- DL manuals

- Laguna

- Saw

- MTSAW17536110-0130

- Manual

Laguna MTSAW17536110-0130 Manual

Summary of MTSAW17536110-0130

Page 1

Fusion tablesaw manual © 2015 laguna tools, inc. All rights reserved. Laguna tools 2072 alton parkway irvine, california 92606 ph: 800.234.1976 www.Lagunatools.Com model mtsaw17536110-0130 model mtsaw17536110-0130 model mtsaw17536110-0130

Page 2

1 table of contents read carefully before operating the machine .....................................................2 10” table saw .........................................................................................................................4 grounding instructions ........................

Page 3

2 read carefully before operating the machine read this manual completely and observe all warning labels on the machine. We always make every attempt to provide a safe, reliable, easy-to-use piece of machinery. Safety, however, is ultimately the responsibility of the individual machine operator. As ...

Page 4

3 17. Avoid working from awkward or off balance positions. Do not overreach while cutting; keep both feet on floor. Never lean over or reach over the blade and never pull the work piece over the blade from behind. 18. Use out feed support or have an assistant help when ripping long material. 19. Kee...

Page 5

4 10” table saw thank you for choosing this table saw. This unit is carefully tested and inspected before shipment. To ensure optimum performance and trouble free operation a reasonable amount of care and attention is required. To get the most from your new table saw, please take the time to read th...

Page 6

5 grounding instructions 1. All grounded, cord connected tools: in the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment grounding conductor and...

Page 7

6 moveable caster & machine leveling the machine is supplied with (2) casters with leveling adjustors and (2) adjustable feet. To level the machine adjust the leveling adjustors on the castors using a open wrench and adjust the leveling feet. Reset protector your saw comes equipped with a manual-res...

Page 8

7 safety switch the table saw is equipped with a push-button switch that will accept a safety padlock (not included). See fig. 1. To safeguard your machine from unauthorized operation and accidental starting by young children, the use of a padlock is required. P: with a screw driver, push a solvent-...

Page 9

8 . , . Assembling the table saw install the table extension wings attach the table extension wings to the main table using 8x12mm hex head bolts (4 per wing), and 8 lock washers. Align the table extensions with the table and loosely attach the bolts. Place a straightedge on the table and extension ...

Page 10

9 . 5. From the right side of the saw, slide the upper slot of the right front rail onto the square head bolts (for 36” rail only) 6. Fit the 2 rails together(for 36” rail only) 7. Tighten down the nuts to firmly secure the front rails to the table. Rear rail installed 36” rear rail with 2 pieces of...

Page 11

10 fitting the start /stop switch the switch box assembly slides onto the rail slot and can be adjusted to any position to suit you, but it is suggested that it is close to the end of the aluminum rail. Once in position clamp in position by tightening the nuts. Install blade guard the blade guard as...

Page 12

11 loosen lock knob if you could not loosen the knob by hands, use the arbor wrench. See fig. 4 anti-kick back pawl the anti-kickback pawls allow the work piece to travel in only one direction. If the work piece moves backwards, the pawls will dig into the work piece to slow or stop it fig. 5. The p...

Page 13

12 table insert see fig. 8 to install the zero clearance insert: 1. Disconnect saw from power! 2. Check to make sure the blade is properly installed. 3. Install the table insert 4. Adjust the table insert set screws with a 2.5mm hex wrench to make sure the insert is flush with the table then turn th...

Page 14

13 . . , fence assembly align the fence parallel to the blade 1. Slide the fence to the right t-slot on your saw table top. Lock down the fence handle and make a visual check that the fence is parallel with the t-slot all along its length. Also, you can place a small 3/4” thick block of wood, uprigh...

Page 15

14 . . Level the fence the fence should be parallel to the table and sit approximately 2mm above the table’s surface (so the fence will not scratch the table and a thin work piece will not get stuck or jammed under the fence). To level and adjust the height of the fence: 1. Loosen the hex nut f on t...

Page 16

15 push stick always use a push stick fig. 19 to reduce the risk of injury. This will keep your hands away from the blade while cutting. To maintain control when cutting large work pieces, start the cut by feeding by hand then use a push sticks to finish the cut. Miter gauge the miter gauge is equip...

Page 17

16 maintenance & adjustments periodic maintenance • inspect/test the on/off switch before each use. Do not operate the saw with a damaged switch - replace a damaged switch immediately • inspect the saw blade for damage or chipped teeth before each use. Replace a damaged or chipped blade immediately....

Page 18

17 . Adjusting the 45° & 90° bevel stops 1. Disconnect the machine from the power source. 2. Raise the blade to its highest position and lift the blade guard. 3. Loosen the bevel lock knob and turn the blade tilting hand wheel clockwise until it stops. 4. Verify the angle of the blade with a combina...

