- DL manuals

- Lambda

- Power Supply

- GENESYS 10KW

- Technical Manual

Lambda GENESYS 10KW Technical Manual

Summary of GENESYS 10KW

Page 1

Technical manual for genesys tm 10kw/15kw programmable dc power supplies document: 83-530-000 rev b lambda americas 405 essex road, neptune, nj 07753 tel: (732) 922-9300 fax: (732) 922-9334 web: www.Lambda-hp.Com.

Page 2

83-530-000 rev. B 1 warranty this lambda americas product is warranted against defects in materials and workmanship for a period of five years from date of shipment. During the warranty period, lambda americas will, at its option, either repair or replaces products, which prove to be defective. Limi...

Page 3

Page: 83-530-000 rev b 2 safety instructions caution the following safety precaution must be observed during all phases of operation, service and repair of this equipment. Failure to comply with the safety precautions or warnings in this document violates safety standards of design, manufacture and ...

Page 4

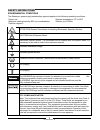

83-530-000 rev. B 3 safety instructions environmental conditions the genesys tm power supply series safety approval applies to the following operating conditions: *indoor use *ambient temperature: 0°c to 50°c *maximum relative humidity: 80% (no condensation) *altitude: up to 3000m *pollution degree ...

Page 5

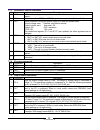

Page: 83-530-000 rev b 4 warranty ......................................................................................................... 1 chapter 1 general information ............................................................. 6 1.1 user manual content ...........................................

Page 6

83-530-000 rev. B 5 chapter 7 rs232 & rs485 remote control ....................................... 46 7.1 introduction................................................................................................46 7.2 configuration ....................................................................

Page 7

Page: 83-530-000 rev b 6 chapter 1 general information 1.1 user manual content this user’s manual contains the operating instructions, installation instructions and specifications of the genesys tm 15kw and 10kw power supply series. The instructions refer to the standard power sup- plies, including ...

Page 8

83-530-000 rev. B 7 1.2.3 control via the serial communication port the following parameters can be programmed via the serial communication port: 1. Output voltage setting. 2. Output current setting. 3. Output voltage measurement. 4. Output on/off control. 5. Output current measurement. 6. Foldback ...

Page 9

Page: 83-530-000 rev b 8 1.3 accessories 1.3.1 general accessories are delivered with the power supply or separately upon ordering. The list below shows the possible accessories and ordering numbers. 1.3.2 serial link cable serial link cable for linking power supplies by rs485 communication can be p...

Page 10

83-530-000 rev. B 9 warning ieee 488/rs232 option there is a potential shock hazard at the rs232-485 and the ieee ports when using power supplies with rated or combined voltage greater than 400v and the positive output of the power supply is grounded. Do not connect the positive output to ground whe...

Page 11

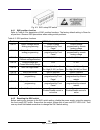

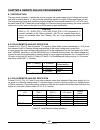

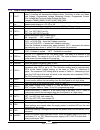

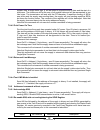

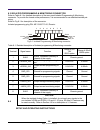

Page: 83-530-000 rev b 10 1.1 standard models - 10kw 1.Rated output voltage v 7.5 10 12.5 20 25 30 40 50 60 80 100 125 150 200 250 300 400 500 600 2.Rated output current a 1000 1000 800 500 400 333 250 200 167 125 100 80 66 50 40 33 25 20 17 3.Rated output power kw 7.5 10.0 10.0 10.0 10.0 10.0 10.0 ...

Page 12

83-530-000 rev. B 11 5. Dynamic characteristics v 7.5 10 12.5 20 25 30 40 50 60 80 100 125 150 200 250 300 400 500 600 1. Up-prog. Response time, 0~vomax full-load ms 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 2. Down-prog response time full-load ms 100 100 100 100 1...

Page 13

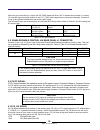

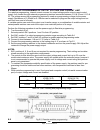

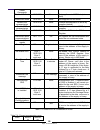

Page: 83-530-000 rev b 12 1. Functions: 1. Voltage/current setting 2. Ovp/uvl setting 3. Actual voltage/current readback 4. Voltage/current setting readback 5. Ovp/uvl setting readback 6. Output on/off 7. Foldback protection setting 8. Status readback (cc/cv , ovp , otp , foldback, ac fault) 9. Mode...

