- DL manuals

- Laguna

- Saw

- MBAND14BX110-175

- Manual

Laguna MBAND14BX110-175 Manual

Bandsaw Manual

LAGUNA TOOLS

2072 Alton Parkway

Irvine, California 92606

Ph: 800.234.1976

www.lagunatools.com

Part No. MBAND14BX110-175

LT14BX Bandsaw 110V 1.75HP 13" Resaw

Part No. MBAND14BX220-250

LT14BX Bandsaw 220V 2.5HP 13" Resaw

© 2017, Laguna Tools, Inc. LAGUNA® and the LAGUNA Logo®

are the registered trademarks of Laguna Tools, Inc. All rights reserved.

Summary of MBAND14BX110-175

Page 1

Bandsaw manual laguna tools 2072 alton parkway irvine, california 92606 ph: 800.234.1976 www.Lagunatools.Com part no. Mband14bx110-175 lt14bx bandsaw 110v 1.75hp 13" resaw part no. Mband14bx220-250 lt14bx bandsaw 220v 2.5hp 13" resaw © 2017, laguna tools, inc. Laguna® and the laguna logo® are the re...

Page 3

3.

Page 4

4.

Page 5

5 table a ampere rating volts total length of cord in feet 120 25 50 100 150 240 50 100 200 300 more than not more than minimum gage for cord 0 6 18 16 16 14 6 10 18 16 14 12 10 12 16 16 14 12 12 16 14 12 not recommended grounding instructions 1. All grounded, cord-connected tools: in the event of a...

Page 6

6 as a properly grounded outlet box. 3. Grounded, cord-connected tools intended for use on a supply circuit having a nominal rating of 150 –250 volts, inclusive: this tool is intended for use on a circuit that has an outlet that looks like the one illustrated in sketch d. The tool has a grounding pl...

Page 7

7 locking the bandsaw. It is strongly recommended that the bandsaw is never be left unattended in the unlocked condition. To lock the machine it is recommended that a cover (not supplied) is made to lock the control panel. We have supplied two concepts for locking the panel (see below). The cover ca...

Page 8

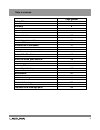

8 table of contents. Page number safety rules 3 warranty 9 specification sheet 10 noise emission 10 receiving your machine 11 introduction to bandsaws 11 what you will receive with your bandsaw 12 parts of the bandsaw 14 where to locate your machine 18 unpacking your machine 18 assembly and setup 19...

Page 9

Limited warranty new machines and accessories sold by laguna tools carry a one-year warranty effective from the date of shipping. Machines sold through dealers must be registered with laguna tools within 30 days of purchase to be covered by this warranty. Laguna tools guarantees all new machines and...

Page 10

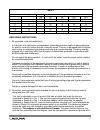

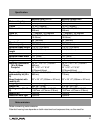

10 specification. Mband14bx110-175 mband14bx220-250 motor voltage/hp 115v / 1 3/4 hp 230v / 2 1/2 hp breaker 15 amp 15 amp throat 13 5/8" (346mm) 13 5/8" (346mm) table cast iron 16" x 21 1/2" (406.4mm x 546mm) 16" x 21 1/2" (406.4mm x 546mm) table tilt - 7 degrees + 45 degrees - 7 degrees + 45 degre...

Page 11

11 supplementary precautions cannot be precisely determined. In addition to noise level and exposure time, other factors affecting potential hearing loss include characteristics of the working environment. (for example, adjacent machines can affect the total level of ambient noise.) it is also possi...

Page 12

12 this bandsaw is designed to give you years of safe service. Read this owner’s manual in its entirety before assembly or use. The bandsaw is generally defined as a saw blade in the form of an endless steel band that rotates around two or more wheels. This blade is a continuous metal band with teet...

Page 13

13 fence guide bar table ratchet handles & washers rubber feet and fixings table fence guide bar attachment parts t bar.

Page 14

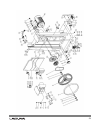

14 parts of the bandsaw. Note: the mobility kit and light are optional. 4 2 1 9 8 7 9 5 8 10 17 14 18 16 6 12 13 11 15 3 1. Tension indicator window 10. Rip fence assembly 2. Switch 11. Dust port 4” 3. Motor 12. Quick-release blade tension lever 4. Frame 13. Blade tracking knob 5. Blade tension hand...

