- DL manuals

- Lambda

- Power Supply

- EMS 10-100

- Operator's Manual

Lambda EMS 10-100 Operator's Manual

Summary of EMS 10-100

Page 1

Tdk lambda ems 15-300-2-d manual get pricing & availability at apexwaves.Com call today: 1-800-915-6216 email: sales@apexwaves.Com https://www.Apexwaves.Com/power-supplies/tdk-lambda/ems-series/ems%2015-300-2-d.

Page 2

Lambda emi 405 essex road, neptune, nj 07753 tel: (732) 922-9300 fax: (732) 922-9334 operator manual for ems power supply 83-473-000 revision j model serial number.

Page 3

Table of contents 4 - 1 4.1 principles of operation 4 - 1 4 theory of operation 3 - 13 3.11 load connection 3 - 12 3.10 remote turn on 3 - 12 3.9.1 remote sensing (p.S. With output voltage over 300v ) 3 - 12 3.9 remote sensing (p.S. With output voltage 300v or less) 3 - 11 3.8 remote meters (p.S. Wi...

Page 4

5 - 3 5.4 troubleshooting 5 - 2 5.3.3 current channel and ammeter calibration 5 - 2 5.3.2 voltage channel and voltmeter calibration 5 - 1 5.3.1 analog meter zero calibration 5 - 1 5.3 calibration 5 - 1 5.2 inspection and cleaning 5 - 1 5.1 introduction 5 - 1 5 calibration and troubleshooting 4 - 5 4...

Page 5

List of figures 4 - 1 figure 4.1: simplified ems power supply 3 - 12 figure 3.15: remote sensing 3 - 11 figure 3.14: series operation, master/slave 3 - 10 figure 3.13: series operation 3 - 10 figure 3.12: parallel operation, master/slave 3 - 9 figure 3.11: parallel operation 3 - 8 figure 3.10: remot...

Page 6

1 general information 1.1 introduction this manual contains instructions for the operation and maintenance of the 600w, 1kw, 2kw, 2.5kw, and 5kw ems power supply series manufactured by lambda emi, inc. Of neptune, nj. The ems series has been developed specifically for laboratory test and burn-in app...

Page 7

5. Use extreme caution when connecting the high voltage output cable including the separate ground connecting the supply to the load. 6. Ensure all load capacitors are completely discharged prior to connection. Never handle the output cable when the power supply is operating. 7. Always replace fuses...

Page 8

1.3.3 regulation a. A regulation of less than 0.1 % of the maximum rated output is maintained over the entire range of the input line voltage given in table 1.1 b. Voltage mode: a load change of 100% (from full load to no load) will cause an output voltage deviation of less than 0.1% of maximum outp...

Page 9

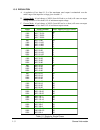

250 250 ems 600-4 ems 600-8 2500 5000 150 150 ems 300-8 ems 300-16 2500 5000 120 120 ems 150-16 ems 150-33 2500 5000 100 100 ems 100-25 ems 100-50 2500 5000 100 100 ems 80-30 ems 80-60 2500 5000 75 75 ems 60-40 ems 60-80 2500 5000 75 75 ems 40-60 ems 40-125 2500 5000 75 75 ems 30-80 ems 30-165 2500 ...

Page 10

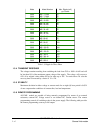

Caution! Hazardous voltages may be present on the terminal block or inside the j1 connector. Insure unit is powered off and disconnected prior to servicing. Refer to section 1.2 voltage mode ±5% ± 2.5 % ± 5 % ± 2.5 % output voltage 0 - 1 ma 0 - 5k Ω 0-10vdc 0-5 vdc programming method current mode ±5...

Page 11

1.5 environmental specifications Ÿ operating temperature: 0-50°c without derating Ÿ storage temperature: -40 to +85°c Ÿ operating humidity: 20 - 95% rh non-condensing Ÿ storage humidity: 20-95% rh non-condensing Ÿ altitude: 10,000 ft. 1.5.1 electrical installation categories Ÿ overvoltage category i...

Page 12

1.9 cooling all units are forced air cooled with air entering through the front and sides and exiting through the rear. A thermostat protects the unit from excessive ambient temperature as well as inadequate forced air cooling. Restart is automatic upon removal of thermal overload. 1.10 model number...

Page 13

This instrument received comprehensive mechanical and electrical inspection before shipment. Immediately upon receipt from the carrier, and prior to operation, this instrument should be visually inspected for any damage that may have been incurred during shipment. If such inspection reveals internal...

Page 14

2 inspection and installation 2.1 visual inspection prior to shipment, this instrument was inspected and found to be free of mechanical and electrical defects. As soon as the unit is unpacked, inspect for any damage that may have occurred in transit. Verify the following: a. Check the operation of t...

Page 15

A. Install single phase line terminals marked ac. Connect gnd line to terminal marked gnd. B. For units marked ce, the product provides more than 3.5ma of earth leakage current. Protective earth connection is essential before connecting the supply. An appropriate warning marking is placed on the rea...

Page 16

Units with the -ce suffix have been tested to the emc requirements of en 50081-1 and en 50081-2, however in the presence of high ambient rf noise, shielding may be required on the load or the remote control cables. 83-473-000 revision j 2 - 3 inspection and installation.

Page 17

2.4 electrical inspection to ensure that no internal damage was incurred during shipment, a preliminary test should be performed as follows: a. Rotate voltage and current knobs completely counter clockwise. B. Apply appropriate ac input power to the supply. With no load connected to the output termi...

