- DL manuals

- Lake Shore

- Temperature Controller

- 350

- User Manual

Lake Shore 350 User Manual

User’s Manual

Model 350

Temperature Controller

Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, Ohio 43082-8888 USA

sales@lakeshore.com

service@lakeshore.com

www.lakeshore.com

Fax: (614) 891-1392

Telephone: (614) 891-2243

Methods and apparatus disclosed and described herein have been developed solely on company funds of Lake Shore

Cryotronics, Inc. No government or other contractual support or relationship whatsoever has existed which in any

way affects or mitigates proprietary rights of Lake Shore Cryotronics, Inc. in these developments. Methods and appa-

ratus disclosed herein may be subject to U.S. Patents existing or applied for.

Lake Shore Cryotronics, Inc. reserves the right to add, improve, modify, or withdraw functions, design modifications,

or products at any time without notice. Lake Shore shall not be liable for errors contained herein or for incidental or

consequential damages in connection with furnishing, performance, or use of this material.

Rev. 1.3

P/N 119-057

09 January 2014

|

www.lakeshore.com

Summary of 350

Page 1

User’s manual model 350 temperature controller lake shore cryotronics, inc. 575 mccorkle blvd. Westerville, ohio 43082-8888 usa sales@lakeshore.Com service@lakeshore.Com www.Lakeshore.Com fax: (614) 891-1392 telephone: (614) 891-2243 methods and apparatus disclosed and described herein have been dev...

Page 2

Model 350 temperature controller limited warranty statement warranty period: three (3) years 1.Lake shore warrants that products manufactured by lake shore (the "product") will be free from defects in materials and workmanship for three years from the date of purchaser's physical receipt of the prod...

Page 4

Model 350 temperature controller.

Page 8

Model 350 temperature controller 2.5.5 resistor thermal noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 2.5.6 vibration noise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 10

Model 350 temperature controller 4.4.1 negative temperature coefficient (ntc) resistor sensor input setup . . . . . . 66 4.4.2 positive temperature coefficient (ptc) resistor sensor input setup . . . . . . . 66 4.4.3 range selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 12

Model 350 temperature controller 6.3.1 physical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116 6.3.2 hardware support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 14

Model 350 temperature controller.

Page 16

2 c hapter 1: introduction model 350 temperature controller in short, the model 350 cryogenic temperature controller brings a new level of power, precision, and performance to critical low temperature physics research. It is ideal for use with he-3 systems, adiabatic demagnetization refrigerators (a...

Page 18

4 c hapter 1: introduction model 350 temperature controller 1.4.3 measurement isolation optocouplers isolate the analog front end of the model 350 from digital circuitry and the instrument chassis. Optical isolation minimizes the effect of digital noise on the measurement and breaks ground loops. 1....

Page 19

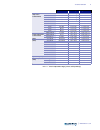

Sensor temperature range (sensors sold separately) model useful range magnetic field use negative temperature coefficient rtds cernox™ cx-1010 0.1 k to 325 k 1 t > 2 k & b " 19 t cernox™ cx-1030-ht 0.3 k to 420 k 1 t > 2 k & b " 19 t cernox™ cx-1050-ht 1.4 k to 420 k 1 t > 2 k & b " 19 t cernox™ cx-...

Page 20

Typical sensor performance example lake shore sensor temperature (k) nominal resistance/ voltage typical sensor sensitivity 2 measurement resolution: temperature equivalents electronic accuracy: temperature equivalents temperature accuracy including electronic accuracy, calcurve™ and calibrated sens...

Page 22

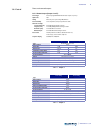

8 c hapter 1: introduction model 350 temperature controller 1.6.2 sensor input configuration sensor input configuration rtd diode (option) thermocouple (option) capacitance (option) measure- ment type 4-lead differential 4-lead dif- ferential 2-lead differential, room temperature compensated 4-lead ...

Page 24

10 c hapter 1: introduction model 350 temperature controller 1.6.4.2 analog outputs (outputs 3 and 4) control type closed loop pid, pid zones, warm up heater mode, still heater, adr con- trol, manual output, or monitor output warm up heater mode settings warm up percentage 0 to 100% with 1% resoluti...