Page 15

15 1. Tension indicator / window. Tension indicators are designed to indicate the compression of a spring. As a rule, the greater the spring compression, the greater the tension on the blade. The tension scale does not register until the blade is relatively taut and is located on the inside of the b...

Page 16

16 8. Blade guide adjustment hand wheel. The upper blade guides are attached to the blade guide shaft. The shaft is vertically adjustable with a hand wheel. The guides should be adjusted so the guides are just above the wood being cut. This gives the blade maximum stability and is also the safest wa...

Page 17

17 14. Optional mobility kit. The optional mobility kit is fitted to the base of the bandsaw and consists of two fixed wheels at the front of the bandsaw and a swivel wheel at the back of the band saw. The swivel wheel is activated and deactivated with a foot lever. With the swivel wheel deactivated...

Page 18

18 20. Blade tilt and tension mechanism. The upper wheel is attached to the tilt and tension mechanism. This mechanism adjusts the wheel so that the bandsaw blade can be adjusted for blade tracking. This is achieved by a screwed handle at the back of the machine that pushes on the mechanism and adju...

Page 19

19 spring and could cause injury. Your bandsaw will be shipped in custom packaging consisting of a heavy-duty cardboard box and styrofoam internal packaging. 1. Open the cardboard box and remove the loose parts and top styrofoam. 2. Lift the bandsaw out of the packaging. You will need two or more pe...

Page 20

20 1. Support the bandsaw on wooden blocks. 2. Fit the swivel assembly to the back of the bandsaw with the provided bolts. 3. Fit the front wheels to the front of the bandsaw with the bolts provided and remove the two rubber feet that are close to the front wheels.. Note. Never operate the bandsaw w...

Page 21

21 tilt blanking disc tilt stop bolt table tilt hole tilt blanking disc the table has a reference stop bolt that is used to quickly align the table after tilting. The stop bolt hits the tilt-blanking disc when it is positioned over the table tilt hole. When the tilt blanking disc is moved away from ...

Page 22

22 trunion clamp stud ratchet handle with the table fitted to the trunions, assemble the two ratchet handles and flat washers. How to adjust the table for square to the blade. This will be detailed later in the manual. Fitting the table rule. Attach the rule to the table with the fixings supplied. D...

Page 23

23 fitting the fence. 1. Fit the fence bar to the table with the screws and spacers supplied. Note. The distance between the fixing holes and the end of the bar is not symmetrical, and the end that has the longest distance must be at the back of the bandsaw (closest to the column). 2. Slide the fenc...

Page 24

24 the fence support and the fence are held off the table with a nylon-support allen screw. This screw ensures that the fence and the fence support do not damage the table. The screw is adjustable to compensate for wear. Note. The fence clamp screw is shown removed. Fitting the table insert. The mac...

Page 25

25 fitting the optional light. Fixing screws and cable clips light fitted in position suggested cable route light plugged into socket the light is fitted to the top of the bandsaw as shown. The light is supplied with a three-pin plug to suit either 110v or 220v depending on your machine votlage. The...

Page 26

26 connecting the bandsaw to the electricity supply. 110v electrical plug and cable 220v electrical plug and cable the bandsaw is supplied pre-wired with a 110v 3-pin plug or 220v 3-pin plug. It is recommended that the bandsaw be connected to a 15 amp breaker. The start/stop switch activates the mot...

Page 27

27 before starting the bandsaw. Read and understand the instruction manual before operating the saw. 1. If you are still not thoroughly familiar with the operation of the bandsaw, get advice from a qualified person. 2. Make sure the machine is properly grounded and that the wiring codes are followed...

Page 28

28 fitting a blade to the bandsaw. A lot of people do not like to change the blades and go to great lengths to avoid doing it. To use the bandsaw to its greatest advantage, you will have to use the appropriate blade and track it quickly. This is a habit that can be easily developed. If you use a ste...

Page 29

29 8. Open the blade guard door. Slide the blade over the top flywheel and feed through the slot at the side of the vertical column. Then feed the blade into the blade guard slot and close the blade guard door. 9. Deactivate the quick action blade tension lever and rotate the blade tension wheel so ...

Page 30

30 note. Tensioning the blade is covered later in the manual. 2. Refit the plastic blanking block. Note: the blade must be fully tensioned for final tracking . Note: never track the blade with the saw running . Note. There is a window on the side of the bandsaw that allows the blade on the upper fly...

