- DL manuals

- Lamborghini Caloreclima

- Boiler

- ALMA 24 MBS W TOP

- Installation And Maintenance Manual

Lamborghini Caloreclima ALMA 24 MBS W TOP Installation And Maintenance Manual

24 MBS W TOP

28 MBS W TOP

32 MBS W TOP

LIBRETTO DI INSTALLAZIONE E MANUTENZIONE

INSTALLATION AND MAINTENANCE MANUAL

MANUAL DE INSTALACIÓN Y MANTENIMIENTO

CALDAIA MURALE A GAS CON BOLLITORE AD ACCUMULO - ALTO RENDIMENTO - MODULANTE

WALL-MOUNTED GAS BOILER WITH STORAGE WATER HEATER - HIGH EFFICIENCY - MODULATING

CALDERA MURAL DE GAS CON INTERCAMBIADOR DE ACUMULACIÓN - ALTO RENDIMIENTO - MODULANTE

PREG

ASI CONS

EGNARE

L’INSERTO

”LIBRE

TTO

D’US

O”

AL

SIG.

UTENTE

PLEASE MAKE SURE TH

AT THE

“USE MANUAL” IS HAND

ED

OVER THE USER

LOS

ROGAMO

S Q

UE

ENTREGU

EN EL

“MANU

AL

DE

USO

” AL

SR. USUARIO

Summary of ALMA 24 MBS W TOP

Page 1

24 mbs w top 28 mbs w top 32 mbs w top libretto di installazione e manutenzione installation and maintenance manual manual de instalaciÓn y mantenimiento caldaia murale a gas con bollitore ad accumulo - alto rendimento - modulante wall-mounted gas boiler with storage water heater - high efficiency -...

Page 2

- - lamborghini calor s.P.A. Dott. Felice bo’ (general manager) ________________________________ conformity the alma mbs w top boilers are in conformity with: • gas directive 90/396/eec • efficiency directive 92/42/eec (✫✫✫) • electromagnetic compatibility directive 89/336/eec • low voltage directiv...

Page 3

- - english contents general safety warnings and rules page 46 description “ 47 optional accessories “ 47 main component structure “ 48 dimensions “ 49 circulator “ 49 technical data “ 50 sanitary hot water performance “ 50 identification “ 53 hydraulic circuit “ 54 control panel “ 55 display “ 56 p...

Page 4

- - general safety warnings and rules • the instruction manuals provided form an integral part of the boiler and consequently must be carefully kept and must always accompany the boiler, even in the case of transfer to another owner or user or transfer to another system. In the event of damage or lo...

Page 5

- - general english description the boilers operate fully automatically and the gas flow is controlled by an electronic control unit with the following cha- racteristics: - continuous modulation on both circuits - possibility of adjusting the heat output - possibility of adjusting slow ignition. The...

Page 6

- - general main component structure 1 sanitary water expansion tank 2 water heater sensor 3 heating expansion tank. 4 delivery sensor 5 circulator 6 3-way electric valve 7 safety flow switch 8 modulating coil 9 gas valve 10 sanitary water unit - 8 bar safety valve - flow regulator - check valve - i...

Page 7

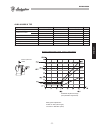

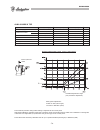

- - general english dimensions mm Ø 80 split Ø 80 intake Ø 100 concentric flow rate (l/h) output (mbar) circulator output/head available to the system minimum safety flow switch activation ∆p 1,2 m..

Page 8

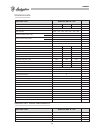

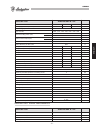

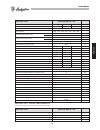

- 0 - general technical data sanitary hot water performance continuous delivery without flow limiter ∆t=30°c 11,4 l/min continuous delivery with flow limiter 12 l/min peak draw in the first 10 min. 157 sanitary water pressure 8 bar description alma 24 mbs w top fuel g20 g30 g31 gas supply pressure (...

Page 9

- 1 - general english sanitary hot water performance continuous delivery without flow limiter ∆t=30°c 13,3 l/min continuous delivery with flow limiter - l/min peak draw in the first 10 min. 172 sanitary water pressure 8 bar description alma 28 mbs w top fuel g20 g30 g31 gas supply pressure (nominal)...

Page 10

- 2 - general sanitary hot water performance continuous delivery without flow limiter ∆t=30°c 15,2 l/min continuous delivery with flow limiter - l/min peak draw in the first 10 min. 192 sanitary water pressure 8 bar description alma 32 mbs w top fuel g20 g30 g31 gas supply pressure (nominal) 20 28-3...

Page 11

- - general english identification the alma boiler is identifiable by the labels on the packaging and the technical data plate found inside the boiler as shown in the figure. Warning • tampering with, removing, missing identification plates or anything else that does not allow certain identification...

