Summary of REVO 18

Page 2

2 dear craftsman: thank you for your purchase and welcome to the laguna tools group of discriminating craftsman. I understand that you have a choice of where to purchase your machines and appreciate the confidence you have in our products. Every machine sold by laguna tools has been carefully design...

Page 3

3 table of contents. Page number safety rules 4 warranty 9 noise emission 10 specification sheet 10 receiving your machine 11 introduction to your machine 11 parts of the machine 11 what you will receive with the machine 16 where to locate your machine 17 unpacking your machine 18 assembly and setup...

Page 4: Règles

4 safety rules. "warning": for your own safety read instruction manual before operating lathe (a) wear eye protection. (b) do not wear gloves, a necktie, or loose clothing. (c) tighten all locks before operating. (d) rotate work piece by hand before applying power. (e) rough out work piece before in...

Page 5

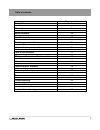

Table a ampere rating volts total length of cord in feet 120 25 50 100 150 240 50 100 200 300 more than not more than minimum gage for cord 0 6 18 16 16 14 6 10 18 16 14 12 10 12 16 16 14 12 12 16 14 12 not recommended grounding instructions 1. All grounded, cord-connected tools: in the event of a m...

Page 6

Fig. 1.

Page 7

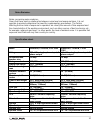

7 locking the lathe it is strongly recommended that the lathe is never be left unattended in the unlocked condition. To lock the machine it is recommended that a cover (not supplied) is made to lock the control panel. We have supplied two concepts for locking the panel (see below). The cover can be ...

Page 8

8 wooden safety cover padlocks emergency stop switch plastic safety cover padlocks.

Page 9

9 limited warranty. New woodworking machines sold by laguna tools carry a one-year warranty from the date of shipping. Laguna tools guarantees all new machines sold to be free of manufacturer's defective workmanship, parts, and materials. We will repair or replace, without charge, any parts determin...

Page 10

10 noise emission. Notes concerning noise emission: given that there exists a relationship between noise level and exposure times, it is not possible to precisely determine the need for supplementary precautions. The factors affecting the true level of exposure to operators are clearly the amount of...

Page 11

11 receiving your machine. Note. It is probable that your machine will be delivered by a third party. Before you unpack your new machine you will need to first inspect the packing, invoice and shipping documents supplied by the driver. Insure that there is no visible damage to the packing or the mac...

Page 12

12 identification. There is a plate at the back of the machine listing all the manufacturing data, including the serial number, model, etc. Lathe bed. The bed is a machined heavy steel welded construction. Underside of lathe bed.

Page 13

13 lathe legs. The legs are cast iron, and their heavy construction gives the machine a low center of gravity and ensures that it is very stable. The legs are supplied with adjustable feet to allow the machine to be leveled. Legs with adjustable feet assembled head stock. The head stock is cast iron...

Page 14

14 tail stock. The tail stock is of cast iron construction, and the spindle has a travel of 4 1/2 in. It can accommodate centers and other tools which have a number 2 morse taper. The tail stock can be moved to any position on the lathe bed and locked to suit the job at hand. Tool rest. The tool res...

Page 15

15 electrical system. 220v: the electrical control system (vfd) is housed at the back of the head stock, the vfd converts single phase 220v to three phase. There is a speed readout at the front of the lathe with controls to fine adjust the rpm of the spindle. . A power cord with 220v plug is provide...

Page 16

16 what you will receive with the lathe. Head stock tool rest tail stock drive &live center storage tool storage leg bed banjo adjustable feet leg.

Page 17

17 face plate tool rack rotating center adjustable feet tail stock bracket removal tool drive center knock out rod head stock bracket tail stock knob tool rest comes fitted to banjo where to locate your machine. Before you remove your machine from the packaging, select the area where you will use yo...

Page 18

18 unpacking your machine. To unpack your machine you will need tin snips, a knife, and a wrench. 1. Using the tin snips, cut the banding that is securing the packing box (if fitted). Warning: extreme caution must be used, because the banding will spring and could cause injury. Lathe in packaging le...

Page 19

19 note. The machine is heavy. Ensure that you have enough people to do the job safely. Note. If you have any doubt about the described procedure, seek professional assistance. Do not attempt any procedure that you feel is unsafe, or that you do not have the physical capability of achieving. 5. Lowe...

Page 20

20 stop tailstock clamp handle lay the bed on 2" x 4" timbers in the upside down position. Lift the legs to the vertical position and lower them onto the bed. Secure with the fixing screws provided. Note. At least two people will be needed to perform the assembly, one to hold the leg in position and...