Page 31

31 close all the doors and ensure that all the guards are fitted. Start the band saw and look at the blade from the front of the machine. Start to detension the blade very slowly until the blade starts to flutter (wobble from side to side). Then start to tension the blade until the blade stops flutt...

Page 32

32 supporting the blade above and below the back blade guide, giving the blade unsurpassed stability. The laguna guide also incorporates patented ceramic as the blade support material. The advantage of this material is its ability to resist wear, and with care it should give years of safe service. P...

Page 33

33 adjusting the blade guides. The blade should run through the center of the rear blade guide, and the sid e guides should be parallel with the blade. If they have been moved out o f adjustment, adjust as follows : top upper side guides parallel adjustment . Loosen the side guides and move out as f...

Page 34

34 lower blade guide. The lower blade guides have two locking screws that, when released, allow the guide assembly to be moved forward and back. Rotate the blade by hand and ensure that it is tracking consistently in the correct position. Loosen the side guides and move out from the blade. Loosen th...

Page 35

35 using the bandsaw. Although the bandsaw is usually associated with cutting curves, a variety of straight cuts are easily made with the saw. In fact, it is often used to rip wood because it is much safer than a radial arm saw and also has a smaller saw cut, so it wastes less wood. This becomes ver...

Page 36

36 is the angle of drift, and you will have to set the fence to the pencil line. 4. To adjust the fence, loosen the clamp bolts that attach it to the cast bracket. Move the fence so that it lines up with the pencil mark on the table and retighten the clamp screws. Method 2. 1. Set the fence parallel...

Page 37

37 table rule adjustment slot fence position. The aluminum fence can be used in two height positions (high and low). The low position is handy for cutting thin wood and is used where the fence in the high position would make it awkward to complete cuts. The fence in the high position is used for sup...

Page 38

38 resawing. Resawing is the process of cutting a board in half along its height. The bandsaw is perhaps the most creative tool in the shop because of its ability to cut thick or thin, straight or curved. The ability to cut thick stock such as re-sawing, making veneers, book matching or cutting flit...

Page 39

39 advantage if you are cutting a job that has a tendency to nip the blade. The smaller the set, the smaller the saw cut and the larger the radius that can be cut; the wood waste is less. On tipped blades (resaw king) there is no set, as the tip is wider than the backing material. Thickness. The thi...

Page 40

40 width. The dimension from the back of the blade to the front of the teeth. The wider the blade, the stiffer the blade and the straighter the cut. This is usually called beam strength. But wide blades cannot cut small radiuses. The narrower the blade, the more flexible the blade and the greater th...

Page 41

41 1. 1/4" 6 tpi. This is a small, aggressive blade that is suitable for tight curves and fast cutting where a good surface finish of the cut is not important. 2. 1/4" 14 tpi. This is a small, fine blade suitable for reasonably tight cuts where the surface finish is important but speed of cut is les...

Page 42

42 4. After use it is recommended that you slacken the tension, especially overnight. (be sure to place a clearly visible note on the machine that you have done this. 5. Misalignment of the flywheels. 6. Irregularity of flywheel surface, for instance, an accumulation of sawdust while cutting resinou...

Page 43

43 would work for a particular curve, place a dime (roughly 5/8") over the pattern. The 3/16" blade can cut a curve bigger than the dime, but not smaller. You can use everyday items such as coins or a pencil to determine which blade to use. A quarter is the size of the tightest cut that can be made ...

Page 44

44 step 1 step 2 note: in order to show the hand/thumb position of the man in the photographs, he is not wearing gloves, but gloves must be worn as the blade could cause injury. Step 3 done.

Page 45

45 method two. There is another variation of this that works well with small blades but simply is not possible for larger bandsaw blades, unless you're very big and strong. This method works the same as the method above, but rather than holding the blade with both hands, grasp the blade at the top w...

Page 46

46 method three. The steering wheel method. Start with the blade in front of you, as if you're holding a steering wheel with your hands at the 9 o'clock and 3 o'clock positions. Simultaneously twist your left hand up and your right hand down. As the blade starts to fold, move your hands closer toget...

Page 47

47 maintenance. All tools and machines require regular maintenance, and the bandsaw is no exception. This section details the general maintenance and care of your bandsaw. In general, we recommend that you only use a teflon-based lubricant on the bandsaw. While regular oil attracts dust and dirt, te...

