3/4" (9.525mm x 19.05mm) table height 38" (965mm) fly wheel cast iron resaw capacity 12" (305mm) minimum blade length 114 3/4" (2,914mm) maxi...

Page 10: Receiving Your Machine

10 . It is probable that your machine will be delivered by a third party. Before you unpack your new machine, you will need to first inspect the packing, invoice and shipping documents supplied by the driver. Ensure that there is no visible damage to the packing or the machine. You need to do this p...

Page 11

11 continuous sawing action. Because the direction of the blade is always downward toward the table, there is little danger (except for special cuts) that the wood will be thrown back at the operator, which is called a kickback. There is always danger of kickback when a circular saw is being used. F...

Page 12

12 fence parts and hand wheel fence guide bar table ratchet handles fence lock knob feet & screws t-handle fence bar parts and fixings table fixings note: the mobility kit and light are optional.

Page 13: Parts of The Bandsaw

13 2 1 5 6 8 10 14 7 15 16 12 13 4 9 11 3 17 1. Tension indicator window 10. Rip fence assembly 2. Switch 11. Dust p ort 4” 3. Motor 12. Quick-release blade tension lever 4. Frame 13. Blade tracking knob 5. Blade tension handle 14. Optional mobility kit 6. Blade tracking window 15. Optional light 7....

Page 14

14 tension indicators are designed to indicate the compression of a spring. As a rule, the greater the spring compression, the greater the tension on the blade. The tension scale does not register until the blade is relatively taut and is located on the inside of the body of the bandsaw. The tension...

Page 15

15 the upper blade guides are attached to the blade guide shaft. The shaft is vertically adjustable with a hand wheel. The guides should be adjusted so the guides are just above the wood being cut. This gives the blade maximum stability and is also the safest way to operate the bandsaw. There are tw...

Page 16

16 the optional mobility kit is fitted to the stand and consists of two fixed wheels at the back of the bandsaw and a swiveling wheel at the front of the band saw. The swivel wheel is activated and deactivated with a foot lever. With the swivel wheel deactivated, the bandsaw sits on two feet. The op...

Page 17: Where to Locate Your Bandsaw

17 rotated, will move the wheel up or down. The machine has a quick-acting blade release mechanism that is located at the back of the machine and will remove the tension from the blade to speed the removal and fitting of blades. The mechanism has a spring, which helps to keep the tension constant as...

Page 18: Assembly and Set Up

18 2. Lift the bandsaw out of the packaging. You will need two or more people, as the bandsaw is heavy. 3. Lift the bottom styrofoam out and remove the parts that are packaged under the bandsaw and packaging. Fixing bolts stand viewed from inside the stand consists of two sets of panels. Two side pa...

Page 19

19 optional mobility kit support bracket fixing screw front mobility wheel with spring fitted mobility front wheel screwed onto the shaft the mobility kit consists of a front swivel wheel and two wheels at the back of the bandsaw. 1. Fit the support bracket this will hold the bracket in position. (i...

Page 20

20 2. Fit the front swivel wheel on the stand as shown by bolting in position through the stand onto the support bracket. Do not fully tighten the screws, as the height of the wheel will have to be adjusted to suit the stand. 3. Fit the spring onto the shaft and then screw the wheel onto the shaft 5...

Page 21

21 bandsaw raised off the ground you will probably find that it is easier to fit the stand to the bandsaw with it in the horizontal position and then lifting it to the vertical position as shown in the above photographs. If you lay your bandsaw down as shown, it must be a minimum of 8" off the groun...

Page 22

22 that you feel is unsafe or that you do not have the physical capability of achieving, as the bandsaw is heavy. You will probably find it easier to assemble the stand to the bandsaw prior to fitting the other part (table, etc.), as it is lighter. With the stand aligned to the bandsaw, fit the fixi...

Page 23

23 table mounted to the bandsaw trunion clamp stud ratchet handle with the table fitted to the trunions, assemble the two ratchet handles. Adjusting the table for square to the blade is covered latter in the manual. Loosen the clamping screw so that the handle can slide on the shaft. Align the screw...

