- DL manuals

- Lambda

- Power Supply

- Genesys 1500W

- Technical Manual

Lambda Genesys 1500W Technical Manual

Summary of Genesys 1500W

Page 1

Technical manual for genesys tm 750w/1500w programmable dc power supplies document: 83-507-013 rev a lambda americas 405 essex road, neptune, nj 07753 tel: (732) 922-9300 fax: (732) 922-9334 web: www.Lambda-emi.Com.

Page 2

83-000-015 rev. C.

Page 3

83-507-013 rev. A genesys™ manual supplement for units equipped with “iemd” option. Also refer to manual 83-030-200 iemd..

Page 4

83-507-013 rev. A table of contents warranty pg. 1 safety instructions pg. 2 german safety instructions pg. 4 chapter 1 general information pg. 6 1.1 user manual content pg. 6 1.2 introduction pg. 6 1.2.1 general description pg. 6 1.2.2 models covered pg. 6 1.2.3 features and options pg. 6 1.2.4 mul...

Page 5

83-507-013 rev. A table of contents 3.8.8 address setting pg. 18 3.8.9 baud rate setting pg. 18 3.9 connecting the load pg. 18 3.9.1 load wiring pg. 18 3.9.2 current carrying capacity pg. 18 3.9.3 wire termination pg. 19 3.9.4 noise and impedance effects pg. 20 3.9.5 inductive loads pg. 20 3.9.6 mak...

Page 6

83-507-013 rev. A table of contents 5.15.1 basic parallel operation pg. 41 5.15.2 advanced parallel operation pg. 41 5.16 daisy-chain shut-off connection pg. 44 5.17 front panel locking pg. 44 5.17.1 unlocked front panel pg. 44 5.17.2 locked front panel pg. 44 chapter 6 remote analog programming pg....

Page 7

83-507-013 rev. A table of contents 7.10.6 status control commands pg. 62 7.11 status, error and srq registers pg. 62 7.11.1 general description pg. 62 7.11.2 conditional registers pg. 63 7.11.3 service request: enable and event registers pg. 64 7.12 serial communication test set-up pg. 67 chapter 8...

Page 8

83-507-013 rev. A 1 warranty this lambda americas inc. Product is warranted against defects in materials and workmanship for a period of five years from date of shipment. During the warranty period, lambda americas inc. Will, at it’s option, either repair or replaces products, which prove to be defe...

Page 9

83-507-013 rev. A 2 safety instructions caution the following safety precautions must be observed during all phases of operation, service and repair of this equipment. Failure to comply with the safety precautions or warnings in this document violates safety standards of design, manufacture and inte...

Page 10

83-507-013 rev. A 3 safety instructions environmental conditions the genesys tm power supply series safety approval applies to the following operating conditions: *indoor use *ambient temperature: 0°c to 50°c *maximum relative humidity: 90% (no condensation) *altitude: up to 3000m *pollution degree ...

Page 11

83-507-013 rev. A 4 sicherheits-installations anweisungen vorsicht vor anschluss an das netz ist die aufstellanleitung wie nachstehend beschrieben zu beachten. Die nachstehenden sicherheitsanweisugen mussen während aller phasen des betriebes, des services und der reparatur dieser ausrustung beachtet...

Page 12

83-507-013 rev. A 5 anderungen and bauteileersatz ersatzteilaustausch – und anderungen durfen nur von autorisiertem lambda emi service-personen durchgefuhrt werden. Fur reparaturen oder anderungen ist das gerat zur lambda emi service-niederlassung zu retournieren. Sicherheits-hinweise umweltbedingun...

Page 13

83-507-013 rev. A 6 chapter 1 general information 1.1 user manual content this user’s manual contains the operating instructions, installation instructions and specifications of the genesys tm 1500w and 750w power supply series. The instructions refer to the standard power supplies, including the bu...

