- DL manuals

- Laguna

- Saw

- MTSS000020

- Manual

Laguna MTSS000020 Manual

Summary of MTSS000020

Page 1

Ts / tss tablesaw manual laguna tools 2072 alton parkway irvine, california 92606 ph: 800.234.1976 www.Lagunatools.Com © 2017, laguna tools, inc. Laguna® and the laguna logo® are the registered trademarks of laguna tools, inc. All rights reserved. Model number: mtss000020

Page 3

3 table of contents safety rules warranty noise emission specification sheet receiving your machine unpacking your machine introduction to your machine assembly and set up where to locate your machine operating your machine maintenance troubleshooting accessories electrical drawing spare parts explo...

Page 4

4 safety rules as with all machinery there are certain hazards involved with the operation and use. Using it with caution will considerably lessen the possibility of personal injury. However, if normal safety precautions are overlooked or ignored, personal injury to the operator may result. If you h...

Page 5

Limited warranty new machines and accessories sold by laguna tools carry a one-year warranty effective from the date of shipping. Machines sold through dealers must be registered with laguna tools within 30 days of purchase to be covered by this warranty. Laguna tools guarantees all new machines and...

Page 6

6 noise emission notes concerning noise emission given that there exists a relationship between noise level and exposure times, it is not precise enough to determine the need for supplementary precautions. The factors affecting the true level of exposure to operators are clearly the amount of time e...

Page 7

7 standard equipment supplied with ts spare blank throat plate insert rip fence extension table with legs blade guard tool kit options for ts miter gauge spare blank throat plate insert sliding table mobility kit scoring unit standard equipment supplied with tss spare blank throat plate insert exten...

Page 8

8 tss floor plan ts floor plan.

Page 9

9 receiving your machine. Note . It is probable that a third party will deliver your machine. Before you unpack your new saw you will need to first inspect the packing, invoice and shipping documents supplied by the driver. Insure that there is no visible damage to the packing or the machine. You ne...

Page 10

10 cabinet the cabinet has a large footprint and is a welded construction manufactured from heavy gauge steel plate [4mm [0.16”] thick]. The cabinet houses all the parts of the machine and the heavy construction ensures that the saw is stable. This weight also helps to absorb any vibration that is p...

Page 11

11 sliding table. The sliding table is manufactured from heavy aluminum extrusion. The table is supported by ball bearings that roll on polished round steel rods. The clearance between the ball bearings and the polished round steel guide rods is adjustable. The advantage of the bearing system is tha...

Page 12

12 where to locate your machine. Before you remove your machine from the pallet select the area where you will use your machine. There are no hard and fast rules for its location but below are a few guidelines. 1 / there should be an area at the front and back of the machine suitable for the length ...

Page 13

13 fitting the optional mobility kit [if ordered] slide the axel through the lower inside holes on the side of the machine and fit the spacer [large washer] onto the axel. Fit the wheel assembly, nut and washer on to the axel. To activate the moblity kit, insert the handle into the tube and rotate s...

Page 14

14 assembly and set up what you will receive with the machine . Lifting hooks and tools optional mobility kit fence system optional straight line rip bracket extension table and spare throat plate miter fence.

Page 15

15 cleaning the machine. Remove the rust protection grease with wd 40 or similar solvent it is important that you remove all the grease and re lubricate with a teflon bases lubricant as teflon has less tendency to attract sawdust and cause clogging. You should also wax the table, as this also protec...

Page 16

16 switch cover shown open to start your machine, release the red stop button by moving the button to the right. The door will be released and the green button will be accessible. Press the green button, and the machine will start. To stop the machine, press the red button. The machine should never ...

Page 17

17 to fit a blade, disconnect the saw from the power. Move the arbor to the maximum up position. Rotate the saw arbor so that the hole in the arbor lines up with the hole in the saw table. Insert the locking rod, and loosen the arbor nut. Remove the large clamping disc, and fit the blade. When refit...