Page 26

12 c hapter 1: introduction model 350 temperature controller 1.7 safety summary and symbols observe these general safety precautions during all phases of instrument operation, service, and repair. Failure to comply with these precautions or with specific warn- ings elsewhere in this manual violates ...

Page 27

Figure 1-3 safety symbols ! Direct current (power line) equipment protected throughout by double insulation or reinforces insulation (equivalent to class ii of iec 536—see annex h) caution: high voltages; danger of electric shock; background color: yellow; symbol and outline: black caution or warnin...

Page 28

14 c hapter 1: introduction model 350 temperature controller.

Page 30

Dilution refrigerator helium dewar vacuum insulation 4 he reservoir vacuum space 1 k pot vacuum chamber still heat exchangers mixing chamber sample holder 4 he 3 he dilute 3 he 3 he dilute 16 c hapter 2: cooling system design and temperature control model 350 temperature controller helium dewar: vac...

Page 32

18 c hapter 2: cooling system design and temperature control model 350 temperature controller 4 he reservoir: reservoir of liquid 4 he at atmospheric pressure that provides bulk cooling down to 4.2 k. Pre-cools gasses entering the vacuum space and acts as a radiation shield for refrigeration compone...

Page 34

20 c hapter 2: cooling system design and temperature control model 350 temperature controller since electrical noise is everywhere it is better to begin each installation with a good instrumentation strategy than it is to deal with noise after measurements are com- promised. Most parts of a good str...

Page 36

22 c hapter 2: cooling system design and temperature control model 350 temperature controller no measurement cable of any length should be run from the model 350 without a shield. The shield provides a low impedance path to measurement common that prevents the voltage change at the source from being...

Page 38

24 c hapter 2: cooling system design and temperature control model 350 temperature controller section 1.5 includes typical sensor characteristics for cernox™, germanium, ruthe- nium oxide rtd’s at 100 mk. Estimates of the thermal resistance of typical sensors are used to demonstrate how excitation c...

Page 40

26 c hapter 2: cooling system design and temperature control model 350 temperature controller once the total uncertainty is calculated, the noise or instrument measurement reso- lution can be factored in. The instrument noise is calculated using the measurement resolution listed in table 1-3. The te...

Page 42

28 c hapter 2: cooling system design and temperature control model 350 temperature controller 2.8 temperature sensor selection this section attempts to answer some of the basic questions concerning temperature sensor selection. Additional useful information on temperature sensor selection is availab...

Page 44

30 c hapter 2: cooling system design and temperature control model 350 temperature controller it is important to look at instrument specifications before ordering calibrated sen- sors. A calibrated sensor is required when a sensor does not follow a standard curve if you wish to display in temperatur...

Page 46

32 c hapter 2: cooling system design and temperature control model 350 temperature controller 2.10.6 lead wire different types of sensors come with different types and lengths of electrical leads. In general a significant length of lead wire must be added to the sensor for proper ther- mal anchoring...

Page 48

34 c hapter 2: cooling system design and temperature control model 350 temperature controller not everyone uses the lowest excitation range available. This is due to noise, or more appropriately signal to noise. Noise from a variety of sources affects the small signals used to make resistance measur...

Page 50

36 c hapter 2: cooling system design and temperature control model 350 temperature controller foil heaters are thin layers of resistive material adhered to, or screened onto, electri- cally insulating sheets. There are a variety of shapes and sizes. The proper size heater can evenly heat a flat surf...

Page 52

38 c hapter 2: cooling system design and temperature control model 350 temperature controller by adding the integral to proportional contributions, the error that is necessary in a proportional only system can be eliminated. When the error is at 0, controlling at the setpoint, the output is held con...

Page 54

40 c hapter 2: cooling system design and temperature control model 350 temperature controller 2.14 manual tuning there has been a lot written about tuning closed loop control systems and specifically pid control loops. This section does not attempt to compete with control theory experts. It describe...