Page 12

- - general hydraulic circuit a sanitary hot water outlet b sanitary cold water inlet c gas d system return e system delivery 1 magnesium anode 2 water heater sensor 3 water heater 4 ignition electrode 5 control electrode 6 exchanger 7 fan 8 flue gas pressure switch 9 thermometer 10 delivery sensor ...

Page 13

- - general english control panel the alma boilers are equipped with the instruments shown below. D boiler status display p1 boiler function selection button (summer/winter - on/off) p2 cyclic function selection p3 heating temperature increase button p4 heating temperature decrease button p5 sanitar...

Page 14

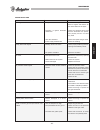

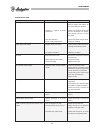

- - general button function symbol display pressing the button for 3 seconds the following functions are displayed: summer ----> winter holding the button pressed down for 3 seconds the boiler switches off. Pressing the button the following information is cyclically displayed: sanitary water tempera...

Page 15

- - general english parameter programming simultaneously press the buttons p2 and p3 for 10s to access the programming menu where the left digit indicates the parameter number, and the centre and right digits the parameter value. When the programming menu has been accessed, the left digit will blink...

Page 16

- - general description of operation and functions heating mode the heating operating mode starts if requested by the ambient thermostat and if the operating selector is set to “winter”. The circulator, fan (mbs) and switching valve are activated and, after checking that there is air flow, burner ig...

Page 17

- - general english description circulator activation temperature for anti-freeze 8 °c circulator deactivation temperature for anti-freeze 10 °c burner activation temperature for anti-freez 6 °c anti-freeze function deactivation temperature 15 °c burner output during anti-freeze minimum post-circula...

Page 18

- 0 - general fan and air flow check (mbs models) if an ignition request is received, the system checks for the absence of air flow (contact open) of the flue gas pressure switch, and if the test is passed the fan is activated. When air flow is detected (contact closed) the ignition sequence is star...

Page 19

- 1 - general english heating mode with external sensor (optional) operation is the same as in normal heating mode with the difference that the delivery temperature is calculated in relation to the external temperature read by the sensor and the k factor. The k factor is set with the p3 and p4 butto...

Page 20

- 2 - general operation with remote control (optional) the boiler can be operated with a rc03.54 remote control. The rc03.54 remote control is an intelligent hourly programmer complete with ambient sensor suitable for adjustment and control of wall-mounted gas boilers for heating and production of s...

Page 21

- - general english wiring diagrams br burner ci circulator dy display ea ignition electrode er combustion control electrode mvg gas valve modulator pa air pressure switch fl safety flow switch (water) re resistor se external sensor (optional) sm delivery sensor sb water heater sensor ta ambient the...

Page 22

- - general integrated flame control electronic flame control unit intended for direct ignition of the main burner by means a capacitive discharge spark generator and flame detection control by means of the ionisation phenomenon. Operating sequence when the request contact is closed and after checki...

Page 23

- - installation english a product receipt the boiler is delivered packed in one protective cardboard box. Handling after unpacking, manually handle the boiler; tilt and lift it gripping at the points indicated in the figure. Warnings • use appropriate safety devices. • do not litter the packaging m...

Page 24

- - installation hydraulic connection after securing the support hooks, position the template so that it sits flush with the wall. Starting from the end unions previously fitted on the template, proceed with installation of all the pipes: system delivery, system return, cold water, hot water, and po...

Page 25

- - installation english installation the boiler must be installed by qualified persons. The installation must be in conformity with the provisions of the law regarding evacuation of the combustion products in accordance with the regulations in force. The combustible gases must be evacuated through ...

Page 26

- - installation turning on filling the system slowly open the feed cock until the system reaches a pressure of 1.5 bar indicated on the hydrometer and then close it. Check that the cap on the automatic air escape valve positioned on the circulator is loosened, and repeatedly activate the circulator...

Page 27

- - installation english flue gas exhaust connection the boiler operates by combustion in a sealed chamber and therefore does not require any particular ventilation, and can also be housed in compartments, storerooms, technical spaces, etc. There are also various possibilities for exhaust of the com...

Page 28

- 0 - installation installation concentric vent fit the concentric elbow positioning it in the desired direction, fit the seal onto it and then fit the appropriate baffle (see table below). Fit the air intake and flue gas exhaust pipes respecting the dimensions indicated in the respective installati...

Page 29

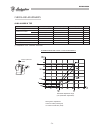

- 1 - installation english split vent 24 mbs 28 mbs baffle Ø 44 mm baffle Ø 48 mm no baffle (standard hole) baffle Ø 50 mm baffle Ø 44 mm no baffle (standard hole) 0,5 ÷ 5 > 5 ÷ 20 > 20 ÷ 30 length (m) scarico sdoppiato 32 mbs baffle Ø 50 mm no baffle (standard hole) 0,5 ÷ 10 10 ÷ 30 lunghezza (m) w...