Page 14

83-507-013 rev. A 7 ∗ remote sensing to compensate for voltage drop of power leads. ∗ external analog programming and monitoring standard (0-5v or 0-10v, user selectable). ∗ cooling fan speed control for low noise and extended fan life. ∗ zero stacking-no ventilation holes at the top and bottom surf...

Page 15

83-507-013 rev. A 8 1.2.9 cooling and mechanical construction the genesys tm series is cooled by internal fans. At the installation, care must be taken to allow free air- flow into the power supply via the front panel and out of the power supply via the rear panel. The gene- sys tm power supplies ha...

Page 16

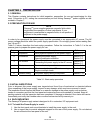

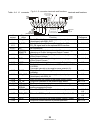

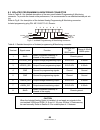

83-507-013 rev. A 9 chapter 2 specifications.

Page 17

83-507-013 rev. A 10

Page 18

83-507-013 rev. A 11 notes: *1: minimum voltage is guaranteed to maximum 0.2% of the rated output voltage. *2: minimum current is guaranteed to maximum 0.4% of the rated output current. *3: for cases where conformance to various safety standards (ul, iec etc.) is required, to be de- scribed as 100-2...

Page 19

83-507-013 rev. A 12 2.13 genesys tm 750w & 1500w power supplies outline drawings.

Page 20

83-507-013 rev. A 13 chapter 3 installation 3.1 general this chapter contains instructions for initial inspection, preparation for use and repackaging for ship- ment. Connection to pc, setting the communication port and linking genesys tm power supplies are de- scribed in chapter 7. 3.2 preparation ...

Page 21

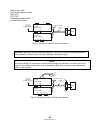

83-507-013 rev. A 14 3.4.2 rack mount slides (optional): use rack mount slides: general devices p/n: cc3001-00-s160 or equivalent to install the unit in a standard 19” equipment rack. Refer to fig. 3-1 for slides assembly instructions. Use three #10- 320x0.38”(max.) screws at each side. To prevent i...

Page 22

83-507-013 rev. A 15 fig.3-2: stripped wires installed in strain relief screw-on locknut 3.7.1 ac input connector, 1500w models the ac input connector is a 3-terminal wire clamp located on the rear panel. Use suitable wires and tightening torque as follows: 1. Wire diameter: 12awg or 10awg. 2. Tight...

Page 23

83-507-013 rev. A 16 screw, insert the stripped wire into the terminal and tighten the screw securely (4.4-5.3 lb-inch). 5. Route the wires inside the cover to prevent pinching. Fasten the cover to the unit using the m3x8 flat head screws provided. Refer to fig.3-3 for details. 3.8 turn-on checkout ...

Page 24

83-507-013 rev. A 17 3. Connect a dvm with appropriate cables for the rated voltage to the output terminals. 4. Turn the front panel ac power switch to on. 3.8.3 constant voltage check 1. Turn on the output by pressing the out pushbutton so the out led illuminates. 2. Observe the power supply volt d...

Page 25

83-507-013 rev. A 18 refer to section 5.5 for explanation of the fold function prior to performing the procedure below. 1. Ensure that the output voltage is set to approx. 10% of the unit rating. 2. Adjust the current encoder to set the output current setting to approx. 10% of the unit rating. 3. Mo...

Page 26

83-507-013 rev. A 19 minimize the voltage drop (1v typical maximum) to prevent excessive output power consumption from the power supply and poor dynamic response to load changes. Please refer to tables 3-2 and 3-3 for minimum wire length (to limit voltage drop) in american and european dimensions re...

Page 27

83-507-013 rev. A 20 where shielding is used, connect the shield to the chassis via a rear panel ground screw. Even if noise is not a concern, the load and remote sense wires should be twisted-pairs to reduce coupling, which might impact the stability of power supply. The sense leads should be separ...

Page 28

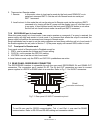

83-507-013 rev. A 21 fig. 3-5: load wires connection, 6v to 60v models fig. 3-6: bus-bars shield mounting 80v to 600v models warning hazardous voltages exist at the outputs and the load connections. To protect personnel against accidental contact with hazardous voltages, ensure that the load and its...

