- DL manuals

- Lambda Electronics

- Power Supply

- 71

- Instruction Manual

Lambda Electronics 71 Instruction Manual

Summary of 71

Page 1

Instruction manual power supply model ____71____ spec._______ lambda electronics corp. College point 56, n. Y..

Page 2

Instruction manual for regulated power supply model 71 manufactured by lambda electronics corp. Corona 68, new york issue a model no. 71 1-55-123 serial no. 1525.

Page 3

Instruction manual for regulated power supply model 71 1. General description 1. General description. The model 71 power supply described in this manual is designed for general purpose use in industry, laboratory, radio station and school to supply power to electronic and other equipment. The dc out...

Page 4

2. Electrical specifications: input; 105-125 vac, 50-60 cps, 475 w (max) dc output no. 1; (regulated for line and load) voltage: 0-500 vdc (continuously variable) current; 0-200 ma (over entire voltage range) regulation (line); 0.15% or 0.3 volt (whichever is greater) regulation (load); 0.15% or 0.3...

Page 5

Ambient temperature and duty cycle: continuous duty at full load up to 40°c (104°f) ambient. Overload protection: external overload protection ac and dc systems utilize magnetic circuit breakers. Trip- free. Instant manual reset. Front panel. Internal failure protection fuses, access through rear of...

Page 6

Tube complement: tube type quantity function 5r4·gy 1 rectifier 6x4 1 rectifier 6w6-gt 6 control tubes 6n030 1 time delay relay 12ax7 3 voltage amplifier 5651 1 voltage reference 0a2 1 voltage stabilizer 3. Mechanical specifications: size and weight and finish size 13" h x 8-3/4" w x 14-1/2" d weigh...

Page 7

Ii. Operating instructions. Model 71 1. Operating controls. A) the "ac" circuit-breaker is in series with the ac line and controls power to the supply. When the toggle of the "ac" breaker is in the "on" position, the adjacent pilot- light indicator marked "ac" is illuminated, the heaters of all the ...

Page 8

G) the "bias" control is a wirewound potentiometer which permits the bias output voltage to be set to any value from zero to the maximum output voltage of either bias voltage range. H) the "output voltage" meter is a 3-1/2 inch panel instrument which indicates either the "hv" output or "bias" voltag...

Page 9

For minimum output ripple, it is recommended that either the positive or negative high voltage dc output terminal be grounded. C) "bias° output connections: the regulated dc bias-output voltage is available at the front panel terminals marked "bias". The positive "bias" connection is internally tied...

Page 10

E) after approximately 30 seconds, throw the "dc" circuit-breaker to the "on" position. The pilot-light indicator marked "dc" will be illuminated, and the internal plate-power·relay will close. If the "dc" circuit breaker is thrown to the "on" position before the 30 second time delay has elapsed, th...

Page 11

The "ac" breaker on again will restore operation. If the supply is off for more than one minute the thermal delay- relay may re-cycle before dc voltage will be present at the output terminals. (see caution note in paragraph 3 above). B) high voltage dc output circuits: an overload or short circuit o...

Page 12

6. Noise and ripple output: the noise and ripple output of the high-voltage dc supply should be less then 5 millivolts rms and the dc bias supply less than 5 millivolts rms at all voltages and load conditions within the specifications. Measurement of thls level of voltage may be made with an ac vtvm...

Page 13

Iii. Maintenance safety notice dangerous voltages exist in this equipment. Observe the usual safety precautions when operating or servicing the equipment to avoid shock or injury. 1. General. Under normal conditions no special maintenance of the model 71 regulated power supply is required except for...

Page 14

B) 6n030 time-delay·relay: the 6n030 1s most readily checked under actual operatlng conditions. If the power supply is turned on from a cold start, and the "dc" circuit·breaker left in the "on" position, the internal plate-power-relay will c1ose with an audible click, and the "dc on" pilot light lnd...

Page 15

If a major discrepancy exists, loosening of the two set screws in the knob will permit readjustment of its position. C) set the "/\hv" control to its center or "0" position. D) set the "voltmeter" switch to the "hv" position. E) with no external ac or dc load on the power supply, turn both "ac" and ...

Page 16

6. Typical power supply failure conditions and their portable causes. Safety notice dangerous voltages exist in this equipment. Observe the usual safety precautions when operating or servicing the equipment to avoid severe shock or injury. Refer to the schematic diagram for proper operating voltages...

Page 17

If upon removal of any tube v2-v6, this condition is eliminated, replace this faulty tube with a new tube. 2) filament burnout of 12ax7. V8. Lf tubes v2-v6 ere all found to be good, the 12ax7, v8 may have a burned out filament. This is slmply checked for by replacing the l2ax7 with a new tube. 3) lo...

Page 18

D) presence of positive 1) filament burnout of l2ax7, low level "hv" voltage as v11. This is easily checked compared with that by replacement with a new indicated on the "hv" dial, tube. Poor regulation and high ripple. (no external load 2) check voltage across applied to "hv" output.) capacitor, c2...

Page 19

F) apparent satisfactory 1) faulty 6w6-gt tubes, v2 operation at low current through v6, will cause values with supply failure remaining 6w6-gt tubes to at 200 ma external and carry excess load. Tubes 105 line. Should be visually inspected for filament burnout. If burnout is not apparent, then tubes...

Page 20

7. Maintenance of the powerstat ("hv" control). A) determining defective operation: when the brush contact of the "powerstat" indicates excessive wear (less than 1/32" of the carbon brush extends from the brush holder) or arcing occurs when the "powerstat" is rotated with a load on the supply result...

Page 21

3. Separate the assembly from panel by unscrewing of the four phillips head screws holding the unit to the front panel. 4. Powerstat and precision potentiometer assembly may now be separated from panel. B) replacement of powerstat or precision potentiometer. 1. Remove powerstat potentiometer assembl...

Page 22

6. Check the assembly for smooth rotation and reassemble into equipment. B) replacement of the "voltmeter" and "bias range" switches. The replacement of either of these switches can be facilitated by removing the panel as outlined above. _safety notice_ dangerous voltages exist in this equipment. Ob...

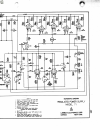

Page 24

Notes 1. Tolerance of wirewound resistors is +/-5%, unless noted. Schematic diagram 2. Voltage rating of capacitors is 600 vdc, unless noted. 3. Tolerance of capacitors is +/-10%, unless noted. Regulated power supply 4. Arrows indicate clockwise rotation of potentiometer shafts. 5. V indicates conne...