- DL manuals

- Lamber

- Dishwasher

- 015-ek-plus

- Instruction Manual

Lamber 015-ek-plus Instruction Manual

Summary of 015-ek-plus

Page 1

Instructions manual dishwashing machines rev.13-2015 015/24l - l24-ek-plus l25-ek - l305-cv.

Page 2

2.

Page 3

3 declaration of conformity the following : lamber snc di affaba f. E c. – via italia 6 – 26855 lodi vecchio (lo) italy declare under our responsibility that: apparatus: dishwasher with pull through rack trademark: lamber manufacturer : lamber type / model 015/24l / l24-ek / l25-ek / l305-cv matr………...

Page 4

4 waste of electrical and electronic equipment directive (weee,raee in italy) 2002/96/ec and subsequent 2003/108/ec the marking shown below indicates that the product cannot be disposed of as part of normal household waste. Electrical and electronic equipment (eee) can contain materials harmful to h...

Page 5

5 indice italiano general notes pag. 06 introduction and safety notes pag. 07 learn to use the appliance pag. 08 first section - for the user pag. 09 control panel pag. 10 working and use pag. 11 instructions before washing pag. 11 washing pag. 12 achievements pag. 13 stand by, self-washing pag. 13 ...

Page 6

6 general norms english thank you for purchasing our dishwashing machine. Perfect washing-up results as far as hygiene concerns and a correct operation of the dishwashing machine can be assured only in case the instructions reported in the present manual are carefully followed. We hope the informati...

Page 7: Introduction

7 introduction english and safety notes introduction - the machines are industrial pass-through-dish-washing machines . - noise level of the machine: 015/24l-l24-ek : lpa=63,5 db(a) / l25-ek : lpa=59,5 db(a) / l305-cv : lpa=67 db(a) (norms en iso 4871 and en iso 11204) preliminary observation carefu...

Page 8

Water inlet 3/4" stainless steel upper rotating washing steam condenser fan extractablesteam condenser filter stainless steel lower rotating washing stainless steel tank filters stainless steel suction pump filter double skin with insulation 20mm (only for l25-ek / l305-cv) double skin with insulati...

Page 9: Instructions For The User

Instructions for the user.

Page 10

1 10 a c d e dis.1 control panel cycle pushbutton wash time selection pushbutton interactive display programming pushbutton b main switch 09-2013.

Page 11: English

11 english first section - for the user working and use the dishwashing machine can wash up to 960/320 dishes per hour. The machine protection degree is ip21, therefore it should not be washed with direct high pressure jet water; the correct placing of the objects is an essential condition for a goo...

Page 12

12 at the end of the filling phase of the tank on the interactive display will appear the following information (from left to right): -temperature of washing; -time of washing; -number of cycle; -temperature of rinsing.. The data of the temperature tank and boiler, flashes slowly and increases in va...

Page 13

13 7 - at the end of the wash cycle , the message “end wash” will appear followed by a short beep. The led turns off and the b button appear the temperature data and the data number and duration of the cycle. Open the hood of your dishwasher. Remove the basket and tilting it, shake it lightly to bri...

Page 14

14 machine «off» hood closed remove the overflow wait the end of the drain (with drain pump press button) keep button pressed for 3 sec. 1 2 3 4 - self-washing cycle: with the machine ”on” do the following operations:: -1 put the machine off by pressing the push-button “a” ( led off) -2 remove the o...

Page 15

15 -3 press the “b” button for 3 seconds and wait for the complete emptying of the tank; -4 close the hood of the dishwasher; -5 then press the “e” button for 3 seconds at the end of the descaling cycle (approx. 35 minutes) will appear on the led the words “end of the descaling cycle”. List of autom...

Page 16: Dishes Positioning

1 1 2 2 3 3 4 pp12-18 cod.Cc00024 (2x) cb cod.Cc00019 (1x) g cod.Cc00045 (2x) 4 5 5 6 6 7 8 9 415 500 500 5 1 2 3 4 6 2 1 3 4 5 6 7 8 9 dishes positioning to achieve optimal cleaning results, make sure that tableware is correctly stored inside the dishwasher. Dishes must be placed in the plastic bas...

Page 17

Cleaning and preventive maintenance precaution and cleaning instructions - important : before carrying out the cleaning and maintenance operations, disconnect the equipment from the mains power supply: - follow the directions on the maitenance in this guide; - wear protective clothing and gloves whe...

Page 18

Daily cleaning of the interior of the dishwasher attention. Before carrying out cleaning the inside of the machine, make sure that there are no foreign objects that could damage the rusty steel inside the tank. The eventual rust particles could come from non- stainless steel dishes, from baskets or ...

Page 19

Remove the overflow pipe remove from the tank by means of a brush or cloth if any, residual dirt. Clean the filter drawer wipe with a cloth the tank and check for any debris on the bottom. Clean the pump inlet filter by means of a brush clean the washing reel. Check for any debris inside. Insert the...

Page 20

20 insert the filter tank in its place replace the lower washing arm keeping with a hand the washing arm in place, screw the rinse arm. (only for l305-cv) clean the filter of the steam condenser that is placed in the upper part of the hood; insert in its place the filter drawer screw the lower rinse...

Page 21

Detergent and rinse-aid attention. During the use of chemicals is advisable to wear appropriate clothing, such as gloves and protectives glasses. It’s therefore important to consider some factors. Firsf of all, it is necessary to use only strongly anti-foaming alkali and chlore products specific for...

Page 22

22 problems - causes - solutions problems causes solutions the machine doesn't catch main switch is switched off; turn on the main switch; power plug is not inserted insert the power plug the water doesn't go in water cock closed; open water cock; the overflow is not in place; reassemble the overflo...