Page 29

83-507-013 rev. A 22 fig.3-7: load wires connection to the output connector load wires negative (-) output/return positive output (+) +v -v fig.3-8: shield assembly a a +v -v fig.3-9: protective shield and wires assembly load wires -v the 80v to 600v models have a four terminal wire clamp output con...

Page 30

83-507-013 rev. A 23 sensing (default). Fig.3-10 shows recommended load and sensing connections for a single load. The local sense lines shown are default connections at the rear panel j2 sense connector. Local sensing is suitable for appli- cations where load regulation is less critical. 3.9.8 conn...

Page 31

83-507-013 rev. A 24 - - rem.Sense local sense ocal sense rem.Sense +l + load lines, twisted pair, shortest length possible. +v -v load#1 + load#3 + load#2 + power supply fig.3-12: multiple loads connection, radial distribution, local sense 3.9.10 multiple load connection with distribution terminals...

Page 32

83-507-013 rev. A 25 warning output terminal grounding there is a potential shock hazard at the rs232/rs485 and the ieee ports when using power supplies with rated or combined voltage greater than 400v with the positive output of the power supplies grounded. Do not connect the positive out- put to g...

Page 33

83-507-013 rev. A 26 1. Ensure that the ac on/off is in the off position. 2. Remove the local sense jumpers from j2. 3. Connect the negative sense lead to terminal j2-5 (s) and the positive sense lead to terminal j2- 1(+s) of the j2 mating connector. Ensure that the j2 mating connector is plugged se...

Page 34

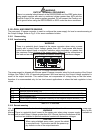

83-507-013 rev. A 27 chapter 4 front and rear panel controls and connectors 4.1 introduction the genesys tm power supply series has a full set of controls, indicators and connectors that allow the user to easily setup and operate the unit. Before starting to operate the unit, please read the followi...

Page 35

83-507-013 rev. A 28 number control/indicator description section 4 current display 4 digit, 7 segment led display. Normally displays the out- put current. When the prev button is pressed, the display indicates the programmed setting of output current. 5 current indicator green led, lights for const...

Page 36

83-507-013 rev. A 29 15 prev indicator green led, lights when prev button is pressed 16 fine button voltage and current fine/coarse adjustment control. Oper- ates as a toggle switch. In fine mode, the voltage and current encoders operate with high resolution and in coarse mode with lower resolution ...

Page 37

83-507-013 rev. A 30 when using several power supplies in a power system, the first unit remote-in is connected to the computer and the remaining units are daisy-chained, remote-in to remote-out. 4 remote out connector rj-45 type connector, used for daisy-chaining power supplies to form a serial com...

Page 38

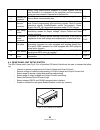

83-507-013 rev. A 31 4.4.1 sw1 position function refer to table 4-3 for description of sw1 position functions. The factory default setting is down for all positions. Table 4-3: sw1 positions functions position function down (factory default) up sw1-1 output voltage remote analog programming output v...

Page 39

83-507-013 rev. A 32 -extraction tool: amp, 91232-1 or equivalent. -manual pistol grip tool: handle:amp, p/n:58074-1 head:amp, p/n:58063-2 before making any connection, turn the ac on/off switch to the off position and wait until the front panel display has turned off. Caution terminals 12, 22 and 2...

Page 40

83-507-013 rev. A 33 fig.4-4: j1 connector terminals and functions 14 15 16 17 18 19 20 21 22 23 24 25 1 2 3 4 5 6 7 8 10 11 12 13 9 same ground as p/s negative sense (-s) isolated from ps outputs, same ground as rs232/rs485 imon ipgm_rtn vpgm_rtn loc/rem signal if_com if_com ena_in vmon com cv/cc i...

