- DL manuals

- Lamber

- Dishwasher

- M115

- Instruction Manual

Lamber M115 Instruction Manual

Summary of M115

Page 1

Dishwashers with pull-through rack instructions manual m115 r0 6/2012.

Page 3

Declaration of conformity the following : lamber snc di affaba f. E c. – via italia 6 – 26855 lodi vecchio (lo) italy declare under our responsibility that: apparatus: dishwasher with pull through rack trademark: lamber manufacturer : lamber mod. M115 / m115-as matr…………….. For which this declaration...

Page 4

4 waste of electrical and electronic equipment directive (weee,raee in italy) 2002/96/ec and subsequent 2003/108/ec the marking shown below indicates that the product cannot be disposed of as part of normal household waste. Electrical and electronic equipment (eee) can contain materials harmful to h...

Page 5

5 washing rinsing m o d e l m o d e l m115 left-right m115 right-left.

Page 6

6 technical data and description the table reported at page 5 shows the basic models of conveyor dishwashers and identifies the single washing areas to which additional modules can be added to improve their performance. Accessories cold pre-washing steam condenser - cvm fan kw drying – as fan kw hea...

Page 7

7 description characteristics * body and tank in stainless steel construction 18/10 aisi 304, * tunnel composition: - 1 wash - wash arms : 3 upper + 2 lower - 1 rinse - rinse arms : 1 upper + 1 lower * completely automatic, * upper and lower fixed washing ( 55÷60 °c ) * upper and lower fixed rinsing...

Page 8

8 contents general norms page 09 introduction and safety norms page 10 unpacking and delivery checks page 12 1 – instructions for the user page 13 first section - for the user – operation before washing page 14 switch-on and use of the dishwashing machine mod. M115 page 16 washing of dishes – during...

Page 9: M115

9 instructions manual dishwashing machine m115 the automatic-rack conveyor dishwashing machines of the m115 series are designed to wash any kinds of dishes . The modular system and the various optionals available allow the make-up of dishwashing machines with the most appropriate features in order t...

Page 10: Introduction

10 introduction and safety norms introduction this equipment is destined only to the use it has been conceived for: tableware washing such as dishes, glasses, cups, cutlery, trays, etc. Using it to wash machine components or objects whose dimensions are superior to the machine working passage is imp...

Page 11

11 general safety regulations this safety code has been compiled in your interest. Strict adherence to these rules will reduce the risks of injury both to yourself and to others; personnel working with this machine must adhere strictly to all statutory safety regulations as well as the specific rule...

Page 12

12 unpacking and delivery checks when the case with the machine has been received, unpack it as follows: - remove the upper cover and the wooden case side walls, take care not to damage the machine, - remove possible accessories boxes, - remove the protecting cellophane, - make sure that the machine...

Page 13: Instructions For The User

Instructions for the user.

Page 14: M115

14 m115 first section - for the user operation before working b efore starting the working operation be sure that : - the wall-mounted on/off switch is switched on; - the water and steam* cocks are open; - water and steam (*) are present in the system; - the filters are in their housings - curtains ...

Page 15

15 descaling when hard water is used you can find, inside the machine and also on objects, calcareous sediments which must be removed both for hygienic and operating reasons by a descaling operation. Operating process and frequency of this intervention are suggested by your cleansing agent supplier ...

Page 16

16 switch-on and use of the dishwashing machine mod. M115 h g d i p m legend m – overload cut-out indicator g - machine ready indicator d – machine on indicator i - stop pushbutton h – start pushbutton p – switch on/off b efore starting the working operations make sure that : - the cock is open and ...

Page 17

17 to switch off completely the machine, press the switch "p" into position "off" and turn the wall switch in position off. If lamp m lights on, that indicates possible anomalies at the motors. The red mushroom-shaped emergency pushbutton "p" has to be used in case of anomaly. Once the trouble has b...

Page 18

18 washing of dishes 1) fisrt of all, remove any food residues and any oily masses . 2) knives , forks and spoons should be previously softened; the same applies to dishes, should they be washed a long time after their use . 3) arrange the dishes as shown in the figures (page 22) . 4) push the rack ...

Page 19

19 baskets cestelli-m115-gb/cdr pp12/18 g8 cva (option) take care ! Baskets with dishes or trays must be put into the washing tunnel as shown in the picture. M115 cb.

Page 20

20 after washing operations precaution and cleaning instructions 1 – high temperatures can be reached inside the machine (90°c). Affter power supply has been removed, wait until the machine has reached the room temperature, before working on it; - never leave tools, parts or other loose material on ...

Page 21

21 machine prolonged stop in case the machine is not used for some weeks it is advisable to carry out an accurate cleaning of all components inside to avoid the formation of unpleasant smells. In case of a very long standstill, it is advisable to oil the stainless steel surfaces with white mineral o...