Page 23

23 descaling when hard water is used you can find inside the machine and also on dishes calcareous sediments which must be removed both for hygienic and operating reasons by a descaling operation. Operating process and frequency of this intervention are suggested by your cleansing agent supplier who...

Page 24

24 useful hints for stainless steel maintenance stainless steel is so called because it is not affected by oxidation; this dues its resistance to a thin molecular layer of oxide on the surface which protects againts further oxidation. There are, however, substances which can modify or destroy this l...

Page 25

25 instructions for the installer the following instructions are addressed to a qualified personnel, the only one authorised to carry out checks and repair, if any. The manufacturer declines any responsibility in the case of interventions made by a non qualified personnel. ..

Page 26

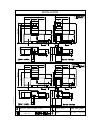

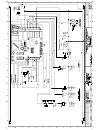

S ca- l2 5-e k- di s pl a y- 2 01 4 1450 14 50 1865 1865 185 0 18 50 1435 14 35 780 (l 25 -e k) (l25-ek) (l25 -ek ) (l 25 -e k) (l25 -e k) ()01 5/ 24l- l24- ek (015/24l- ) l24-ek ()0 15/ 24l- l2 4- ek ()0 15 /2 4l- l2 4- ek ()0 15 /2 4l-l2 4-e k 20 0 400 510 765 180 870 41 5 2070 700 700 670 750 780...

Page 27: English

27 english second section - for the installer during the installation, carry out a good machine levelling, which is a prerequisite for a correct operation. The manufacturer cannot assume any responsability for any damage to persons or property deriving from the non-observance of the above-specified ...

Page 28

28 water connections carefully comply with any national or regional regulations in force. Water installation must have the following characteristics: temperature: 55°c dynamic pressure : - 2 ÷ 4 bar (200÷400 kpa); -for machines with incorporated water- softener: dynamic pressure: 3 ÷ 4 bar (300 ÷ 40...

Page 29

Detergent dispenser, rinse-aid dispenser and limescale : programming for programming see section configuration user technical-programming the control acts on the percentage values from 0% to 100% with the logic time/pause according to the values shown in the following table: 0% always off 10% 0,5s o...

Page 30

30 machines, must be used and they must be produced by well-known reliable firms. Mean concentration of the cleansing agents in powder must be 1,5÷2,5 g/lt. Mean concentration of liquid cleansing agents must be 2÷4 g/lt. In order to avoid scales and corrosions, put cleansing agent above water level ...

Page 31

Detergent replacement and cleaning of the detergent pump hoses guidelines to be followed when replacing detergent : - if you leave the machine without detergent, crystallization arises due to the formation of air bubbles - set up again detergent pump hose anytime you use a new detergent - the whole ...

Page 32

Keyboard interactive membrane machine off on/off push-button "a" for 1 second when the machine is on (logo lamber appears) (with the machine empty the display will show off after 10" seconds) (just with machine full) machine on on/off push-button "a" for 1 second when the machine is in off (temperat...

Page 33

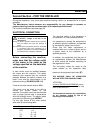

User technical-configuration programming push-button "+" and push-button enter "d" for 5 second with the machine ff and hood open cod. Pin 1000 to view the unit of measure °c to confirm temperatures during unit of measure c to confirm temperatures during °f washing cycle press push-button rinse p1 t...

Page 34

Total cycles (number of cycles performed) n°…… (not editable) to confirm partial cycles reset n° yes/no to confirm reset n …… yes/no to confirm ("yes" to reset value) automatic starting yes to confirm no time phase 2 time to confirm filling of the tank (10÷360") discharge yes to confirm (d i ) no (d...

Page 35

Stand by yes to confirm no if you turn the machine on stand by stops after 1 hour and sets the values of rinse temperature on 60°c. The display will show the word economy soft-start si to confirm soft-start si to confirm no regeneration si to confirm (water softener) no filling time drain time to co...

Page 36

Tables fitting plan with corner versions unscrew the basket lock “s” and screw it in the position by drawing “2”, fixing it to the existing holes (see drawing “3a”). Then bend the support by using the apposite key, as shown in drawing “3b”, up to the position indicated in “3c”. Corner version 1 re g...

Page 37

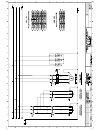

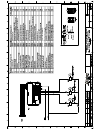

Col-l25-ek-display-2014 4 1 2 3 2 1 3 4 2 1 3 4 4 1 2 3 connections scheme boiler elements brown brown black black black black staples staples tank elements.

Page 42

Components sq1 ad ad ad km4 km1 km3 ka1 fr1 km2 s3 s4 morsetti s1 cnp-l25-ek-display-2014 eh1 m1 yv1 1 3 2 1 2 3 4 fa 9 fa 1 fa 2 fa 3 fa 4 fa 5 fa 6 fa 7 fa 8 fa 1 0 fa 1 1 fa 1 2 fa 1 3 fa 1 4 fa 1 5 p1 p2 pcb1 p.C.Board soft touch control panel control board basis eh2 ms1 optional 1 10

Page 43

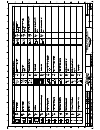

Mod. 015/24l l24-ek-plus l25-ek l305-cv gb specifications dimensions l x w x h 670x765x1460 670x765x1460 670x765x1450 670x765x1700 mm washing capacity di h /h 1080-540-360 (1440) 1080-540-360 (1440) 1080-540-360 (1440) 1080-540-360 (1440) nr washing capacity dishes/h (1440) (1440) (1440) (1440) nr. ...