Page 14

83-530-000 rev. B 13 1. 208 volts input models 1. Esd --- 2. Fast transients --- 3. Surge immunity --- 4. Conducted immunity --- 5. Radiated immunity --- 6. Power frequency magnetic field 7. Conducted emission --- 8. Radiated emission --- 2. 400 volts input models (ce mark) 1. Esd --- 2. Fast transi...

Page 15

Page: 83-530-000 rev b 14 chapter 3 installation 3.1 general this chapter contains instructions for initial inspection, preparation for use and repackaging for ship- ment. Connection to pc, setting the communication port and linking genesys tm power supplies are de- scribed in chapter 7. 3.2 prepara...

Page 16

83-530-000 rev. B 15 some components inside the power supply are at ac/dc voltage even when the on/off switch is in the “off” position. To avoid electric shock hazard, disconnect the line and load and wait 15 minutes before removing cover. There is a potential shock hazard if the power supply chassi...

Page 17

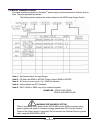

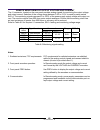

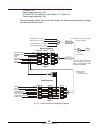

Page: 83-530-000 rev b 16 input terminal block with cover. Input terminal block input rating label note: the figure shows input connection from left side. For connection from right side reverse the input cover. Figure 3.1 3.7.1 recommended cable size for input connection input voltage current rms am...

Page 18

83-530-000 rev. B 17 3.8 turn-on checkout procedure 3.8.1 general the following procedure ensures that the power supply is operational and may be used as a basic in- coming inspection check. Refer to fig. 4-1 and fig. 4-2 for the location of the controls indicated in the procedure. 3.8.2 prior to op...

Page 19

Page: 83-530-000 rev b 18 7. Remove the shunt from the power supply output terminals. 3.8.5 ovp check refer to section 5.3 for explanation of the ovp function prior to performing the procedure below. 1. Turn the front panel ac power switch to on position and turn on the output by pressing out pushbu...

Page 20

83-530-000 rev. B 19 warning turn off the ac input power before making or changing any rear panel connection. Ensure all live circuits are discharged and that all connections are securely tightened before applying power. There is a potential shock hazard when using a power supply with a rated output...

Page 21

Page: 83-530-000 rev b 20 3.9.2 noise and impedance effects to minimize the noise pickup or radiation, the load wires and remote sense wires should be twisted pairs to the shortest possible length. Shielding of sense leads may be necessary in high noise envi- ronments. Where shielding is used, conne...

Page 22

83-530-000 rev. B 21 fig. 3-11: remote sensing, single load fig. 3-12: multiple loads connection, radial distribution, local sense 3.9.6 multiple load connection with distribution terminals if remotely located output distribution terminals are used, the power supply output terminals should be connec...

Page 23

Page: 83-530-000 rev b 22 fig. 3-13: multiple loads connection with distribution terminal 3.9.7 grounding outputs either the positive or negative output terminals can be grounded. To avoid noise probems caused by common-mode current flowing from the load to ground, it is recommended to ground the ou...

Page 24

83-530-000 rev. B 23 terminal function j2-1 remote positive sense (+s) j2-2 local positive sense. Connected internally to the positive output terminal (+ls). J2-3 not connected (nc) j2-4 local negative sense. Connected internally to the negative output terminal (-ls). J2-5 remote negative sense (-s)...

Page 25

Page: 83-530-000 rev b 24 3.11 repackaging for shipment to ensure safe transportation of the instrument, contact the lambda sales or service facility near you for return authorization and shipping information. Please attach a tag to the power supply describing the problem and specifying the owner, m...

Page 26

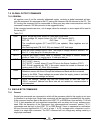

83-530-000 rev. B 25 voltage al arm fin e prev/ ovp uvl fol d rem/l oc out dc volts dc amps current genesys power supply tm 19 1 3 12 10 4 8 5 6 18 16 17 15 14 13 11 9 7 voltage alarm fine prev/ ovp uvl fold rem/loc out dc volts dc amps current genesys power supply tm 6 1 2 chapter 4 front and rear ...

Page 27

Page: 83-530-000 rev b 26 number control/indicator description section 1 voltage control high resolution rotary encoder for adjusting the output voltage. Also adjusts the ovp/uvl levels and selects the address 5.2.1 5.3.1 5.4.1 7.2.2 2 voltage indicator green led, lights for constant-voltage mode op...