Page 56

42 c hapter 2: cooling system design and temperature control model 350 temperature controller 2.14.4 tuning derivative if an experiment requires frequent changes in setpoint, derivative should be consid- ered. See figure 2-4(e). A derivative setting of 0, off, is recommended when the con- trol syste...

Page 58

44 c hapter 2: cooling system design and temperature control model 350 temperature controller.

Page 60

46 c hapter 3: installation model 350 temperature controller always turn off the instrument before making any rear panel connections. This is espe- cially critical when making sensor to instrument connections. Model 350 rear panel 3.4 line input assembly this section describes how to properly connec...

Page 62

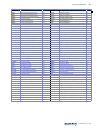

Standard input connector details pin symbol description 1 i– –current 2 v– –voltage 3 none shield 4 v+ +voltage 5 i+ +current 6 none shield 48 c hapter 3: installation model 350 temperature controller 3.5.2 sensor lead cable the sensor lead cable used outside the cooling system can be much different...

Page 64

50 c hapter 3: installation model 350 temperature controller d run different inputs and outputs in their own shielded cable d use twisted wire inside the cooling system d use similar technique for heater leads d use a grounded receptacle for the instrument power cord d consider ground strapping the ...

Page 66

52 c hapter 3: installation model 350 temperature controller remove all insulation, then tighten the screws on the thermocouple wires. Keep the ceramic terminal blocks away from heat sources including sunlight and shield them from fans or room drafts. Thermocouple input definition and common connect...

Page 68

54 c hapter 3: installation model 350 temperature controller 3.6.3 heater output wiring heater output current is what determines the size (gauge) of wire needed to connect the heater. The maximum current that can be sourced from heater output 1 is 1.732 a. When less current is needed to power a cool...

Page 70

56 c hapter 3: installation model 350 temperature controller 3.6.5.4 programming voltages under 10 v a voltage divider figure 3-11 can be used to reduce the control output voltage if the programming input of the power supply has a range of less than 0 v to 10 v to ensure full output resolution, and ...

Page 72

58 c hapter 4: operation model 350 temperature controller 4.2 front panel description this section provides a description of the front panel controls and indicators for the model 350. 4.2.1 keypad definitions the keypad is divided into two sections. The direct operation section includes all keys to ...

Page 74

60 c hapter 4: operation model 350 temperature controller display annunciators: include symbols for sensor inputs and their respective tempera- tures and units. Display annunciators annunciator function a sensor input a b sensor input b c sensor input c d sensor input d d1 sensor input d, channel 1 ...

Page 76

62 c hapter 4: operation model 350 temperature controller option is installed, all eight sensor inputs and channels are displayed, and the display mode can be configured as large or small. When it is configured as large, the input name is not shown and the sensor reading is displayed in large charac...

Page 78

64 c hapter 4: operation model 350 temperature controller d input and units: each available display location has an associated input and units setting. The input parameter determines which sensor will be used as the input of the displayed data. The input can be any of the four sensor inputs, or none...

Page 80

66 c hapter 4: operation model 350 temperature controller 4.4.1 negative temperature coefficient (ntc) resistor sensor input setup ntc resistor sensors include cernox™, rox, thermox and others detailed in table 4-7. More detailed specifications are provided in table 1-2. When configured for ntc rtd,...

Page 82

68 c hapter 4: operation model 350 temperature controller the current reversal parameter defaults to on anytime the sensor type parameter is changed to ptc rtd or ntc rtd. Menu navigation: input setupqinput (a, b, c, or d)qcurrent reversalq(off or on) default: on interface command: intype 4.4.5 ther...

Page 84

70 c hapter 4: operation model 350 temperature controller 4.4.6.2 temperature coefficient selection capacitance sensors can have both a positive and negative temperature coefficient (slope). They have a positive temperature coefficient at very low temperatures and a negative temperature coefficient ...

Page 86

72 c hapter 4: operation model 350 temperature controller during normal operation, only the curves that share the input type you have selected are displayed. If the curve you wish to select does not appear in the selection sequence make sure the curve format matches the recommended format for the in...

Page 88

74 c hapter 4: operation model 350 temperature controller 4.4.10 input name to increase usability and reduce confusion, the model 350 provides a means of assigning a name to each of the four sensor inputs. The designated input name is used on the front panel display whenever possible to indicate whi...