Page 18

18 leveling screws ts throat plate insert the throat plate is made from cast iron, and has a phenolic insert. A spare insert is provided that you can machine to suite your requirements [dado, zero clearance, etc]. There are two types of throat plate, tss and ts. To adjust the ts throat plate, adjust...

Page 19

19 loosening the clamp screw, and adjusting the jacking screws, the plate can be adjusted for level to the table, and for parallel to the table. Ensure that the clamping screws are tight before you use the saw. Retaining clip insert tss throat plate on the tss, releasing the clips and sliding the in...

Page 20: Scorin

20 dado cuter fitting the dado cutter dado cutter to fit the dado cutter, disconnect the machine from the power and remove the arbor nut, clamping disc, and spacer. Fit the dado and lock in position with the clamp washer and arbor nut. Ensure that the lock rod is removed before you start the machine...

Page 21

21 straight edge extension table jack screw using a straight edge, adjust the legs so that with the straight edge flat on the main table the part of the extension table that is directly above the legs is level with the table. Above the table fixing bolts are leveling screws. Adjust the leveling scre...

Page 22

22 electrical connection note the machine is not supplied with an electrical plug or cable, as the type of plug and cable, will be dependant on the installation. A qualified electrician must carry out the electrical installation. Switch box open ground fitting the electrical cable. The electrical ca...

Page 23

23 13 / hold the work piece firmly against the table. Do not attempt to saw stock that does not have a flat surface facing down. 14 / use a push stick at the end of a cut. This is the most dangerous time, because the cut is complete and the blade is exposed. Push sticks are commercially available. 1...

Page 24

24 to fit the measurement tape. Marking the fence tube assembling the measurement tape 1 / clean the steel tube with solvent to remove all traces of grease and dirt. 2 / with a blade fitted, and the power disconnected from the machine, fit the fence to the tube and push it up against the blade so th...

Page 25

25 lublicate the non painted surfaces of the tube with wax or teflon lubricant. This will ensure that the fence runs smoothly and that the tube is protected from rust. Adjusting the fence vertically parallel to the saw table. Adjusting wrench squaring the fence the angle tube assembly will have to b...

Page 26

26 tss sliding table push pull handle the push pull handle is fitted under the table for shipping and will have to be removed and re fitted to the side of the table. To release the table, remove the red transport brackets [one at each end of the table] and withdraw the table lock knob. The table wil...

Page 27

27 optional straight line rip stop adjusting screws lock handles fit the optional straight-line rip stop at the end of the table as shown. The optional side extension table, comes with the clamp bar attached. Loosen the ratchet handles and slide the bar into the slot on the side of the side of the s...

Page 28

28 miter fence locking screw hole miter fence flip stop the miter fence [cross cut fence] is fitted into the sliding table slot and locating by tightening the lock screw into the hole in the table slot. Fit the clamp shaft through the casting into the “t” bolt and tighten. The machine is provided wi...

Page 29

29 fine tuning the miter fence. Several methods are acceptable to fine-tune the fence but we have found that the following is a very practical way to achieve a square panel. 1 / clamp the fence locked at 90 degrees against the stop. 2 / clamp a sheet onto the sliding table and cut a straight edge [e...

Page 30

30 optional miter gauge. Jack screw clamp screw optional miter gauge dowel pin the miter gauge has an adjustable pointer; it also has a dowel pin that locks the miter gauge at 15-degree positions. The fence can be moved to different positions on the miter gauge to suit the job that you are doing. Th...

Page 31

31 push the shaft through the casting so that the dowel pin lines up with the slot in the bush. Make sure that the spring is in position. Assemble the stop bushing, and the screw in the back of the casting. Assemble the vertical adjustment assembly on the back of the trunnion assembly. Fit the locki...

Page 32

32 motor support shaft motor shaft nut assemble the motor to the support shaft. Push the support shaft through the trunnion and tighten the nut ensuring that the washer is fitted. Do not over tighten the nut, as the motor must be able to move. Drive belt spring spring shaft assemble the spring, shaf...