Page 21

21 assemble the head stock, tool rest and tailstock back onto the bed of the lathe and fit the stops. Note. If you have any doubt about the described procedure, seek professional assistance. Do not attempt any procedure that you feel is unsafe, or that you do not have the physical capability of achi...

Page 22

22 if you decide to fit the tool rest after fitting the tail stock, follow the below procedure. Fit the tool rest onto the bed of the lathe ensuring that the washer recess fits into the slot in the bed. Fit the banjo onto the bed with the bolt through the washer and assemble the nut onto the thread....

Page 23

23 fitting the stock knob. Screw the tail stock knob onto the tail stock handle. Connecting the electrical supply. Ensure that the electrical supply corresponds with that of the machine (single phase 220v or 110v). It is recommended that you use a 15-amp main breaker. Note. A qualified electrician m...

Page 24

24 fitting the rotating center. Ensure that the bore of the tail stock is clean. The rotating center has a number 2 morse taper that fits into the tail stock. Push the center into the tail stock bore firmly, and ensure that it is securely located. To remove the center, rotate the adjusting handle un...

Page 25

25 ensure that the bore of the head stock is clean. The drive center has a number no. 2 morse taper that fits into the head stock push the center into the head stock bore firmly, and ensure that it is securely located. To remove the center, push the removal shaft into the back of the head stock, and...

Page 26

26 head stock clamp lever. The head stock clamp lever allows the head stock to be released and moved to any position on the lathe bed. It is located at the back of the head stock. Emergency stop button start / stop buttons speed display forward / reverse switch variable speed adjustment knob head st...

Page 27

27 variable speed adjustment knob. Increase speed decrease speed the variable speed adjustment knob adjusts the spindle speed. Turns clockwise to increase the speed, turns counter-clockwise to decrease the speed high / low speed. The lathe has two sets of pulleys for high (135 - 3500 rpm ) and low (...

Page 28

28 indexing the spindle. The spindle has 3 sets of indexing holes 14 / 36 / 48. The selection plunger is located at the end of the head stock. To move between the 3 sets of holes, loosen the clamp knobs and slide the indexing plunger assembly to align with the selected hole set. Clamp in position wi...

Page 29

29 indexing holes clamping knobs hole selection indicator hole selection indexing plunger indexing plunger engaged indexing plunger disengaged.

Page 30

30 maintenance. General. Keep your machine clean. At the end of each day, clean the machine. Wood contains moisture, and if sawdust or wood chips are not removed they will cause rust. In general, we recommend that you only use a teflon-based lubricant on the lathe. Regular oil attracts dust and dirt...

Page 31

31 the tailstock should be slid along the bed to check for any area that it binds in the bed slot. The same procedure as above should be conducted on the head stock should it be required. Note. It is very unlikely that the headstock will require adjustment as it is not moved as often as the tailstoc...

Page 32

32 center point alignment. The tailstock has two clamp screws that are accessible from the top of the tailstock. The clamp screws hold the slide plate to the tailstock casting. There is clearance in the holes that allows the tailstock to be moved in relation to the slide plate. The headstock also ha...

Page 33

33 troubleshooting. Lathe will not start. 1. Check that the start switch is in the correct position. 2. Check that the electrical power cord is plugged into the power outlet. 3. Check that the electrical supply is on (reset the breaker). 4. With the power disconnected from the machine, check that th...

Page 34

34 machine vibrates. 1. Machine not level on the floor. Re-level the machine ensuring that it has no movement. 2. Damaged drive belt. Replace the belt. 3. Job is not balanced. Change to slower speed and/ or balance the job. 4. Damaged pulley. Replace the pulley. 5. Worn spindle bearing. Replace the ...

Page 35

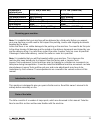

35 electrical drawing..

Page 36

36 exploded view drawings and parts list..

Page 37

37.

Page 38

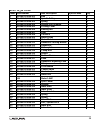

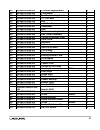

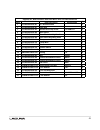

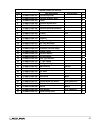

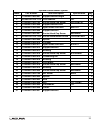

38 revo 18│36 lathe index part number item description specification qty 1 plarevo1836-101 bed 1 2 plarevo1836-102 spindle pulley 1 3 plarevo1836-103 spring 1 4 plarevo1836-104 spindle lock plunger 1 5 plarevo1836-105 locking collar 1 6 plarevo1836-106 bearing nut 1 7 plarevo1836-107 door 1 8 plarev...