Page 22

22 this way all washing operations are stopped preventing dangerous jets of hot water from spurting out. Operation is restored only when the door are closed again and the start button “h” pressed. Emergency stop pushbutton the machine is equipped with a red mushroom-shaped pushbutton on yellow field...

Page 23

23 washing flow control system pos. “1” pos. “2” highest power (position 1) lowest power (position 2) the flow control system is a device that allows you to act on the intensity of the washing power. This can be useful by washing glasses, when it is necessary to reduce the washing jet power. This de...

Page 24

Useful hints of stainless steel maintenance stainless steel is so called because it is not affected by oxidation,this is due to a thin molecular layer of oxide on the surface which protects againts further oxidation. There are, howevwr, substances which can modify or destroy this layer,giving rise t...

Page 25: Instructions For The

Instructions for the installer the following instructions are addressed to a qualified personnel, the only one authorised to carry-out checks and repair, if any. The manufacturer declines any responsibility in the case of interventions made by a non qualified personnel..

Page 26

26.

Page 27: M115

M115 second section - for the installer the following instructions are addressed to qualified personnel who is the only one authorized to carry out the inspections and the necessary repairs. The machine should be installed in “normal” environment, that is to say, indoors, free of dust, explosion-pro...

Page 28

28 as regards the introduction of the liquid rinse aid product, use the passage “c” , placed near the water inlet group. This coupling will allow an appropriate introduction of the liquid rinse aid product. In order to do this use a fitting with non-return valve. 0200196 0201455 for the electrical c...

Page 29

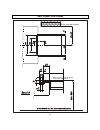

29 positioning during installation, carry out a good levelling of the machine in order to make it correctly work (doors, basket forward feeding). In order to do so use the adjustable feet. After removing front panels, position the machine over the connections. Assemble the inlet and outlet shelves f...

Page 30

30 water connections carefully comply with any national or regional regulations in force. Hot water supply arrange a gate valve in an easily accessible place, with a tap having a 3/4"gas thread spout at its end and connect to the water inlet valve (fig.1) - temperatur between 55° and 60°c, - dynamic...

Page 31

31 water draining reachable from the machine front side after opening the front panel (to do this turn the two front screws out); arrange a discharge at floor level provided with siphon and connect to the floor drain by means of a hose provided with an adequate inclination. Make sure the drain hose ...

Page 32

32 vapours suction for machines equipped with splashguard with collar or normal collar, carry out the necessary connection as showed in fig. 4. In any case it is necessary to provide a way to scavenge steam through a hood or a similar system. Testing before starting machine: during the testing opera...

Page 33

33 torque limiter the limiter has already been described at paragraph “safety devices”. It is located in connection with the drawbar and it is calibrated during testing by the manufacturer. In case it is necessary to calibrate it again, proceed as follows: 1. Switch the machine off ; 2. Remove the p...

Page 34

34 steam condenser as regards the machines provided with “vapour condensing” device, pay attention to the following: the adjustment of the device is carried out by means of the regulator valve (cock “v”) placed inside the machine base plate and marked with its special label. The manufacturer should ...

Page 35

35 a list of drawbacks possibly occurring with the use of the dishwashing machine, their causes and possible remedies 1 - lamp d (ls1) does not turn on upon switching the machine on a - check that the wall-mounting swith is on and the respective fuses are not burnt. B - maybe lamp ls1 has burnt. In ...

Page 36

36 a - check that the wheel of micro fc1 projects sufficiently from the bracket and is operated by the shelf. B - check that micro fc1 is effective and the respective cable is connected correctly. 7 - the tanks don't stop being filled upon reaching the desired level a - check that the trap of the pr...

Page 37

37 a - check that the thermostats are effective and calibrated . B - check that the temperature of the feeding water is from 50° to 60° c, as specified . C - check that the thermostats relevant to the tanks are set to the right temperatures and operate correctely . D - check that the fuses and the c...

Page 38

38 - check that the coil of remote switch mt03 is not broken - check all elements of boiler heaters r1 - check the security thermostat ct1 is on for machines with steam heating - check that the steam inlet gate is open and it is present with a pressure not less than 0,5 bars, - check that the filter...

Page 39

39 b - check that the filter of the condenser battery is not clogged by fat residuals. In such an event, wash it with boiling water and detersive. Rinse thoroughly. C - check that overload cutout is not triggered. If so, restore it. This drawback is dispalyed by lamp m(ls3) being on . D - check that...

Page 40

40 attention ! English eti-manov-traino for a correct working of the machine (pumps, fans, etc.), please check that the inside the machine (fig.”a” ) turns anticlockwise, or that the shaft under the washing tank (fig.”b”) turns in the direction indicated by the yellow arrow on the motor body. Pull-t...

Page 41

41 table connection scheme muro/mur/wall/wand piano di lavoro, plan de travail work table, arbeitstisch.

Page 42

42.