Page 90

76 c hapter 4: operation model 350 temperature controller example 1: a 50 ), 30 w heater is connected to output 1. Power limit voltage compliance limit i = squrt(p/r) i = 50 v/r i = squrt(30 w/50)) i = 50 v/ 50 ) i = 0.77 a i = 1 a user max current should be set to the smaller of the two or 0.77 a. ...

Page 92

78 c hapter 4: operation model 350 temperature controller if desired, the control parameters can be changed manually, just like closed loop pid mode, but they will be automatically updated once the setpoint crosses a zone boundary. The control algorithm used for each zone is identical to that used i...

Page 94

80 c hapter 4: operation model 350 temperature controller to set d, first configure the front panel display to show the desired control loop infor- mation, then use the d key on the front panel. A quick way to access the setting if the control loop information is not already being displayed is to pr...

Page 96

82 c hapter 4: operation model 350 temperature controller the ramping feature is useful by itself, but it is even more powerful when used with other features. Setpoint ramps are often used with zone control mode. As tempera- ture is ramped through different temperature zones, control parameters are ...

Page 98

84 c hapter 4: operation model 350 temperature controller 4.6.1 usb the usb interface is provided as a convenient way to connect to most modern com- puters, as a usb interface is provided on nearly all new pcs as of the writing of this manual. The model 350 usb driver, which must be installed before...

Page 100

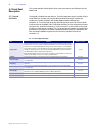

Autotune stages stage description purpose for stage reason for failure possible solution 0 testing initial conditions determine if autotuning can be initiated curve not assigned to input, heater not on, or temperature not within 5 k of setpoint ensure curve is assigned to input, heater is on, and te...

Page 102

Record of zone settings heater range a off a low control input a default proportional (0.1–1000) integral (0.1–1000) derivative (0–200) mhp output (0–100%) ramp rate (0.1–100 k/min) a c a med a high a d a b a a heater range a off a low control input a default proportional (0.1–1000) integral (0.1–10...

Page 104

90 c hapter 5: advanced operation model 350 temperature controller 5.5.2 warm up control the warm up control parameter determines what happens when the control set- point is reached. The options are: d auto-off: once the heater range is set to on, the warm up percentage voltage is applied to the out...

Page 106

92 c hapter 5: advanced operation model 350 temperature controller 5.7 alarms and relays 5.7.1 alarms each input of the model 350 has high and low alarm capability. Input reading data from any source can be compared to the alarm setpoint values. A reading higher than the high alarm setpoint triggers...

Page 108

94 c hapter 5: advanced operation model 350 temperature controller 5.7.2 relays there are two relays on the model 350 numbered 1 and 2. They are most commonly thought of as alarm relays, but they may be manually controlled also. Relay assign- ments are configurable as shown in figure 5-6. Two relays...

Page 110

Typical curve parameters sensor type typical lake shore model format limit (k) temperature coefficient typical sensor resolution silicon diode dt-670 v/k 475 negative 0.00001 v gaalas diode tg-120 v/k 325 negative 0.00001 v platinum 100 pt-100 ) /k 800 positive 0.001 ) platinum 1000 –* ) /k 800 posi...

Page 112

98 c hapter 5: advanced operation model 350 temperature controller 5.9.1.2 add a new breakpoint pair the last breakpoint of a curve is signified by the first pair that contains a 0 value for both the temperature and sensor portions. Curves are limited to 200 breakpoint pairs, so if 200 pairs already...

Page 114

100 c hapter 5: advanced operation model 350 temperature controller 5.10 softcal™ the model 350 allows you to perform inexpensive sensor calibrations with a set of algorithms called softcal™. The two softcal™ algorithms in the model 350 work with dt-400 series silicon diode sensors and platinum sens...

Page 115

Acceptable temperature range for dt-400 series silicon diode softcal™ sensors softcal point one liquid helium boiling point 4.2 k softcal point two liquid nitrogen boiling point 77.35 k softcal point three room temperature point 305 k 2 – 10 k 50 – 100 k 200 – 325 k 325 350 300 275 250 225 200 175 1...