Page 33

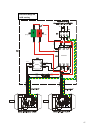

33 fitting the scoring switch with the power disconnected, fit the switch and attach the wiring as detailed in the diagram at the back of the manual. Note. Never start the machine with both motors engaged at the same time. It will damage the magnetic contactor. Note. The electrical box is provided w...

Page 34

34 fit the scoring blade. Note . Scoring blades are supplied with shims that are used to adjust the width of the scoring blade, to suite the saw blade that you are using. Note . The scoring blade rotates in the opposite direction to the main blade. Adjust the blade so that it is 1/16’ above the saw ...

Page 35

35 maintenance and troubleshooting all tools and machines require regular maintenance, and the table saw is no exception. This section details the general maintenance and care of your table saw. In general we recommend that you only use a teflon based lubricant on the table saw. Regular oil attracts...

Page 36

36 rust the table saw is made from steel and cast iron. All none painted surfaces will rust if not protected. It is recommended that the table be coated with wax. All moving none painted surfaces should be lubricated / protected with a teflon based lubricant. Limit stop scoring unit fitted limit sto...

Page 37

37 do not attempt this procedure unless excessive movement has taken place during shipping. Top nut sliding table adjustment bottom nut 1 / lock the sliding table in position with the table lock knob. 2 / using a straight edge across the sliding table check the gap between the straight edge and the ...

Page 38

38 a second way to check is to measure the distance between the miter slot and the slot in the sliding table. The miter slot is parallel with the saw blade and is a good reference point. If adjustment is needed proceed as follows. 1 / loosen three of the lower clamp nuts. Do not adjust the top bolts...

Page 39

39 sliding table ground steel rods damaged or warn. Remove end cover clamp screws steel rods if the steel rods become damaged or warn, a new face can be presented to the ball bearings as follows. 1 / loosen the clamping screws at each end of the sliding table. 2 / with a brass rod, knock the rod out...

Page 40

40 3 / check that the guide plate is not jamming. Clean and re lubricate. Ensue that you clean the whole guide plate by moving the saw arbor to fully up and fully down, cleaning the exposed part of the guide plate. 4 / inspect the guide plate and bearing plate for ware and damage. If damaged or warn...

Page 41

41 miter gauge slot to saw blade adjustment. Table spring pin trunnion spring pin table adjustment bolt [jack] the table and the trunnion assembly are doweled to the body of the saw with 2 [each] spring pins. The pins stop movement during transport. The miter slot is factory set to run parallel with...

Page 42

42 table dip in the middle. Note only adjust the table in very small steps over a period of time. Cast iron is a very brittle material and will break if over stressed. 1 / lay an engineer’s straight edge across the table. 2 / using feeler gauges measure the gap under the straight edge. 3/ remove the...

Page 43

43 motor tries to start but will not turn. 1 / with the power disconnected from the machine. Try to turn the blade by hand. If the blade will not turn check the reason for the jamming. Typical reasons is wood jamming the blade. 2 / capacitor faulty. Replace the capacitor. 3 / motor faulty. Replace t...

Page 44

44 causes of the blade dulling. 1 / wrong blade for the job. 2 / over feeding the job. 3 / cutting painted wood or abrasive material. Accessories the following accessories are available from laguna tools. Miter gage. Mobility kit. Side extension tables for the tss. Flip stops for the tss miter fence...

Page 45

45 electrical circuit.

Page 46

46 a1 a2 1l1 3l2 5l3 2t1 4t2 6t3 l1 l2 gnd power from wall contactor 2 2 2 2 4 0 4 0 40 4 0 4 4 4 4 4 2 4 2 2 0 19 1 9 2 0 4 3 4 2 42 (off-red) p e (on-green) y e l/ g re e n r e d r e d r e d r e d red b la c k b la c k r e d b la c k b la c k r e d b la c k yel/green 40a red p e 44 43.