Page 28

83-530-000 rev. B 27 13 ovp/uvl button over voltage protection and under voltage limit setting. -press once to set ovp using voltage encoder (the cur- rent display shows “oup”) -press again to set the uvl using voltage encoder (the current display shows “uul”). 5.3 5.4 14 prev button main function: ...

Page 29

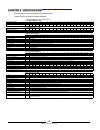

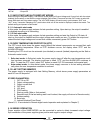

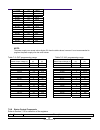

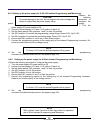

Page: 83-530-000 rev b 28 7 6 5 4 3 9 8 2 10 platform a output range 7.5v - 80v safety (pe) gnd must be connected. 1 sw1 j2 in out platform b output range 100v - 300v 7 6 5 4 3 9 8 1 2 10 2 10 1 8 7 6 5 4 3 9 platform c output range 400v - 600v safety (pe) gnd must be connected. Safety (pe) gnd must...

Page 30

83-530-000 rev. B 29 number item description section 1 ac input connector m6 stud terminal suitable for ring lugs. 3.7.1 3.7.2 2 dc output bus-bars up to 300v models. Stud terminals for models above 300v. 3.9.6 3 remote-in connector rj-45 type connector, use for connecting power supplies to rs232 or...

Page 31

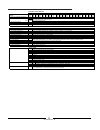

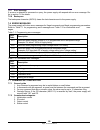

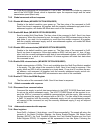

Page: 83-530-000 rev b 30 fig. 4-3: sw1 setup dip switch 4.4.1 sw1 position function refer to table 4-3 for description of sw1 position functions. The factory default setting is down for all positions. Observe esd precautions when setting switch positions. Table 4-3: sw1 positions functions position...

Page 32

83-530-000 rev. B 31 4.5 rear panel j1 programming and monitoring connector the j1 programming and monitoring connector is a db25 subminiature connector located on the power supply rear panel. Refer to table 4-4 for description of the connector functions. The power supply de- fault configuration is ...

Page 33

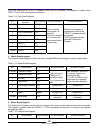

Page: 83-530-000 rev b 32 table 4-4: j1 connector terminals and functions j1 contact signal name function reference j1-1 ena_in enable/disable the power supply output by dry-contact (short/open) with ena_out. Sec. 5.8 j1-2 j1-3 if_com isolated interface common. Return for the so control, ps_ok signa...

Page 34

83-530-000 rev. B 33 chapter 5 local operation 5.1 introduction this chapter describes the operating modes that are not involved in programming and monitoring the power supply via its serial communication port (rs232/rs485) or by remote analog signals. Ensure that the rem/loc led on the front panel ...

Page 35

Page: 83-530-000 rev b 34 -enabled output, power supply in constant voltage mode: press the prev button and then ro- tate the current encoder knob. The current meter will show the programmed current limit for 5 seconds after the adjustment has been completed, and then will return to show the actual ...

Page 36

83-530-000 rev. B 35 5.4 under voltage limit (uvl) the uvl prevents adjustment of the output voltage below a certain limit. The combination of uvl and ovp functions, allow the user to create a protection window for sensitive load circuitry. 5.4.1 setting the uvl level setting the uvl can be made whe...

Page 37

Page: 83-530-000 rev b 36 when the unit is shut-off by j1 signal, the voltage display will show “so” to indicate the unit state. J1 contact 15 is the so signal input and contacts 2 and 3, if_com, are the signal return (connected internally). Contacts 2, 3 and 15 are optically isolated from the power...

Page 38

83-530-000 rev. B 37 *foldback *ieee failure (with optional ieee interface) *ac fail *output off 5.11 safe start and auto-restart modes when turning on the power supply, it can start to its last setting of output voltage and current limit with the output enabled (auto-restart) or start with the outp...

Page 39

Page: 83-530-000 rev b 38 5.14.1 series connection for increased output voltage in this mode, two units are connected so that their outputs are summed. Set the current limit of each power supply to the maximum that the load can handle without damage. It is recommended that diodes be connected in par...

Page 40

83-530-000 rev. B 39 3. Programming by external resistor: programming by external resistor is possible. Refer to sec- tion 6-5 for details. 4. Programming via the serial the communication port is referenced to the if_com communication port (rs232/rs485): which is isolated from the power supply outpu...

