- DL manuals

- Lamborghini Caloreclima

- Boiler

- XILO T 24 M W TOP

- Installation And Maintenance Manual

Lamborghini Caloreclima XILO T 24 M W TOP Installation And Maintenance Manual

1

24 M W TOP

U/IT

24 MS W TOP

U/IT

AZIENDA CERTIFICATA ISO 9001

MANUALE DI

INSTALLAZIONE E

MANUTENZIONE

INSTALLATION

AND MAINTENANCE

MANUAL

MANUAL PARA

LA INSTALACIÓN Y

EL MANTENIMIENTO

MANUAL DE

INSTALAÇÃO E

MANUTENÇÃO

PREGASI CONSEGNARE

L'INSERTO "MANUALE D'USO"

AL SIG. UTENTE

PLEASE MAKE SURE THAT THE

"USE MANUAL" IS HANDED

OVER TO THE USER

TENGAN LA AMABILIDAD DE

ENTREGARLE AL USUARIO EL

"MANUAL DE USO"

FAVOR ENTREGAR O

"MANUAL DE USO"

AO SR. UTENTE

CALDAIA MURALE A GAS TERMO - ALTO RENDIMENTO - MODULANTE

WALL-HUNG GAS BOILER FOR HEATING - HIGH EFFICIENCY - MODULATING

CALDERA MURAL A GAS PARA CALEFACCIÓN - ALTO RENDIMIENTO - MODULANTE

CALDEIRA DE PAREDE A GÁS PARA CALEFACÇÃO - ALTO RENDIMENTO - MODULANTE

Summary of XILO T 24 M W TOP

Page 1

1 24 m w top u/it 24 ms w top u/it azienda certificata iso 9001 manuale di installazione e manutenzione installation and maintenance manual manual para la instalaciÓn y el mantenimiento manual de instalaÇÃo e manutenÇÃo pregasi consegnare l'inserto "manuale d'uso" al sig. Utente please make sure tha...

Page 2

7 readcarefullyallwarningandinstructionscontainedinthismanualattheygiveimportant safety instructions regarding installation and maintenance. Keep this manual for future reference. Installationmustbecarriedoutbyqualifiedpersonnelwhowillberesponsibleforrespecting existingsafetyregulations. Gb.

Page 3

32 congratulations... ... On an excellent choice. We thank you for the preference accorded to our products. Lamborghini caloreclima has been actively present in italy and throughout the world since 1959 with a widespread network of agents and concessionary agents to constantly guarantee the presence...

Page 4

33 general instructions ● this booklet constitutes an integral and essential part of the product. Read carefully the instructions contained in this booklet as they provide important directions regarding the safety of installation, use and maintenance. Preserve this booklet with care for any further ...

Page 5

34 description these boilers are fully automatic and gas control is effected by an electronic control unit having the following characteristics: - continuous modulation mode on heating circuit; - possibility to adjust the heating output; - possibility to adjust the slow ignition; - possibility of be...

Page 6

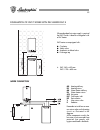

35 main components legend 1 fumes pressure switch 2 fan 3 heating sensor 4 total safety thermostat 5 exchanger 6 burner 7 ignition electrodes 8 control electrode 9 automatic air bleed valve 10 safety valve 11 no-water pressure switch 12 circulator 13 filling cock 14 gas valve 15 modulating coil 16 g...

Page 7

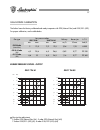

36 dimensions mm circulating pump features system delivery/pressure 100 max. 3000 220 105 440 770 100 max. 3000 160 330 boiler version: mod. M type b11 bs mod. Ms type c12-c32-c42-c52-c62-c82 category: ii 2h3+ cl nox: 1 (m) - 2 (ms) technical features xilo t 24 m w top xilo t 24 ms w top 220 440 770...

Page 8

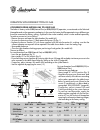

37 the boilers leave the factory calibrated and ready to operate with g20 (natural gas) and g30/g31 (lpg). For proper calibration, see the table below: burner pressure curves - output gas-nozzle calibration xilo t 24 m xilo t 24 ms slow ignition adjustment 3.5 mbar g20 (natural gas) (m) - 3 mbar g20...