Page 24

24 table rule with fixings table with rule mounted attach the rule to the table with the fixings supplied. Do not fully tighten the bolts, as the position of the rule will have to be adjusted to suit the blade, which will be detailed latter in the manual. Spacer fence bar fence support fence support...

Page 25

25 1. Fit the fence bar to the table with the screws and spacers suppliers. Note. The distance between the fixing holes and the end of the bar is different, and the end that has the longest distance must be at the back of the bandsaw (closest to the column). 2. Slide the fence support onto the fence...

Page 26: Testing The Bandsaw

26 fixing screws and cable clips light fitted in position suggested cable route light plugged into 110v socket the light is fitted to the top of the bandsaw as shown. The light is supplied with a 110-volt three-pin plug. The cable must be held in position with the clips provided and positioned so th...

Page 27

27 5. Wear a dust mask; long-term exposure to the fine dust created by the bandsaw is not healthy. 6. Remove your tie, rings, watch and all jewelry. Roll up your sleeves; you do not want anything to get caught in the saw. 7. Make sure that the guards are in place and use them at all times. The guard...

Page 28

28 3. Check that the machine is clear of all tools and other loose objects. 4. Check that all the adjusting and locking handles are tight. 5. Check that there is no blade fitted; it is far safer to test the machine without a blade fitted. 6 . Start the bandsaw by pulling the red start/stop button ou...

Page 29

29 . A lot of people do not like to change the blades and go to great lengths to avoid doing it. To use the bandsaw to its greatest advantage, you will have to use the appropriate blade and track it quickly. This is a habit that can be easily developed. If you use a step-by-step method of tracking a...

Page 30

30 9. Deactivate the quick action blade tension lever and rotate the blade tension wheel so that the blade can fit over the lower flywheel. 10. Activate the quick action blade tension lever. 11. Apply light tension to the blade with the blade tension wheel. Tracking large blades . There has been a l...

Page 31

31 1. To track the blade s tart rotating the wheels by hand in the normal direction. As you do this, watch the blade to determine where the blade wants to track. If the blade is tracking too far forward or backward, make small adjustments with the tracking adjustment knob located at the back of the ...

Page 32

32 plug the machine into the power. Turn the machine on for a second and switch off. Watch how the blade runs. If the blade tracks well, then run the machine at full power. If the blade tracking needs adjustment, repeat adjustment. Tension the blade as described in method 1. Close all the doors and ...

Page 33

33 welcome to a new era in bandsawing. You have purchased a bandsaw with a revolutionary blade guide system that is designed to give you years of safe, high- quality bandsawing. Most blade guides are designed to support the blade on the sides and either above or below the side guides at the back of ...

Page 34

34 7. The side guide blocks must be tightened before running the machine to avoid jamming the blade and damaging the machine and/or guide blocks. 8. When cutting gummy or green wood, the blade can become covered with resin. You will find that the surround guide system ceramic blocks remove the resin...

Page 35

35 guide to obtain the correct clearance until you gain experience. Tighten the clamp screws and remove the paper. Rotate the blade by hand, ensuring that the weld of the blade does not hit the ceramic blocks, as this will cause damage. If the blade has a bad weld, dress the blade or return it to yo...

Page 36: Using The Bandsaw

36 before you cut any wood, read the safety rules at the front of this manual. Although the bandsaw is usually associated with cutting curves, a variety of straight cuts are easily made with the saw. In fact, it is often used to rip wood because it is much safer than a radial arm saw and also has a ...

Page 37

37 1. Make a straight pencil line on the edge of a board. 2. Feed the wood into the blade cutting next to the pencil mark. If the blade is drifting, you will have to compensate by angling the wood to keep the cut straight. 3. Stop the cut in the middle of the wood and mark (with pencil) the angle on...

Page 38

38 table rule adjustment slot there is a rule that is fitted to the side of the table and can be used as a quick guide on the distance that the fence is from the blade. Note. The rule will have to be adjusted each time the fence is adjusted for drift, as this will change the distance the fence is fr...