Page 48

48 replacing the drive belt. Drive belt adjusting bolt motor drive pulley drive belt flywheel shaft nut to replace the belts you will have to remove the lower flywheel. 1. Loosen the motor clamp bolts and move the motor so that the tension is completely removed from the drive belt. Remove the blade....

Page 49

49 rust. The bandsaw is made from steel and cast iron. All non-painted surfaces will rust if not protected. It is recommended that the table be protected by coating with wax if the machine is not in constant use. All moving non-painted surfaces (guides, rack and pinion, etc.) should be lubricated/pr...

Page 50

50 adjusting the table square to the bandsaw blade. Note. The machine is set in the factory and no adjustment should be required but during transportation movement may occur. To access the adjustment screws, you will have to tilt the table up to 45 degrees and lock in position. The adjustment is mad...

Page 51

51 bolt to pass through the table tilt hole, and the table can be moved to the maximum amount of tilt (-7 degrees). To adjust the table square to the blade. 1. Check that the stop bolt is in contact with the tilt-blanking disc. 2. Place an engineers square on the table top and bring up to the side o...

Page 52

52 2. Internal breaker faulty. Replace the breaker. Motor tries to start but will not turn. 1. With the power disconnected from the machine, open the doors and try to turn the wheel by hand. If the wheel is not turning, check the reason for the jamming. Typical reasons are: guides too tight, wood ja...

Page 53

53 the blade makes a clicking noise. Bad weld. Dress the weld or change the blade. Blade overheats. 1. Dull blade. Change the blade or resharpen the blade. 2. Pitch is too small for the depth of cut. Change to a blade with the correct pitch. 3. Guides too tight. Adjust the guides. 4. Wood too hard f...

Page 54

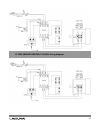

54 lt14bx (mband14bx220-0175)220v wiring diagram..

Page 55

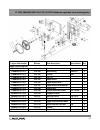

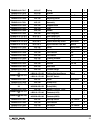

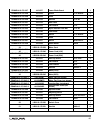

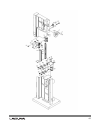

55 lt14bx (mband14bx110-0175)110/220v bandsaw exploded view drawing/parts . Laguna part number supplier part number item description specification qty upper wheel assembly pband1412-175-1 1412-101 hex nut m14x1.5- lh 1 pband1412-175-2 1412-102 ball bearing 6202llu 2 pband1412-175-3 1412-103 c-ring r...

Page 56

56 pband1412-175-17 1412-117 spring 1 pband1412-175-18 1412-118 bracket 1 pband1412-175-19 1412-119 pin Ø4x20 1 pband1412-175-20 1412-120 adjusting screw 1 pband1412-175-21 1412-121 blade tension arm assembly 1 pband1412-175-22 1412-122 support block 1 pband1412-175-23 1412-123 plate 1 pband1412-175...

Page 57

57 pband1412-175-45 1412-145 screw 1/4"-20x3/4" 1 pband1412-175-46 1412-146 lock knob 1 mband14bx110-175- 47 14bx110-175-147 saw body 1 pband1412-175-48 1412-148 lock knob 1 pband1412-175-49 1412-149 adjusting knob 1 pband1412-175-50 1412-150 tension label 1 pband1412-175-51 1412-151 upper door 1 mb...

Page 58

58.

Page 59

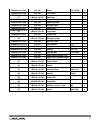

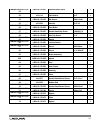

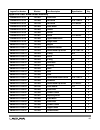

59 laguna part number supplier part number item description specification qty lower wheel and motor assembly pband1412-175-2-1 1412-101 hex nut m14x1.5- lh 1 pband1412-175-2-2 1412-102 ball bearing 6202llu 2 pband1412-175-2-3 1412-103 c-ring r35 2 pband1412-175-2-4 1412-104 pu tire 1 pband1412-175-2...

Page 60

60 pband1412-175-2-27 1412-227 lower blade guard 1 pband1412-175-2-28 1412-228 screw 1/4"-20x3/4" 1 pband1412-175-2-29 1412-229 plate 1 pband1412-175-2-30 1412-132 hex nut 1/4”-20 1 pband1412-175-2-31 1412-133 door stud 1 pband1412-175-2-32 1412-232 flat washer 1/4” 1 pband1412-175-2-33 1412-233 nyl...