Page 9

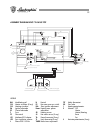

38 electrical connections - wiring diagrams the boiler must be connected to an earthed, single-phase 230v-50 hz mains supply by means of a three-wire cable, ensuring that connections to the phase and neutral terminals are made correctly. A bipolar switch must be used with contacts opening to at leas...

Page 10

39 legend bm modulating coil cib heater circulator (if any) cir heating circulator ea ignition electrode ec control electrode f fuse fc flue control jp1 methane/lpg selector jp2 post-circulation selector l phase 230 v 50 hz n neutral ps no-water pressure switch rla slow ignition adjustment rmax. Hea...

Page 11

40 assembly diagram xilo t 24 ms w top legend bm modulating coil cib heater circulator (if any) cir heating circulator ea ignition electrode ec control electrode f fuse jp1 methane/lpg selector jp2 post-circulation selector l phase 230 v 50 hz n neutral pa air pressure switch ps no-water pressure sw...

Page 12

41 malfunctions and adjustments constant light: ignition shutdown fast flashing light: tst shutdown constant light: no water fast flashing light: sensor fault slowly flashing light: air pressure switch (ms) flue control (m) a rla timer g30/g31 lpg g20 natural gas (post.Circ.Off) heating post.Circ. O...

Page 13

42 water connection fit the supporting hooks and attach the assembly template, moving it up to the wall; fit all the pipes, starting with the end pipe fittings already mounted on the template: system supply, system return, cold water, hot water, any gas pipes and electric mains leads with room therm...

Page 14

43 water circuit legend a system supply b gas c cold water inlet d system return e heater return f heater supply 1 exchanger 2 modulator coil 3 heating sensor 4 gas valve 5 filling tap 6 safety valve 7 no-water pressure switch 8 circulator 9 burner 10 expansion tank 11 fume pressure switch 12 fan 13...

Page 15

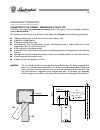

44 installation to be carried out by qualified personnel. The installation must be in compliance with the stipulations of the law regarding the evacuation of combustion materials according to the regulations in force. The gas fume evacuation must be effected with a pipe of a diameter not less than t...

Page 16

45 connection to the chimney - version xilo t 24 m w top the boiler is envisaged being connected to a chimney and/or a flue pipe; it can also discharge combustion products directly outside. The connection to the chimney or to the flue must be made with a flue pipe with the following specification: ●...

Page 17

46 fume evacuation/air intake 1 concentric flue pipe, from the roof c32 2 concentric flue pipe, from the terrace c32 3 double flue pipe from separate flues c42 4 concentric flue pipe, connected to concentric flues c42 5 concentric flue pipe, from an external wall c12 6 double flue pipe from the terr...

Page 18

47 flue exhaust installation attention: use only air intake/ fume evacuation kits produced by lamborghini caloreclima. Concentric flue pipe fit the concentric elbow pipe positioning it on the desired direction and insert on it the sealing gasket. Then fit the appropriate diaphragm (see table below)....

Page 19

48 gas pressure adjustments with honeywell vk 4105 valve all boilers are tested and calibrated in the factory. At first ignition it is necessary to check and set up the boiler to adapt it to the system characteristics. The gas pressure at the burner must be checked through the pressure plug placed o...

Page 20

49 switching off prolonged switching off if the boiler should remain inactive at length close the gas tap and cut electrical power supply to the appliance. Temporary switching on/off proceed in one of the following ways: ● use the room thermostat; ● use the adjustment potentiometer (on the instrumen...

Page 21

50 if a room thermostat is to be installed we recommend our class piu’ timer-thermostat which, in addition to guaranteeing comfort and precise temperature regulation, provides a wide range of heating programmes. Alternatively there is the digital timer-programmer. Warning: the 230 v room thermostat ...

Page 22

51 gas type l.C.V. Kcal/h 8.550 29.330 22.360 diaphragm (h) xilo t 24 ms ms Ø m Ø burner jets Ø mm. 1,25 0,77 0,77 delivery jets pressure mbar xilo t 24 m nox class 1 1 1 m ms 3 - 6,4 6,4 - 6,2 6,2 3 3 m 3 /h max. Min. Max. Min. 3,04 0,89 1,16 12,5 26,8 34,5 2,2 6,5 8,5 12,5 25,6 33 3 6,3 8,6 operat...

Page 23

52 fault-finding chart 1 no ignition 2 crackling ignition 3 smell of gas 4 smell of unburnt gas and bad burner combustion 5 condensation in the boiler 6 cold radiators in winter fault cause remedy a. Gas tap closed b. Boiler in “lock-out” mode c. No flame detection d. No ignition spark e. Air inside...