Page 39

39 1. Loosen the clamp screws that are located on the cast bracket. 2. Slide the aluminum fence off the cast iron bracket. 3. Slide the aluminum fence back onto the bracket using the second slot and retighten the clamp screws. Resawing is the process of cutting a board in half along its height. The ...

Page 40

40 the thicker the blade, the stiffer the blade and the straighter the cut. The thicker the band, the greater the tendency for the blade to break. The size of the teeth. This is usually quoted in teeth per inch (tpi). The larger the tooth, the faster the cut because the tooth has a large gullet and ...

Page 41

41 the dimension from the back of the blade to the front of the teeth. The wider the blade, the stiffer the blade and the straighter the cut. This is usually called beam strength. But wide blades cannot cut small radiuses. The narrower the blade, the more flexible the blade and the greater the tende...

Page 42

Bandsaw, you will probably have a good idea of the blades that are suitable for you. If you lack the experience or are unsure of the type of work you will be doing with your machine, we recommend that you purchase a selection similar to that listed below, which is a good general selection and will t...

Page 43

43 . 1. Excessive blade thickness in relation to the flywheel diameter. 2. Defective welding. 3. Incorrect tension, particularly if the blade is over tensioned; the tension spring no longer fulfills its function. 4. After use it is recommended that you slacken the tension, especially overnight (plac...

Page 44

44 without backtracking any curve that has a radius as much as or more than is shown on the chart. For example: a 3/16" blade will cut a circle with a 5/16" radius or a 5/8" diameter. To test if a 3/16" blade would work for a particular curve, place a dime (roughly 5/8") over the pattern. The 3/16" ...

Page 45

45 de. Without a doubt it is more difficult to explain how to coil a bandsaw blade than it is to actually do it. Nevertheless, below are easy-to-follow instructions on folding a blade. While wearing a jacket or long-sleeved shirt and gloves, hold the blade in front of you in one large loop, with the...

Page 46

46 there is another variation of this that works well with small blades but simply is not possible for larger bandsaw blades, unless you're very big and strong. This method works the same as the method above, but rather than holding the blade with both hands, grasp the blade at the top while holding...

Page 47

47 the steering wheel method. Start with the blade in front of you, as if you're holding a steering wheel with your hands at the 9 o'clock and 3 o'clock positions. Simultaneously twist your left hand up and your right hand down. As the blade starts to fold, move your hands closer together while tilt...

Page 48

48 . All tools and machines require regular maintenance, and the bandsaw is no exception. This section details the general maintenance and care of your bandsaw. In general, we recommend that you only use a teflon- based lubricant on the bandsaw. Regular oil attracts dust and dirt, and the teflon ten...

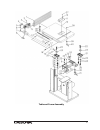

Page 49

49 drive belt adjusting bolt motor drive pulley drive belt flywheel shaft nut to replace the belts you will have to remove the lower flywheel. 1. Loosen the motor clamp bolts and move the motor so that the tension is completely removed from the drive belt. 2. Remove the flywheel shaft nut that clamp...

Page 50

50 all bearings are sealed for life and do not require any maintenance. If a bearing becomes faulty, replace it. The bandsaw is made from steel and cast iron. All non-painted surfaces will rust if not protected. It is recommended that the table be protected by coating with wax if the machine is not ...

Page 51

51 2. Internal breaker faulty. Replace the breaker. Tries to start but will not turn. 1. With the power disconnected from the machine, open the doors and try to turn the wheel by hand. If the wheel is not turning, check the reason for the jamming. Typical reasons are: guides too tight, wood jammed i...

Page 52

52 . Bad weld. Dress the weld or change the blade. . 1. Dull blade. Change the blade or resharpen the blade. 2. Pitch is too small for the depth of cut. Change to a blade with the correct pitch. 3. Guides too tight. Adjust the guides. 4. Wood too hard for the selected blade. Change the blade. 5. Bla...

Page 53: Electrical Drawing

53 electrical drawing.

Page 54

54 industrial work light: optional exploded view drawings and parts list.

Page 55

55 lower wheel and motor assembly.