Page 116

102 c hapter 5: advanced operation model 350 temperature controller 5.10.3 softcal™ with platinum sensors the platinum sensor is a well-accepted temperature standard because of its consis- tent and repeatable temperature response above 30 k. Softcal™ gives platinum sen- sors better accuracy than the...

Page 118

104 c hapter 5: advanced operation model 350 temperature controller.

Page 120

106 c hapter 6: computer interface operation model 350 temperature controller 6.2.1 changing ieee-488 interface parameters the ieee-488 address must be set from the front panel before communication with the instrument can be established. Menu navigation: interfaceqenabledqieee-488 interfaceqieee-488...

Page 122

108 c hapter 6: computer interface operation model 350 temperature controller 6.2.4 status system overview the model 350 implements a status system compliant with the ieee-488.2 standard. The status system provides a method of recording and reporting instrument informa- tion and is typically used to...

Page 123

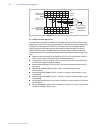

Model 350 status system 7 6 5 4 3 2 1 0 pon cme exe qye opc and or and and and and 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 and and and or and and and 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 and rqs mss generate service request—reset by serial poll read by *stb? 7 6 5 4 3 2 1 0 and or and and 7 6 5 4 3 2 1 0 and sta...

Page 124

110 c hapter 6: computer interface operation model 350 temperature controller 6.2.4.4 status byte register the status byte register, typically referred to as the status byte, is a non-latching, read-only register that contains all of the summary bits from the register sets. The status of the summary...

Page 126

Standard event status register 7 6 5 4 3 2 1 0 pon cme exe qye opc and or and and and and 7 6 5 4 3 2 1 0 8 4 2 1 standard event status register *esr? (*esr? Reads and clears the register) standard event status enable register *ese, *ese? Not used not used not used pon cme exe qye opc not used not u...

Page 127

Operation event register 7 6 5 4 3 2 1 0 or 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 operation condition register opst? Operation event register opstr? Operation event enable register opste, opste? Cal ramp1 ramp2 ovld alarm cal ramp1 ramp2 ovld alarm cal com com com ramp1 ramp2 atune nrdg atune nrdg atune n...

Page 128

114 c hapter 6: computer interface operation model 350 temperature controller d message available (mav), bit (4): this bit is set when a message is available in the output buffer 6.2.6.2 service request enable register the service request enable register is programmed by the user and determines whic...

Page 129

Programming example to generate an srq command or operation description *esr? Read and clear the standard event status register *ese 32 enable the command error (cme) bit in the standard event status register *sre 32 enable the event summary bit (esb) to set the rqs *abc send improper command to ins...

Page 130

116 c hapter 6: computer interface operation model 350 temperature controller 6.3 usb interface the model 350 usb interface provides a convenient way to connect to most modern computers, as a usb interface is provided on nearly all new pcs as of the writing of this manual. The usb interface is imple...

Page 132

118 c hapter 6: computer interface operation model 350 temperature controller 3. It is recommended to keep the same default folder. Take note of this folder loca- tion and click next. 4. An “extraction complete” message will be displayed. Click to clear the show extracted files checkbox, and click f...

Page 134

120 c hapter 6: computer interface operation model 350 temperature controller 6.3.4.1 character format a character is the smallest piece of information that can be transmitted by the inter- face. Each character is ten bits long and contains data bits, bits for character timing, and an error detectio...

Page 136

122 c hapter 6: computer interface operation model 350 temperature controller are zeros. This means that the first 24 bits of the static-ip address (192.168.0) represent the subnet, and the last 8 bits (12) represent the device. D gateway address: a gateway is a network traffic routing device that i...

Page 138

124 c hapter 6: computer interface operation model 350 temperature controller the model 350 can be configured to communicate with a primary and a secondary dns server using the primary dns address and the secondary dns address parame- ters. Multiple dns servers are sometimes used for redundancy, but...

Page 140

126 c hapter 6: computer interface operation model 350 temperature controller d module error: the model 350 has lost contact with the ethernet module; this may indicate a damaged ethernet module d acquiring address: the model 350 is attempting to configure the ip address parameters using the enabled...