Page 19

18 . Blade height adjustment the blade height adjustment hand wheel a is located on the front of the saw and there is a lock knob b on the hand wheel that allows you to lock the wheel and secure the blade at the desired height fig. 26. To raise or lower the blade: 1. Loosen the blade height lock kno...

Page 20

19 type of cut ripping cutting a wood plank or sheet of plywood lengthwise to reduce its width is called “ripping”. To rip stock, hold the work with both hands pushing it into the blade as well as firmly against the rip fence so that it is cut straight. • never rip or cut wood without using the mite...

Page 21

20 , cross cutting cutting against the grain, to shorten the length of a board, is crosscutting. With some smaller sized and rectangular pieces, you often have the choice of ripping or crosscutting. Always use the miter gauge, when crosscutting; never cut a piece unsupported. The miter gauge may be ...

Page 22

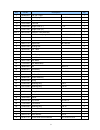

21 wiring diagrams 1.75hp.110/220v.60hz.1ph.

Page 23

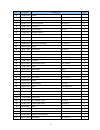

22 2hp.220v.60hz.1ph.

Page 24

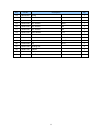

23 parts diagrams.

Page 25

24.

Page 26

25.

Page 27

26.

Page 28

27 parts list key part no. Descriptions q'ty 1 923135-000 rip fence assembly 1 1.1 250483-615 end cap 4 1.2 310100-909 adaptor 2 1.3 000002-308 hex. Screw m6*1.0p*45 1 1.4 171993-904 bracket 1 1.5 250602-621 frictional plate 1 1.6 048701-101 square bolt m8*1.25p*20 6 1.7 250799-620 pointer 2 1.8 001...

Page 29

28 key part no. Descriptions q'ty 2.8 171154-904 rod 1 2.9 130270-903 rod bracket -left 2 2.10 130271-903 rod bracket -right 2 2.11 000302-103 pan head screw m4*0.7p*10 2 2.12 360960-901 pin 2 2.13 250818-620 right cover 1 2.14 250819-620 protective shield -right 1 2.15 008302-100 anti-loose nut m5*...

Page 30

29 key part no. Descriptions q'ty 3.12 380069-901 ring 1 3.13 230217-901 flat head screw m6*1.0p*8 1 3.14 571614-000 miter scale 1 4 051050-000 extension table 2 5 520001-311 box 710*320*50 2 6 922130-000 table insert assembly 1 7 250822-616 bolt 1 8 001901-104 set screw m5*0.8p*12 5 9 001903-103 se...

Page 31

30 key part no. Descriptions q'ty 36 130272-903 clamper support 1 37 380998-902 pulley 1 38 010006-000 retaining ring stw-15 1 39 030213-002 bearing 6002 2 40 360964-000 long rod 1 41 051099-000 shaft gear 1 42 000104-114 cap screw m8*1.25p*50 1 43 160002-903 bushing 1 44 172946-904 rod 1 45 160067-...

Page 32

31 key part no. Descriptions q'ty .7 250699-615 end cap - right 1 .8 001102-604 self-tapping screw m4*1.59p*12 4 .9 173138-308 rear rail 1 .10 310274-909 front rail 1 .11 573035-000 length scale ( l ) 0"~12" 1 .12 572537-000 length scale ( r ) 52" 1 50.2.2 923142-000 extension table assembly 1 .1 00...

Page 33

32 key part no. Descriptions q'ty 74 170912-156 pointer 1 75 172945-902 bracket 1 76 006001-022 flat washer 6.3*13*1.0t 2 77 000303-104 pan head screw m5*0.8p*12 4 78 230297-615 fixing pin 2 79 008302-100 anti-loose nut m5*0.8p 2 80 170932-901 clamper support 1 81 170933-901 fixed plate 1 82 000302-...

Page 34

33 key part no. Descriptions q'ty 112 280186-901 spring 1 113 380988-901 knob 1 114 130269-903 block 1 115 040002-000 hex. Wrench 2.5mm 1 116 040004-000 hex. Wrench 4mm 1 117 040006-000 hex. Wrench 6mm 1 118 040203-000 open wrench 11*13 1 119 170399-904 spanner 2 128 006001-033 flat washer 6.7*16*1....

Page 35

Laguna tools is not responsible for errors or omissions. Specifications subject to change. Machines may be shown with optional accessories. © 2015, laguna tools, inc. Laguna® and the laguna logo® are the registered trademarks of laguna tools, inc. All rights reserved. 2072 alton parkway. Irvine, ca ...