Page 47

47 a1 a2 1l1 3l2 5l3 2t1 4t2 6t3 l1 l2 gnd power from wall contactor switch 2 2 2 2 4 0 4 0 40 4 0 4 4 4 4 4 2 4 2 2 0 19 1 9 2 4 2 0 2 5 4 3 4 3 4 2 4 4 42 1 3 2 4 (off-red) 19 20 19 20 24 25 43 43 44 p e (on-green) y e l/ g re e n y e l/ g re e n r e d r e d r e d r e d red red b la c k b la c k r...

Page 48

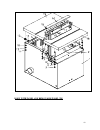

48 parts breakdown for the tss and ts table saws. Note. Some parts shown in this manual may vary with the parts delivered with your machine. We are constantly up grading the design of the machine and reserve the right to change the machine and / or the specification with out notice. Ordering spare-p...

Page 49

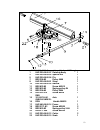

49 body with panel and removable panel [ts].

Page 50

50 body with panel and removable panel [ts] 1 st-01.01.01.00.00 body 1 2 ps.00.00.09 safety device 1 3 din 985 nut М12 din 4 4 206-83 pulley АМ12 4 5 din 985 nut М8 din 4 6 un 732 pulley Ф9ХФ35Ф2,5 4 7 1234-85 bolt М8Х25 2 8 ps.00.00.03 stud m12 2 9 2171-83 screw М10Х30 2 10 206-83 pulley АМ10 6 11 ...

Page 51

51 body with panel [tss].

Page 52

52 body with panel [tss] 1 st01.01.01.00.00 body 1 2 din 912 screw М10x45 4 3 bds 833-82 spring pulley 10 Н 4 4 bds 206-78 pulley АМ10 4 5 st01.01.00.00.13 bolt 4 6 st01.01.00.00.14 stud 1 7 bds 744-83 nut М10 1 8 un732 pulley Ф35ХФ10Х2.5 2 9 st01-01.00.00.02 panel 1 10 iso 7380 screw М6Х16 11 11 bd...

Page 53

53 lnr 460.00.00.00 crosscut fence [optional 18” long] 1 lnr 230.00.00.07 rotating body 1 2 lnr 230.00.09.03 special nut 1 5 lnr 230.00.00.04 pin 1 7 bds 206-83 pulley АМ8 1 9 lnr 230.00.09.01 strap 1 10 lnr 230.00.00.03 narrow 1 11 bds 832-83 screw М4Х12 1 12 bds 833-82 spring pulley 4n 1 13 bds 20...

Page 54

54 lnr 230.00.00.00 crosscut fence [optional 9” long] 1 lnr 230.00.00.07 rotating body 1 2 lnr 230.00.09.03 special nut 1 5 lnr 230.00.00.04 pin 1 7 bds 206-83 pulley АМ8 1 9 lnr 230.00.09.01 strip 1 10 lnr 230.00.00.03 arrow 1 11 bds 832-83 screw М4Х12 1 12 bds 833-82 spring pulley 4n 1 13 bds 206-...

Page 55

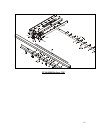

55 34 36 37 38 lu.00.00.00 rip fence [ts].

Page 56

56 lu.00.00.00 rip fence [ts] 1 lu.00.00.09 guide pipe 1 2 lu.00.00.07 carrying square 1 3 bds 1234-85 bolt М6Х14 7 4 din 965a screw М6Х25 4 5 lu.00.00.01 rear carrying square 1 6 bds 744-83 nut М6 9 7 bds 206-83 washer АМ6 17 8 din 965a screw М6Х35 6 9 bds 206-83 washer АМ8 17 10 bds 744-83 nut М8 ...

Page 57

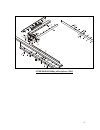

57 34 35 33 36 lumf.00.00.00 sliding table rip fence [tss].