Page 61

61 mband14bx110-175-2- 52 14bx110-175-252 limited switch cord 1 mband14bx110-175-2- 53 1412-112 flat washer 3/8" 1 mband14bx110-175-2- 54 14bx110-175-254 set screw m6x1.0x45 2 mband14bx110-175-2- 55 1412-336 hex nut 3/8"-16 3 mband14bx110-175-2- 56 14bx110-175-256 foot brake 1 mband14bx110-175-2- 57...

Page 62

62.

Page 63

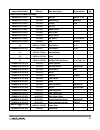

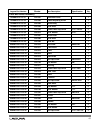

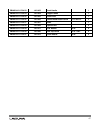

63 laguna part number supplier part number item description specification qty table and fence assembly pband1412-175-3-1 1412-301 aluminum fence 1 pband1412-175-3-2 1412-302 plastic adjusting screw 1 pband1412-175-3-3 1412-303 fence body 1 pband1412-175-3-4 1412-304 lock knob 2 pband1412-175-3-5 141...

Page 64

64 pband1412-175-3-33 1412-333 set screw 5/16"-18x5/8" 2 pband1412-175-3-34 1412-334 hex cap screw 5/16"-18x1-3/4" 3 pband1412-175-3-35 1412-335 hex cap screw 3/8"-16×2" 1 pband1412-175-3-36 1412-336 hex nut 3/8"-16 1 pband1412-175-3-37 1412-337 phillips flat head screw m4x0.7x8 1 pband1412-175-3-38...

Page 65

65.

Page 66

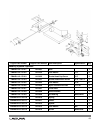

66 laguna part number supplier part number item description specification qty upper and lower blade guides assembly pband1412-175-4-1 1412-401 lock knob 1 pband1412-175-4-2 1412-208 set screw 5/16"-18x3/8" 2 pband1412-175-4-3 1412-143 set screw 1/4"-20x3/8" 1 pband1412-175-4-4 1412-404 hand wheel 1 ...

Page 67

67 pband1412-175-4-33 1412-433 lock handle 1 pband1412-175-4-34 1412-434 support shaft 1 pband1412-175-4-35 1412-435 lock knob 1 pband1412-175-4-36 1412-436 socket head button screw 1/4"-20x1/2" 2 pband1412-175-4-37 1412-437 base 1 pband1412-175-4-38 1412-438 special bolt 2 pband1412-175-4-39 1412-2...

Page 68

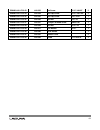

68 laguna part number supplier part number item description specification qty mobility system: optional pband1412-175-6-1 1412-601 rod 1 pband1412-175-6-2 1412-232 flat washer 1/4" 6 pband1412-175-6-3 1412-603 socket head cap screw 1/4"-20x1- 3/4" 2 pband1412-175-6-4 1412-421 socket head button scre...

Page 69

69 pband1412-175-6-15 1412-615 connecting plate 2 pband1412-175-6-16 1412-616 foot pedal 1 pband1412-175-6-17 1412-617 socket head button screw 1/4"-20x3/8" 2 pband1412-175-6-18 1412-618 plate 1 pband1412-175-6-19 1412-619 spacer 2 pband1412-175-6-20 1412-620 support plate 1 pband1412-175-6-21 1412-...

Page 70

70 laguna part number supplier part number item description specification qty 115v industrial work light: optional pband1412-175-7-1 1412-701 work light 115v 1 pband1412-175-7-2 1412-702 screw m4x0.7x20 4 pband1412-175-7-3 1412-703 flat washer m4 4 pband1412-175-7-4 1412-704 hex nut m4x0.7 4 pband14...

Page 71

71 laguna part number supplier part number item description specification qty 230v industrial work light: optional pband14bx220-250-7-1 14bx220-250-701 work light 230v 1 pband1412-175-7-2 1412-702 screw m4x0.7x20 4 pband1412-175-7-3 1412-703 flat washer m4 4 pband1412-175-7-4 1412-704 hex nut m4x0.7...

Page 72

Laguna tools is not responsible for errors or omissions. Specifications subject to change. Machines may be shown with opt ional accessories. © 2017, laguna tools, inc. Laguna® and the laguna logo® are the registered trademarks of laguna tools, inc. All rights reserved . 2072 alton parkway. Irvine, ca...