Page 30

- 2 - installation reduced length in metres component accessories 80Ø male-female pipe 60Ø 45°elbow 80Ø 90° male-female elbow condensate trap 80Ø wind-resistant terminal for combustion products 80Ø air intake protection terminal 80/125 roof vent + tee reducer for separate ducts horizontal vent verti...

Page 31

- - installation english electrical connections the boiler must be connected to a 230v - 50hz single-phase + earth power supply respecting the line-neutral polarity. The connection must be made using a bipolar magnetothermal switch with contact opening of at least 3.5 mm. During installation or if t...

Page 32

- - installation - open the instrument panel - to remove the instrument panel lid remove the screws (2).

Page 33

- - installation english turning off extended periods of inactivity if the boiler is to remain inactive for a long period of time, close the gas cock and cut the power to the boiler. Temporary turning on/off this can be achieved in one of the following two ways: - from the ambient thermostat. - from...

Page 34

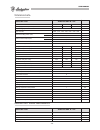

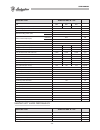

- - installation permitted adjustment range (see parameter adjustment). Checks and adjustments (*) temperature: 15°c - pressure: 1013 mbar. Burner pressure outlet slow ignition adjustment: 3 mbar for g20 (natural gas) 7.5 mbar for g30-g31 (lpg) burner pressure curve -output efficiency description g2...

Page 35

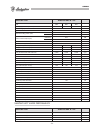

- - installation english burner pressure curve -output efficiency description g20 (natural gas) g30 (lpg) g31 (lpg) nominal supply pressure 20 28 - 30 37 mbar pressure at nozzles maximum 13,5 28,3 36,2 mbar minimum 2 5,5 7,6 mbar flow rate 3,2 0,9 1,2 m 3 /h burner nozzles 1,25 0,77 0,77 Ø mm gas ba...

Page 36

- - installation the maximum pressure during boiler heating is adjusted via the control panel. After all the calibration operations have been completed, close and seal the pressure outlet used. Calibration of slow ignition is electronic and adjustable (for optimisation and gas change) via the contro...

Page 37

- - installation english checking combustion and efficiency of the air pressure switch to access the flue gas analysis flange operate as follows: - undo the screw (a) and remove the rubber cap (b): p1 = flue gas port; p2 = air port. Checking the efficiency of the air pressure switch - loosen the two...

Page 38

- 0 - installation for conversion operate as follows: - remove the cover and open the sealed chamber. - undo the retaining screws (1) and remove the burner (2). - replace all the burner nozzles (3) with the nozzles provided in the conversion kit, checking that the dia- meter is as shown in the table...

Page 39

- 1 - installation english adjusting the minimum pressure the gas pressure at the burner must be checked through the pressure outlet positioned on the gas valve outlet pipe using a water pressure gauge or a micro pressure gauge - remove the protection cover (g). - disconnect the power cable (12v) fr...

Page 40

- 2 - maintenance maintenance in order to assure that the boiler remains functional and efficient within the limits laid down by current legislation and/or regulations, the boiler must be subjected to regular inspection. The frequency of inspection depends on the installation and utilisation conditi...

Page 41

- - maintenance english troubleshooting fault cause remedy failed ignition safety thermostat tripped no water air pressure switch tripped flue gas thermostat tripped (flue control) heating sensor failure sanitary water sensor failure smell of unburnt gas and poor burner com- bustion - no gas - detec...

Page 42

Bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento lamborghini calor s.P.A. Via statale, 2 0 dosso (ferrara) italia tel. Italia 02/11 - export 02/1 fax italia 02/2 - export 02/ le illustrazioni e i dati riportati so...

Page 43

24 mbs w top 28 mbs w top 32 mbs w top libretto utente user manual manual de uso caldaia murale a gas con bollitore ad accumulo - alto rendimento - modulante wall-mounted gas boiler with storage water heater - high efficiency - modulating caldera mural de gas con intercambiador de acumulaciÓn - alto...

Page 44

- 2 - lamborghini calor s.P.A. Dott. Felice bo’ (general manager) ________________________________ conformity the alma mbs w top boilers are in conformity with: • gas directive 90/396/eec • efficiency directive 92/42/eec (✫✫✫) • electromagnetic compatibility directive 89/336/eec • low voltage direct...

Page 45

- 2 - english contents general safety warnings and rules page 26 description “ 27 optional accessories “ 27 technical data “ 28 sanitary hot water performance “ 28 identification “ 31 control panel “ 32 display “ 33 parameter programming “ 34 description of operation and functions “ 35 maintenance “...