Page 58

58 lumf.00.00.00 sliding table rip fence [tss] 1 lumf.00.00.09 guide pipe 1 2 lumf.00.00.07 carrying square 1 3 bds 1230-85 bolt М6Х14 6 4 din 965a screw М6Х25 4 5 lumf.00.00.01 rear carrying square 1 6 bds 744-83 nut М6 9 7 bds 206-83 washer АМ6 16 8 din 965a screw М6Х35 6 9 bds 206-83 washer АМ8 1...

Page 59

59 lvc1219 – 00.00.00 circular saw miter fence [tss 4’ long].

Page 60

60 lvc1219 – 00.00.00 circular saw miter fence [tss 4’ long] 1 lvc600-00.00.02 cotter 1 2 lvc600-00.00.05 arrow 1 3 un 6404 screw М6Х6 2 4 lvc600-00.00.03 laminated fabric pad 1 5 lvc600-00.00.04 basis 1 6 din 912 8.8 screw М8Х16 2 7 din 134 pulley ø10,5 xø22 x 2,5 1 8 din 127b pulley 2-8h 2 9 gn603...

Page 61

61 lvc600 – 00.00.00 circular saw miter fence [optional 2’long].

Page 62

62 lvc600 – 00.00.00 circular saw miter fence [optional 2’ long] 1 lvc600-00.00.02 cotter 1 2 lvc600-00.00.05 arrow 1 3 un 6404 screw М6Х6 2 4 lvc600-00.00.03 laminated fabric pad 1 5 lvc600-00.00.04 basis 1 6 din 912 8.8 screw М8Х16 2 7 din 134 pulley ø10,5 xø22 x 2,5 1 8 din 127b pulley 2-8h 2 9 g...

Page 63

63 mf1270.03.00.00.00 sliding table (mf) l=1270 [tss].

Page 64

64 mf1270.03.00.00.00 sliding table (mf) l=1270 [tss] 1 s1270.03.00.00.01 sliding table movable part 1 2 s1270.03.00.00.09 moulding 2 3 s1270.03.00.00.11 sliding table immovable part 1 4 s1270.03.00.00.06 guide 8 5 bds 12620-75 dowel ds- 3 (Ф8) 8 6 БДС 664-70 wooden screw 5Х45 8 7 s2300.09.02.01.00 ...

Page 65

65 mus.00.00.00 plate extension table ОК.00.00.00 support leg [tss &ts] 1 st- 01.01.00.00.02 panel 1 2 bds 206-83 pulley АМ12 2 3 bds 1234-85 bolt М12Х30 2 4 mus.01.00.00 extension table 800x900 1 5 din 913 stop screw М6Х16 2 6 ОК.00.00 support leg 2 6 ОК.00.00 leg 2 7 К34885 thrust М8Х50 2.

Page 66

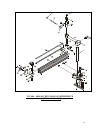

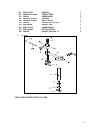

66 rc.00.00.00-t scoring / [optional tss &ts] 44 45.

Page 67

67 rc.00.00.00-t scoring unit [optional tss & ts] 1 rc.00.00.12 nut 1 2 rc.00.00.11 pressing pulley 1 3* optional circular saw 120 Х 20 Х 2,5 1 4 rc.00.00.07 arbor 1 5 bds 3389-83 stud 1- 6Х6Х16 1 6 bearing 6004-2rs. C3 2 7 rc.00.00.06 bushing 1 8 bds 2171-83 screw М10Х25 1 9 rc.00.00.15 axle box 1 ...

Page 68

68 rcd 00.00.00 scoring unit with dado [optional tss &ts].

Page 69

69 rcd 00.00.00 scoring unit with dado [optional tss &ts] pos. Description name quan tity 1. Rc 00.00.12 nut 1 2. Rc 00.00.11 pressing pulley 1 3.* circular disk ø120 x ø20 x 2 1 4. Rcd 00.00.04 support 1 5. Din 1481 spring pin ø5 x 18 3 6. Rcd 00.00.06 shaft 1 7. Din6885 a feather 1-6x6x16 1 8. Rcd...