Page 56

56 stand assembly.

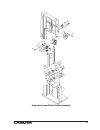

Page 57

57 table and fence assembly.

Page 58

58 upper and lower blade guides assembly.

Page 59

59 upper wheel assembly.

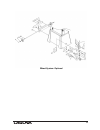

Page 60

60 wheel system: optional.

Page 61

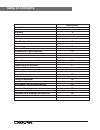

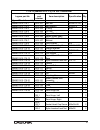

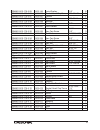

61 lt14-12 [mband1412-175] 110 volt bandsaw laguna part no supplier part number item description specification qty upper wheel assembly pband1412-175-1 1412-101 hex nut m14x1.5- lh 1 pband1412-175-2 1412-102 ball bearing 6202llu 2 pband1412-175-3 1412-103 c-ring r35 2 pband1412-175-4 1412-104 pu tir...

Page 62

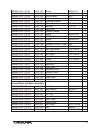

62 pband1412-175-26 1412-126 screw m4x0.7x8 10 pband1412-175-27 1412-127 hex nut #10-24 4 pband1412-175-28 1412-128 lock washer #10 4 pband1412-175-29 1412-129 flat washer #10 4 pband1412-175-30 1412-130 tracking window 2 pband1412-175-31 1412-131 screw #10-24×1/2" 4 pband1412-175-32 1412-132 hex nu...

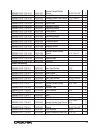

Page 63

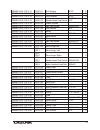

63 pband1412-175-2-11 1412-211 flat washer 5/16" 4 pband1412-175-2-12 1412-212 spindle pulley 1 pband1412-175-2-13 1412-213 lock washer 5/16" 3 pband1412-175-2-14 1412-214 socket head cap screw 5/16"-18x1- 1/2" 3 pband1412-175-2-15 1412-215 lower spindle 1 pband1412-175-2-16 1412-216 hex cap screw m...

Page 64

64 pband1412-175-2-43 1412-108 lock washer 3/8" 2 pband1412-175-2-44 1412-244 hex nut m14x1.5 1 pband1412-175-2-45 1412-245 motor 1 1412- 245mf motor fan (not shown) 1 1412- 245mfc motor fan cover (not shown) 1 1412- 245jb junction box (not shown) 1 1412- 245jbc junction box cover (not shown) 1 pban...

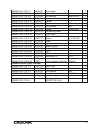

Page 65

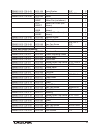

65 pband1412-175-3-25 1412-142 lock washer 1/4" 6 pband1412-175-3-26 1412-326 socket head cap screw m6x1.0x16 1 pband1412-175-3-27 1412-327 pointer 1 pband1412-175-3-28 1412-328 screw m5x0.8x8 1 pband1412-175-3-29 1412-329 bracket 1 pband1412-175-3-30 1412-242 flat washer 3/8" 2 pband1412-175-3-31 1...

Page 66

66 pband1412-175-4-21 1412-421 socket head button screw 5/16"-18x1/2" 4 pband1412-175-4-22 1412-422 guide bar 1 pband1412-175-4-23 1412-423 socket head cap screw 1/4” - 20x5/8” 4 pband1412-175-4-24 1412-142 lock washer 1/4" 2 pband1412-175-4-25 1412-425 lock knob 4 pband1412-175-4-26 1412-426 cerami...

Page 67

67 pband1412-175-6-7 1412-607 fixed plate 1 pband1412-175-6-8 1412-608 wheel bracket 1 pband1412-175-6-9 1412-609 du bearing mb1620du 1 pband1412-175-6-10 1412-610 spring 1 pband1412-175-6-11 1412-611 caster 1 pband1412-175-6-12 1412-612 spacer 2 pband1412-175-6-13 1412-613 flat washer m5 1 pband141...

Page 68: Laguna Tools

© 2013 laguna tools, inc. All rights reserved. Laguna tools 17101 murphy ave. Irvine, california 92614 ph: 800.234.1976 www.Lagunatools.Com.