Page 39

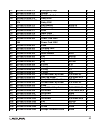

39 35 plarevo1836-135 tool rest support base 1 36 plarevo1836-136 cord holder 1 37 plarevo1836-137 tool rest locking handle 1 38 plarevo1836-138 12" tool rest 1 39 plarevo1836-139 leg 2 40 plarevo1836-140 lock handle 1 41 plarevo1836-141 handwheel 1 42 plarevo1836-142 quill 1 43 plarevo1836-143 tail...

Page 40

40 71 plarevo1836-171 emergency stop 1 72 plarevo1836-172 spacer 2 73 plarevo1836-173 fwd/rev switch 1 74 plarevo1836-174 relay 220v 1 plarevo1836-110-150- 174 relay 110v 1 75 plarevo1836-175 ball bearing 6205llu 1 76 plarevo1836-176 ball bearing 6207llu 1 77 plarevo1836-177 pillar 2 78 plarevo1836-...

Page 41

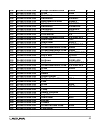

41 106 plarevo1836-1106 phillips flat head screw m6x16 4 107 plarevo1836-1107 screw m3x4 2 108 plarevo1836-1108 motor cord 1 109 plarevo1836-1109 flat washer d3xd8x1t 2 110 plarevo1836-1110 nylon insert lock nut m18x2.5 3 111 plarevo1836-1111 hex nut 3/8-16unc 4 112 plarevo1836-1112 flat washer d10x...

Page 42

42 143 plarevo1836-1143 o-ring p29 1 144 plarevo1836-1144 speed label 1 145 plarevo1836-1145 cap 4 146 plarevo1836-1146 socket head button screw 1/4-20uncx3/8" 8 147 plarevo1836-1147 headstock bracket 1 148 plarevo1836-1148 socket head cap screw 3/8-16uncx1- 1/4" 2 149 plarevo1836-1149 tailstock bra...

Page 43

43 optional headstock guard index part number item description specification qty 1 plarevo1836-201 plunger 1 2 plarevo1836-202 retaining collar 2 3 plarevo1836-203 guard 1 4 plarevo1836-204 set screw 1/4-20uncx1/4" 2.

Page 44

44.

Page 45

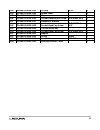

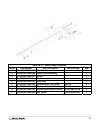

45 optional 20" bed extension with riser block and tool rest extension index part number item description specification qty 1 plarevo1836-301 20" bed extension 1 2 plarevo1836-147 stop bolt 2 3 plarevo1836-195 socket head cap screw 3/8-16uncx1" 3 4 plarevo1836-304 riser block 1 5 plarevo1836-305 ris...

Page 46

46 optional 12" swing-away extension index part number item description specification qty 1 plarevo1836-401 12" bed extension 1 2 plarevo1836-402 draw latch assembly 1 3 plarevo1836-403 hinge 1 4 plarevo1836-404 pin 2 5 plarevo1836-147 stop bolt 1 6 plarevo1836-406 socket head cap screw m6x12 4 7 pl...

Page 47

47 optional comparator index part number item description specification qty 1 plarevo1836-501 center 2 2 plarevo1836-502 lock handle 2.

Page 48

48 optional industrial flood light index part number item description specification qty 1 plarevo1836-601 work light 1 2 plarevo1836-602 screw m4x15 4.

Page 49

49.

Page 50

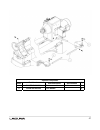

50 optional inverter for vacuum index part number item description specification qty 1 plarevo1836-801 connecting shaft 1 2 plarevo1836-802 vacuum adaptor body 1 3 plarevo1836-803 cover 1 4 plarevo1836-804 vacuum system box 1 5 plarevo1836-805 plate 1 6 plarevo1836-806 vacuum generator bracket 1 7 p...

Page 52

52 optional deluxe wheel system index part number item description specification qty 1 plarevo1836-901 support bracket-right 2 2 plarevo1836-1115 lock washer 3/8" 24 3 plarevo1836-195 socket head cap screw 3/8-16uncx1" 24 4 plarevo1836-904 support bracket-left 2 5 plarevo1836-905 nylon insert lock n...

Page 53

53 optional 3" riser blocks index part number item description specification qty 1 plarevo1836-701 3" riser blocks 2 2 plarevo1836-702 socket head cap screw 3/8-16uncx3-1/2" 4 3 plarevo1836-1115 lock washer 3/8" 8 4 plarevo1836-1146 socket head button screw 1/4-20uncx3/8" 4 5 plarevo1836-705 support...

Page 56

Laguna tools is not responsible for errors or omissions. Specifications subject to change. Machines may be shown with optional accessories. © 2017, laguna tools, inc. Laguna® and the laguna logo® are the registered trademarks of laguna tools, inc. All rights reserved. 2072 alton parkway. Irvine, ca 9...