Page 46

- 2 - user manual safety warnings and rules • the instruction manuals provided form an integral part of the boiler and consequently must be carefully kept and must always accompany the boiler, even in the case of transfer to another owner or user or transfer to another system. In the event of damage...

Page 47

- 2 - user manual english description the boilers operate fully automatically and the gas flow is controlled by an electronic control unit with the following cha- racteristics: - continuous modulation on both circuits - possibility of adjusting the heat output - possibility of adjusting slow ignitio...

Page 48

- 2 - user manual technical data sanitary hot water performance continuous delivery without flow limiter ∆t=30°c 11,4 l/min continuous delivery with flow limiter 12 l/min peak draw in the first 10 min. 157 sanitary water pressure 8 bar description alma 24 mbs w top fuel g20 g30 g31 gas supply pressu...

Page 49

- 2 - user manual english sanitary hot water performance continuous delivery without flow limiter ∆t=30°c 13,3 l/min continuous delivery with flow limiter - l/min peak draw in the first 10 min. 172 sanitary water pressure 8 bar description alma 28 mbs w top fuel g20 g30 g31 gas supply pressure (nomi...

Page 50

- 0 - user manual sanitary hot water performance continuous delivery without flow limiter ∆t=30°c 15,2 l/min continuous delivery with flow limiter - l/min peak draw in the first 10 min. 192 sanitary water pressure 8 bar description alma 32 mbs w top fuel g20 g30 g31 gas supply pressure (nominal) 20 ...

Page 51

- 1 - user manual english identification the alma boiler is identifiable by the labels on the packaging and the technical data plate found inside the boiler as shown in the figure. Warning • tampering with, removing, missing identification plates or anything else that does not allow certain identifi...

Page 52

- 2 - user manual control panel the alma boilers are equipped with the instruments shown below. D boiler status display p1 boiler function selection button (summer/winter - on/off) p2 cyclic function selection p3 heating temperature increase button p4 heating temperature decrease button p5 sanitary ...

Page 53

- - user manual english button function symbol display pressing the button for 3 seconds the following functions are displayed: summer ----> winter holding the button pressed down for 3 seconds the boiler switches off. Pressing the button the following information is cyclically displayed: sanitary w...

Page 54

- - user manual parameter programming simultaneously press the buttons p2 and p3 for 10s to access the programming menu where the left digit indicates the parameter number, and the centre and right digits the parameter value. When the programming menu has been accessed, the left digit will blink; us...

Page 55

- - user manual english description of operation and functions heating mode the heating operating mode starts if requested by the ambient thermostat and if the operating selector is set to “winter”. The circulator, fan (mbs) and switching valve are activated and, after checking that there is air flo...

Page 56

- - user manual description circulator activation temperature for anti-freeze 8 °c circulator deactivation temperature for anti-freeze 10 °c burner activation temperature for anti-freez 6 °c anti-freeze function deactivation temperature 15 °c burner output during anti-freeze minimum post-circulation...

Page 57

- - user manual english fan and air flow check (mbs models) if an ignition request is received, the system checks for the absence of air flow (contact open) of the flue gas pressure switch, and if the test is passed the fan is activated. When air flow is detected (contact closed) the ignition sequen...

Page 58

- - user manual heating mode with external sensor (optional) operation is the same as in normal heating mode with the difference that the delivery temperature is calculated in relation to the external temperature read by the sensor and the k factor. The k factor is set with the p3 and p4 buttons. N....

Page 59

- - user manual english operation with remote control (optional) the boiler can be operated with a rc03.54 remote control. The rc03.54 remote control is an intelligent hourly programmer complete with ambient sensor suitable for adjustment and control of wall-mounted gas boilers for heating and produ...

Page 60

- 0 - user manual adjusting the minimum pressure the gas pressure at the burner must be checked through the pressure outlet positioned on the gas valve outlet pipe using a water pressure gauge or a micro pressure gauge - remove the protection cover (g). - disconnect the power cable (12v) from the mo...

Page 61

- 1 - user manual english maintenance in order to assure that the boiler remains functional and efficient within the limits laid down by current legislation and/or regulations, the boiler must be subjected to regular inspection. The frequency of inspection depends on the installation and utilisation...

Page 62

- 2 - user manual troubleshooting fault cause remedy failed ignition safety thermostat tripped no water air pressure switch tripped flue gas thermostat tripped (flue control) heating sensor failure sanitary water sensor failure smell of unburnt gas and poor burner com- bustion - no gas - detection o...

Page 63

Bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento lamborghini calor s.P.A. Via statale, 2 0 dosso (ferrara) italia tel. Italia 02/11 - export 02/1 fax italia 02/2 - export 02/ le illustrazioni e i dati riportati so...