Page 41

83-507-013 rev. A 34 chapter 5 local operation 5.1 introduction this chapter describes the operating modes that are not involved in programming and monitoring the power supply via its serial communication port (rs232/rs485) or by remote analog signals. Ensure that the rem/loc led on the front panel ...

Page 42

83-507-013 rev. A 35 -enabled output, power supply in constant voltage mode: press the prev button and then rotate the current encoder knob. The current meter will show the programmed output current for 5 seconds after the adjustment has been completed, and then will return to show the actual load c...

Page 43

83-507-013 rev. A 36 5.4 under voltage limit (uvl) the uvl prevents adjustment of the output voltage below a certain limit. The combination of uvl and ovp functions, allow the user to create a protection window for sensitive load circuitry. 5.4.1 setting the uvl level setting the uvl can be made whe...

Page 44

83-507-013 rev. A 37 when the unit is shut-off by a j1 signal, the voltage display will show “so” to indicate the unit state. J1 contact 15 is the so signal input and contacts 2 and 3, if_com, are the signal return (connected in- ternally). Contacts 2, 3 and 15 are optically isolated from the power ...

Page 45

83-507-013 rev. A 38 5.11 safe-start and auto-restart modes when turning on the power supply ac on/off, it can start to its last setting of output voltage and current with the output enabled (auto-restart mode) or start with the output disabled (safe-start mode). Press and hold the out button to sel...

Page 46

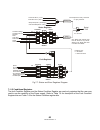

83-507-013 rev. A 39 +s + - -s -ls +ls power supply +s + + - - -s -ls +ls power supply load +s + - -s -ls +ls power supply +s + + - - -s -ls +ls power supply load fig.5-1: series connection, local sensing fig.5-2: series connection, remote sensing (*) (*) (*) (*) (*) diodes are user supplied. 5.14.1...

Page 47

83-507-013 rev. A 40 fig.5-3: series connection for positive/negative output voltages +s + - -s -ls +ls power supply +s + + - - -s -ls +ls power supply (*) (*) (*) diodes are user supplied. 3. Programming by external resistor: programming by external resistor is possible. Refer to sec- tion 6-5 for ...

Page 48

83-507-013 rev. A 41 5.15 parallel operation up to four units of the same voltage and current rating can be connected in parallel to provide up to four times the output current capability. One of the units operates as a master and the remaining units are slaves. The slave units are analog programmed...

Page 49

83-507-013 rev. A 42 • sw1 position 2 - down in the master supply and up in all slave supplies. • connect a short between j1-8 and j1-12 in all slave supplies. • connect j1-25 of the master supply to j1-10 of all slave supplies. • connect j1-16 of the master supply to j1-15 of the ‘first’ slave supp...

Page 50

83-507-013 rev. A 43 caution make sure that the connection between –v terminals is reliable to avoid disconnection during operation. Disconnection may cause damage to the power supply. Note with local sensing it is important to minimize the wire length and resistance. Also the positive and negative ...

Page 51

83-507-013 rev. A 44 5.16 daisy-chain connection it is possible to configure a multiple power supply system to shut down all the units when a fault condition occurs in one of the units. When the fault is removed, the system recovers according to its setting to safe-start or auto-restart mode. Setup ...

Page 52

83-507-013 rev. A 45 caution com (j1-12), vpgm_rtn (j1-22) and ipgm_rtn (j1-23) terminals of j1 connect internally to the –sense potential (-s). Do not connect these termi- nals to any potential other than –sense (-s), as it may damage the power supply. Chapter 6 remote analog programming 6.1 introd...

Page 53

83-507-013 rev. A 46 caution to maintain the power supply isolation and to prevent ground loops, use an isolated programming source when operating the power supply via remote analog programming at the j1 connector. 6.4 remote voltage programming of output voltage and output current perform the follo...

Page 54

83-507-013 rev. A 47 for resistive programming, internal current sources, for output voltage and/or output current control, supply 1ma current through external programming resistors connected between j1-9 & 22 and j1-10 & 23. The voltage across the programming resistors is used as a programming volt...