Page 18

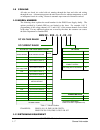

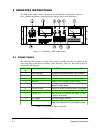

3 operating instructions the ems power supply could be operated in several different configurations. Section 3 gives a detailed description of configuring the supply to the desired application. Figure 3.1: front panel, (5kw model shown) 3.1 front panel the following table provides a listing of the c...

Page 19

3.2 operating modes the voltage and current controls set the boundary limits for the load voltage and current respectively. The relationship between the control settings and the load resistance determines whether the power supply operates in constant voltage or constant current mode. Automatic cross...

Page 20

3.3 programming modes caution hazardous voltages may be present on the terminal block or inside the j1 connector on units with outputs above 50vdc. Insure unit is powered off and disconnected prior to servicing. Refer to section 1.2 the power supply could be configured for either local or remote pro...

Page 21

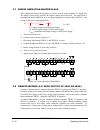

Table 3.2: tb1/j1 3.3.1 local programming when shipped from the factory, each supply is configured for constant voltage, constant current, local programming, local sensing, single unit mode of operation. In this mode of operation the voltage and the current control knobs assert control over the outp...

Page 22

Figure 3.5: remote programming by external resistance, voltage mode 83-473-000 revision j 3 - 5 operating instructions.

Page 23

Caution an opening in the remote programming circuit is effectively a high programming resistance and will allow an uncontrolled voltage rise exceeding the maximum output of the power supply. This may cause possible damage to the power supply and/or load. For this reason, any programming resistor sw...

Page 24

1. Remove the jumpers between terminals tb1/j1-4, and tb1/j1-5. 2. Connect a 5k ohm, 1% 0.5w resistor between tb1/j1-4 and tb1/j1-6. 3. Connect the programming current source between terminals tb1/j1-4 (positive) and tb1/j1-6 (negative). Figure 3.7: remote programming by external current, voltage mo...

Page 25

Figure 3.8: remote programming by external resistance, current mode caution an opening in the remote programming circuit is effectively a high programming resistance and will allow an uncontrolled current rise exceeding the maximum output of the power supply. This may cause possible damage to the po...

Page 26

Figure 3.9b: remote programming by external voltage, current mode (as per option) c. External dc current: a current of 0 to 1ma programs the output from zero to full rated current. Configure the strapping connections on tb1/j1 as shown on figure 3.10. 1. Remove the jumper between terminals tb1/j1-9,...

Page 27

Unit drifts upward, it will become current limited rather than carry an excessive share of load current. Important: in order to run power supplies with ovp in parallel, modifications must be made. Please contact the factory for further instructions, before connecting supplies with ovp in parallel. F...

Page 28

Figure 3.12: parallel operation, master/slave 3.6 series operation two ems power supplies can be operated in series simply by connecting the negative output terminal of one unit to the positive output terminal of the other. In this configuration each unit is adjusted independently, and the total out...

Page 29

3.7 series operation master/slave this configuration allows the customer to use two or more power supplies as a single unit. The master power supply controls the output voltage across the load. The supply that is designated the master should be set to a voltage higher than or equal to that of the sl...

Page 30

The leads to the remote meters should be twisted, and if strong ac or rf fields are present, the lead should be shielded. One end of the shield should be grounded to terminal tb1/j1-14 and the other end left floating. 3.9 remote sensing (p.S. With output voltage 300v or less) in applications where t...

Page 31

3.10 remote turn on external voltage source: connect either an external 12-24 vdc voltage supply or a 24-115 vac voltage supply to pins tb1/j1-15 & 16. The link between terminals 16 & 17 must be removed. Note: terminals are polarity sensitive dc. Terminal 15 is positive and terminal 16 is negative. ...

Page 32

4 theory of operation 4.1 principles of operation the basic principle of operation is outlined in this section. A simplified diagram of the ems power supply is shown below in figure 4.1. The power supply is made of the input section ( rectifier and the filter), the inverter (a200 bd.), the output se...

Page 33

Frequency current loops. In the half bridge ( 600w/ 1kw ) only one transistor is turned on at a time. In the full bridge, the two diagonally opposite transistors q1 and q4 or q2 and q3 are turned on simultaneously. The result of this switching is to produce a quasi-square waveform that is impressed ...

Page 34

Pwm. When the voltage rises above 13v, pin 7 of u4 latches low, and thus q5 will turn off if permitted by diodes cr12, cr14, cr16 and cr17, controlled respectively by the remote turn-on, thermostat protection, overvoltage protection and turn-on delay circuits. (3) overvoltage protection the overvolt...

Page 35

4.5.3 set-point reference separate constant current sources provide reference voltages for the voltage and current channels. The collector current of q1 drives the voltage control potentiometer that is located on the front panel, whereas q2 drives the current control potentiometer. The positive bias...

Page 36

Current and voltage. The 1524 also provides an accurate 5.1 volt dc reference which is used for the under and over voltage lockout circuits. The pwm also contains an amplifier which converts the error signals phase by 180° (at dc) so the signal into the pwm has the proper phase. The pwm also provide...

Page 37

5 calibration and troubleshooting 5.1 introduction a regularly scheduled maintenance of once a year is recommended for the ems series power supply. As a minimum, maintenance should consist of a thorough cleaning of the interior, and a visual inspection of the fans and components on the printed circu...

Page 38

Proceeding to the next step. The digital meter doesn’t have a zero adjustment and the full scale is on the back of the meter, or on the a100 pcb r406 or r402. 5.3.2 voltage channel and voltmeter calibration 1. Disconnect any load from output of the power supply. 2. Connect a digital voltmeter across...

Page 39

5.4 troubleshooting using this section in conjunction with section iv and the schematics that are provided in this manual, will help tremendously in troubleshooting the power supply by isolating and locating the cause of the fault. Before attempting to troubleshoot the power supply, perform section ...