Page 41

Page: 83-530-000 rev b 40 5.15 parallel operation up to three units of the same voltage and current rating can be connected in parallel to provide up to three times the output current capability. One of the units operates as a master and the remaining units are slaves. The slave units are analog pro...

Page 42

83-530-000 rev. B 41 with local sensing it is important to minimize the wire length and resistance. Also the positive and negative wire resistance should be as close as possible to each other to achieve current balance between power supplies. 5.16 daisy-chain connection it is possible to configure a...

Page 43

Page: 83-530-000 rev b 42 caution com (j1-12), vpgm_rtn (j1-22) and ipgm_rtn (j1-23) terminals of j1 connect internally to the -sense potential (-ls). Do not connect these termi- nals to any potential other than -sense (-ls), as it may damage the power supply. Chapter 6 remote analog programming 6.1...

Page 44

83-530-000 rev. B 43 caution to maintain the isolation of power supply and prevent ground loops, use an isolated programming source when operating the power supply via remote analog programming at j1 connector. 6.4 remote voltage programming of output voltage and current limit perform the following ...

Page 45

Page: 83-530-000 rev b 44 6.5 resistive programming of output voltage and current limit for resistive programming, internal current sources, for output voltage and/or output current control, supply 1ma current through external programming resistors connected between j1-9 & 22 and j1-10 & 23. The vol...

Page 46

83-530-000 rev. B 45 remote monitoring of output voltage and current the j1 connector, located on the rear panel provides analog signals for monitoring the output voltage and output current. Selection of the voltage range between 0-5v or 0-10v is made by setup switch sw1-4. The monitoring signals re...

Page 47

Page: 83-530-000 rev b 46 chapter 7 rs232 & rs485 remote control 7.1 introduction this chapter describes the operation of the genesys tm 10kw and 15kw power supplies via the serial communication port. Details of the initial set-up, operation via rs232 or rs485, the command set and the communication ...

Page 48

83-530-000 rev. B 47 tx and rx are used for rs232 communication. Txd +/- and rxd +/- are used for rs485 communication. Refer to rs232 and rs485 cable description for connection details. 2. There are two remote modes: 1. Remote: in this mode, return to local can be made by the front panel rem/loc or ...

Page 49

Page: 83-530-000 rev b 48 7.4 connecting power supplies to rs232 bus 7.4.1 single power supply 1. Select the desired interface rs232 or rs485 using rear panel setup switch sw1-6 (section 4-4). -rs232: down position -rs485: up position 2. Connect rear panel in connector to the controller rs232 or rs4...

Page 50

83-530-000 rev. B 49 note the address (adr n) command must return an “ok” response before any other commands are accepted. Refer to figure 7-5 for typical connection. - set rear panel setup switch sw1-6 to its up position. - using the linking cable (refer to fig. 7-6), connect each unit out connecto...

Page 51

Page: 83-530-000 rev b 50 7.5.7 error message if an error is detected in command or query, the power supply will respond with an error message. Re- fer to section 7.6 for details. 7.5.8 backspace the backspace character (ascii 8) clears the last character sent to the power supply. 7.6 error messages...

Page 52

83-530-000 rev. B 51 7.7.3 initialization control commands # command description 1 adr n adr is followed by address, which can be 0 to 30 and is used to access the power supply. 2 cls clear status. Sets feve and seve registers to zero (refer to section 7-11). 3 rst reset command. Brings the power su...

Page 53

Page: 83-530-000 rev b 52 7.7.5 output control commands-cont. 7 dvc? Display voltage and current data. Data will be returned as a string of ascii char- acters. A comma will separate the different fields. The fields, in order, are: meas- ured voltage, programmed voltage, measured current, programmed ...

Page 54

83-530-000 rev. B 53 7.8 global output commands 7.8.1 general all supplies, even if not the currently addressed supply, receiving a global command will exe- cute the command. No response to the pc issuing the command will be returned to the pc. The pc issuing the command will be responsible to delay...

Page 55

Page: 83-530-000 rev b 54 all single byte commands will be executed in 1 ms or less. This does not include any response sent to the host/ieee board, which is dependent upon the response length and the serial transmission speed (baud rate). 7.9.2 global commands without response 7.9.2.1 disable md mo...