Page 24

53 installation of xilo t boiler with pac heater pac s where abundant hot water supply is required the xilo t boiler is ideal for use together with a pac heater. Pac heaters are equipped with: ● circulator ● safety valve ● automatic air bleed valve ● discharge tap ✼ pac s 80 = 450 mm pac s 120 = 600...

Page 25

54 installing the hot water sensor in the pac heater pac s boiler and heater electrical connections the hot water sensor must be housed in the heater well a. When effecting heater electrical connections use the lead-grip b and connect the wires at the terminal block c as illustrated in the wiring di...

Page 26

55 adjusting the boiler via the control panel turning dial a to the heating + hot water ( )* position as illustrated in the figure readies the boiler for operation with the heater. Hot water temperature adjustment is effected by means of dial b on the boiler control panel. ✼ or hot water ( ) b a.

Page 27

56 legend bm modulating coil cir heating circulator cib heater circulator mb ignition electrode ea ignition electrode ec control electrode f fuse fc flue control jp1 methane/lpg selector jp2 post-circulation selector l phase 230 v 50 hz n neutral ps no-water pressure switch rla slow ignition adjustm...

Page 28

57 assembly diagram xilo t 24 ms w top + pac s legend bm modulating coil cir heating circulator cib heater circulator (if any) mb heater terminal block ea ignition electrode ec control electrode f fuse jp1 methane/lpg selector jp2 post-circulation selector l phase 230 v 50 hz n neutral pa air pressu...

Page 29

58.

Page 30

116 bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento 08/2005 cod. 97.50608.0/1 lamborghini calor s.P.A. Via statale, 342 44040 dosso (ferrara) italia tel. Italia 0532/359811 - export 0532/359913 fax italia 0532/35...

Page 31: 24 M W Top

1 azienda certificata iso 9001 24 m w top u/it 24 ms w top u/it pt 23 caldeira de parede a gÁs para calefacÇÃo alto rendimiento - modulante manual do utente Àtenção do sr. Instalador: entregue este manual de uso ao utente gb 9 wall-hung gas boiler for heating for high efficiency - modulating user ma...

Page 32

9 index page general instructions _______________________________________________ 10 instruction for the use _____________________________________________ 11 checkings and maintenance _______________________________________ 12 dimensions mm ______________________________________________________ 13 i...

Page 33

10 general instructions ● this booklet constitutes an integral and essential part of the product and should be preserved for any further consultation. Read carefully the instructions contained in this booklet as they provide important directions regarding the operation of the appliance, allowing a g...

Page 34

11 instruction for the use ● in case of breakdown and/or malfunctioning of the appliance, disconnect it avoiding any attempt of repair or direct intervention. Call exclusively professionally qualified personnel. Any repair must be carried out by an after-sale service centre “lamborghini service” aut...

Page 35

12 checks and maintenance ● prima di avviare la caldaia far verificare da personale qualificato “lamborghini service”: a) that the data on the information plate corresponds to that required by the gas, electrical and water supply networks; b) that the pipes which branch off from the boiler are lined...

Page 36

13 dimensions mm should the boiler shut down it must be reset by rotating functions selector switch 6 to position a. Xilo t 24 m w top 100 max. 3000 220 105 440 770 100 max. 3000 160 330 220 440 770 160 330 152,5 xilo t 24 ms w top 1 lock-out warning light 2 on/off warning light 3 malfunction warnin...

Page 37

14 ignition - operation - shutdown instructions ignition open the gas tap and tun the selector switch (6) to the desired position. The burner will ignite automatically. Should ignition fail to take place check the lock-out warning light (1) and fault warning light (3) to see if they have come on. Tu...

Page 38

15 fault-finding chart 1 no ignition 2 crackling ignition 3 smell of gas 4 mell of unburnt gas and bad burner combustion 5 condensation in the boiler 6 cold radiators in winter fault cause remedy a . Gas cock closed b . “lock-out” button locked c . No flame detection d . No ignition spark e . Air in...

Page 39

32 bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento lamborghini calor s.P.A. Via statale, 342 44040 dosso (ferrara) italia tel. Italia 0532/359811 - export 0532/359913 fax italia 0532/359952 - export 0532/359947 0...