Page 142

128 c hapter 6: computer interface operation model 350 temperature controller ethernet configuration page: provides a means of reconfiguring the ethernet config- uration parameters of the model 350. Ethernet configuration page ethernet status page: provides status and statistics related to the curre...

Page 144

130 c hapter 6: computer interface operation model 350 temperature controller the applications are launched from the utilities web page using java™ web start technology. This allows the application to run outside of the web browser in a stand- alone window. The application can only be launched using...

Page 146

132 c hapter 6: computer interface operation model 350 temperature controller 6.5.3 instrument configuration backup utility the instrument configuration backup utility provides the means to export the current configuration of the model 350 to a file, or to import a saved configuration from a file to...

Page 148

134 c hapter 6: computer interface operation model 350 temperature controller the configuration panel can be collapsed to increase the size of the chart. To collapse the configuration panel, simply click on collapse configuration panel (12). When col- lapsed, the same button becomes an expand config...

Page 150

136 c hapter 6: computer interface operation model 350 temperature controller 6.6 command summary this section provides a listing of the interface commands. A summary of all the com- mands is provided in table 6-6. All the commands are detailed in section 6.6.1, and are presented in alphabetical ord...

Page 151

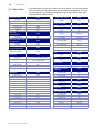

Command summary command function page command function page cls clear interface cmd 138 inname? Sensor input name query 147 ese event status enable register cmd 138 intsel interface select cmd 147 ese? Event status enable register query 138 intsel? Interface select query 147 esr? Standard event ...

Page 152

138 c hapter 6: computer interface operation model 350 temperature controller 6.6.1 interface commands this section lists the interface commands in alphabetical order. Interface commands key begins common interface command ? Required to identify queries s[n] string of alphanumeric characters with le...

Page 154

140 c hapter 6: computer interface operation model 350 temperature controller stb? Status byte query input stb?[term] returned [term] format nnn remarks acts like a serial poll, but does not reset the register to all zeros. The integer returned represents the sum of the bit weighting of the status...

Page 156

142 c hapter 6: computer interface operation model 350 temperature controller analog? Monitor out parameter query input analog? [term] format n specifies which unpowered analog output to query the monitor out parameters for: 3 or 4. Returned ,,,,[term] format n,n,±nnnnn,±nnnnn,n (refer to command fo...

Page 158

144 c hapter 6: computer interface operation model 350 temperature controller dflt factory defaults command input dflt 99[term] remarks sets all configuration values to factory defaults and resets the instrument. The “99” is included to prevent accidentally setting the unit to defaults. Diocur diode...

Page 160

146 c hapter 6: computer interface operation model 350 temperature controller htrset heater setup command input htrset ,,, current>,[term] format n,n,n,+n.Nnn,n specifies which heater output to configure: 1 or 2. Heater resistance setting (output 1 only): 1 = 25 ), 2 = 50 ) . Specifies the maximum h...

Page 162

148 c hapter 6: computer interface operation model 350 temperature controller intype input type parameter command input intype ,,,, tion>,, [term] format a,n,n,n,n,n specifies input to configure: a - d (d1 - d5 for 3062 option) specifies input sensor type: 0 = disabled 1 = diode (3062 option only) 2...

Page 164

150 c hapter 6: computer interface operation model 350 temperature controller mdat? Minimum/maximum data query input mdat? [term] format a specifies which input to query: a - d (d1 - d5 for 3062 option). Returned ,[term] format ±nnnnnn,±nnnnnn remarks returns the minimum and maximum input data. Also...

Page 166

152 c hapter 6: computer interface operation model 350 temperature controller opste operational status enable command input opste [term] format nnn remarks each bit has a bit weighting and represents the enable/disable mask of the corre- sponding operational status bit in the operational status regi...

Page 168

154 c hapter 6: computer interface operation model 350 temperature controller range heater range command input range ,[term] format n,n specifies which output to configure: 1–4. For outputs 1 and 2: 0 = off, 1 = range 1, 2 = range 2, 3 = range 3, 4 = range 4, 5 = range 5 for outputs 3 and 4: 0 = off...