Page 56

83-530-000 rev. B 55 register data, a single dollar sign, $, will be added to signal the end of data and the start of a checksum. The checksum will be the sum of all register data and will be represented in two hex bytes. The transmission will end with the cr character. If repetitive sending of srqs...

Page 57

Page: 83-530-000 rev b 56 global commands disable md mode 1010 0000 none set supplies out of md mode (de- fault) enable md mode 1010 0001 none set supplies into md mode disable srq retransmission 1010 0010 none disable retransmission of srqs by supplies (default) enable srq retransmission 1010 0011 ...

Page 58

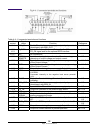

83-530-000 rev. B 57 7.5-1000 0.0 1000.0 10-1000 0.0 1000.0 12.5-800 0.0 800.0 20-500 0.0 500.0 25-400 0.0 400.0 30-333 0.0 333.0 40-250 0.0 250.0 50-200 0.0 200.0 60-167 0.0 167.0 80-125 0.0 125.0 100-100 0.0 100.0 125-80 0.0 80.0 150-66 0.0 66.0 200-50 0.0 50.0 250-40 0.0 40.0 300-33 0.0 33.0 400-...

Page 59

Page: 83-530-000 rev b 58 1 stt? Reads the complete power supply status. Returns ascii characters representing the following data, separated by commas: mv pc pv sr mc fr example response: mv(45.201),pv(45), mc(4.3257), pc(10), sr(30), fr(00) 2 flt? Reads fault conditional register. Returns 2-digit h...

Page 60

83-530-000 rev. B 59 voltage supply in cv. Cv. 1 constant current cc output is on and the supply in cc. Output is on and the supply is not in cc. 2 no fault nflt the power supply is operating normally or fault reporting is not enabled. See “out n” com- mand in section 7.7.5. One or more faults are a...

Page 61

Page: 83-530-000 rev b 60 the fault event will set a bit if a condition occurs and it is enabled. The register is cleared when feve?, cls or rst commands are received. Table 7-13: fault event register bit enable bit name fault symbol bit set condition bit reset condition 0 (lsb) spare bit spare 1 ac...

Page 62

83-530-000 rev. B 61 0 (lsb) constant voltage cv 1 constant current cc 2 no fault nflt 3 fault active flt changes in status occurs and it is enabled. The change can set a bit, but when the change clears the bit remains 4 auto-restart enabled 0 always zero 5 fold enabled 0 always zero 6 spare 0 alway...

Page 63

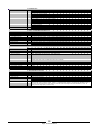

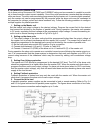

Page: 83-530-000 rev b 62 srq messages response messages command error (”cnn”) execution error (”enn”) query response (”message”) command response (”ok”) cv cc nflt flt ast fde 0 lcl cv cc nflt flt 0 0 0 lcl 0 0 0 status registers condition enable event constant voltage constant current no fault fau...

Page 64

83-530-000 rev. B 63 chapter 8 isolated analog programming option 8.1 introduction isolated analog programming is an internal option card for analog programming of the genesys tm power supply series. The option is factory installed and cannot be obtained with gpib (ieee-488) inter- face. Output volt...

Page 65

Page: 83-530-000 rev b 64 caution when the isolated analog option is installed, do not apply any signals to the non-isolated vpgm and ipgm (j1-9 and j1-10) pins. All other j1 features may be used normally. Refer to section 4.5 for a description of j1 features. 8.3 isolated programming & monitoring c...

Page 66

83-530-000 rev. B 65 caution to prevent damage to the unit, do not program the output voltage and current to higher then the power supply rating. Note j1-8 and j1-12 must be shorted together with a jumper. Note j1-8 and j1-12 must be shorted together with a jumper. Note sw1 position 3 and 4 must be ...

Page 67

Page: 83-530-000 rev b 66 chapter 9 maintenance 9.1 introduction this chapter provides information about maintenance, calibration and troubleshooting. 9.2 units under warranty units requiring repair during the warranty period should be returned to a lambda authorized service facility. Refer to the a...

Page 68

83-530-000 rev. B 67 symptom check action ref output voltage will not adjust. Front panel cc led is on. Is the unit in constant current mode? Check current limit setting and load current. 5.2.1 5.2.2 output voltage will not adjust front panel cv led is on. Check if output voltage is adjusted above o...