Page 55

83-507-013 rev. A 48 the j1 connector, located on the rear panel provides analog signals for monitoring the output voltage and output current. Selection of the voltage range between 0-5v or 0-10v is made by setup switch sw1-4. The monitoring signals represent 0 to 100% of the power supply output vol...

Page 56

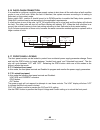

83-507-013 rev. A 49 chapter 7 rs232 & rs485 remote control 7.1 introduction this chapter describes the operation of the genesys tm 3300w power supplies via the serial communi- cation port. Details of the initial set-up, operation via rs232 or rs485, the command set and the com- munication protocol ...

Page 57

83-507-013 rev. A 50 note tx and rx are used for rs232 communication. Txd +/- and rxd +/- are used for rs485 communication. Refer to rs-232 and rs-485 cabling and connection details. 2. There are two remote modes: 1. Remote: in this mode, return to local can be made by the front panel rem/loc or via...

Page 58

83-507-013 rev. A 51 7.4 md mode option (factory installed) 7.4.1 md mode description the gen supply is capable of operating in a multi drop environment - more than 1 supply con- ducting serial communications on a single serial bus. A maximum of 31 gen supplies can oper- ate in this single bus. Upon...

Page 59

83-507-013 rev. A 52 7.5 connecting power supplies to rs232 or rs485 bus 7.5.1 single power supply 1. Select the desired interface rs232 or rs485 using rear panel setup switch sw1-6 (section 4-4). -rs232: down position -rs485: up position 2. Connect rear panel in connector to the controller rs232 or...

Page 60

83-507-013 rev. A 53 note the address (adr n) command must return an “ok” response before any other commands are accepted. 7.5.2 multi power supply connection to rs232 or rs485 bus up to 31 units can be connected (daisy chained) to the rs232 or rs485 bus. The first unit connects to the controller vi...

Page 61

83-507-013 rev. A 54 7.6.7 error message if an error is detected in command or query, the power supply will respond with an error message. Refer to section 7.7 for details. 7.6.8 backspace the backspace character (ascii 8) clears the last character sent to the power supply. 7.7 error messages the po...

Page 62

83-507-013 rev. A 55 # command description 1 adr n adr is followed by address, which can be 0 to 30 and is used to access the power supply. 2 cls clear status. Sets feve and seve registers to zero (refer to section 7-11). 3 rst reset command. Brings the power supply to a safe and known state: output...

Page 63

83-507-013 rev. A 56 acters. A comma will separate the different fields. The fields, in order, are: meas- ured voltage, programmed voltage, measured current, programmed current, over voltage set point and under voltage set point. Example: 5.9999,6.0000,010.02,010.00,7.500,0.000 8 filter nn set the l...

Page 64

83-507-013 rev. A 57 27 ms? Returns the master/slave setting. Master: n= 1, 2, 3, or 4 slave: n=0 notes: 1. In advanced parallel mode (refer to sec. 5.15.2), “n” is the total system current. 2. In advanced parallel mode, “mc?” returns the master unit current multiplied by the number of slave units +...

Page 65

83-507-013 rev. A 58 7.10 single byte commands 7.10.1 general single byte commands are commands in which all the necessary data for the supply to act upon is contained in a single byte. Single byte commands will be executed immediately by the supply. If the command requires data to be sent to the ho...

Page 66

83-507-013 rev. A 59 7.10.3 global commands with response 7.10.3.1 disconnect from communications command the supply to end all data transmissions to the host pc/ieee board and cease its role as the active addressed supply. The host pc/ieee board will be required to re-send the ‘adr nn’ command to r...

Page 67

83-507-013 rev. A 60 send aa hex followed by the address of the supply in binary. If not installed, the supply will return a ‘1’. If installed, the supply will return a ‘0’. 7.10.5 addressed commands without response 7.10.5.1 acknowledge srq send (0xe0 + address) (1 byte binary - send 2 times sequen...