Page 170

156 c hapter 6: computer interface operation model 350 temperature controller srdg? Sensor units input reading query input srdg? [term] format a specifies which input to query: a - d (d1 - d5 for 3062 option). Returned [term] format ±nnnnnn remarks also see the rdgst? Command. Temp? Thermocouple jun...

Page 172

158 c hapter 6: computer interface operation model 350 temperature controller zone control loop zone table parameter command input zone ,,,,, ,, ,,,,[term] format n,nn,+nnnnn, +nnnnn,+nnnnn,+nnnn,+nnnnn, n,n, +nnnn [term] specifies which heater output to configure: 1 – 4. Specifies which zone in the...

Page 174

160 c hapter 7: options and accessories model 350 temperature controller cal-350-data†* instrument calibration/recalibration with certificate and data. Es-2-20 stycast® epoxy 2850-ft, catalyst 9 (20 packets, 2 g each).Stycast® is a common, highly versa- tile, nonconductive epoxy resin system for cry...

Page 176

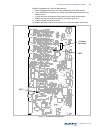

162 c hapter 7: options and accessories model 350 temperature controller the components on this board are electrostatic discharge sensitive (esds) devices. Follow esd procedures in section 8.11 to avoid inducing an electrostatic discharge (esd) into the device. 1. Turn model 350 power switch off. Un...

Page 178

164 c hapter 7: options and accessories model 350 temperature controller.

Page 180

166 c hapter 8: service model 350 temperature controller 8.3 ieee interface troubleshooting this section provides ieee interface troubleshooting for issues that arise with new installations, old installations, and intermittent lockups. 8.3.1 new installation 1. Check the instrument address. 2. Alway...

Page 182

168 c hapter 8: service model 350 temperature controller 8.7.1 default values the factory defaults can be reset, and the user curves cleared, using the factory reset menu. To access the factory reset menu, press and hold the escape key for 5 s. Once the menu appears, set either reset to defaults or ...

Page 184

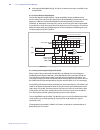

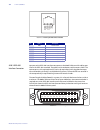

170 c hapter 8: service model 350 temperature controller 8.10 rear panel connector definition the sensor input, heater output, terminal block, usb, ethernet, and ieee-488 connec- tors are defined in figure 8-3 through figure 8-8. For thermocouple connector details refer to figure 3-8. Sensor input a...

Page 185

Terminal block for relays and output 3 and 4 terminal block pin and connector details pin description 1 output 3+ 2 output 3– 3 output 4+ 4 output 4– 5 relay 1 normally closed 6 relay 1 common 7 relay 1 normally open 8 relay 2 normally closed 9 relay 2 common 10 relay 2 normally open usb pin and con...

Page 186

Ethernet pin and connector details epwr - epwr - rxd- epwr+ epwr+ rxd+ txd- txd+ ethernet pin and connector details pin symbol description 1 txd+ transmit data+ 2 txd- transmit data- 3 rxd+ receive data+ 4 epwr+ power from switch+ (not used) 5 epwr+ power from switch+ (not used) 6 rxd- receive data-...

Page 187

Ieee-488 rear panel connector details pin symbol description 1 dio 1 data input/output line 1 2 dio 2 data input/output line 2 3 dio 3 data input/output line 3 4 dio 4 data input/output line 4 5 eoi end or identify 6 dav data valid 7 nrfd not ready for data 8 ndac no data accepted 9 ifc interface cl...

Page 188

174 c hapter 8: service model 350 temperature controller 8.11.2 handling electrostatic discharge sensitive components observe all precautions necessary to prevent damage to esds components before attempting installation. Bring the device and everything that contacts it to ground potential by providi...

Page 190

176 c hapter 8: service model 350 temperature controller 8.13 record of updates made to the firmware table 8-8 and table 8-9 describe the updates made to the temperature controller in each version. Instrument firmware updates instrument firmware version features added 1.1 model 3062 scanner option c...

Page 192

178 c hapter 8: service model 350 temperature controller.