Page 70

70 35. Rc 00.00.25 belt pulley 1 36. Rc 00.00.34 pulley 1 37. Bds1359-83 screw m 5x16 1 38. Din 7991 screw m 8x20 1 39. Belt 20 х 1, l=510 1 40. S2300.28.00.00.19 pulley 1 41. S2300.28.00.00.20 belt pulley 1 42. Din 471 ring for shaft ø12 1 43. Din 985 nut m10 1 44. Bds2171-83 screw m 8x25 3 45. Rc ...

Page 71

71 sf 250m.08.00.00.00 bracket table [tss &ts] 1 sf250m.08.00.00.01 slide block 1 2 bds 206-83 pulley АМ10 2 3 gn603-73-m10-20dgr handle 2 4 sf2300.15.01.00.00 extension table 500Х320 1 5 bds 1362-83 stop screw М6Х16 2.

Page 72

72 108 108 108 89 88 24 86 49 st01-02.00.00.00 main circular saw / 1-phase motor 2,2kw [tss & tss].

Page 73

73 st01-02.00.00.00 main circular saw / 1-phase motor 2,2kw / 1 gn6336.4-st-40-m8-40 handle М8Х40 2 2 krmc-st 11.01 small hand wheel for folding handle 1 3 gn 698.3-26- М6 flywheel handle, black 1 4 gn 698-kt-26-m10 flywheel handle, black 1 5 din7991 screw М6Х12 1 6 БДС 832-83 screw М4Х10 4 7 БДС 83...

Page 74

74 49 bds 744-83 nut М10 2 50 st 01-02.00.00.58 colomn 1 51 st 01-02.00.59.00-02 motor cradle / esr 90l / 1 52 din 7349 pulley ø17 x ø 40 x 6 1 53 din 985 nut М16 1 54 motor 1 55 st 01-02.00.00.63 belt pulley 1 56 belt spz 630 mn, lp≈ld≈lw= 630mm 2 57 s2300.02.00.00.43 pulley Ф40ХФ24Х4 1 58 din 985 ...

Page 75

75 99 bds 2170-77 ring В70 1 100 s2300.02.37.00.08 thrust ring 1 101 din 913 screw М8Х8 2 102 s2300.02.37.00.10 carrier 1 103 s2300.02.37.00.13 belt pulley 1 104 un 732 pulley ø8 х ø35 х 2,5 1 105 bds 833-82 pulley 2- 8Н 1 106 bds 2171-83 screw М8Х20 1 107 bds 3389-83 cotter 8Х7Х20 1 108 din 988 pul...

Page 76

76 [optional tss] 1 st 01-10.00.03 cotter 1 2 st 01.10.00.04 pad 1 3 st 01-10.00.05 thrust 1 4 lvc 600-00.00.10 colomn 1 5 lvf 00.11.00.12 body 1 7 gn603-63-m8-20-dgr handle М8Х20 2 8 lvf.00.11.01.00 support 1 9 lvf 00.11.02.00-01 lever 1 10 lvf 00.11.00.04 guide 1 11 dm5-321.40.30.14 spring 1 12 bd...

Page 77

77 u – 00.00.00 stop 90° [tss] 1. U-00.00.01 thrust bolt 1 2. Bds 744-83 nut- М8 2 3. Din 913 screw М8Х12 1 4. Din 915 screw М8Х16 1 5. У-00.04.00 basis 1 6. Bds1230-85 bolt М8Х30 1 7. У-00.00.02 strap 1.

Page 78

Laguna tools is not responsible for errors or omissions. Specifications subject to change. Machines may be shown with opt ional accessories. © 2017, laguna tools, inc. Laguna® and the laguna logo® are the registered trademarks of laguna tools, inc. All rights reserved . 2072 alton parkway. Irvine, ca...