Page 68

83-507-013 rev. A 61 acknowledge srq 111x xxxx none acknowledge srq. If retransmission of srq is enabled, it will remain en- abled for the next srq. X xxxx is the address of the supply in binary. Test if md mode is installed byte 1 1010 1010 byte 2 xxxx xxxx 0 or 1 returns a 0 if not installed or a ...

Page 69

83-507-013 rev. A 62 6 0.5 7.50 6 0 5.70 8 0.5 10.0 8 0 7.60 12.5 1.0 15.0 12.5 0 11.9 20 1.0 24.0 20 0 19.0 30 2.0 36.0 30 0 28.5 40 2.0 44.0 40 0 38.0 60 5.0 66.0 60 0 57.0 80 5.0 88.0 80 0 76.0 100 5.0 110.0 100 0 95.0 150 5.0 165.0 150 0 142 300 5.0 330.0 300 0 285 600 5.0 660.0 600 0 570 7.10.6...

Page 70

83-507-013 rev. A 63 srq messages response messages command error (”cnn”) execution error (”enn”) query response (”message”) command response (”ok”) cv cc nflt flt ast fde 0 lcl cv cc nflt flt 0 0 0 lcl 0 0 0 status registers condition enable event constant voltage constant current no fault fault au...

Page 71

83-507-013 rev. A 64 7.11.2 conditional registers (continued) table 7-8: fault condition register bit fault name fault symbol bit set condition bit reset condition 0 (lsb) spare bit spare fixed to zero fixed to zero 1 ac fail ac ac fail has occurred. The ac input returns to normal. 2 over temperatur...

Page 72

83-507-013 rev. A 65 refer to tables 7-10 to 7-13 for details of the enable and event registers. 1. Fault enable register the fault enable register is set to the enable faults srqs. Table 7-10: fault enable register bit enable bit name fault symbol bit set condition bit reset condition 0 (lsb) spare...

Page 73

83-507-013 rev. A 66 3. Status enable register the status enable register is set by the user to enable srqs for changes in power supply status. Table 7-12: status enable register bit status name status symbol bit set condition bit reset condition 0 (lsb) constant voltage cv 1 constant current cc 2 n...

Page 74

83-507-013 rev. A 67 7.12 serial communication test set-up use the following instructions as basic set-up to test the serial communication operation. 1.Equipment: pc with windows hyper terminal, software installed, genesys tm power supply, rs232 cable. 2. Pc set-up: 2.1 open hyper terminal……………………. ...

Page 75

83-507-013 rev. A 68 chapter 8 isolated analog programming option 8.1 introduction isolated analog programming is an internal option card for analog programming of the genesys tm power supply series. The option is factory installed and cannot be obtained with a gpib (ieee-488) in- terface. Output vo...

Page 76

83-507-013 rev. A 69 caution when the isolated analog option is installed, do not apply any signals to the non-isolated vpgm and ipgm (j1-9 and j1-10) pins. All other j1 features may be used normally. Refer to section 4.5 for a description of j1 features. 8.3 isolated programming & monitoring connec...

Page 77

83-507-013 rev. A 70 caution to prevent damage to the unit, do not program the output voltage and current to higher than the power supply rating. Note j1-8 and j1-12 must be shorted together with a wire jumper. Note j1-8 and j1-12 must be shorted together with a wire jumper. Note sw1 position 3 and ...

Page 78

83-507-013 rev. A 71 chapter 9 maintenance 9.1 introduction this chapter provides information about maintenance, calibration and troubleshooting. 9.2 units under warranty units requiring repair during the warranty period should be returned to a lambda authorized service facil- ity. Refer to the addr...

Page 79

83-507-013 rev. A 72 symptom check action ref output voltage will not adjust. Front panel cc led is on. Is the unit in constant current mode? Check output current setting and load current. 5.2.1 5.2.2 output voltage will not adjust front panel cv led is on. Check if output voltage is adjusted above ...